Use Case ID

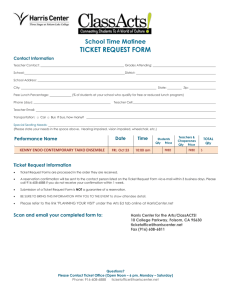

advertisement

1. 2. 3. 4. 5. 6. PS_001 – Scan & Pack ............................................................................................... 1 PS_002 – Pick & Pack ................................................................................................ 3 PS_003 – Print Multi-Pick-ticket UCC 128 Label ..................................................... 6 PS_004 – Create Assortment Order ............................................................................ 9 PS_005 – Create Bill of Lading ................................................................................ 11 PS_006 – Create Consolidated Bill of Lading .......................................................... 12 1. PS_001 – Scan & Pack Description Use Case ID Title Actors Pre-conditions Description Usage Flow of Events PS_001 Scan & Pack This use-case is used to scan and pack items into cartons based on a pick ticket. High 1. In the “Packing & Shipping” main screen, the user selects “Scan & Pack” option. 2. On the Scan and Pack screen the user selects the “Purchase Order No” for the order received from the customer. 3. The list of all the Pick Tickets with the respective Ship To locations is displayed. 4. The user selects the Pick Ticket which is being scanned and packed. 5. The user will scan all the items as required by the pick ticket. 6. Once completed, the user generates the UCC-128 shipping ID and completes the operation Sub-flow/ Scenarios 1. When a carton is full, the user records this information by clicking the “Box Full” button and the system will start recording the total number of boxes packed. 2. If the user scans more than the items required as per the pick ticket, the system should alert the user and should ignore the scan of the excess items. 3. Though the default Ship To is the location of the logged in user, it should be possible to change the Ship From and select another warehouse. 4. The Box Info has to be modified from what is automatically generated. 5. It should be possible to change the carrier. The default carrier is taken from the Pick Ticket. 6. It should be possible to switch to Manual Pick & Pack from here. - Alternate Flows Special Requirements Assumptions Business Rules 1. The following formula should be used to generate the UCC128 ID. 2. User interface Select PO Description: This field is used to select the received P.O. No Ship From Select Pick Ticket Bill To Store # Completion Date Order Pick Scan Pick No Select Pick Ticket Purchase Order for which the packing is being done. Data Type: Numeric Validation 1. This is a selection of all the Purchase orders received from the customers. 2. Required 3. Default – None Description: This field describes the location from where the shipping is done. This is by default the location of the logged in user. Description: The bill to location of the Pick Ticket. Description: The store for which this pick-ticket is generated. Description: The completion date for the Purchase Order. Description: The total number of items that are ordered for this Store. Description; The total number of items that are allocated in the pick ticket. Description: The total number of items that are scanned already. Description: The number of the pick ticket for this order. Bill To Store # Completion Date Order Pick Scan Pick No Item List Style Color Qty Size (1..n) Scan Summary Total Picked Total Scanned Balance Scan Details Item No Style Color Size Picked Qty Packed Qty Description: The bill to location of the Pick Ticket. Description: The store for which this pick-ticket is generated. Description: The completion date for the Purchase Order. Description: The total number of items that are ordered for this Store. Description; The total number of items that are allocated in the pick ticket. Description: The total number of items that are scanned already. Description: The number of the pick ticket for this order. Description: The Description: The Description: The this item. Description: The number of items displayed. Code of the Style to be packed. color of the item to be packed. total number of items to be scanned for sizes in the size scale are displayed and for each size to be scanned is Description: The total number of items to be picked as per the pick ticket. Description: The total number of items already scanned. Description: The number of items to be still scanned. Description: Sl No of the item. Description: The Code of the Style to be packed. Description: The color of the item to be packed. Description: The Size of the Item being packed. Description: The total number of items to be picked as per the pick ticket. Description: The total number of items already scanned. Screen Flow Create UPC Block 2. PS_002 – Pick & Pack Description Use Case ID Title PS_002 Pick & Pack Create UPC Block Actors Pre-conditions Description Usage Flow of Events Sub-flow/ Scenarios This use-case is used to pick and pack items into cartons based on a pick ticket. High 1. In the “Packing & Shipping” main screen, the user selects “Pick & Pack” option. 2. On the Scan and Pack screen the user selects the “Purchase Order No” for the order received from the customer. 3. The list of all the Pick Tickets with the respective Ship To locations is displayed. 4. The user selects the Pick Ticket, which is being packed. 5. The user will manually pack all the items as required by the pick ticket. 6. Once completed, the user generates the UCC-128 shipping ID and completes the operation 1. When a carton is full, the user records this information by clicking the “Box Full” button and the system will start recording the total number of boxes packed. 2. Though the default Ship To is the location of the logged in user, it should be possible to change the Ship From and select another warehouse. 