Integrating improved chemicals management into business

advertisement

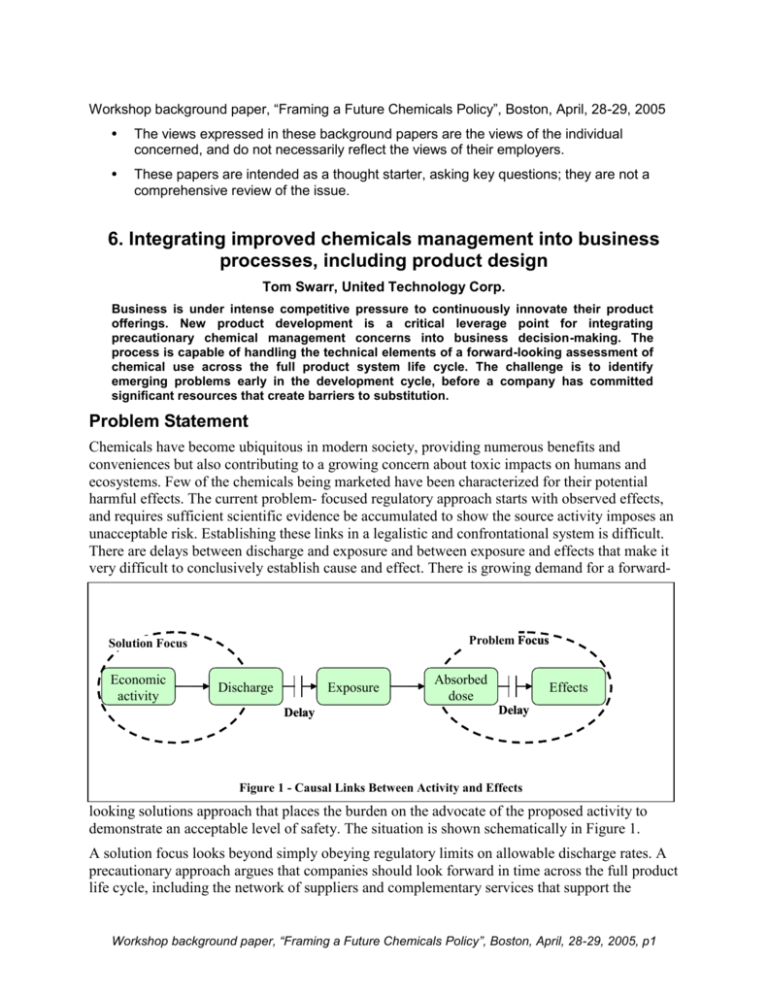

Workshop background paper, “Framing a Future Chemicals Policy”, Boston, April, 28-29, 2005 • The views expressed in these background papers are the views of the individual concerned, and do not necessarily reflect the views of their employers. • These papers are intended as a thought starter, asking key questions; they are not a comprehensive review of the issue. 6. Integrating improved chemicals management into business processes, including product design Tom Swarr, United Technology Corp. Business is under intense competitive pressure to continuously innovate their product offerings. New product development is a critical leverage point for integrating precautionary chemical management concerns into business decision-making. The process is capable of handling the technical elements of a forward-looking assessment of chemical use across the full product system life cycle. The challenge is to identify emerging problems early in the development cycle, before a company has committed significant resources that create barriers to substitution. Problem Statement Chemicals have become ubiquitous in modern society, providing numerous benefits and conveniences but also contributing to a growing concern about toxic impacts on humans and ecosystems. Few of the chemicals being marketed have been characterized for their potential harmful effects. The current problem- focused regulatory approach starts with observed effects, and requires sufficient scientific evidence be accumulated to show the source activity imposes an unacceptable risk. Establishing these links in a legalistic and confrontational system is difficult. There are delays between discharge and exposure and between exposure and effects that make it very difficult to conclusively establish cause and effect. There is growing demand for a forward- Problem Focus Solution Focus Economic activity Discharge Exposure Delay Absorbed dose Effects Delay Figure 1 - Causal Links Between Activity and Effects looking solutions approach that places the burden on the advocate of the proposed activity to demonstrate an acceptable level of safety. The situation is shown schematically in Figure 1. A solution focus looks beyond simply obeying regulatory limits on allowable discharge rates. A precautionary approach argues that companies should look forward in time across the full product life cycle, including the network of suppliers and complementary services that support the Workshop background paper, “Framing a Future Chemicals Policy”, Boston, April, 28-29, 2005, p1 product offering, to consider how chemicals- as actually used by suppliers, manufacturing personnel, service technicians, etc. - could cause harmful effects to humans and ecosystems. It is countered that the precautionary approach would block innovation and is simply not economically practical in today’s global market. The objective is to integrate chemical safety considerations into routine business decisions. The current approach starts with the effect and attempts to trace causal links back to the source activity, which is already challenge when considering acute effects triggered by point sources. When considering chronic effects resulting from the cumulative impacts of numerous diffuse sources (such as consumer products) it is virtually impossible. The rapid cycle of new product offerings will overwhelm any backward looking approach. Building precaution into product development practices is a critical success factor. The first section of this paper will provide an overview of a generic product development process and identify key decisions that gradually lock- in specific technologies, materials, and risks. The second part will address the arguments regarding innovation and economic practicality. Dare to be naïve. – Buckminster Fuller Generic Product Development Process New product development is a business decision- making process. It is supported by technical activities, such as research and development or design and analysis, and can be described as the evolution of information punctuated by decisions (Ullman, 2001). Decisions commit resources, financial and human, to drive actions, which ultimately produce the positive benefits intended and the unanticipated negative consequences that trigger regulatory actions. A generic stage- gate new product development process shown in Figure 2 is representative for many companies, although the specific names and number of stages may vary (Cooper, 2001). A stage has a defined set of tasks that generate information, typically in the form of deliverables such as drawings, reports, etc. needed to support key business decisions. A gate is an executive level review, which