Summary of Comments from the

advertisement

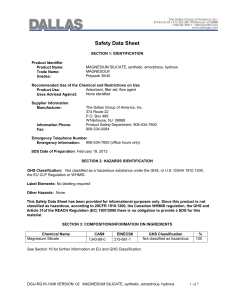

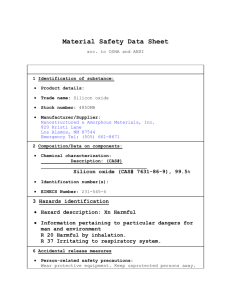

July 29, 2010 Comments from the Synthetic Amorphous Silica and Silicate Industry Association To ACGIH on NIC on TLV of Calcium Silicate The Synthetic Amorphous Silica and Silicate Industry Association (SASSI) is a nonprofit organization incorporated in the District of Columbia as a 501(c)(6) entity on July18, 2007 by eight founding members. Key tenets of SASSI’s mission focus on furthering the understanding of synthetic amorphous silica and silicate health and safety data within the industry, monitoring the regulation of synthetic amorphous silica and silicate by government, educating the public and government on the views of the industry, and consulting and cooperating with officials and agencies on matters having an industrywide significance. Consistent with our mission, the members of SASSI would like to take this opportunity to submit comments on the 2010 ACGIH TLV Notice of Intended Changes proposal to lower the exposure limit for Calcium Silicate from 10 mg/m3 (inhalable) to 0.5 mg/m3 (respirable) for non-fibrous calcium silicate. The NIC for fibrous calcium silicate is 1 fiber/cc. A. Executive Summary: The 2010 ACGIH TLV Notice of Intended Changes (NIC) includes a proposal to lower the exposure limit for Calcium Silicate (CAS# 1344-95-2) from 10 mg/m3 (inhalable) to 0.5 mg/m3 (respirable) for non-fibrous calcium silicate. The NIC for fibrous calcium silicate is 1 fiber/cc. The draft ACGIH documentation for the proposed change references a study done by Hanke et al as its primary basis for the proposed change. The Hanke study found a dose dependent decrement in pulmonary function in wollastonite mine and mill workers. However, SASSI does not believe that a study using wollastonite, a fibrous monocalcium silicate, is relevant to use as the basis for establishing a TLV for non-fibrous, precipitated calcium silicates manufactured by several of our member companies. Additionally, although tobermorite and xenolite are synthetically manufactured by a hydrothermal reaction between quartz and calcites, none of the materials commercialized by SASSI member companies use this process. Synthetic calcium silicates prepared by the reaction of calcium chloride and sodium silicate or calcium hydroxide and sodium silicate or suspended silica do not contain fibrous or crystalline structure, and have been shown not to cause the serious chronic respiratory symptoms associated with wollastonite. SASSI believes that studies conducted on synthetic amorphous silica are a more relevant basis for establishing a TLV for non-fibrous, precipitated calcium silicates. (This rationale has recently been validated by the European Chemicals Agency (ECHA) in the acceptance of the registration dossier for calcium silicate under REACH. That dossier utilized data on synthetic amorphous silica as the primary basis for establishing a health effects classification. Calcium Silicate was considered non-hazardous). B. List of Recommendations: SASSI recommends maintaining the current TLV for synthetic Calcium Silicate; nonfibrous at 10 mg/m3 (inhalable). C. Rationale: Following our review of the NIC proposal and the reference to Hanke et al “Respiratory morbidity in wollastonite workers” (British Journal of Industrial Medicine 1984; 41:474479) as the basis for the revision, we would like to take this opportunity to highlight several concerns for consideration by ACGIH. 1. Although all calcium silicate is classified under one CAS number 1344-95-2 the physical form of mined wollastonite versus synthetic, precipitated calcium silicate is significantly different. In particular for this consideration, the presence of fibrous particulates in wollastonite substantially contributes to the respiratory effects highlighted in the Hanke study. Synthetic, precipitated calcium silicate does not contain crystalline structures. 2. Additionally, we believe the Hanke study failed to control for generic mining exposures that may cause lung injury, as a result the study identified health effects due to mining and milling and not specifically health effects specific to wollastonite. 3. We do acknowledge that it is common knowledge that a fibrous structure is more difficult for the lungs to clear, but we emphasize that there is rich scientific profile of the safety of synthetic amorphous silica which have repeatedly shown that the amorphous particle does not share the same health effects of crystalline structures. 