Properties of Connective Tissues

advertisement

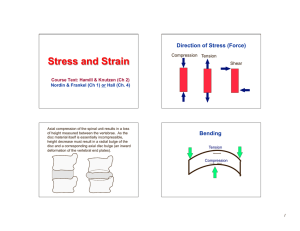

Lecture 2 Objectives: 1. 2. Continue with concepts of Stress/Strain and Load/Deformation Biomechanics of bone and articular cartilage Properties of Connective Tissues Stress/Strain Stress = Force/Area (N/cm2, N/m2(pascals), MN/m2 (Mpascals)) Stress = Load Strain = Length / Original Length (percentage change) Strain = deformation Types of Stress: Tensile (distractive) – 2 externally applied forces that are equal and act along the same line in opposite directions = tensile force/cross-sectional area Compresssive – 2 externally applied forces that are equal and act along the same line toward each other on opposite sides of the structure = compressive force/cross-sectional area Shear – 2 externally applied forces that equal, parallel, and applied in opposite directions but not in the same line. Plastic Region Yield Point or Elastic Limit Stress or Load Ultimate Failure or Fracture Point Elastic Region Strain or Deformation Elastic Range – no permanent deformation occurs Yield Point – point at which permanent deformation will begin 1 Plastic Range – if structure is unloaded, permanent deformation results Stress/Strain of Various Materials Plastic Region Metal Glass Stress Bone Rubber Strain Young’s Modulus = slope in the elastic region = stress/strain stiffness of material Young’s Modulus Viscoelasticity – considers 2 properties of a material Elasticity – ability to return to its original shape following deformation after the removal of the deforming load Non-time dependent – returns Stores energy (RUBBER BAND) Viscosity – a material’s ability to dampen/lessen shear forces time and rate dependent properties Viscoelastic – sensitive to the duration of the force application Creep – occurs when a viscoelastic solid is subjected to a constant load Typically responds with a rapid initial deformation followed by a slow, time-dependent, increasing deformation until equilibrium is reached. RAPID INITIAL DEFORMATION SLOW, INCREASING DEFORMATIONEQUILIBIUM (CREEP) 2 Creep Deformation Time Hysteresis Viscoelastic materials do not store all of the energy that is transferred to them when deformed by an applied force. Energy is transferred into another form and not available for recovery. LOSS (TRANSFER) OF ENERGY = ENERGY EXPENDED – ENERGY REGAINED (HYSTERESIS) Example Muscle – When muscle is loaded via an eccentric contraction some energy is stored in the series elastic component (SEC) of the muscle (actin and myosin fibers), and some is lost as heat. Stretch Muscle – transfer of energy into heat could be detrimental (inflammation) Loading Load Unloading Hysteresis – loss (transfer) of energy Deformation Connective Tissue Ligaments, tendons, bones, synovium, labra, cartilage, bursa, fat pads, etc. 3 Composed of two parts: 1. Extra-cellular matrix 2. Cells – blast and clast –type cells for synthesis and maintenance of extracellular matrix, also defense-like cells. The specific composition and proportions of these components is dependent on the function of the connective tissue. Extra-cellular matrix 1. Non-fibrous – ground substance (proteins) – glycoproteins and proteoglycans Functions – water binding, support, and protection 2. Fibrous Collagen (white protein) – most abundant (30% of all protein in mammals) Non-elastic – often oriented/configured to allow for elastic-like qualities (crimp). Elastin (yellow protein) – elastic properties Biomechanics of Bone Bone – hardest connective tissue in the body Look at its biomechanical functions and you will know why: 1. protection 2. link 3. attachments for muscles 4. facilitate movement as levers (rigid) Components of Bone Inorganic – rigid/hard (minerals) Ca and PO3 (65-70% of dry wt.) Organic – flexible/resilient (protein) – collagen fibers (25-30 % of dry wt.) Collagen composes 95% of extracellular matrix Ground Substance – Glycoaminoglycans (GAG) cementing substance 5% of extracellular matrix Water – 25% of weight, 85% of the water is found in the organic matrix Cells – osteoblasts/clasts, fibroblasts/clasts Fundamental unit of bone is the osteon or haversian system Concentric layers/lamellae Collagen is intertwined in the osteons which increases the resistance to mechanical stresses Types of bone Cortical/Compact Bone – OUTER – 5-30% porosity more dense Withstands compression > tensile > shear 4 Cancellous/Trabecular/Spongy- INNER – 30-90% porosity Highly Responsive to the loads placed on it (Wolff’s Law), therefore which forces it withstands best is varies (compression and tensile) Mechanical behavior (behavior due to forces and moment/torque) of bone is affected by: 1. 2. 3. 4. 5. loading mode – type of force/torques rate of loading frequency of loading geometric characteritics mechanical properties of materials 1. Loading modes a. tensile – Base of 5th metatarsal @ attachment of the peroneus brevis tendon, Calcaneous @ attachment of Achilles (gastro/soleus) What can be done to reduce the load at the site of attachment? Heel lift for achilles problem while healing b. compressive – vertebrae secondary to muscular contractions/lifts and femoral neck fractures secondary to osteoporosis With elderly individuals who suffer a hip fracture, how and when does the hip actually fracture? What forces are better to increase bone content? How much force is too much????? c. shear – tibial plateau fracture (fractures occur mostly in cancellous bone) d. bending – bending about an axis resulting in tensile and compressive forces 3 point bending 4 point bending – dual force couple magnitude is proportional to their distance from the axis Skier’s Fx Examination of the knee:Valgus versus varsus stresses in the knee? The use of these concepts in orthotics fabrication 5 e. torsion – twisting/torque/moment about the logitudinal axis magnitude is proportional to the distance from the axis f. combined loading – explains most fractures 2. Rate of Loading Since bone is viscoelastic its behavior varies with the rate at which it is loaded High loading Rate Load Low loading Rate Deformation Load to failure rate almost doubled (bone was actually 50% stiffer) 3. Frequency of Loading Load Injury Repetition 6 Stress/Fatigue Fracture Model Strenuous Exercise Fatigued Muscle Loss of Shock Absorbing Capacity Rely on passive elements as opposed to active and passive Altered Gait Abnormal Loading Altered Stress Distribution High Compression Combined High Tension Slow Process Fast Oblique Cracks Debonding of osteons / transverse cracks Oblique Fracture Transverse Fractures Repetition is often the evil - HNP Mechanism for other types of injuries in the body – OA, RSI, CTD 4. Geometric Properties of the object Stress = force/area (large the cross-sectional area stiffer and stronger the bone) Longer the bone the more susceptible to bending moments Iatrogenically induced Stress Raisers (length of defect < diameter of bone) –screws and empty screw holes Reduction in the energy storage capability and overall strength Open section defect ( length > diameter) Torsional type forces appear to be worst Effect of Bone Remodeling on Geometry 7 Load Deformation Curve Effects of Immobilization on Bone in Rhesus monkeys Normal Load Immobilized Deformation 8