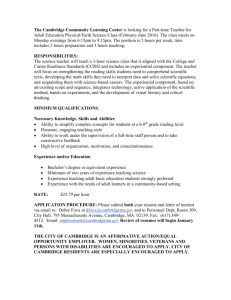

cv - JRS Electronics LTD

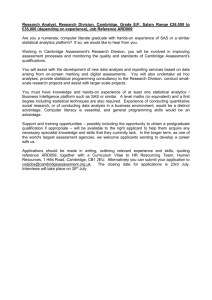

advertisement

James Stigwood Date of Birth: Nationality: Marital status: Contact: E-Mail: Mobile: Driving Licence: Compnay: Website: Education 29.08.80 British Married 24 Strympole Way, Highfields Caldecote, Cambridge, CB23 7ZJ jstigwood@hotmail.com 07872 582263 Full UK – Clean. JRS Electronics www.jrselectronics.co.uk HNC in ELECTRONICS: which includes Micro-Electronics, Digital & Analogue electronics, design, business studies, Maths and Science. ISEB Intermediate Qualified: Software Testing and Analysis Microsoft Certified: TS: Microsoft .NET Framework 3.5, Windows Forms Application Development NVQ level 3 in ENGINEERING AND MANUFACTURE: which includes health and safety, electrical measurement, electrical wiring, effective working relationships and handling engineering information. It also includes how to use mills, lathes and engineering materials. 2 A-Levels in Geology and Geography at Netherhall Sixth Form 9 G.C.S.E's at Netherhall school Experience October 2011 to Present: Green Energy Options LTD Hardwick, Cambridge (Contract) http://www.greenenergyoptions.co.uk/ System Testing and managing the PAT/SAT testing for Home Energy Devices, hardware & software based. Communicating on a regular basis with Project managers, R&D engineers and the support team. Working to UI and Product requirements. August 2011 to September 2011: ITT Defence, Basingstoke (4-6 week Contract) http://www.ittdefence.co.uk/ Board testing on RF/Controller products for M.O.D. Testing to a given procedure and fault finding using schematics down to component level. Conforming to M.O.D practices working to tight timescales. July2011 to August 2011: Cambridge Broadband Networks, Cambridge (1 month Contract) http://www.greenenergyoptions.co.uk/ Labview programming for performing CPK analysis on Log file reports from manufacturing results in China. Involving SQL database to perform search criteria. Writing and implementing a custom design from the requirements stage within a small team to exploit QA issues to be reported back to R&D. March 2011 to June 2011: Green Energy Options LTD Hardwick, Cambridge (made Redundant) http://www.greenenergyoptions.co.uk/ Position: Hardware/Software Systems Test Engineer. Testing next generation IHD (In House Displays) that record and display your Energy consumption, for domestic and commercial solutions. Working for customers such as Scottish Power. System Tested both Hardware and Software to ensure a High level of Test completion was achieved and all data/bugs recorded using Bugzilla. Scripting test specifications for product continuity and writing up test completion reports. Involved in testing Web services as well as software tools to support the product. Product Acceptance Testing, with customer visits and providing detailed feedback to all areas of the company. Provided detailed outlines for Automation and designed and developed test solutions for reducing and improving test time and quality. These include a Heating controller Data Logger and a Parse for reading back test data. Working alongside Zigbee technology and full wireless testing of products, including 868Hz and 2.4Ghz. September 2006 to April 2011: Crystal Vision LTD Whittlesford, Cambridge http://www.crystalvision.tv/ Position: Product Verification/R&D Engineer Crystal Vision design and Manufacture Audio and Video broadcast equipment for the likes of BBC, ITV and SKY. In my current position I am responsible for verifying all new designs in the R&D department, from the User manual to Software and Hardware. I document Bugs/Errors on Bugzilla/Mantis and write reports to the Head of R&D, and also write the Test Specs for Production and provide new product training. In verifying the product I test both the Audio and Video aspects from Jitter, Cable lengths, Video Levels, Freq Response and Video CRC/EDH errors using TEK WFM700/7120’s in SD/HD and 3G Video Standards, as well as Composite and Component Video. The Audio tests include THD+N, Levels, XTALK, Freq Response and Audio Phase using Prism DScope measuring Equipment. I have also been called out to do customer visits and provide support to some of our biggest customers including the BBC, and design bespoke applications which were used for the PGA Tour Golf this year. I have also designed and built test jigs for production in order to simplify the process, increase Quality and reduce production times. These have ranged from simple switch boxes to writing programs in VB.net to control Prism Audio equipment for an Audio product and Easywire for Cable testers. Crystal Vision’s products are controlled over Networks, this will involve setting MAC address and perform IP address checks as well as testing the PC Control software for our products. I also Design and Manage the XJTAG programs for Sub contractors who test our products externally. These are generally Continuity tests as well has LED/Button checks and on-board Flash/DRAM tests insuring as much of the board is tested before the boards arrive. This involves implementing Design Schematics from PAD’s and tailoring my designs to specific products. I am also currently studying for a Microsoft Qualification in Visual Studio 2008, paid for by Crystal Vision. October 2004 to September 2006 Primagraphics Ltd/Curtiss Wright Controls, Cambridge (Contract to Full) http://www.cwcembedded.com/ Position: Test Engineer/Junior Development Engineer Working as a Test Engineer which involved testing VME PCB radar solutions and PCI/PMC radar graphical interfaces for the military. My work included testing radar graphical interface cards working with all video formats, programming, board testing and system testing using Windows, Linux and Unix computer systems as well as other standard test and repair duties. Fault finding down to s.m.t devices on both Analogue and Digital circuits. Communicating with both Development and Manufacturing