Student 2 Response [DOC 5.5MB]

advertisement

![Student 2 Response [DOC 5.5MB]](http://s3.studylib.net/store/data/007571711_2-3cbbcd5b03a7c7464229c747c2a73572-768x994.png)

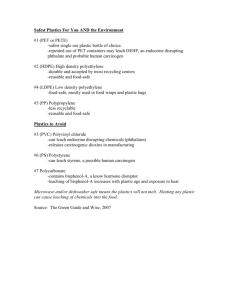

DESIGN AND TECHNOLOGY M ATERI ALS INVESTIG ATI ON PLASTICS General note: Most of the evidence of a particular performance standard against each specific feature is cumulative. Planning Analysis of information to develop solutions to an identified design brief. This is relevant insofar as materials for the major product are identified. Communication of product design ideas using relevant technical language. One of the most relevant specific features. Testing, modification, and validation of ideas or procedures. By testing materials the student can provide evidence of this specific feature. WORD COUNT- 700 Investigating Identification of a need, problem or challenge. Investigation in the Materials Application assists students in identifying appropriate materials for the major product. Investigation of product material options and analysis for product use. One of the most relevant specific features. Evaluating Reflection on materials, ideas or procedures, with recommendations. One of the most relevant specific features. Page 1 of 10 Stage 2 Design and Technology student response for use in 2011 533570809 (October 2010) © SACE Board of South Australia 2010 Introduction I am redesigning a plastic bottle shape and associated holder on my designed product this year, and I am to make a prototype using computer aided manufacturing. It is the materials used for possible product of this prototype that I am going to test. The two plastics which I have selected are P.E and P.V.0 to test, as both have properties that would allow successful manufacture for my prototype. Suitable properties for my prototype manufacture are: Manufacture easily and quickly Finish well and be painted Hardness, impact and be scratch resistant Thermoplastic Page 2 of 10 Stage 2 Design and Technology student response for use in 2011 533570809 (October 2010) © SACE Board of South Australia 2010 Investigating Considered identification of a need, problem, or challenge. In this case the need is to choose appropriate materials for a prototype of a bottle with holder. Competent investigation into product material options, and analysis for product use. At this stage, only the intention has been outlined. This combines with other sections identified in this report of the investigation to set the appropriate standard. Material Properties I am testing High Density Polyethylene and Polyvinyl Chloride because these plastics both contain necessary properties for my prototype. I am looking for a plastic that is easy to bend and shape but isn't too flexible that it will bend out of shape. I am also looking for a plastic that won't snap or break when dropped and has a nice surface finish which isn't rough. I am hoping that by conducting these plastic tests that I can find the material best suited for my prototype. A plastic bottle should not break or snap or be dented if it is squeezed, dropped, bounced or thrown etc. This would be tested through the hardness test, which will prove which plastic is more resistant to heavy impact i.e. scratching To help prove which plastic is more flexible I will use the elasticity test. This will show which plastic is more flexible and if it will bend back into shape. A plastic bottle can't lose its shape once it has been moulded but must be easy to mould to begin with. The machine test will give me an idea of which plastic has a better surface finish. A plastic bottle doesn't have rough or uneven edges. The surface finish must be smooth and even and have no rough edges. Page 3 of 10 Stage 2 Design and Technology student response for use in 2011 533570809 (October 2010) © SACE Board of South Australia 2010 Planning Competent testing, modification and validation of ideas or procedures. At this stage still only an intention. The ideas tested are the ideas for materials. Polyvinyl Chloride Polyvinyl Chloride, most commonly shortened to P.V.C, is the third most commonly used thermoplastic around the world for manufacturing. P.V.0 is tough and durable with good resistance to chemicals, electricity and is also weather resistant. P.V.0 is also soft and flexible. 1 About 57% of Polyvinyl chloride mass is chlorine. The chemical structure for Polyvinyl chloride relates to a sheet-like structure of polyvinyl chloride or a copolymer of vinyl chloride, which is capable of absorbing water vapor and transmitting water vapor. It is composed of polymeric particles and, modified polymer.2 Investigating Competent investigation into product material options and analysis for product use. 1. http://en.wikipedia.org/wilci/Polyvinyl chloride . 