decides to continue investment in the project or terminate and divert limited resources to more promising projects. It is also the responsibility of management to assure that required tasks in each stage have been adequately completed to support a quality decision. Company Goals & Policies Planning G Conceptual Design G Detailed Design G Testing / Prototype G Production / Launch G Product Review G Supporting Activities Figure 2 - Stage - Gate Product Development Process Company goals and policies define the criteria used to make the gate go- no go decisions. These are constrained by the competitive position of the company, but will include non- financial objectives. The initial planning stage surveys external pressures, public expectations, customer needs, and industry trends to define the requirements for a successful product offering. What will it take to Workshop background paper, “Framing a Future Chemicals Policy”, Boston, April, 28-29, 2005, p2 excite the customer? What is the potential market and profitability? These questions determine the boundaries of the business opportunity and definition of the appropriate system boundaries for environmental evaluations. During conceptual design, the team assesses the strategic fit of the identified business opportunity with company capabilities and objectives to assure resources are focused on the most attractive projects. Is the company excited by this opportunity? Preliminary analyses are used to assure the feasibility of a fully developed conceptual plan that satisfies the customer need consistent with the strategy and capabilities of the company. Detailed design activities develop complete bill-of-material, drawings, manufacturing plans, etc. that meets technical specifications and enables design of the manufacturing and support processes consistent with project cost and quality goals. Can we do it? The concept is translated to hardware and business systems needed to deliver the proposed customer benefits. Detailed plans demonstrate project goals will be met, at least ‘on paper.’ Activities during the next stage demonstrate the feasibility of the product offering by testing prototypes or by analysis and simulation. Prescribed tasks confirm the producibility of the design and verify projected manufacturing costs. Can we deliver a winning solution? The go/ no go decisions are critical, because project costs escalate dramatically in subsequent stages. Market launch introduces the product to selected markets to validate manufacturing processes at production levels. Plans are in place to ramp up volume to meet customer demand at required levels of quality. Support systems are in put place, and product performance in the customer environment is monitored to catch any surprises. If all systems perform as expected, the project is approved for full deployment as a proven product offering. The design team works with the product management function to provide technical and logistic support to maintain the offering at warranted levels of performance. Did we deliver what we promised? After a fixed period in service that will vary with product category and expected lifetime, a formal product review is held to assure lessons learned from the project are captured and used to improve subsequent projects. The stage- gate process can be adapted to the complexity of the project. A clean sheet design of a new global platform is a high-risk project with potentially larger payoffs. These projects would be subject to rigorous analysis requiring completion of all activities and subject to gate review by top management. Derivative designs or regional products would face lower risks, but with lower potential gains. Project leaders would have the option to simplify the development process, skipping certain tasks, and the appropriate level of management would conduct gate reviews. Simple engineering changes to correct product design deficiencies or make minor enhancements are constrained projects with limited risk. The primary objective is to assure proper control to enforce design standards and avoid any new problems. These projects would skip many of the activities and lower level management would conduct the gate reviews. Precautionary Chemical Management A precautionary approach comprises preventative action in the face of uncertainty, shifting the burden of proof to producers, and a more robust process to generate and evaluate safer alternatives (Tickner & Geiser, 2004). The implications of a precautionary approach can be assessed on the stage- gate decisions. Workshop background paper, “Framing a Future Chemicals Policy”, Boston, April, 28-29, 2005, p3 Planning stage activities scan the external environment for unmet needs, market responses of competing companies, shifting social attitudes, technology