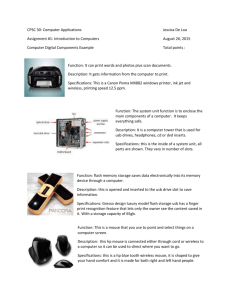

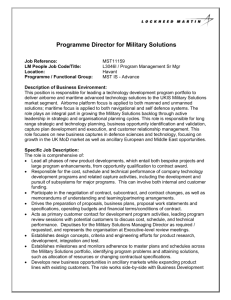

Specification

advertisement