Fluoride uptake characteristics of fly ash

advertisement

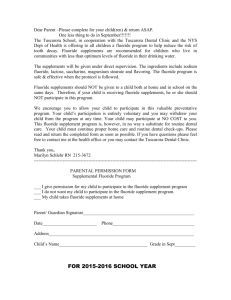

14 Research Report Fluoride Vol. 32 No. 1 14-19 1999 FLUORIDE UPTAKE CHARACTERISTICS OF FLY ASH R Piekos and S Paslawska Gdansk, Poland SUMMARY: Retention of fluoride ion in dynamic experiments on columns packed with fly ash was studied at 20ºC with a series of aqueous solutions containing 1, 5, 10, 20, 50, and 100 mg F-/L. The flow rate through a 450-g bed was ≤ 2 mL/hr. At the lowest F - concentration (1 mg/L), the F - level in the effluent initially increased and then gradually decreased down to 0 mg/L after 120 hours. With higher F - concentrations in the feed solutions, the F concentration in the effluent steadily decreased reaching 0 mg/L after 120 168 hours. We conclude that coal fly ash is an effective sorbent for F - ions, especially at high concentrations in water. Key words: Coal burning, Fluoride removal, Fly ash, Water. INTRODUCTION Wastewaters from phosphate fertilizer plants may contain up to 2 per cent of fluoride.1 Increased levels of fluoride can also be present in effluents from the fluorine industry,1 glass etching,1 and in ground water around aluminum smelters.2,3 The problem of high fluoride concentration in groundwater resources has become an important health-related geo-environmental issue in some areas. Examples include the state of Rajasthan, India, where nearly 3 million people are reported to consume excess fluoride-containing water,4,5 and the upper regions of Ghana, where 23 per cent of wells have fluoride concentrations above the WHO recommended maximum guideline limit of 1.5 mg/L.6 In the Gdansk region, high fluoride levels (1.90 - 3.00 mg/L) were detected in Malbork drinking water supplies.7 Since excessive amounts of fluoride may cause adverse health effects to humans and animals, there is a need for defluoridation of industrial wastewaters. Classical procedures of defluoridation involve precipitation, adsorption, ion exchange, and membrane techniques.8 Of these, the most popular and cost-effective is precipitation of fluoride with lime. However, the resulting calcium fluoride, though sparingly soluble, still poses environmental concern and must be safely disposed of. Fly ash is the major solid waste by-product from coal-fired power plants. It is produced as a fine residue carried off in the flue gases with relatively uniform particle size distribution in the 1 to 100 μm range. The main components of fly ash are silica, alumina, iron oxides, calcium oxide, and residual carbon. The fineness of the fly ash particles and the inherent large surface area (1 to 6 m2 g-1),9 together with the content of unburnt carbon, make it a good candidate for utilization as an inexpensive sorbent. A literature survey revealed that fly ash has been used for removing heavy metals10-17 and radionuclides18 from aqueous solutions, for treatment of wastewaters to remove organic compounds 19-22 and color,23 as a coal desulphurization agent,24 and - together with hydrated lime - for SO2 removal from flue gases.25 ——————————————— *Medical University of Gdansk, Faculty of Pharmacy, Al. Gen. Hallera 107, PL - 80-416 Gdansk, Poland Fluoride uptake by fly ash 15 Dynamic experiments on leaching of trace elements from fly ash, carried out by Dybczynski and co-workers26 have shown that distilled water (1800 mL) leached out ca 23% of fluoride and simulated acid rain (H2SO4, pH 2.5, 1800 mL) ca 38% (both figures taken from a bar graph) of fluoride from 10 g of the material placed in a thin layer between two filter papers, during 6 hours. There is also evidence27 that the capital and operating costs of wastewater treatment by fly ash to remove turbidity, fluoride, and to reduce COD, are