Highly Active Cu Based Catalysts on Carbon nanofibers for

advertisement

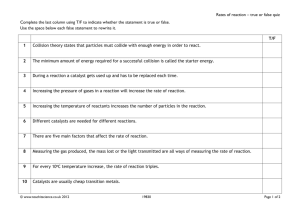

Highly Active Cu Based Catalysts on Carbon nanofibers for Isopropanol Dehydrogenation Ingvar Kvande1, De Chen1, Magnus Rønning1, Hilde J. Venvik2, and Anders Holmen1 1 Departmet of Chemical Engineering, Norwegian University of Science and Technology (NTNU), N-7491 Trondheim, Norway. 2SINTEF Applied Chemistry, N-7465 Trondheim, Norway. Introduction Copper chromite is generally used as catalyst in industrial process for the dehydrogenation of alcohols to aldehydes or ketones. However, new EPA restrictions now prohibit the disposal of chromite in landfills. Thus, there has been a renewed attention to develop new Cu catalysts which contain no chromium. Research has recently been focused on carbon supported copper catalysts [1]. Carbon nanofibers (CNFs) have recently received increasing interests in applications as catalyst supports, since CNFs have many unique properties [2]. The present work deals with preparation, characterization of Cu based catalysts on different CNF supports. The modification of Cu catalyst with CeO2 is studied to increase activity. Experimental For types of carbon nanofibers synthesized in our laboratory, namely platelet (P), carbon filaments(CF), herring bond (HB) and irregular CNF, are used as catalyst supports. The CNFs were purified and some of samples are oxidised by HNO3 or air. The 10wt% Cu catalysts are prepared by incipient wetness impregnation and deposition-precipitation. The CeO2 modified Cu catalysts were prepared by incipient wetness impregnation. The catalysts are calcined at 250 °C for 1 hr in air and reduced in 50% H2 for 6 hr. The catalysts have been characterized by temperature-programmed oxidation (TPO), XRD, SEM and TEM. The surface area of Cu were measured by means of N2O decomposition by using both TPR titration and gravimetric measurement. The activity tests are performed by means of temperature scanning experiments at a partial pressure of isopropanol of 4.4 kPa in a quartz reactor coupling with MS. Results and Discussions Table 1 shows that the dispersion of Cu on CNF is typically about 2-5%, which is in good agreement with literature values both on activated carbon [1] and CNFs [2]. However, it is lower than one on our reference support of activated carbon. The activation energy of Cu on CNFs is between 21-28 kcal/mol, which is also in good agreement with the previously reported value [1]. The selectivity to acetone is almost 100% on most of Cu/CNF catalysts, which is higher than our reference catalyst. Table 1. Catalyst properties and activities at 448K PIpa=4.4kPa. Catalysts Dispersion% Activity TOF (mol/g,s) (s-1*100) 0.26 0.60 0.04 0.27 0.08 0.29 0.5 1.85 2.8 15.25 4.25 2.02 4.4 - E (kcal/mol) 23.3 21.8 28.8 27.5 16.5 15.0 SAcetone% 423 K 100 SAcetone% 473K 96.5 TW/HB 3.2 DP/HB-HNO3 1.6 DP/CF 2.5 100 100 DP/P-HNO3 4.6 0 0.45 Cu12Ce5/P-air 1.2 100 92 Cu17Ce17/P-air 12.4 73 45 Cu17Ce17/CF83 55 air IW/AC 8.4 0.6 0.5 23.6 90 74 CuO 1.7 9.9 Cu0 2.3 11.7 100 99.7 Cu2O 0.04 HNO3 and air indicate oxidant used in preparation, AC is active carbon, Cu12Ce5/Pair indicates 12wt%Cu and 5%Ce on platelet support, which was oxidised by air. Results clearly indicate that adding CeO2 to Cu catalysts can significantly increase the activity and that the selectivity depends on the ratio of Cu/Ce. The best catalysts found in the present work is Cu12Ce5/P-air with high activity and selectivity. with Further almost 100% increasing amount of CeO2 increases activity, 200 nm 50nm Fig. 1 TEM image of Cu/CeO2/CNF, Cu: 17wt% and Ce 17 wt% but decreases selectivity. Both XRD and TEM indicate a low crystallinity of Cu and CeO2 and a TEM image is shown in Fig. 1. It shows a rather uniform layer deposited on the CNF surface. The activation energy on Cu/CeO2/CNF (about 16 kcal/mol) is found to be lower than one on Cu/CNF catalysts (about 25 kcal/mol), indicating a different reaction mechanism on Cu/CeO2/CNF. In conclusion, the Cu/CeO2/CNF is a highly active catalyst with high selectivity. It can possibly be further optimised to increase the activity. Therefore, it might be a good candidate for replacing copper chromite. References: 1. Rioux, R. M. and Vannice, J. Catal. 216 (2003) 362. 2.Ma, J. Park, N, Rodriguez, N. M. and Baker, T. K., J. Phys. Chem. B. 105 (2001) 11994.