Supplementary Information (doc 1760K)

advertisement

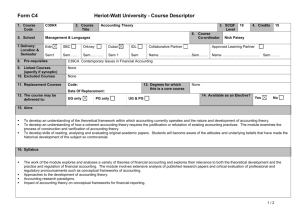

Supplementary Materials 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 Direct Visualization of Swollen Microgels via Scanning Electron Microscopy Using Ionic Liquids Koji Horigomea, Takeshi Uekic, and Daisuke Suzukia,b* a b Graduate School of Textile Science & Technology, Shinshu University 3-15-1 Tokida, Ueda, 386-8567, Japan Division of Smart Textiles, Institute for Fiber Engineering, Interdisciplinary Cluster for Cutting Edge Research, Shinshu University, 3-15-1, Tokida, Ueda, 386-8567 Japan c Department of Materials Engineering, School of Engineering, The University of Tokyo,7-3-1 Hongo, Bunkyo-ku, Tokyo 113-8656, Japan * Author to whom correspondence should be addressed. E-mail: d_suzuki@shinshu-u.ac.jp 19 Direct visualization of swollen microgels using ionic liquids Page 2 1 Table of Contents 2 1. SI Table 1: Summary of the size of the p2VP microgel. 3 2. SI Table 2: Measurements of the weight before or after drying of p2VP microgel dispersion 4 5 6 and the mixture 3. SI Table 3: Measurements of the weight before or after drying of pNIPAm microgel dispersion and the mixture 7 4. SI Figure 1: SEM images of the dried and IL-swollen p2VP microgels. 8 5. SI Figure 2: SEM images of pools of ionic liquid. 9 6. SI Figure 3: SEM image of the dried p2VP microgels without sputtering. 10 7. SI Figure 4: SEM images of pNIPAm hybrid microgels using [Im][NTf2]. 11 8. SI Figure 5: TEM image of the dried hybrid microgels. 12 9. SI Figure 6: AFM images of dried pNIPAm based microgels and IL-swollen pNIPAm based 13 14 microgels. 10. SI Figure 7: Cross section data of dried and IL-swollen microgels. 15 2 Page 3 1 2 3 4 5 SI Table 1. Measurements of the diameter of the p2VP microgels under various conditions. Code Dh [nm] pH NaCl concentration [mM] Dh-pH3 1347 3.3 1 Dh-pH6 234 6.4 1 Dh-pH3-1MNaCl 677 3.1 1000 Ddry 245 - - DIL 523 - - 3 Page 4 1 SI Table 2. Measurements of the weight before or after drying of p2VP microgel dispersion and 2 the mixture. The water content (Z) was calculated by the following equation: Z = Y/X×100 using 3 the measurements. 4 5 4 Page 5 1 SI Table 3. Measurements of the weight before or after drying of the poly(NIPAm-co- 2 GMA)microgel dispersion and the mixture. The water content (Z) was calculated by the 3 following equation: Z = Y/X×100 using the measurements. 4 5 5 Page 6 1 SEM images of the dried and IL-swollen p2VP microgels 2 3 SI Figure 1. SEM image of dried p2VP microgels. (a) A 0.001 wt.% microgel dispersion was 4 deposited on a Pt/Pd substrate and dried at 24 °C. (b) A mixture of the microgel dispersion and 5 [Im][NTf2] was dried at ~25 °C and observed via SEM without Pt/Pd sputtering. The microgels 6 were located near the pools of [Im][NTf2]. In both cases, the sample stage was tilted at 75°. The 7 insets show the magnification of a microgel. 8 6 Page 7 1 SEM images of pools of ionic liquid. 2 3 SI Figure 2. Scanning electron microscopy (SEM) images of the dried state of a mixture of a 4 p2VP microgel dispersion and ionic liquid. 0.5 μL ionic liquid was added to 1 mL dispersion and 5 the mixture (10 µL) was dried on a Pt/Pd substrate. (b) and (c) were magnification of the local 6 area as shown in (a). (b) Pools of ionic liquid. A white arrow indicates one example indicating a 7 pool of ionic liquid. (c) IL-swollen microgels located at near the area of pools 8 9 10 11 7 Page 8 1 SEM image of the dried p2VP microgels without sputtering. 