lower than those by conventional lime precipitation. In view of the advantages of fly ash as a low-cost sorbent, it seemed worthwhile to study its efficiency in removing fluoride ion from high-fluoride waters. MATERIALS AND METHODS Fly ash was collected directly at the electrostatic precipitator of the Gdansk Thermoelectric Power Plant. The grain size of the ash ranged between 1-90 μm with a mean diameter of 20-30 μm. The results of its chemical analysis are as follows: SiO2 52.7%, Al2O3 21.9%, Fe2O3 8.4%, CaO 7.2%, loss on ignition 9.1% (a class F fly ash according to ASTM standards). A slurry prepared from 10 g of the fly ash and 100 mL of water had a pH of 10.1. All chemicals were of analytical reagent grade, and distilled water was used throughout. Sorption experiments were conducted at 20oC in a column (see Figure) packed with 450 g of fly ash. The concentrations of fluoride in water fed on the column were 1, 5, 10, 20, 50 and 100 mg/L. The procedure was as follows: 250 mL of a fluoride solution was first Figure. Schematic of the experimental setup. Fluoride 32 (1) 1999 16 Piekos and Paslawska poured onto the column to moisten the fly ash. Then a 250-mL portion of the solution was placed in the top reservoir and the draining rate was adjusted to ca 2.0 mL/hr. The fluoride level in the effluent was determined every 24 or 48 hrs. potentiometrically by using a fluoride ion-selective electrode. Particulars concerning the analytical procedure are reported elsewhere.28 Each experiment with solution of a given concentration was run in duplicate with a fresh portion of fly ash. RESULTS Results of the measurements are summarized in the Table. Table Results of the measurements F- conc. Aliquot of ef- Sampling in incoming fluent taken for time soln. – mg/L analysis - mL hrs 0 4.0 1 1.0 5 1.0 10 1.0 20 0.1 50 0.1 100 0.1 Fluoride 32 (1) 1999 F- concentration in effluent mg/L First expt. Second expt. Mean 24 48 72 1.0 0.8 0.5 0.8 0.6 0.5 0.9 0.7 0.5 24 48 72 96 1.8 0.8 0.5 0 2.0 1.5 0.9 0 1.9 1.2 0.7 0 24 48 72 96 120 3.8 1.8 1.5 0.5 0 3.9 1.9 1.5 0.3 0 3.8 1.8 1.5 0.4 0 24 48 72 96 120 144 7.5 5.3 3.6 1.9 0.5 0 6.8 5.2 3.9 2.5 0.9 0 7.1 5.2 3.7 2.2 0.7 0 24 72 120 168 12.5 5.5 2.5 0 13 7.0 3.5 0 12.6 6.2 3 0 24 72 120 168 17 12.5 5.5 0 18 13.5 4.2 0 17.5 13 4.8 0 24 72 120 168 25 15 4.8 0 22.5 17.5 5.8 0 24 16 5.3 0 Fluoride uptake by fly ash 17 DISCUSSION Inspection of the results presented in the Table shows that the sorption of fluoride increases with increasing concentration of incoming solution. Pure water leaches fluoride from fly ash in which it is likely to occur in the form of fluorite and metal fluoride complexes. When a solution with low fluoride concentration (1 mg/L) is passed through the column, the fluoride level in the effluent is initially higher than in the incoming solution (1.9 mg/L average after 24 hrs) owing to concurrent leaching of the fluoride contained in fly ash. However, after 120 hrs the effluent becomes completely free of fluoride. It is remarkable that the retention capacity of fly ash increases with increasing fluoride concentration in incoming solution. This finding is best illustrated by the decrease in F- levels of the solutions after 24 hrs. For the 5, 10, 20, 50 and 100 mg/L F- concentrations the respective drops in F - concentration are 24, 28, 36.5, 65 and 76 per cent. Complete retention of the fluoride by fly ash occurs after 120-144 hrs for the lower F - concentrations (1, 5, and 10 mg/L) and after 168 hrs for the higher F - concentrations. The explanation for the high sorption capacity of fly ash with respect to the fluoride ion seems quite straightforward if one considers its high CaO content (7.2%) on the one hand, and a slow flow rate of the