Star refrigeration acknowledges that health and safety hazards may

advertisement

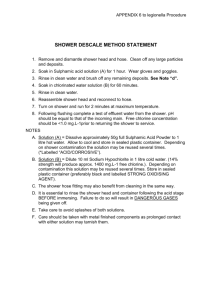

SAFETY GUIDANCE Emergency Drench Showers Page 1 of 3 Legionella is a bacterium that can proliferate in water, particularly stagnant water, such as dead legs to showers. If water droplets containing legionella bacteria are inhaled this can lead to Legionaires disease. As a result there is a requirement under the COSHH regulations to carry out a risk assessment and provide suitable and sufficient control measures to prevent harm. The HSE have produced an Approved Code of Practice covering the control of Legionella bacteria L8 which details the control measures required to minimise the danger to users of showers. This Safety Guidance is based on the requirements of L8. Guidance – Legionnaires’ disease: The control of legionella bacteria in water systems Approved Code of Practice & Guidance L8. Risks from Emergency Showers a) Legionella bacteria will build up in systems particularly where warm water is stagnant e.g. the dead leg serving a drench shower. b) Where water piping runs through a plant room or other warm area the water temperature is likely to be in the ideal range 20oC – 45oC to promote Legionella bacteria growth. c) Nutrients for feeding the bacteria include sludge, scale, rust, algae and organic matter i.e. what you would expect to find in a dead leg serving a shower. d) Even outdoor piping could be an issue as it is likely to be trace heated and thereby warming the stagnant water. e) Inhalation of water droplets from the shower. f) Hot and cold water systems are both potential sources of risk for legionella bacteria. ACOP L8 and Shower Manufacturers Recommendations: The following L8 requirements and manufacturers recommendations are placed on the owner of the shower (usually the client) and are included here for information. a) Under COSHH, risks from Legionella need to be identified and managed e.g. water hygiene risk assessment; reports and actions covering the shower installation and prepared by a specialist. b) Emergency showers in common use are Heated Types with calorifiers/hotwater cylinders with a downstream mixing valve to regulate the temperature to the showerhead; systems with direct in line heaters to warm the water flow to the showerhead, and unheated cool water systems. The manufacturers’ recommendations for the type installed should be followed. c) Heated systems with calorifiers/hot water cylinders should be set to maintain a temperature of 70oC. The water outlet temperature from the calorifier/hot water cylinder must be checked to ensure the heating system and controls are still operating. d) When outlets e.g. Emergency Showers are not in regular use, weekly flushing of these devices for several minutes can significantly reduce the number of Legionella bacteria discharged from the outlet. e) The weekly flushing must be for a sustained period and logged. For heated systems the shower should be run for at least 5 minutes but unheated cool water showers will need to be run for a longer time i.e. until the discharge water temperature drops to the same temperature as the incoming mains water supply. SG037.00 Drench Showers Page 2 of 3 f) Risk assessment may require even more frequent flushing. g) The water hygiene risk assessment may also require any cool water storage tank to be drained and cleaned. h) Where a weekly flushing regime is not in place, the stagnant and potentially contaminated water from within the shower/tap and associated dead legs, needs to be purged to drain before the appliance is used. It is important that this procedure is carried out with the minimum production of aerosols i.e. don’t just run the shower without taking other precautions. Additional piping/valves to a drain may be required to carry out this task or alternatively a discharge tube can be fitted temporarily over the showerhead to shield the operator from the water when testing and/or a P3 filter mask may be worn to prevent the operator breathing any aerosol droplets. i) Automatic drain valves that only drain the showerhead, hose and mixer valve are not recommended as a method of controlling the risk of exposure to legionella. j) Periodic analysis of the water quality is required to ensure that there is no build up of legionella bacteria in the shower, fittings, supply piping system calorifier and water tanks. Star’s Duties Designers Duty: All new installations where a shower is installed will have a letter from Design (See SF.240) stating that the Emergency Drench Shower and system must be maintained to ACOP L8 and manufacturers’ standards. Managers Duties: a) All existing customers with emergency drench showers must be advised in writing that the drench shower and system must be maintained to ACOP L8 and manufacturers standards. A draft letter is attached to this safety guidance note. b) A generic risk assessment for the use of emergency drench showers has been prepared covering sites where there is clear evidence that the shower is maintained to L8 requirements and also sites where there is no clear evidence. This risk assessment must be issued and explained to all staff working on sites where emergency showers are available. c) Site Safety Questionnaires and welfare instructions for each site must include the drench shower and any site-specific risk assessment and method statement issued. Page 3 SG037.00 Drench Showers of 3 «Company» «Address1» «Address2» «City» «PostalCode» «FirstName» «LastName» Ref Date Dear Sirs Emergency Drench Shower Maintenance We are writing to alert you to the risk of the build up of Legionella bacteria in the emergency shower and water system serving the shower. Emergency Showers are a particular risk as they are seldom used, often installed so that the water in some of the pipes could be stagnant and at an ideal temperature for the legionella bacteria to grow and showers produce an aerosol that can be inhaled when in use or during maintenance. The water treatment regime is likely to include Regular draining, flushing and treatment of the water supply system. Weekly operation of the shower. Logging of activities. For further information refer to Approved Codes of Practice L8 available from www.hse.gov.uk. If you already have a water hygiene treatment regime and procedures covering your hot and cold water services and the shower we would be grateful for a copy to help prepare our own risk assessments for working on your site. If you have overlooked the emergency shower system you should contact your water treatment specialist immediately. We will contact you shortly to discuss your site procedures and the risk assessment for using your emergency shower. Yours faithfully for (insert Company) Name MANAGER