2. http://www.freepatentsonline.com/4 17827 1 .html Page 4 of 10 Stage 2 Design and Technology student response for use in 2011 533570809 (October 2010) © SACE Board of South Australia 2010 High Density Polyethylene P.E's chemical name is Polyethylene, the most popular plastic in the world. P.E is a thermoplastic and has a very simple structure, the simplest of all commercial polymers. Polyethylene is very tough and flexible with high resistants to electricity and chemicals. The mechanical properties of PE depend significantly on variables such as the extent and type of branching, the crystal structure, and the molecular weight. Generally, the integrity of end product polyethylene -based material in the plastics industry is based on density and melting point which can be up to 120°C for short periods of time. The chemical structure for polyethylene has a very simple structure. A molecule of polyethylene is nothing more than a long chain of carbon atoms, with two hydrogen atoms attached to each carbon atom.3 Investigating Competent investigation into product material options and analysis for product use. When there is no branching, it is called linear polyethylene, or HDPE. Linear polyethylene is much stronger than branched polyethyle ne, but branched polyethylene is cheaper and easier to make.4 High Density Polyethylene is a good material to test because it has some of the necessary requirements that would be needed for my prototype. 3 4 http://pslc.ws/macrogcss/pe.html http://pslc.ws/macrogcss/pe.html Page 5 of 10 Stage 2 Design and Technology student response for use in 2011 533570809 (October 2010) © SACE Board of South Australia 2010 Planning Analysis of information to develop appropriate solutions to an identified design brief. Design Plastic Assignment Test Materials Elastic test High Density Polyethylene and Polyvinyl Chloride To test both materials to find out which material is more Aim flexible and bends back into shape One 30mm sheet of Polyethylene Equipment One 30mm sheet of Polyvinyl chloride Two 500g weights Place both sheets of plastic on a table and clamp Measure distance from ground to plastic Then add the 500g of weight at the end of each plastic Measure the distance once again Take weights off to see which plastic bends back Method The P.V.C plastic bent with weights on 63mm where as the H.D.P.E bent 151mm. The P.V.C also went back to shape where as the H.D.P.E did not Observation Independent variable N/A My findings for the elasticity test was that the H.D.P.E Conclusion would be a better plastic to make my prototyp e from because it is flexible Page 6 of 10 Stage 2 Design and Technology student response for use in 2011 533570809 (October 2010) © SACE Board of South Australia 2010 Design Plastic Assignment Test Materials Aim Hardness test High Density Polyethylene and Polyvinyl Chloride To test both materials to see which plastic is softer through the width of the dent that is made in each of the plastics. Measurement device Equipment Hole punch P.V.C tube Place either of the sheets of plastic on a hard surface and drop the piece of metal through the tube so it makes a dent in the plastic Planning Analysis of information to develop appropriate solutions to an identified design brief. Do this around 10 times to get more of a consistency with Competent testing and modification and validation of ideas or procedures. The equipment required for the tests to be performed is shown. each dent Method The P.V.C had a smaller bounce when the metal was dropped. It showed a consistency of a 2.20 mm dent The H.D.P.E had a much longer bounce with each drop and had a consistency of a 2.80-3mm dent. Observation Independent variable N/A My findings for the hardness test was that the P.V.C plastic was Conclusion able to withstand the metal more and would be suitable for my prototype Page 7 of 10 Stage 2 Design and Technology student response for use in 2011 533570809 (October 2010) © SACE Board of South Australia 2010 Investigating Practical evidence of competent investigation into product material options and analysis for product use. Design Plastic Assignment Test Materials Aim Equipment Machine test High Density Polyethylene and Polyvinyl Chloride To test both plastics to find out which material has a better surface finish NC Machine Catia computer program Create geometry of a circ le and a triangle for a 10cm in length P.V.C and H.D.P.E and then process through the NC machine Method Observation Independent variable Conclusion Page 8 of 10 Planning Analysis of information to develop appropriate solutions to an identified design brief. Competent testing, modification and validation of ideas or procedures. The H.D.P.E had a really rough surface finish where as the P.V.C had a must cleaner and smoother finish N/A My findings for the machine test was that the P.V. C would be a much better plastic to machine for my prototype because it had a much more appropriate surface finish Stage 2 Design and Technology student