solution through the column (ca 40 mL/24 hrs) on the other. The hydration of the oxide is responsible for the high pH of the water slurry of fly ash (pH exceeding 10). The resulting calcium hydroxide reacts with the fluoride to afford a sparingly soluble calcium fluoride. A simple calculation shows that in the total quantity of 450 g of fly ash packed in the column, there is 32.4 g (0.58 mole) of CaO, whereas 500 mL of the most concentrated F- solution (100 mg/L) contains only 0.0025 mole of F-. Strong sorptive capacity of residual carbon is also likely to contribute to this process. Recent investigations into the morphology and bulk physicochemical properties of this fly ash component, carried out by Hurt and associates,29 led to the following conclusions (numbering by the present authors): i. “The residual carbon samples show signs of significant oxidation that has led to highly porous, fragmented particle structures, and visible fused surface ash. ii. “Residual carbon does not consist of fuel particles that have largely avoided high-temperature oxidizing trajectories in the boiler; rather it has undergone complete devolatilization…, high-temperature treatment and significant, though incomplete, oxidation; iii. “The residual carbon particles are generally quite macroporous, providing good access to oxygen to penetrate to the particle interior; iv. “There is no evidence that a significant fraction of the carbon is encapsulated by inorganic matter at the whole-particle scale; [and] v. “The residual carbon samples have microporous surface area of 100 200 m2g-1 carbonaceous material.” Fluoride 32 (1) 1999 18 Piekos and Paslawska Especially supportive to our belief are conclusions (iii) and (v) above. Firstly, large pores of the carbon which are capable of accommodating oxygen molecules with the diameter of ca 300 pm, can also provide good access to much smaller fluoride ion with the diameter of 172 pm. Secondly, the surface area of the carbon (100 to 200 m2g-1) is much larger than that of bulk fly ash (1 to 6 m2g-1).9 We conclude that a double mechanism is likely to operate in the retention of fluoride by fly ash: chemical binding by calcium hydroxide and physical sorption by residual carbon particles. This paper was presented and discussed at the XXIInd Conference of the International Society for Fluoride Research in Bellingham, Washington USA (24-27 August, 1998). REFERENCES 1 2 3 4 5 6 7 8 9 10 11 12 Różycka D, Grobelny M. Perspectives for fluorine removal from wastewaters of phosphate fertilizer industry (in Polish). Chemik 4 92-93 1998. Sahu SK, Pati SS, Badapanda RK. Fluorine content in ground water around an aluminum industry in Hirakund, Orissa. Environmental Ecology 16 (1) 169-171 1998. Arnesen AKM. Effect of fluoride pollution on pH and solubility of Al, Fe, Ca, Mg, K and organic matter in soil from Årdal (Western Norway). Water, Air and Soil Pollution 103 375-388 1998. Agrawal V, Vaish AK, Vaish P. Groundwater quality: focus on fluoride and fluorosis in Rajasthan. Current Science 73 (9) 743-746 1997. Maithani PB, Ravindra G, Banerjee R, Balaji BK, Ramachandran S, Singh R.Anomalous fluoride in groundwater from western part of Sironi district, Rajasthan and its crippling effects on human health. Current Science 74 (9) 773-777 1998. Apambire WB, Boyle DR, Michael FA. Geochemistry, genesis, and health implications of fluoriferous groundwaters in the upper regions of Ghana. Environmental Geology (Berlin) 33 (1) 13-24 1997. Gajewska R, Nabrzyski M, Fluorides in potable water and in imported and home-made tooth pastes (in Polish). Bromatologia i Chemia Toksykologiczna 26 5-11 1993. Dieye A, Mar C, Rumeau M. Process of drinking water defluoridation (in French). Trib. Eau 47 (568) 