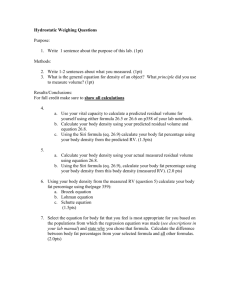

Quality Control Project

advertisement

Quality Control in the Beef Industry In this project, you will investigate quality control in industry. You will construct and interpret a control chart to decide whether to modify a manufacturing process. You will work with means, standard deviations, ranges, upper and lower control limits, and confidence intervals. Background Quality control is critical in a wide variety of industries. Most producers attempt to make the dimensions of their product conform to certain limits. In many cases these limits are required for safety reasons. One of the basic tools of statistical process control is the control chart, in which the value of some aspect of the product is tracked over time. For example, a meat packer might want the average fat content of ground beef to be 25%. It is not possible to have exactly 25% fat in every package of ground beef, so the packer sets maximum and minimum allowable limits on fat content. The beef packer collects random samples of ground beef and measures the fat content. The mean and range of the values are recorded and tracked over time using x and R control charts. The x-chart shows the means of random samples of the product taken over some time period. The R-chart refers to the ranges of the samples. The control chart shows the 2 measures concurrently. The measured fat content should fall well within the specified limits, with the number of samples containing more than 25% fat being roughly the same as those with less than 25%. A) Bullet Questions Why is it important for products to be uniform or consistent? (1) List some industries and their products that must be consistent or it could result in safety problems. (1) Are there any products where it might be beneficial for products to not be consistent? (1) B) Getting Started 1. The heights of Canadian women approximate a normal distribution, with a mean of 162.6 cm and a standard deviation of 6.4 cm. What percent of the female population do you expect to have heights between 154 cm and 172 cm? (3) 2. The masses of apples in a shipment are normally distributed, with a mean of 110 g and a standard deviation of 16 g. Without using your calculator, state a range of masses that includes 68% of the apples. (1) C) Project Presentation 3. A meat packing plant operates 24 h per day. Over a period of 8 days, 5 random samples of ground beef are chosen per 8-h shift. The fat content of each sample is measured and the Shift x x R Shift R average fat content, x , and the range of fat 1 24.7 2.3 13 25.1 3.8 content, R, of the 5 samples are recorded. The 2 25.5 4.1 14 24.6 3.3 data are shown to the right. Follow these x instructions to construct an and R control 3 25.0 5.2 15 24.2 3.6 chart for these data. 4 25.2 3.1 16 25.8 4.5 a) Enter the shift number in Ll, the means of 5 26.3 1.7 17 25.5 3.8 the samples, x , in L2, and the ranges of the samples, R, in L3 on your TI-83 6 28.4 3.5 18 24.0 4.1 calculator, or computer. Note: Enter all 7 26.2 2.2 19 24.3 2.9 shifts 1 – 24 in L1 , and all means in L2, 8 24.7 4.1 20 26.1 4.2 and all ranges in L3 b) Calculate the mean and standard deviation of the means ( x ) of the samples. (L2) 9 24.5 3.7 21 23.8 3.0 10 24.5 6.3 22 25.4 5.3 11 23.4 1.4 23 26.0 5.2 12 22.9 2.5 24 25.3 5.0 c) This mean of means, the grand average, determines the centre line, CL, on the control chart. The upper control limit, (UCL), is at 3 standard deviations above the grand average. The lower control limit, (LCL) is at 3 standard deviations below the grand average. Determine the values of UCL and LCL for these data. (2) . d) With shift number on the x - axis and average fat content on the y-axis, plot the control chart lines, CL, UCL, LCL. Use graph paper or a spreadsheet. If you want this data, download this file from the website http://cabennet.mvsd.ca. Plot the data on this chart. It will end up looking similar to this. (You must make your own!!) Do yours on graph paper or a spreadsheet. Label it #3d and staple it on. (4). mean x vs shift 30 28 26 24 22 20 0 5 10 15 20 25 shift e) Explain what you think happened during shift #6. Use you chart to answer. (1) f) Generate the R -chart using the same method. Show all work. 4. The UCL and the LCL are at 3 standard deviations from the mean. a) How much of this data distribution is between them? (1) b) What % of data should be outside these limits? (1) 5. Is the fat content of the ground beef within statistical control? In real life, x and R charts have to be modified slightly because of the nature of data collection. Read below to find our about interpreting control charts. (2) Interpreting Control Charts Patterns or trends within control charts may indicate that problems are developing within the manufacturing process. Some rules of thumb are: Points that fall outside the control limits can be attributed to "assignable cause," which can be corrected by modifying production. Seven or more points in a row either above or below the centre line indicate that some aspect of the production process is off target. Seven or more points in a row either increasing or decreasing indicate a change in the production process. Points should not follow a repeating cycle. When all points fall within the specified limits and none of the trends described above are present, the process is said to be within statistical control.