managers on a day to day basis. Prototype Testing for Production release with Design Engineers and working to many different ISO standards. Left due to Production and test department moving to sub-contractors. March 2004 to September 2004 Leica Microsystems, Cambridge: (contract) http://www.leica-microsystems.com/ Position: Test/Repair Engineer I wanted to gain more experience in the electronic industry so went back to contracting. Leica Manufacture Electron beam Microscopes for the Semiconductor industry and work in high precision clean room conditions. At Leica my job roles include testing and repairing analogue and digital PCB’s, final test of racks, working and liaising with the development engineers in modifying current products. June 2003 to March 2004 Drake Electronics, Cambridge: (contract to Full) http://www.clearcom.com/index.php Position: Test/Design Engineer Contracted at Drake for 5 months and was then offered a full time position. Drake Electronics are the market leader in broadcast intercom solutions. My job roles there included, testing and repairing RF intercom products down to component level. Calibrating and setting up intercom products as part of a system. Modifying and testing prototype products ready for production release. Writing new procedures and improving on old on various products June 2003 to July 2004 Dominos Print, Barhill, Cambridge: (contract) http://www.domino-printing.com/Global/en/Home.aspx Position: Rework/Repair Engineer Just a short 4 week Contract to help with some re-work and repairing of some print heads before they had a full time position filled. April 2003 to June 2004 Powertron, Cambridge: (contract) http://www.martekpower.com/ Position: Test Engineer Contracted at Powertron testing and repairing power supplies for the rail and Automotive industry. Managed the up keep of in house test equipment and built soak bays for extensive load testing May 2001 to April 2003 Arcam, waterbeach, Cambridge: (made redundant) http://www.arcam.co.uk/ Position: Test/ATE Engineer Whilst in my last year of my HNC I joined Arcam. Arcam are a British HIFI manufacturing company. My roles include fault finding to component level, maintaining and controlling hi-tech test equipment on a production line, Designing and building new test jigs from a design specification using AP measuring equipment to test the full range of our products. Fixing and testing top of the range audio and video hifi equipment. I also had to make regular trips to Wales to commission and install new equipment often working long hours. Made redundant after 2 years due to Company restructure. Nov 2000 to May 2001 Tannoy Audix, Saffron Walden: Position: Trainee Test Engineer At Tannoy Audix I was in control of calibrating Tannoy systems, including microphones and speakers. Part of my training included how to fault find and repair down to s.m.t components, working within a small group of engineers and seek relevant information to complete a job. Sept 1998 to Nov 2001 Krupp Camford, Bourn, Cambridge: (Apprenticeship) Position: Apprentice Electrician I attended college for 1 year where I studied my NVQ 2 and my first year's ONC. In the second year I was working 4 days a week with Krupp and studying 1 day a week for my second year of the ONC. Working at Krupp taught me how to work confidently & safely on my own, using the skills that I learnt at college to complete a job. I also learnt how to work effectively in a team, & how to communicate well with others using technical terms. I had to prioritise my workload, balancing often-conflicting demands in a fast paced environment. Skills: Personal skills: Reliable, good time keeper, trustworthy Committed, completer/finisher The enthusiasm and tenacity to complete a job under pressure Proactive, diplomatic Enjoy working in a team, good communicator, but able to work on my own Resourceful Always willing to learn new skills New skills learnt: Working under Baseline Security Clearance, passing security checks for the MOD Programming devices using, Lattice, METlab and Quartus Zigbee Testing: - Range, Power, interference, as well as 868Hz Software lifecycle and Tools testing. Product Acceptance Testing of Energy Display Monitors Unix/Shell Scripting on IHD (In House Displays) for Test Solar Panel Energy Testing with integration Data Logging Working under IS90001, ISO9100, ISO14000 and 5s Fully trained on TEK WFM700/7120s/8300, Agilent Function generators Prism Audio DScope programming using VB.NET and Audio Tests Eprom programming (STAG) XJTAG, Design, Programming and Testing. Visual Studio Programming Testing and repairing RF equipment Basic Labview programming and testing using test fixtures. Fully Trained on a large range of test equipment including scopes, signal generators, RF Team building exercises Exhibition and Stand set-up Soldering of SMT devices Fault finding to component/S.M.T level 0805/0603/0402 Anti- static training Audio precision course for automatic testing As an apprentice I was actively running and maintaining a state of the art automotive production line. This involved gaining new skills in order to run the line, such as fault finding, production management, fixing breakdowns and learning the specifications of a new product. Obtained a mobile 'manlift licence' in 1999. Attended ARISTOROB training (welding information for robots) at the sister plant in Bedford, which proved invaluable when running the production line. Interests Weight training: Train three times a week, & have provided personalised training to others. General Interest for Electronics: Consumer, from HiFi to Mobile Communications Thai boxing: Where I used to take active participation in Regional competitions. Travelling: Recent 3 week self-organised tour of China. Photography: Currently set up and run the Caldecote Photography Club. Cycling: Completed the London to Cambridge bide ride, organised Isle of white – Round the Island bike ride. Raised £1000’s for the British Heart Foundation