Response to the reviewers` comments

advertisement

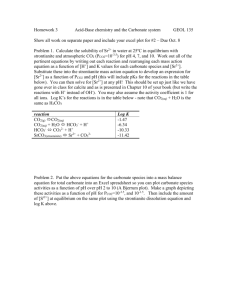

A submicron broadband surface-plasmon-polariton unidirectional coupler (supplementary information) Huimin Liao, Zhi Li, and Qihuang Gong State Key Laboratory for Mesoscopic Physics and Department of Physics, Peking University, Beijing 100871, China Section 1/ Implementation of the different calculation models In this Section, the implementation of the different calculation models used in the manuscript is illustrated in detail. The pure surface-plasmon-polariton (SPP) model The pure SPP model calculates equations (S1) and (S2) which include all the contributions from the SPP components. Considering the SPP multiple reflections at the two grooves, the finally resulted SPP amplitudes away from the groove-doublet to the left AL and to the right AR are expressed as AL A1 A2 t1 exp( ik sppd ) A1r2 t1 exp( ik spp 2d ) A2 r1r2 t1 exp( ik spp 3d ) A1r2 r1r2 t1 exp( ik spp 4d ) (S1) A1 [ A2 exp( ik sppd ) A1r2 exp( ik spp 2d )]t1 [ r1r2 exp( ik spp 2d )] n n 0 AR A2 A1t 2 exp( ik sppd ) A2 r1t 2 exp( ik spp 2d ) A1r2 r1t 2 exp( ik spp 3d ) A2 r1r2 r1t 2 exp( ik spp 4d ) (S2) A2 [ A1 exp( ik sppd ) A2 r1 exp( ik spp 2d )]t 2 [ r2 r1 exp( ik spp 2d )]n n 0 Here, A1 and A2 denote the complex amplitudes of SPPs (to one direction) directly excited by groove 1 and groove 2, as schematically illustrated in Fig. S1(a). The SPP transmission and reflection coefficients (corresponding to incident SPPs to transmitted SPPs conversion and incident SPPs to reflected SPPs conversion) at groove 1 and groove 2 are represented by t1, r1 and t2, r2, respectively. Since SPPs are TM-polarized, all the above quantities are evaluated through the Hz component of the EM field. Figure S1 | Schematic diagrams of the SPP excitation and scattering processes in the pure SPP model. (a) SPP excitation by two grooves with normal incidence. (b) SPP transmission and reflection at a groove with left incidence. The variables A1, A2, t1, r1, t2, r2 are evaluated by performing numerical simulations by the finite element method (FEM), using COMSOL Multiphysics. With normally illumination by a wide Gaussian beam, the complex amplitude of the directly excited SPPs (A1 or A2) by a single nanogroove (groove 1 or groove 2) can be extracted at 25 μm away from the nanogroove (a sufficiently large distance to avoid the influence of CWs). Using the eigenmode of the SPPs on the metal surface to incident from left boundary and propagate along the metal surface, and then comparing the resulted EM field with and without the existence of the nanogroove, the SPP transmission and reflection coefficients of a nanogroove can be achieved (also being extracted at 25 μm away from the nanogroove), as schematically shown in Fig. S1(b). For instance, typical calculated values are A1=0.221e-0.80i, A2=0.221e0.80i, t1=0.848e0.17i, r1=0.235e2.34i, t2 =0.866e-0.21i, r2 =0.219e-2.34i with groove widths of w1=w2=80 nm and groove depths of h1=67 nm, h2=134 nm [the parameters used in Fig. 2(a)-(c) in the manuscript]. From the calculated results, it is also verified that the approximation of t1, t2≈1 and r1, r2 ≈0 are roughly reasonable. This approximation leads to the simplified expressions of equations (3) and (4) in the manuscript. Calculation of the modified model including the CW contributions As is known that, in addition to SPPs, quasi-cylindrical waves (CWs) also give evident contributions to the total field on the metal surface at short distances from an electromagnetic field source (such as nanogrooves and nanoholes). Therefore, for small groove separations, CWs excited by one groove will be partly scattered into SPPs at the other groove, which will change the total SPP intensities. To include the CW contributions quantitatively, we use a modified model which takes into account cross conversions between SPPs and CWs. Generally, the total EM field on the metal surface excited by a nanogroove can roughly be expressed as H ( x) spp H 0 exp( ik spp x) cw H 0 ( x / ) m exp( ik 0 x) (S3) This equation is the same as the equation (1) in Ref. 32, with the first term representing the