3. The Box Info has to be modified from what is automatically generated. 4. It should be possible to change the carrier. The default carrier is taken from the Pick Ticket. - Alternate Flows Special Requirements Assumptions Business Rules 1. The following formula should be used to generate the UCC128 ID. 2. MANUFACTURER# PICKTICKET# Sl No User interface Select PO Description: This field is used to select the received P.O. No Ship From Select Pick Ticket Purchase Order for which the packing is being done. Data Type: Numeric Validation 1. This is a selection of all the Purchase orders received from the customers. 2. Required 3. Default – None Description: This field describes the location from where the shipping is done. This is by default the location of the logged in user. Bill To Store # Completion Date Order Pick Scan Pick No Select Pick Ticket Bill To Store # Completion Date Order Pick Scan Pick No Item List Style Color Qty Size (1..n) Item Details Style Color Picked Qty Scanned Qty Pack Qty Screen Flow Description: The bill to location of the Pick Ticket. Description: The store for which this pick-ticket is generated. Description: The completion date for the Purchase Order. Description: The total number of items that are ordered for this Store. Description; The total number of items that are allocated in the pick ticket. Description: The total number of items that are scanned already. Description: The number of the pick ticket for this order. Description: The bill to location of the Pick Ticket. Description: The store for which this pick-ticket is generated. Description: The completion date for the Purchase Order. Description: The total number of items that are ordered for this Store. Description; The total number of items that are allocated in the pick ticket. Description: The total number of items that are scanned already. Description: The number of the pick ticket for this order. Description: The Description: The Description: The this item. Description: The number of items displayed. Code of the Style to be packed. color of the item to be packed. total number of items to be scanned for sizes in the size scale are displayed and for each size to be scanned is Description: The Code of the Style to be packed. Description: The color of the item to be packed. Description: The total number of items to be picked as per the pick ticket. Description: The total number of items already scanned. Description: The quantity of the item being packed. Data Type: Numeric Validation 1. Required 2. Default – None 3. PS_003 – Print Multi-Pick-ticket UCC 128 Label Description Use Case ID Title Actors Pre-conditions Description Usage Flow of Events Sub-flow/ Scenarios PS_003 Print Multi-Pick-Ticket UCC 128 Label This use case is used to generate the Pick Ticket for packing the items based on Forecast for customers like JC Penny. Medium 1. In the “Packing & Shipping” main screen, the user selects “Create UCC 128 for Multiple Pick Tickets” option. 2. The criteria selection screen is displayed where the user selects the criteria to select the pick-tickets. 1. Though the default Ship To is the location of the logged in user, it should be possible to change the Ship From and select another warehouse. 2. The Box Info has to be modified from what is automatically generated. 3. It should be possible to change the carrier. The default carrier is taken from the Pick Ticket. 4. Once the Box information is entered for one style, the system should ask the user, if he would like to set the information for all the styles. - Alternate Flows Special Requirements Assumptions Business Rules 1. The following formula should be used to generate the UCC128 ID. 2. The following options are available for the Selection Criteria: “Purchase Order Number”, “Order Number”, “PO Date”, “Completion Date” and “Pick Ticket No” 3. The following options are available: a. 1 label per packing list – create one shipping label per pick ticket b. 1 label per line item (1 style & 1 color) - create shipping label per style and color c. 1 label per style/color/size (base on qty/box) - base on the style setup to generate shipping label. d. Print label based on the Quantity Per e. Print label based on Style/Color Packed Ratio – end user enter prepack ratio before generate UCC 128 Label f. Print Label based on QTY per box (Mix Style) – End user enters maximum qty per carton. User interface Criteria Screen Customer Select Criteria Select <Type> Numbers Select Date Rage Distro No Create based on Inventory Availability UCC Type Description: The customer for whom the UCC Label has to be created. Data Type: Numeric Validation 1. This is a selection of all the customers available in the system for who the open purchase orders are present. 2. Required 3. Default – None Description: The criteria to select the Pick tickets to generate the UCC 128 Label. Data Type: Numeric Validation 1. This is a drop down of the options available to select the pick tickets. 2. Required 3. Default – None Description: This field is displayed if the Selection Criteria is “PO Number”, “Order Number” or “Pick Ticket No”. It is possible to select multiple numbers. Data Type: String Validation 1. Required 2. Default – None Description: This field is displayed if the Selection Criteria is “PO Date” or “Completion Date”. It is possible to select a start date and a end date. Based on these dates the Pick Tickets are selected. Data Type: Date Time Validation 1. Required 2. Default – None Description: Based on the customer and the pick tickets, the distro locations are listed and the appropriate items can be selected. Data Type: Number Validation 1. Required 2. Default – None Description: The user checks this check box if the Inventory availability has to be checked and the UCC to be created based on the available inventory. Data Type: Boolean Validation 1. Default – False Description: The type of the UCC Label to be generated. Data Type: Numeric Validation 1. This is a drop down of the options available to generate UCC label. 