4. We believe there exists a rich scientific profile of the safety of amorphous silica and that the amorphous particle has been repeatedly shown to NOT share any of the health effects of crystalline silica. We reiterate that the rationale has recently been validated by the European Chemicals Agency (ECHA) in the acceptance of the registration dossier for calcium silicate under REACH. That dossier utilized data on synthetic amorphous silica as the primary basis for establishing a health effects classification. Calcium Silicate was considered non-hazardous. It was justified to utilize synthetic amorphous silica data based on the fact that synthetic amorphous silica and synthetic amorphous calcium silicate resulted in a similar toxicology profile in a chronic inhalation study conducted on Silica T (synthetic amorphous silica) and Hi Sil 404 (synthetic amorphous calcium silicate). . (Also see: “Inhalation Study- Rats and Guinea Pigs: Silica T and Hi Sol 404, Final Report, Hazeltine Laboratories, Inc., May 26, 1966.”) D. Citable Material: 1. Production of synthetic amorphous calcium silicates: An overview of contemporary production processes utilized by SASSI member companies. (See: Attachment I.) 2. “Inhalation Study- Rats and Guinea Pigs: Silica T and Hi Sol 404, Final Report, Hazeltine Laboratories, Inc., May 26, 1966.” (Complete study will be submitted to ACGIH separately.) 3. Product Information: (a) PPG Inhibisil 0202a Material Safety Data Sheet (b) PPG Inhibisil 73 Sell Sheet (c) Grace Davison Shieldex AC 5 Product Data Sheet (d) Grace Davison Shieldex AC 5 Material Safety Data Sheet 4. European Centre for Ecotoxicology and Toxicology of Chemicals (ECOTOC) Joint Assessment of Commodity Chemicals No. 51 on “Synthetic Amorphous Silica (CAS No. 7631-86-9) We appreciate your consideration of our comments and concerns. We are open to meeting with you and discussing any opportunity to assist ACGIH in completing a comprehensive and accurate review of synthetic calcium silicate. Please contact me to determine how we can support the efforts of your organization. Sincerely yours, David A. Pavlich Association Manager Synthetic Amorphous Silica and Silicate Industry SASSI Member Companies: – – – – – – – – J.M. Huber Corporation Evonik Degussa Corporation Wacker Chemical Corp. Cabot Corporation Rhodia Inc. PPG Industries, Inc. PQ Corp. W.R. Grace & Co. SASSI Website: www.sassiassociation.org Attachment I Production of the synthetic amorphous calcium silicates 1. BASICS Synthetic amorphous calcium silicate (silicic acid, calcium salt) is an amorphous form of the reaction product of calcium chloride or hydroxide with sodium silicate or suspended silica, respectively. The production process for synthetic amorphous calcium silicate can be divided into the following batch or continuous unit operations: * raw material storage, * synthesis (precipitation), * solid-liquid filtration, * drying, * storage, package and shipment. Optionally, the product can be milled, granulated or surface treated after the drying step. 2. PROCESS STAGES 2.1 Reaction Process Calcium Silicate: (yNa2O*nSiO2) + zCaCl2 -> (nSiO2*zCaO*xNa2O) + (y-x)NaCl (n = 2 to 4) (yH2O*nSiO2) + zCa(OH)2-> (nSiO2*zCaO) + yH2O Depending on the intended application of the silicates, individual precipitation parameters such as temperature (40 – 95 °C), pH (4.5 – 12.5), flows, residence time (up to several hours), mixing energy, reactor geometry, etc. have to be selected. By regulating these parameters, a wide range of silicate products with different characteristics can be produced. The solid content of this step is typically characterised by a density of between 50 and 200 g/l. Today, only batch precipitation processes in stirred vessels have attained economic importance, although continuous precipitation techniques have been reported. 2.2 Filtration Process The suspension received from precipitation is filtered. For this purpose, standard filter presses, membrane filter presses or belt/drum filters are used. In comparison to filter presses, which operate in a batch cycle, drum- and belt-filters work in a continuous way. Equipment selection is dependent on the properties and structure of the silicate produced. The solid content of the filter cake typically varies between 15 to 35 wt%, depending on the filter technique employed. After filtration a washing step follows to remove salts (normally done in the filtration equipment). The level of salt retained in the product depends on the intended application of the final silicate. 2.3 Filter Cake Treatment Sometimes, in order to achieve certain product properties, the filter cake is re-suspended using high shear forces and then sent to the drying process. 2.4 Drying Process Drying follows filtering and washing of the calcium silicate suspension derived from the precipitation process. Drying is performed according to different processes again depending on the characteristics required for the final product. In industrial scale operations belt dryers, turbine dryers, recycle dryers, rotary drum dryers and spray dryers are used. This step allows finely divided, homogenous powder with excellent absorption and free flow properties to be produced. 2.5 Milling Process After drying, the product is often milled in jet mills or mechanical mills. During this process, the particle size distribution and sieve residue characteristics of the product are primarily modified. 2.6 Granulation Process For certain applications a dust free product is required, and to fulfil this requirement, the spraydried or milled product has to be granulated.