Newer Developments In Extending Shelf Life Of

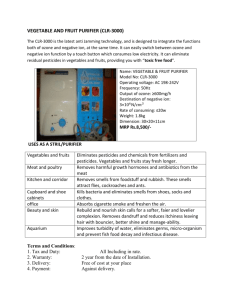

advertisement