SPP component and the second term representing the CW component. This equation is an approximate expression which can be utilized to evaluate the CW component from the total field through a simple fitting procedure. In our calculations, we follow the more rigorous mode decomposition method in Ref. 31 to evaluate the CW component more precisely. By taking advantage of the mode orthogonality, the mode decomposition method can evaluate the complex amplitude of the SPP component by overlap integral between the total scattered EM field and the eigenmode of the SPPs [equation (4) in Ref. 31]. Then, subtracting the SPP component from the total scattered EM field, the resulted residual field near the metal surface is just the CW component. Figure S2 displays a typical example of the calculated CW component (red line) together with the SPP component (blue line) at 10 nm above the metal surface. It is clearly seen that the CW component presents a short-range nature compared with the SPP component. Figure S2 | Calculated Re(Hz) excited by a nanogroove with normal incidence using the mode decomposition method. The black, blue and red lines indicate the total scattered field, the SPP field and the CW field, respectively. Figure S3 | Schematic diagrams of the field scattering processes by a nanogroove in the modified model. (a) The incident SPP field is scattered into forward-propagating SPP, backward-propagating SPP, forward-propagating CW and backward-propagating CW, with corresponding scattering coefficients denoted by tsp,sp, rsp,sp, tcw,sp, rcw,sp. (b) The incident CW field is scattered into forward-propagating SPP, backward-propagating SPP, forward-propagating CW and backward-propagating CW, with corresponding scattering coefficients denoted by tsp,cw, rsp,cw, tcw,cw, rcw,cw. In the previous pure SPP model, the related scattering process at a nanogroove is relatively simple since only the incident SPPs to transmitted SPPs conversion and incident SPPs to reflected SPPs conversion need to be considered [described by the SPP transmission coefficient t and reflection coefficient r, as shown in Fig. S1(b)]. However, the situation becomes much more complicated if the CW component is considered as well, as schematically illustrated in Fig. S3. In this case, the total field excited by a nanogroove can be divided into the SPP component and the CW component. Figure S3(a) demonstrates the scattering process of the excited SPP component by the counterpart groove. The incident SPPs can be scattered into forward-propagating SPPs, backward-propagating SPPs, forward-propagating CWs and backward-propagating CWs, with corresponding scattering coefficients denoted by tsp,sp, rsp,sp, tcw,sp, rcw,sp, respectively. Similarly, the scattering process of the excited CW component by the counterpart groove is illustrated in Fig. S3(b). Evidently, such cross conversions between SPPs and CWs will modify the total SPP intensities launched by the groove-doublet structure. To include all the above scattering processes, we use a transfer matrix method in which the scalar equations (S1) and (S2) are modified into matrix equations. For example, equation (S1) becomes AspL Asp1 A A T1 P sp2 T1 PR2 P sp1 AcwL Acw1 Acw2 Acw1 . (S4) Asp2 Asp1 T1 PR2 PR1 PR2 P ... T1 PR2 PR1 P Acw2 Acw1 Here, the EM field near the metal surface is represented by a vector, with the first element Asp denoting the SPP component and the second element Acw denoting the CW component. The transmission and reflection of the total EM field at a groove are described by the matrices R and T. The propagation of the total EM field over a distance of d is denoted by the matrix P(d). The specific expressions of the matrices are rsp,sp R rcw,sp t rsp,cw t p (d ) , T sp,sp sp,cw , and P(d ) sp t rcw,cw 0 cw,sp tcw,cw . pcw (d ) 0 In the expression, Psp(d)=exp(iksppd) describes the propagating of the SPP component while Pcw(d) describes the propagating of the CW component. Next, we demonstrate the calculation process of the matrix equation (S4). According to the hybrid-wave concept in Ref. 31, the ratio of the excited SPP component to the excited CW component by a groove does