Wind Notes

advertisement

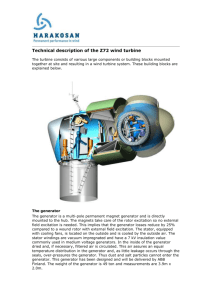

WIND POWER (revised 2013) Traditional use of wind to pump water on farms – part of rural electrification was that wind mill pumps were removed to promote electrical use. In theory 13 times more wind power than all current worldwide electrical production, but getting it to where it is needed is the issue Wind produced via solar energy – hot air rises, cool air falls – day and night breezes of the ocean or mountain. Wind currents act like ocean currents and are predictable – prevailing winds Small scale – remote locations, sometimes combined with solar, or a small generator, can be off-grid or grid-tied systems, grid tied means it is connected to the larger electrical system. Large scale wind farms - costs of wind generation has dropped dramatically – if environmental costs are factored in, wind is cheapest alternative energy Large installations can be started slowly and built up unit by unit. Competition from cheap natural gas has changed this equation. Design types horizontal axis – most common Vertical axis type Three blade most common, but two and even single blade units are made Large units require substantial cooling of the generator bearings In large systems when the wind varies the rotation of the generator must be constant since it has to parallel with other generators to produce the correct voltage and frequency. Uses an adjustable gearbox = an auto transmission in reverse to keep the generator operating at a constant speed and voltage. Site location is critical – even a small difference in placement can make a large difference Wind systems are 25-40% efficient and improving Large systems use pitch control of the blades to optimize wind use, like a sailing ship or a helicopter Big farms require very little maintenance due to advanced engineering, automation, and remote monitoring. Problems with public perception of aesthetics or scenic views, cats kills 279 million birds, wind farms 50,000 small wind ( lower, smaller blades)= fewer kills Small scale systems up to 20 kilowatts First make the house efficient only makes power when wind is blowing so batteries or grid tied systems are needed for other times Small wind tower at least 30 feet high and 200 feet from houses trees etc. the higher the better due to ground level wind turbulence. Wind generators are noisy – and can through ice in the winter Economics Bigger is more costly, but produces more, taller is better, the labor is not much more for bigger units, maintenance is not much more = bigger is better. Large scale costs are “reasonable” and they can be located in farm land helping rural economies. Environmentally favorable, little CO2 etc. Use much less water than a nuclear or coal plant; 500 gallons per MWh verses 1 gallon per MWh for a wind farm. Small wind Is small wind feasible? Is there enough wind Are towers allowed, zoning laws and covenants If you have remote access with poor access to grid At least $150 a month in electric bills (2007) Can afford long term investments Enough space (at least 1 acre) rural area it might be economically feasible noise (55 Db) First – reduce energy use insulation and weatherization upgrade heating and cooling double pained windows energy efficient lights phantom loads energy efficient appliances (refrigerator uses up to 25% of electrical usage) Small, energy efficient appliances Micro turbines – 20 to 100 kW 10 kW turbine to pump water = wind electric water pumping system is more flexible typical home requries10,000 kWh per year needs over-speed protection and start and stop velocity controls Rotor, generator/alternator, tower, tail most horizontal – up wind (face the wind) Siting wind is a fluid and encounters friction and turbulence like any fluid ground drag – wind slower at the surface most resistance 60 above flat ground and 60 above tallest trees much turbulence around buildings turbulence can cause turbines to hunt (rotate) excessively damaging the turbine wind data maps for general location then a site specific plan is developed tower height, the higher the better and sweep (diameter) of the blades should be 30 feet above any obstacle within 300 ft of houses trees hill etc. To increase a 60 foot 10-kW generator up to 100 ft = 10% cost increase but 29% more power winds higher and truer the higher you go towers stand alone or guyed if the tower is not a tip down type then maintenance done by climbing do not mount on houses needs batteries, inverter, connecting wires 2007 80ft tower 3-10 kW $15 to 50 K Self install?????????? concrete raise tower wiring install batteries maintenance – annual, mechanical and electrical connections, tension guy wires, inspect and repair blades, bearings (replace at 10 years) overall 20 year life span output =local conditions, rotor sweep, air density (thinner air at higher altitudes) siting is critical – general wind flow, but local conditions like hills trees, buildings (up wind) local turbulence grid tie systems will need to meet grid specifications for safety (disconnect when power is out on the grid), synchronized (voltage, frequency power quality) some utilities require liability insurance less wind in summer – use solar or generator to back up off grid at least average annual 9mph wind, grid not nearby, live free or die approach, want clean power Maintenance semi annual – spring and fall calm days lockout blades disconnect from grid climbing gear do you like heights? moving heights listen for unusual sounds turbine – blades, tail, internal components, open or disassemble (?) lose connections, retorque, tension guy wires, rust, cracks lightning control systems over speed connection mechanism climbing safety, harness, tools battery maintenance Generators a generator produces DC, an alternator produces AC rotor contains permanent magnets (some expensive model sue electromagnets) stator (windings where the electricity is induced) direct drive, the rotor connected to the blades more expensive units will use a gearbox between the blades and rotor blades made of composites, fiberglass foam etc. tail keeps blades facing the wind governors and over speed controls most use furling = turn the blades out of the wind to slow them down – the tail moves to position the turbine at an angle to the wind expensive turbines can change the blade pitch shut down system completely stops rotation – mechanical brakes or electric brakes (dynamic brake)