development, and virtually any developing trend that can affect the future of the company. Research has shown there were early warning signals on asbestos, CFC’s, and other toxic chemicals. The early warnings were ignored or resisted (European Environment Agency, 2001). Planning stage scanning activities can be expanded to consider the full product life cycle and to be more sensitive to lay knowledge that may be poorly articulated but no less valuable in identifying negative effects of chemicals. Early and comprehensive identification of the requirements for a product offering should yield improved designs that better satisfy customer needs, while also allowing timely development of substitutes. Expanding the scanning boundaries should stimulate innovation and alternatives assessment by promoting an enhanced appreciation of the larger product system. Conceptual design activities assess the fit of the proposed business opportunity with company capabilities. Each company has developed a portfolio of technologies, manufacturing processes, supply networks, distribution channels, etc. to establish a competitive advantage in its defined market space. There is limited definition of the product design at this stage, but there is considerable information to determine likely material issues ‘if we build this product the way we built the last one.’ Shifting to safer alternatives could require new technologies, qualifying new suppliers, retraining manufacturing personnel, etc. Building in a more complete understanding of the human implications of safe chemical use is a necessary element for a precautionary approach. Early consideration of alternatives enables proper assessment of technical readiness to assure substitutes are available to meet the project schedule. The gate review of detailed design activities freezes the design to support development of all production and support decisions. Specific materials and suppliers are identified enabling a comprehensive assessment of all potentially problematic materials in the fielded product. Capital appropriations are approved for modification or upgrade of manufacturing processes, product distribution, and aftermarket support systems. Risk management plans are in place to monitor deployment of alternatives to assure product functionality is not impacted. It is not sufficient to assess releases strictly in terms of regulatory limits. What is the physical form of the chemical and how will this affect the dispersal/ transport of the released material? What are reasonable user scenarios that can help determine potential exposures? What monitoring would provide early detection of unanticipated effects? This is a critical stage to avoid investments that lock in material choices that carry unnecessary liabilities or risks. Validation with prototypes or quality tests is a final opportunity to verify all assumptions and analyses, before committing major investments for production. It is particularly important to verify the human factors involved in safe chemical use. Do people behave as expected? Are user exposure scenarios reasonable? Do protective measures and equipment work as expected and achieve the desired levels of protection? Are there any unanticipated counter effects caused by substitutes that may negate the environmental and safety benefits? Once a decision has been made to go to full production, there are significant investments at stake that will create barriers to future change. During this stage, the producer must also verify compliance of all suppliers with material restrictions and establish procedures to identify and confirm material content of all procured parts. During market launch and product review, the company is essentially committed to specific technologies and materials. The challenge is to monitor field experience to quickly identify any surprises. Early detection and correction of any problems that impact customers or end- users is Workshop background paper, “Framing a Future Chemicals Policy”, Boston, April, 28-29, 2005, p4 necessary to protect the reputation of the company. This is a challenging task; the profitability of the project will be severely impacted by a redesign to eliminate a defect. The cost of replacing materials can be significantly increased when the parts must be recertified to various safety codes. Conversely, early identification of deficiencies with existing products can be a valuable source of new product concepts. Practical Barriers to Precaution Economics and public access to information are two critical elements of success, and two significant barriers to implementation of a precautionary approach. Given a choice between a product that poisons its users and one that is inherently safe to use, few companies would consciously set out to