not change with the groove structure (only change with the wavelength). So we define g= Acwi/Aspi to denote this ratio. For the evaluation of the matrix R and T, we follow the strategy in Ref. 32. Referring to a form of causality principle where equal causes have equal effects, one expects that the scattered fields of the two diffraction problems (incident with SPPs or CWs) are nearly identical: same scatterings into free space, same excitations of the groove Fabry-Perot resonances and in the context of the cross conversion. If we denote the scattering coefficients by s’, this principle gives s’sp,cw = s’sp,sp. Besides, the ratio of the scattered SPP component to the scattered CW component should be equal to g according to the hybrid-wave concept. This gives s’cw,sp = s’sp,sp · g and s’cw,cw = s’sp,cw · g = s’sp,sp· g. For reflections, because the reflected field is just the scattered field by the groove at the incident side, we have rsp,cw = rsp,sp, rcw,sp = rsp,sp · g, and rcw,cw = rsp,sp · g. All the other three elements in the matrix R is related to rsp,sp which is exactly the SPP reflection coefficient r in the previous pure SPP model. Similar analysis can be applied to the transmission matrix T. Because the transmitted field is the superposition of the scattered field by the groove and the incident field at the outgoing side, we have tsp,sp = 1 + s’sp,sp, tcw,sp = s’cw,sp, tsp,cw = s’sp,cw, tcw,cw = 1 + s’cw,cw. So it can be deduced that tcw,sp = (tsp,sp-1) · g, tsp,cw = tsp,sp-1, tcw,cw = 1 + (tsp,sp-1) · g, with tsp,sp being exactly the SPP transmission coefficient t in the previous pure SPP model. In such a way, both the reflection and transmission matrices can be evaluated. Because the propagation matrix P is a diagonal matrix, the equation (S4) can be rewritten as A A AspL Asp1 T1 P sp2 T1 [ PR2 ] P sp1 AcwL Acw1 Acw2 Acw1 A A T1 [ PR2 ][ PR1 ] P sp2 T1 [ PR2 ][ PR1 ][ PR2 ] P sp1 ... Acw2 Acw1 , (S5) where 1 1 A p (d ) Asp psp (d ) Asp psp (d ) Asp P sp sp Acw pcw (d ) Acw pcw (d ) Acw / psp (d ) Asp pcw (d ) g / psp (d ) and p (d ) PR r sp pcw (d ) g 1 psp (d ) rpsp (d ) pcw (d ) g pcw (d ) g / psp (d ) . pcw (d ) g / psp (d ) 1 Therefore, we do not calculate g and pcw(d) separately but directly extract the value of pcw (d ) g / psp (d ) (that is the ratio of the complex amplitude of the CW component to the complex amplitude of the SPP component at a distance d from the source) in the calculation process of the CW component. Till now, the calculation methods for all the parameters in the modified model have been provided. In the actually calculations, we take into account the first 17 terms in the right side of equation (S4) which is enough to provide a sufficiently precise result [evidenced by the well consistence with the direct FEM simulation results, see Fig. 2 (a)-(c) and Fig. 3(a) in the manuscript]. In fact, using a little fewer terms does not make evident difference, since the reflection coefficient r is typically small. Section 2/ The design process of the unidirectional SPP coupler In this Section, we demonstrate the procedure of finding the solution for realizing the SPP unidirectional launching. A good unidirectional SPP coupler should extinct the launched SPPs to one direction (i.e. AL=0 or AR=0) while excite SPPs to the opposite direction efficiently. Generally, such solution is not quite easy to find because the launched SPP intensities depend on too much factors (such as the amplitudes and phases of the SPPs excited by individual grooves, the SPP transmissions and reflections at the grooves, cross conversions between SPPs and CWs). To simplify the problem, it is reasonable to ignore the complex higher-order terms and cross conversions between SPPs and CWs at first. In this case, the launched SPP intensities to the left and right can be roughly described by equations (3) and (4) in the manuscript. If we further neglect the SPP propagation loss, we can directly obtain the optimal solution for realizing the SPP unidirectional launching. That is A2=(±)i∙A1 and exp(iksppd)=(±)i, which gives AL=0 and AR=2A2, or AL=2A1 and AR=0, depending on the same signs or the opposite