Annealing Problems: Materials Science Exercises

advertisement

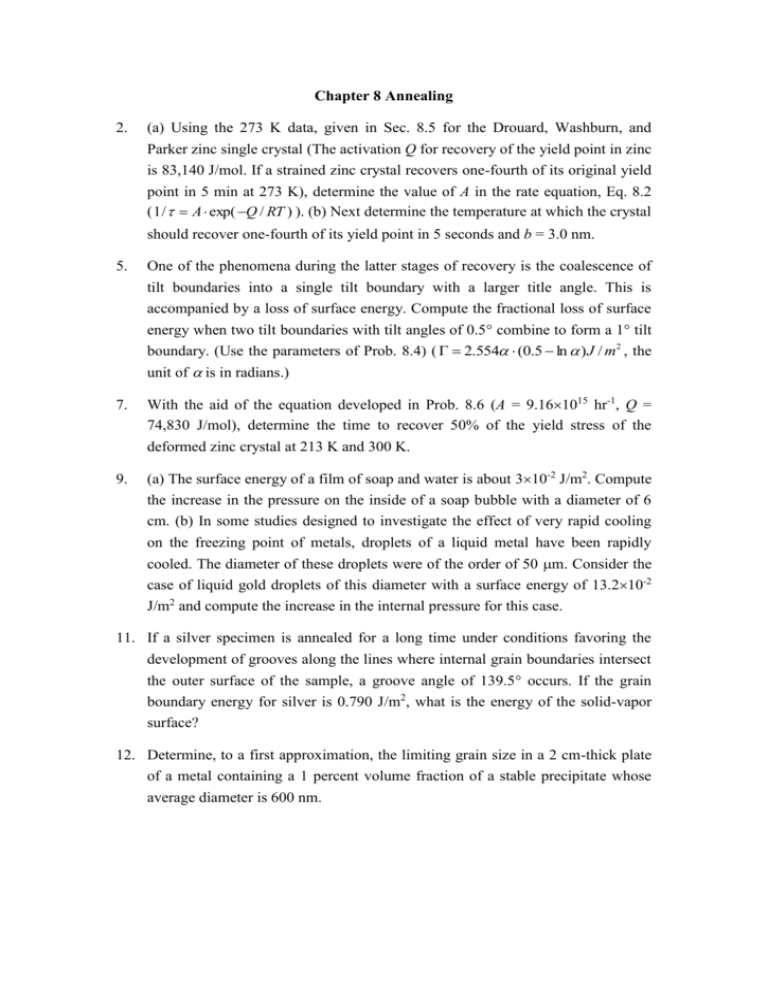

Chapter 8 Annealing 2. (a) Using the 273 K data, given in Sec. 8.5 for the Drouard, Washburn, and Parker zinc single crystal (The activation Q for recovery of the yield point in zinc is 83,140 J/mol. If a strained zinc crystal recovers one-fourth of its original yield point in 5 min at 273 K), determine the value of A in the rate equation, Eq. 8.2 ( 1 / A exp( Q / RT ) ). (b) Next determine the temperature at which the crystal should recover one-fourth of its yield point in 5 seconds and b = 3.0 nm. 5. One of the phenomena during the latter stages of recovery is the coalescence of tilt boundaries into a single tilt boundary with a larger title angle. This is accompanied by a loss of surface energy. Compute the fractional loss of surface energy when two tilt boundaries with tilt angles of 0.5 combine to form a 1 tilt boundary. (Use the parameters of Prob. 8.4) ( 2.554 (0.5 ln ) J / m2 , the unit of is in radians.) 7. With the aid of the equation developed in Prob. 8.6 (A = 9.161015 hr-1, Q = 74,830 J/mol), determine the time to recover 50% of the yield stress of the deformed zinc crystal at 213 K and 300 K. 9. (a) The surface energy of a film of soap and water is about 310-2 J/m2. Compute the increase in the pressure on the inside of a soap bubble with a diameter of 6 cm. (b) In some studies designed to investigate the effect of very rapid cooling on the freezing point of metals, droplets of a liquid metal have been rapidly cooled. The diameter of these droplets were of the order of 50 m. Consider the case of liquid gold droplets of this diameter with a surface energy of 13.210-2 J/m2 and compute the increase in the internal pressure for this case. 11. If a silver specimen is annealed for a long time under conditions favoring the development of grooves along the lines where internal grain boundaries intersect the outer surface of the sample, a groove angle of 139.5 occurs. If the grain boundary energy for silver is 0.790 J/m2, what is the energy of the solid-vapor surface? 12. Determine, to a first approximation, the limiting grain size in a 2 cm-thick plate of a metal containing a 1 percent volume fraction of a stable precipitate whose average diameter is 600 nm.