response for use in 2011 533570809 (October 2010) © SACE Board of South Australia 2010 Conclusion Through testing High Density Polyethylene and Polyvinyl Chloride I h ave come to the conclusion that Polyvinyl Chloride would be the appropriate plastic for my prototype. I came to this conclusion though the results of the tests that conducted. Polyvinyl Chloride is an appropriate plastic compared to High Density Polyethyle ne because it was flexible Planning Competent communication of different quality product design ideas using relevant technical language. and bent back to shape, it was the stronger plastic and Polyvinyl Chloride had the perfect surface finish as to High Density Polyethylene. Polyvinyl Chloride is the better choice for a plastic and I am sure I will be very happy with the outcome of my prototype of a plastic bottle shape made from Polyvinyl Chloride. Additional Comment On balance, a review of the work provides evidence of: competent investigation with the characteristics of some existing products (Investigating) competent investigation into product material options and analysis for product use (Investigating) competent communication of product design ideas, using relevant technical language (Planning) analysis of information to develop appropriate solutions to an identified design brief (Planning). Bibliography Wednesday 8thth of April Last update: 2009 <http://en.wikipedia.org/wiki/Polyyinyl_chloride> Wednesday 8th of April Last update: 2009 <http://images.google.com.au/images?gbv=2&h1=en&safe=actiye&sa=1&q=High+Density +Polyethylene&btnG=Search+Images&aq=f&oq=> Wednesday 8th of April Last update: 2009 <http://images.google.com.au/images?gby=2&h1=en&safe=actiye&sa=1&q=P.V.C&a q=f&oq=> Tuesday 28th of April Last updated: 2005 < http://pslc.ws/macrogcss/pe.html > Friday 1st of May Last updated: 2009 < http://www.freepatentsonline.com/4178271.html > Page 9 of 10 Stage 2 Design and Technology student response for use in 2011 533570809 (October 2010) © SACE Board of South Australia 2010 Evaluating Considered reflection on materials, ideas and procedures, with appropriate recommendations. Stage 2 Design and Technology Performance Standards A Investigating Planning Producing Evaluating Clear, comprehensive, and well-considered identification of a need, problem, or challenge. In-depth analysis of information to develop imaginative, innovative, and enterprising solutions to an identified problem. Sophisticated application of appropriate skills, processes, procedures, and techniques to create a product or system to a precise or polished standard and specification. Insightful and well-considered evaluation of product success against design brief requirements. Accomplished communication of a variety of refined product design ideas, consistently using relevant technical language. Accomplished use of resources, equipment, and materials to create a product or system safely and accurately. Thorough and insightful creation and validation of initial design brief based on needs analysis and task identification. Purposeful investigation and critical analysis of the characteristics of a broad variety of existing products, processes, systems, and/or production techniques. In-depth investigation into product material options and focused and thorough critical analysis for product use. B Focused and perceptive investigation into the impact of products or systems on individuals, society, and/or the environment. Purposeful testing and refined modification and validation of ideas or procedures. Well-considered identification of a need, problem, or challenge. Thoughtful analysis of information to develop enterprising solutions to an identified design brief. Well-considered creation and validation of an initial design brief based on needs analysis and task identification. Thoughtful investigation and analysis of the characteristics of a variety of existing products, processes, systems, and/or production techniques. Detailed investigation into product material options and thorough analysis for product use. Some depth of investigation into the impact of products or systems on individuals, society, and/or the environment. C Considered identification of a need, problem, or challenge. Considered creation and validation of an initial design brief based on needs analysis and task identification. Competent investigation of the characteristics of some existing products, processes, systems, and/or production techniques. Competent investigation into product material options and analysis for product use. Generally thoughtful investigation into the impact of products or systems on individuals, society, and/or the environment. D Identification of a basic need, problem, or challenge. Creation of a basic initial design brief with some consideration of a needs analysis. Identification of the characteristics of some existing products, processes, systems, or