signs are chosen in the brackets. Correspondingly, perfect SPP unidirectional excitation to the right or to the left is obtained with an extinction ratio of infinity. Physically, the second condition [exp(iksppd)=(±)i] corresponds to groove separations of d=(n±1/4)λspp, and the first condition [A2=(±)i∙A1] means that the two nanogrooves should excite SPPs with equal intensities and an initial phase difference of π/2 (this can be satisfied by adjusting the widths and depths of the two nanogrooves). Till now, we have obtained the zero-order approximation solution. However, there are still many possibilities for the choice of the groove widths and depths. So we fix the groove widths at w1=w2=80 nm (0.1λ at the incident wavelength of λ=800 nm) as a typical example. Then, FEM simulations (see Fig. S4) give that groove depths (h1, h2)=(67, 134) nm can provide nearly equal SPP excitation intensities and a phase difference of π/2 which in turn gives AL=0 or AR=0 at groove separations of d=(n±1/4)λspp. Note that, this zero-order approximation solution obtained from equations (3) and (4) in the manuscript is appropriate for all groove separations of d=(n±1/4)λspp if the SPP propagation loss is neglected. 0.35 0.4 0.2 0.25 phase/ Amplitude 0.30 0.20 0.15 0.0 -0.2 0.10 -0.4 0.05 0 50 100 150 h(nm) 200 250 0 50 100 150 200 250 h(nm) Figure S4 | Excited SPPs by a single nanogroove at different groove depths. (a) Calculated SPP amplitude as a function of the groove depth h. (b) Calculated SPP phase as a function of the groove depth h. The incident wavelength is λ=800 nm and the groove width is w=80 nm. The two squares indicate the data points with h= 67 nm and 134 nm. In the second step, we try to get the solution of AL=0 or AR=0 from the more precise expressions of equations (S1) and (S2) which include the effect of SPP multiple reflections. We start from the above zero-order approximation solution of (h1, h2)=(67, 134) nm and d=(n±1/4)λspp. A comparison between equations (S1), (S2) and equations (3), (4) in the manuscript reveals that, one simple choice is to only adjust the groove depths (this will change A1, A2 accordingly) and fix other structure parameters to satisfy AL=0 or AR=0. Calculations show that, when the groove depths are adjusted to (h1, h2)=(62, 118) nm, equation (S1) gives AL=0 at d=(n+1/4)λspp; when the groove depths are adjusted to (h1, h2)=(75, 149) nm, equation (S2) gives AR=0 at d=(n-1/4)λspp. Here, the degenerate zero-order approximation solution obtained from equations (3) and (4) in the manuscript splits into two different solutions for equations (S1) and (S2), because the SPP transmission and reflection coefficients are different for the two grooves (t1≠t2, r1≠ r2). Finally, we turn to the modified model including the CW contribution. Following the strategy in the second step, we further optimize the groove depths from the solutions obtained by equations (S1) and (S2) in the second step. Because the CW component significantly depends on the distance from the source, the solutions for AL=0 or AR=0 using the modified model become different for different groove separations. That is, the solutions for realizing SPP unidirectional launching split further. Table S1 summarizes the calculated groove depths satisfying AL=0 or AR=0 using different models. The groove depths calculated by the modified model deviate from the results calculated by the pure SPP model [equations (S1) and (S2)] more and more as the groove separation gets smaller. This is a clear evidence of the increasing significance of the CW component with decreasing the groove separation. Table S1 | The groove depths (h1, h2) in nm satisfying AL=0 or AR=0 at different groove separations using different models. “Simplified SPP”, “Pure SPP”, “SPP+CW” refer to the simplified expressions of equations (3) and (4) in the manuscript, the pure SPP model using equations (S1) and (S2), and the modified model using equation (S4), respectively. ( w1=w2=80 nm, λ=800 nm) model d=1/4 λspp d=3/4 λspp d=5/4 λspp d=7/4 λspp d=9/4 λspp Simplified (67,134) (67,134) (67,134) (67,134) (67,134) SPP Pure SPP (62,118) (75,149) (62,118) (75,149) (62,118) SPP+CW (65,96) (72,162) (64,111) (73,155) (64,115) Section 3/ Contributions of different physical mechanisms to the bandwidth of the proposed SPP coupler From Fig. 3(a) in the manuscript, we can see that the calculation results (lines) using the modified model containing the CW contributions well match the direct FEM simulation results (scatters) using Comsol Multiphysics. The bandwidths of the proposed SPP coupler at different groove separations are well reproduced by the modified model, including the anomalous bandwidth shrinking phenomenon at d=1/4 λspp. This means that the main physical mechanisms concerning the bandwidth are all included in the modified model. So it is reasonable to analyze the bandwidth behavior of the proposed SPP coupler based on this model. From equation (S4), it can be seen that, there are mainly three types of physical factors which depend on the wavelength and may affect the bandwidth. The first factor is the pure interference factor between the two interfering SPP sources, which is represented by the propagation factor exp(iksppd). This factor has a positive correlation with the groove separation d (the bigger the groove separation, the faster this factor changes with the wavelength). Therefore, this factor may determine the bandwidth behavior at large groove separations. The second factor is the dispersion effects of the individual grooves, especially the wavelength dependences of the directly excited SPPs by the grooves (A1 and A2). Figure S5 (a) and (b) display two-dimensional plots of the amplitude and phase of the excited SPPs (determined at 25 μm away from the source to avoid the influence of CWs) as functions of the groove depth and the incident wavelength. The data were extracted from FEM simulation results with wide Gaussian beam normally illuminated on a single groove (each data point in the two-dimensional plot needs a separate simulation). The resonant character of the SPP excitation is clearly seen, which will affect the wavelength response of the SPP coupler. Because the dispersion effect of individual grooves has nothing to do with the groove separation, the influence of this fixed factor may become evident at small groove separations. The third factor is the contribution from the CW component. Since the CW component decays rapidly with increasing the distance from the source, it is expected that this factor only has significant effect at very small groove separations (generally smaller than the wavelength). Figure S5 | Dispersion effects of the SPPs excited by a single nanogroove. (a) The excited SPP amplitude as a function of the groove depth and the incident wavelength. (b) The excited SPP phase as a function of the groove depth and the incident wavelength. The data were extracted from FEM simulation results with wide Gaussian beam normally illuminated on a single groove and were determined at 25 μm away from the groove to avoid the influence of CWs. Each data point in the two-dimensional plot needs a separate simulation. To verify the above analysis, we provide more numerical calculation results. Table S2 lists the calculated bandwidths of the proposed SPP coupler using different calculation models. Firstly, we focus on the relative contribution of the pure interference factor and the dispersion effects of individual grooves to the bandwidth. In this case, we exclude the CW contributions and calculate the bandwidth using the pure SPP model for simplification and clarification. In the calculation, the wavelength dependences of all the variables (kspp, A1, A2, t1, r1, t2, r2) in equations (S1) and (S2) are taken into account. The variables A1 and A2 as functions of the wavelength are extracted from Fig. S5. The SPP transmission and reflection coefficients (t1, r1, t2, r2) as functions of the wavelength are calculated at different wavelengths by using the eigenmode SPPs incident from left boundary (FEM simulation). It turns out that, the calculated bandwidths by equations (S1) and (S2) are 195, 157, 135, 88, 81 nm at groove separations of d=1/4 λspp, 3/4 λspp, 5/4 λspp, 7/4 λspp, 9/4 λspp. Then, we fix the variables related to the dispersions of