2. Required 3. Default – None Pick Ticket List P.O. No P.O. Date Pick No Store # DC# Order# Distro Pick Scan Box List Style Color Box Weight Box Volume Length Width Height Box Details Style Color Box Weight Length Width Description: The number of the pick ticket. Description: The date on which the purchase order is created. Description: The number of the pick ticket for this order. Description: The number of the store for which the pick ticket is created Description: The distribution center, which is associated with the store. Description: The House Order associated with the Purchase Order. Description: The total number of items that are ordered for this Store. Description; The total number of items that are allocated in the pick ticket. Description: The total number of items that are scanned already. Description: Description: Description: Description: packed. Description: Description: Description: The The The The style to be packed. color of the item to be packed. weight of each of the box being packed. volume of each of the box being The length of each of the box being packed. The width of each of the box being packed. The height of each of the box being packed. Description: The style to be packed. Description: The color of the item to be packed. Description: The weight of each of the box being packed. Data Type: Numeric Validation 1. Required 2. Default – None Description: The length of each of the box being packed. Data Type: Numeric Validation 1. Required 2. Default – None Description: The width of each of the box being packed. Data Type: Numeric Height Validation 1. Required 2. Default – None Description: The height of each of the box being packed. Data Type: Numeric Validation 1. Required 2. Default – None 4. PS_004 – Create Assortment Order Description Use Case ID Title Actors Pre-conditions Description Usage PS_004 Create Assortment Order In cases where customers expect the boxes to be packed as Assortment Orders, this use case is used. High Flow of Events Sub-flow/ Scenarios 1. In the “Packing & Shipping” main screen, the user selects “Pick & Pack” option. 2. On the Scan and Pack screen the user selects the “Purchase Order No” for the order received from the customer. 3. The list of all the Pick Tickets with the respective Ship To locations is displayed. 4. The user selects the Pick Ticket, which is being packed. 5. The user will manually pack all the items that are required for each of the Box. Then these quantities are entered. 6. Then the user selects “Box Full”. The system then checks asks the user if the same Box setup has to replicate for the remaining quantities. 7. Once the user accepts it, multiple boxes are created for all the quantities with the same configuration. 8. Once completed, the user generates the UCC-128 shipping ID and completes the operation 1. When a carton is full, the user records this information by clicking the “Box Full” button and the system will start recording the total number of boxes packed. 2. Though the default Ship To is the location of the logged in user, it should be possible to change the Ship From and select another warehouse. 3. The Box Info has to be modified from what is automatically generated. 4. It should be possible to change the carrier. The default carrier is taken from the Pick Ticket. - Alternate Flows Special Requirements Assumptions Business Rules 4. The following formula should be used to generate the UCC128 ID. 5. User interface Select PO Description: This field is used to select the received P.O. No Ship From Purchase Order for which the packing is being done. Data Type: Numeric Validation 1. This is a selection of all the Purchase orders received from the customers. 2. Required 3. Default – None Description: This field describes the location from where the shipping is done. This is by default the location of the logged in user. Select Pick Ticket Bill To Store # Completion Date Order Pick Scan Pick No Select Pick Ticket Bill To Store # Completion Date Order Pick Scan Pick No Item List Style Color Qty Size (1..n) Item Details Style Color Picked Qty Scanned Qty Pack Qty Description: The bill to location of the Pick Ticket. Description: The store for which this pick-ticket is generated. Description: The completion date for the Purchase Order. Description: The total number of items that are ordered for this Store. Description; The total number of items that are allocated in the pick ticket. Description: The total number of items that are scanned already. Description: The number of the pick ticket for this order. Description: The bill to location of the Pick Ticket. Description: The store for which this pick-ticket is generated. Description: The completion date for the Purchase Order. Description: The total number of items that are ordered for this Store. Description; The total number of items that are allocated in the pick ticket. Description: The total number of items that are scanned already. Description: The number of the pick ticket for this order. Description: The Description: The Description: The this item. Description: The number of items displayed. Code of the Style to be packed. color of the item to be packed. total number of items to be scanned for sizes in the size scale are displayed and for each size to be scanned is Description: The Code of the Style to be packed. Description: The color of the item to be packed. Description: The total number of items to be picked as per the pick ticket. Description: The total number of items already scanned. Description: The quantity of the item being packed. Data Type: Numeric Validation 1. Required 2. Default – None 5. PS_005 – Create Bill of Lading 6. PS_006 – Create Consolidated Bill of Lading