production techniques. Some basic description of material options. Some description of the impact of products or systems on individuals, society, or the environment. E Limited identification of a need, problem, or challenge. Capable communication of different quality product design ideas using relevant technical language. Accomplished and resourceful development of solutions to technical problems that may arise during product or system realisation. Capable application of appropriate skills, processes, procedures, and techniques to create a product or system to a mostly precise or polished standard and specification. Refined and well-considered reflection on materials, ideas and procedures, with sophisticated recommendations. Resourceful and well-informed analysis of the impact of the product or system on individuals, society, and/or the environment. Well-considered evaluation of product success against design brief requirements. Well-considered and detailed evaluation of the effectiveness of the product or system realisation process. Capable use of resources, equipment, and materials to create a product or system safely and mostly accurately. Well-considered reflection on materials, ideas and procedures, with thoughtful recommendations. Thoughtful testing, modification, and validation of ideas or procedures. Thoughtful development of solutions to technical problems that may arise during product or system realisation. Well-informed analysis of the impact of the product or system on individuals, society, and/or the environment. Analysis of information to develop appropriate solutions to an identified design brief. Competent application of skills, processes, procedures, and techniques to create a product or system to an appropriate standard and specification. Considered evaluation of product success against design brief requirements. Competent communication of product design ideas using appropriate technical language. Competent use of resources, equipment, and materials to create a product or system safely and generally accurately. Competent testing, modification, and validation of ideas or procedures. Development of appropriate solutions to technical problems that may arise during product or system realisation. Some identification of information to attempt basic solutions to an identified design brief. Partial application of skills, processes, procedures, and techniques to make one or more articles to a limited standard and specification. Basic communication of some product design ideas with some use of appropriate technical language. Partial testing and some modification of ideas or procedures. Some use of basic resources, equipment, or materials to create a product or system, with some consideration of safety aspects. Considered evaluation of the effectiveness of the product or system realisation process. Considered reflection on materials, ideas and procedures, with appropriate recommendations. Informed analysis of the impact of the product or system on individuals, society, and/or the environment. Description of product progress, with elements of basic testing against design brief requirements. Some description of the effectiveness of the product or system realisation process. Superficial reflection on or description of materials, ideas or procedures, with basic recommendations. Partial development of some basic solutions to technical problems that may arise during product or system realisation. Some consideration of the impact of the product on individuals, society, or the environment. Attempted application of one or more skills, to follow an appropriate process, procedure, or technique. Identification of some product progress, with limited testing. Creation of a very basic initial design brief, with support. Attempted identification of some information to develop limited solutions to an identified design brief. Statement of one or more characteristics of an existing product, process, system, or production technique. Limited communication of one or more product design ideas. Attempted use of resources, equipment, or materials, with emerging awareness of safety issues. Limited description of one or more product material options. Some attempt at testing and limited modification of an idea or procedure. Some attempted description of problems that may arise during product or system realisation. Identification of one impact of a product or system on individuals, society, or the environment. Insightful and detailed evaluation of the effectiveness of the product or system realisation process. Identification of some aspects of the effectiveness of the product or system realisation process. Identification rather than description of materials, ideas or procedures, with one or more recommendations. Emerging recognition of one or more of the impacts of the product on individuals, society, or the environment.