individual grooves (A1, A2, t1, r1, t2, r2) at their values at the central wavelength of λ=800 nm and only allow kspp to change with the wavelength. In this case, the calculated bandwidths by equations (S1) and (S2) become >600, 255, 153, 107, 86 nm at groove separations of d=1/4 λspp, 3/4 λspp, 5/4 λspp, 7/4 λspp, 9/4 λspp. A comparison between the two sets of bandwidths reveals that, the pure interference factor determines the bandwidth at larger groove separations (d=9/4 λspp), since the according bandwidths are nearly the same for the two sets. However, at small groove separations (d≤7/4 λspp), the dispersion effects of individual grooves have significant influences, since the bandwidth is evidently reduced when the wavelength dependences of A1, A2, t1, r1, t2, r2 are taken into account. Furthermore, if we only fix A1, A2 at their values at λ=800 nm and allow kspp, t1, r1, t2, r2 to change with the wavelength, the resulted bandwidths are >600, 254, 153, 108, 84 nm at groove separations of d=1/4 λspp, 3/4 λspp, 5/4 λspp, 7/4 λspp, 9/4 λspp. The results are quite close to the case of fixing A1, A2, t1, r1, t2, r2. This implies that, the wavelength dependences of the excited SPPs by the two grooves (A1 and A2) are important to the bandwidth, while the wavelength dependences of the SPP transmission and reflection coefficients have little effects. This is probably due to the fact that the SPP transmission and reflection coefficients are mainly related to the higher-order terms in equations (S1) and (S2) which give relatively small contributions to the total SPP intensities. Table S2 | Calculated bandwidths at different groove separations using different models. (w1=w2=80 nm, h1 and h2 used in different models are listed in Table S1) model d=1/4 λspp d=3/4 λspp d=5/4 λspp d=7/4 λspp d=9/4 λspp Pure SPP with A1, A2, t1, r1, >600 255 153 107 86 t2, r2 fixed Pure SPP with >600 254 153 108 84 A1, A2 fixed Pure SPP 195 158 135 88 81 SPP+CW 112 171 128 89 79 Although the dispersion effects of individual grooves have significant influence on the bandwidth, they are not sufficient to result in the anomalous bandwidth shrinking phenomenon at d=1/4 λspp. One evidence is that the calculated bandwidth by the pure SPP model (already including the dispersion effects of individual grooves) is the largest at the smallest groove separation of d=1/4 λspp. That is to say, the calculated bandwidths still fulfill the normal rule. Another evidence is that the calculated bandwidth at d=1/4 λspp using the pure SPP model is still much larger than that using the modified model including the CW contributions (see Table S2). Considering the difference between the pure SPP model and the modified model is the CW contribution, it can be inferred that the CW component is responsible to the anomalous bandwidth shrinking at d=1/4 λspp. To get an insight into the detailed mechanism, we list the calculated AL and AR (at d=1/4 λspp) using the two different models at three characteristic wavelengths of λ=750, 800, and 850 nm in Table S3. At the central wavelength of λ=800 nm, AL≈0, indicating the unidirectional launching of SPPs to the right direction with an ultra-high extinction ratio. When the wavelength deviates from λ=800 nm, the extinction ratio decreases due to the increase in AL . Although AR also changes with the wavelength, its relative variation is much smaller than the relative variation of AL because of the much larger absolute value of AR (see Table S3). So the wavelength dependence of the extinction ratio ((AR / AL)2 ) and the corresponding bandwidth are mainly determined by the variation of AL . The more rapidly AL changes with the wavelength, the smaller the resulted bandwidth. This relation is well verified by the calculated bandwidths and the corresponding AL listed in Table S4, since the bandwidth and AL show clearly negative correlation for both the pure SPP model and the modified model. In the calculation, AL is used to evaluate the variation of AL , which is defined as AL ( A( )( A( ) L λ = 850 nm) A( L λ = 800 nm) L λ = 750 nm) A( L λ = 800 nm) Table S3 | Calculated AL and AR at d=1/4 λspp using different