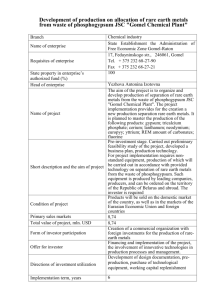

62-672 - Florida Department of Environmental Protection

advertisement