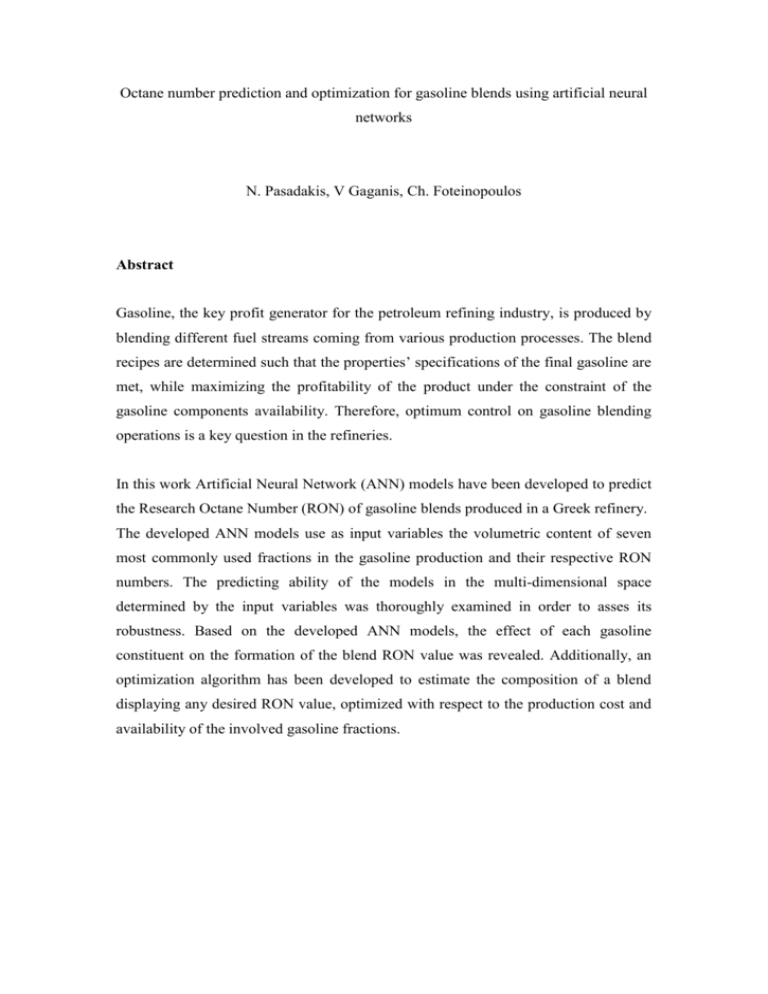

Octane number prediction and optimization for gasoline blends

advertisement

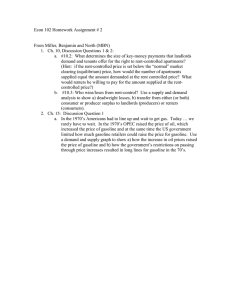

Octane number prediction and optimization for gasoline blends using artificial neural networks N. Pasadakis, V Gaganis, Ch. Foteinopoulos Abstract Gasoline, the key profit generator for the petroleum refining industry, is produced by blending different fuel streams coming from various production processes. The blend recipes are determined such that the properties’ specifications of the final gasoline are met, while maximizing the profitability of the product under the constraint of the gasoline components availability. Therefore, optimum control on gasoline blending operations is a key question in the refineries. In this work Artificial Neural Network (ANN) models have been developed to predict the Research Octane Number (RON) of gasoline blends produced in a Greek refinery. The developed ANN models use as input variables the volumetric content of seven most commonly used fractions in the gasoline production and their respective RON numbers. The predicting ability of the models in the multi-dimensional space determined by the input variables was thoroughly examined in order to asses its robustness. Based on the developed ANN models, the effect of each gasoline constituent on the formation of the blend RON value was revealed. Additionally, an optimization algorithm has been developed to estimate the composition of a blend displaying any desired RON value, optimized with respect to the production cost and availability of the involved gasoline fractions.