models. (w1=w2=80 nm, h1 and h2 used in different models are listed in Table S1) λ=750 nm λ=800 nm λ=850 nm -3.04i 0.99i AL 0.075e 0.0027e 0.071e-2.86i Pure SPP AR 0.45e-1.82i 0.43e1.86i 0.41e1.91i AL 0.10e-2.99i 0.0028e2.66i 0.12e3.03i SPP+CW AR 0.39e-1.95i 0.40e1.68i 0.39e1.60i Table S4 | Negative correlation between the bandwidths and the corresponding AL at different groove separations. (w1=w2=80 nm, h1 and h2 used in different models are listed in Table S1) d Pure SPP SPP+CW 1/4 λspp 3/4 λspp 5/4 λspp 7/4 λspp 9/4 λspp AL 0.140 0.161 0.172 0.285 0.304 bandwidth(nm) 195 157 135 88 81 AL 0.216 0.141 0.199 0.272 0.308 bandwidth(nm) 111 171 128 89 79 After verifying the relation between the bandwidth and AL , we can analyze the anomalous bandwidth shrinking phenomenon at d=1/4 λspp through AL . In the modified model including the CW contributions, we can divide the calculated AL into two parts. One part comes from the pure SPP model and is denoted by ALspp. The other part is contributed by the cross conversions between SPPs and CWs, and is denoted by ALcw. Table S5 displays the calculated ALspp, ALcw and AL in the modified model at λ=750, 800, and 850 nm, with d=1/4 λspp. At λ=800 nm, ALspp and ALcw have nearly equal amplitudes (0.117 and 0.115) and are nearly in antiphase (phase difference of 1.006π). So they just cancel each other and result in AL=(ALspp+ALcw)≈0. As the wavelength deviates from λ=800 nm, the amplitude of ALspp increases while the amplitude of ALcw decreases (see Table S5 and also the red, black solid lines in Fig. S6). Besides, the phase difference between ALspp and ALcw also deviates from π (for instance, 0.73π at λ=750 nm and 1.27π at λ=850 nm). So, ALspp is less canceled by ALcw as the wavelength departs from the best extinction wavelength of λ=800 nm, and the resulted total SPP amplitude AL is high. Thus, the total SPP amplitude AL changes with the wavelength much rapidly (see Table S5 and also the blue solid line in Fig. S6) than the SPP amplitude AL spp contributed by the pure SPP model (see Table S5 and also the red solid line in Fig. S6). Here, the SPP component contributed by cross conversions between SPPs and CWs (ALcw) increases the variation of the total SPP amplitude AL with changing the wavelength, which in turn decreases the bandwidth at d=1/4 λspp. So we get to the conclusion that the near-field CW component has significant contribution to the anomalous bandwidth shrinking behavior at the subwavelength groove separation of d=1/4 λspp. In contrast, the calculated bandwidths at groove separations of d=3/4 λspp, 5/4 λspp, 7/4 λspp, 9/4 λspp using the modified model consist much better with the results using the pure SPP model (see Table S2), because the CW component decays rapidly with increasing the distance from the source and has much less influence at such groove separations. Table S5 | The calculated ALspp, ALcw and AL at d=1/4 λspp model. (w1=w2=80 nm, h1 =65 nm, h2 =96 nm, d =196 nm) λ=750 nm λ=800 nm spp -2.27i AL 0.133e 0.117e1.93i ALcw 0.087e1.72i 0.115e-1.23i AL 0.101e-2.99i 0.0028e2.66i using the modified λ=850 nm 0.160e2.24i 0.113e-1.76i 0.121e3.03i |AL| SPP amplitues (a. u.) 0.5 spp |AL | 0.4 cw |AL | 0.3 0.2 0.1 0.0 650 700 750 800 850 900 950 Wavelength (nm) Figure S6 | Calculated SPP amplitudes at d=196 nm using the modified model with h1 =65 nm and h2 =96 nm. AL spp : red solid line. AL cw : black solid line. AL : blue solid line. For reference, the green solid line displays AL using the pure SPP model (h1 =62 nm and h2 =118 nm). At the end of this section, we supplement two points. The first one is concerning the evaluation of the bandwidth. In this paper, we define the bandwidth of an SPP unidirectional coupler as the wavelength range with extinction ratios of ≥10 dB since an extinction ratio of ≥10 dB is good enough for many applications. According to this definition, all the bandwidths mentioned above are evaluated with the precondition that the extinction ratio at the central wavelength of λ=800 nm has already been optimized to ≥30 dB. This precondition is to approximately satisfy AL=0 or AR=0 at λ=800 nm. Consequently, the bandwidth at a specific