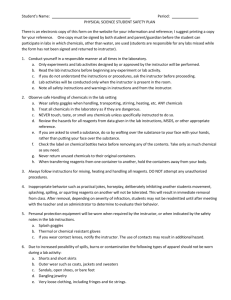

LAB #1: WATER PURIFICATION AND

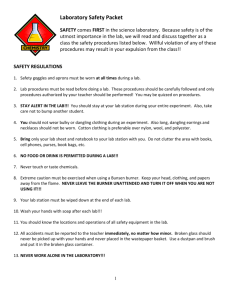

advertisement