design a toxic product. Why then have early warning of toxic products been ignored? It may be that a corporate manager’s fiduciary responsibility to protect the assets entrusted to him by the investors is inherently in conflict with the precautionary approach outlined. A company can be sustainable only if it generates sufficient returns to attract capital investment monies. If the company is overly cautious compared to its competitors, the rate of return will suffer. Investors will shift their money to the better performing companies. Companies that identify potential hazards and safer alternatives may be held liable for imposing unnecessary risks on the public, while the companies that hide potential risks escape accountability. A rigorous alternatives assessment process challenges a company to openly question all committed resources to develop and evaluate inherently safer ways of providing similar value to its customers. The same customers that want inherently safe products also want double-digit returns on their pension funds. The highly interconnected nature of the global economy also works against the precautionary approach. It can be difficult if not impossible top predict ripple effects of any decision to move to safer alternatives. Each material system has various byproducts and wastes that can cause problems. If markets move away from a specific feedstock, there will be economic pressure top create new uses. Competitors will try to innovate to win back lost markets. Selection of a particular material or technology creates pressure for complementary products and services. Individual companies makes hundreds of separate but interrelated decisions that are eventually judged based on the cumulative effects of all those decisions. The speed of innovation can easily overwhelm a precautionary approach. Public engagement in the identification and evaluation of to alternatives is critical to acceptance of recommended actions. Companies fear loss of business sensitive information or public backlash against open communication of risks and hazards. New product investments determine the future success of the company. Open disclosure of product concepts to help identify potential hazards can also alert competitors to planned strategic moves. Managers have a responsibility to protect company information and a civic duty to openly discuss safer alternatives that are in conflict. Rather than asking managers to make moral stands that jeopardize their economic security, we should ask what institutional changes are necessary to align fiduciary responsibilities to protect invested assets with a precautionary approach to chemical management? Workshop background paper, “Framing a Future Chemicals Policy”, Boston, April, 28-29, 2005, p5 Questions • Development of new technologies and regulation of any unwanted effects of those technologies are treated as two distinct processes. How can we open technology planning to public dialogues without compromising business sensitive information? • Early warning signals of previous chemical problems were ignored. How can we better capture the lay knowledge of these early detection signals? Can we create a system that rewards open communication of potential problems? • All technical advances contain risks. Technology has provided significant benefits. Our success in eliminating many acute hazards has exposed more subtle and chronic effects. People die from cancer, because they are less likely to die from childhood and communicable diseases. Can we differentiate between risks imposed by careless or illegal activities and the residual risks that escape honest and thoughtful risk mitigation practices? • Companies make product development decisions based on their assessment of the available data and likely responses of competitors. The economy is highly networked, and the ultimate impacts are the collective outcome of the actions of numerous companies. How do we measure and promote effective action of individual companies in a world shaped by collective outcomes? References Cooper, R. G. (2001). Winning at new products: Accelerating the process from idea to launch. Cambridge, MA: Perseus Publishing. European Environment Agency. (2001). Late lessons from early warnings: The precautionary principle 1896-2000. Environmental issue report No. 22. Luxemborg: Office for Official Publications of the European Communities. Tickner, J. A., & Geiser, K. (2004). The precautionary principle stimulus for solutions- and alternatves- based environmental policy. Environmental Impact Assessment Review, 24, 810-824. Ullman, D. G. (2001). Robust decision- making for engineering design. Journal of Engineering Design, 12(1), 3-13. Workshop background paper, “Framing a Future Chemicals Policy”, Boston, April, 28-29, 2005, p6