2 3 SI Figure 3. Scanning electron microscopy (SEM) image of the dried structure of a p2VP 4 microgel dispersion. The sample was observed via SEM without sputtering (i.e., the microgel 5 was not coated with a Pt/Pd layer). A white arrow indicates one example indicating artifacts due 6 to the accumulation of electrons on the microgel. 7 8 8 Page 9 1 SEM images of pNIPAm based microgels using [Im][NTf2]. 2 3 4 SI Figure 4. Scanning electron microscopy (SEM) images of pNIPAm-based microgels obtained 5 using 0.5μL [Im][NTf2]. A mixture of the microgel dispersion and [Im][NTf2] (10 µL) was dried 6 at room temperature and then observed via SEM without Pt/Pd sputtering. The sample stage was 7 tilted at 75°. The average size was calculated to be 347 nm. The size of the hybrid microgels was 8 thus approximately equal to that of the dried state of the microgel when [Im][NTf2] was used for 9 this observation (372 nm: Figure 3(a) in the main text). Therefore, to observe swollen microgels 10 via this method (as shown in Figure 2 in the main text), selection of the appropriate ionic liquid 11 (IL) is required in order to obtain good affinity between the IL and the cross-linked polymer 12 network in the microgels. For the pNIPAm hybrid microgels containing Au nanoparticles, the 13 water-soluble IL [dema][TfO] was found to be effective. 14 9 Page 10 1 TEM image of the dried hybrid microgels. 2 3 4 SI Figure 5. Transmission electron microscopy image of the dried structure of hybrid microgels. 5 The microgel dispersion (1.5 µL) was dried on a carbon-coated copper grid. The average size of 6 the Au nanoparticles, determined using ImageJ software, was 26 ± 6.8 nm (N = 30), and was in 7 good agreement with the size determined from the FE-SEM observation (Figure 3(b) in the main 8 text). 9 10 Page 11 1 AFM images of dried pNIPAm based microgels and IL-swollen pNIPAm based microgels. 2 3 SI Figure 6. AFM images (scan size: 10×10 μm2) of (a) dried pNIPAm based microgels and (b) 4 the IL-swollen microgels. The measurements data are summarized at the Table. The areas that 5 are indicated by white dotted squares show magnification points, and the magnification images 6 are shown in SI Figure 7. The pNIPAm microgel dispersion was dried at room temperature, and 7 then the samples was dried under reduced pressure. The dried structure was recorded by 8 cantilever (SI Figure 6(a)). The diameter (DAFM-dry) and height (hdry) of the dried pNIPAm 9 microgels were measured to be 315 nm and 201 nm (N=4), respectively. DAFM-dry is good 10 agreement with FE-SEM measurements (DFE-SEM_dry 372 ± 25 nm). In addition, to estimate the 11 swelling of the microgels, we tried to record the topography of IL-swollen microgels. First, the 12 IL was dissolved in water, and then the microgel dispersion was added to the mixture. Next, the 13 mixture was dried on the polystyrene substrate, and then the dried structure was recorded via 14 AFM (SI Figure 6(b)). As a result, the diameter (DAFM-IL) and the height (hIL) of IL-swollen 15 pNIPAm microgels were measured to be 547 nm and 255 nm (N=4), respectively. DAFM-IL is 16 good agreement with FE-SEM measurements (DFE-SEM_IL 555 ± 43 nm). As a result, the swelling 17 ratio, φ, of the IL-swollen pNIPAm microgel was calculated to be 3.82. 18 11 Page 12 1 Cross section data of dried and IL-swollen microgels. 2 SI Figure 7. (a) Cross section data of dried and IL-swollen microgels. Magnifications of AFM 3 images of (b) IL-swollen (c) dried microgel. White doted square in SI Figure 6 indicate the 4 magnification area. 5 12