groove separation has a definite value (for instance, whether the extinction ratio at the central wavelength of λ=800 nm is optimized to 40 dB or 100 dB, the resulted bandwidths have no evident difference). However, the bandwidth may have quite different values without this precondition (for instance, if the extinction ratio at the central wavelength of λ=800 nm is only optimized to 15 dB, the resulted bandwidth will evidently decrease). In the calculations, to satisfy the precondition, the groove depths need to be adjusted according to the different calculation models (the groove depths used in different models are listed in Table S1). The second point is concerning the dispersion effects of individual grooves on the bandwidth. Since the groove depths are slightly different in the different calculation models, one may guess that the abnormal bandwidth shrinking at d=1/4 λspp directly originates from the groove depth changes (which can change the dispersion effects of individual grooves). However, this possibility can be excluded. It can be seen that, the pure SPP part in the modified model (ALspp, the red solid line in Fig. S6, with h1 =65 nm and h2 =96 nm) changes with the wavelength even slower than the SPPs in the pure SPP model (the green solid line in Fig. S6, with h1 =62 nm and h2 =118 nm). So the rapidly variation in AL at d=1/4 λspp in the modified model is mainly due to the contribution of the CW component. Section 4/ Absolute SPP coupling efficiency of the proposed SPP coupler absolute coupling efficiency In the paper, we mainly use a wide Gaussian illumination in the numerical calculations and define the SPP excitation efficiency as the SPP power flow normalized by the light power incident on the two nanogrooves. In this case, the incident light is fixed and only the structure parameters of the groove-doublet are changed, which makes the situation simplified. Otherwise, if a tightly focused Gaussian beam is used, the width of the Gaussian beam has to be optimized together with the structure parameters of the groove-doublet to obtain the best unidirectional excitation of SPPs. This will make the situations complicated due to the increased variables. Well, in real applications, it is essential to know how much of the incident light is eventually coupled to SPPs. To answer this question, we can make additional calculations with changing the width of the Gaussian beam after the optimal structure parameters of the SPP unidirectional coupler has been determined. For instance, figure S7 shows the absolute SPP coupling efficiency in the SPP launching direction as a function of the width of the incident Gaussian beam at λ=800 nm, with the total incident light power being the unity (the structure parameters are w1=w2=80 nm, h1=72 nm, h2=162 nm, and d=587 nm). It can be seen that, more than 20% of the incident light power is converted into the unidirectional SPPs when the Gaussian beam has an optimal beam waist of 500-600 nm (the extinction ratio is as high as 35 dB, and can be further optimized by fine tuning the groove depths). Considering the submicron dimension of the proposed SPP unidirectional coupler, this coupling efficiency is rather impressive. Moreover, the absolute SPP coupling efficiency can be further improved to 24% at increased groove widths of 240 nm (w1=w2= 240 nm, h1=73 nm, h2=266 nm, and d=587 nm) with an optimal beam waist of 600 nm (the extinction ratio is as high as 25 dB, and can be further optimized by fine tuning the groove depths). w = 80 nm w = 240 nm 0.24 0.23 0.22 0.21 0.20 0.19 0.18 0.17 0.16 200 400 600 800 1000 beam waist (nm) Figure S7 | The absolute SPP coupling efficiency in the launching direction as a function of the width of the incident Gaussian beam. The simulation was performed at incident wavelength of λ=800 nm and groove separation of d=587 nm. The black and red lines correspond to groove widths of w1=w2=80 nm (h1=72 nm, h2=162 nm) and w1=w2=240 nm (h1=73 nm, h2=266 nm), respectively. The absolute SPP coupling efficiency of the unidirectional SPP coupler is defined as the portion of incident light power coupled into SPPs in the launching direction.