27-34 1994. Mancy KH, Gates WE, Eye JE, Deb PK. The adsorption kinetics of ABS on fly ash. In: Proceedings of the 19th International Waste Conference, DE Bloodgood, ed., Purdue University, West Lafayette, Ind., pp 146-160. Yadawa KP, Tyagi BS, Panday KK, Singh VN. Fly ash for the treatment of water enriched in lead (II). Journal of Environmental Science and Health 24 (Pt A) 783-808 1989. Weng CH, Huang CP, Treatment of metal industrial wastewater by fly ash and cement fixation. J of Environmental Engineering 120 1470-1487 1994. Sen AK, De AK. Adsorption of mercury (II) by coal fly ash. Water Research 21 885-888 1987. Fluoride 32 (1) 1999 Fluoride uptake by fly ash 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 19 Panday KK, Prasad G, Singh VN. Copper (II) removal from aqueous solution by fly ash. Water Research 19 809-873 1985. Gangoli N, Markey D, Thodos G. Removal of heavy metal ions from aqueous solutions with fly ash. Water Air Soil Pollution 37 13-24 1975. Ferrero F, Gaglia Prati MP. Coal fly ash and alginate for the removal of heavy metals from aqueous solutions. Annali di Chimica 86 125-132 1986. Bulewicz EM, Kozak A, Kowalski Z. Treatment of chromic tannery wastes using coal ashes from fluidized bed combustion of coal. Industrial Engineering Chemical Research 36 4381-4384 1997. Fytianos K, Voudrias E, Tsechpenakis A. Removal of Cr (VI) from aqueous and wastewater samples by fly ash. Journal of Environmental Science and Health, Part A 32 (9 and 10) 2419-2427 1997. Aptak R. Atun G, Güçlü K, Tütem R. Sorptive removal of cesium-137 and strontium-90 from water by unconventional sorbents. II. Usage of coal fly ash. Journal of the Atomic Energy Society of Japan 33 396-402 1996 Banerjee K, Cheremisinoff PN, Cheng SL. Adsorption kinetics of o-xylene by fly ash. Water Research 31 249-261 1997. Mott HV, Weter WJ. Sorption of low molecular weight organic contaminants by fly ash. Water Air Soil Pollution 37 13-24 1975. Banerjee K, Cheremisinoff PN, Cheng SL. Sorption of organic contaminants by fly ash in a single solute system. Environmental Science and Technology 29 2243-2252 1995. Swamy MM, Mall ID, Prasad B, Mishra IM. Removal of phenol by adsorption on coal fly ash and activated carbon. Pollution Research 16 (3) 170175 1997. Gupta GS, Prasad G, Singh VN. Removal of color from wastewater by sorption for water reuse. Journal of Environmental Science and Health A23 (3) 205-217 1988. Yaman S, Küçükbayrak S. Usage of fly ash as a coal desulphurization agent. Proceedings of the International Pittsburgh Coal Conference 18 454459 1996. Fernández J, Renedo A, Garea A, Viguri J, Irabien JA. Preparation and characterization of fly ash/hydrated lime sorbent for SO 2 removal. Powder Technology 94 133-139 1997. Dybczynski R, Kulisa K, Malusecka M, Mandecka M, PolkowskaMotrenko H, Sterlinski S, Szopa Z. A comprehensive study on the contents and leaching of trace elements from fly-ash originating from Polish hard coal by NAA and AAS methods. Biological Trace Element Research 26 335-345 1990. Ma Z, Zhou F, Wu B, Xing Q, Yang W. Treatment of fluorine-containing water and wastewater by using fly ash (in Chinese). Zhongguo Huanjing Kexue 11 (6) 460-463 1991. See Chemical Abstracts 117 (8) 76161 1992. Piekos R, Paslawska S. Leaching characteristics of fluoride from coal fly ash. Fluoride, 31 (4) 188-192 1998. Hurt RH, Davis KA, Yang NYC, Headly TJ, Mitchell GD. Residual carbon from pulverized-coal-fired boilers. 2. Morphology and physicochemical properties. Fuel 74 (9) 1297-1306 1995. Fluoride 32 (1) 1999 20 Piekos and Paslawska —————————————————————— Published by the International Society for Fluoride Research Editorial Office: 17 Pioneer Crescent, Dunedin 9001, New Zealand Fluoride 32 (1) 1999