Steam Distillation of Lemongrass Oil Lab Manual

advertisement

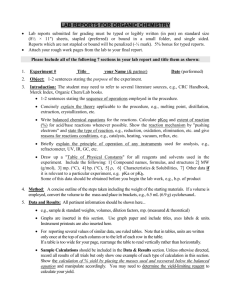

Winter 2009 CH241L PCC Sylvania Tristan Jenkins Exp#5 Steam Distillation of Lemongrass Oil Pre-Lab Complete items numbered 1-8 (omit number 3) as described in your lab syllabus. Make sure your data table includes the appropriate physical properties (chemical structure, molecular weight, densities, boiling points for liquids, hazards, and purpose) for all the chemicals used in this lab including the product. You will use the density values to identify which substance is in which layer during extraction. Remember to write in pen in your lab notebook, and to turn in your carbon copies before you start the lab. START YOUR PROCEDURE AND OBSERVATIONS ON A SEPARATE PAGE. Additional Pre-lab questions to be turned in at the start of lab. 1. What is a drying agent and why is it used in this lab? 2. How can you quickly identify the separate liquid layers in your reaction tubes? 3. What is an extraction and how is it carried out in the lab? 4. What are the other compounds in Lemongrass Oil and why would one want to extract citral? 5. Provide the approximate percentages of the major components in Lemongrass Oil. Questions of the Day: What is a steam distillation and under what conditions does one choose to perform this type of distillation? How is this technique different from simple and fractional distillation that were performed last week? Background for Steam Distillation When a mixture of cyclohexane and toluene is distilled, the boiling point of these two miscible liquids is between the boiling points of each of the pure components. By contrast, if a mixture of benzene and water (Immiscible liquids) is distilled, the boiling point of the mixture will be found below the boiling point of each pure component. Since the two liquids are essentially insoluble in each other, the benzene molecules in a droplet of benzene are not diluted by water molecules from nearby water droplets, and hence the vapor pressure exerted by the benzene is the same as that of benzene alone at the existing temperature. The same is true of the water present. Because they are immiscible, the two liquids independently exert pressures against the common external pressure, and when the sum of the two partial pressures equals the external pressure, boiling occurs. Benzene has a vapor pressure of 760 mm Hg at 80°C, and if it is mixed with water, the combined vapor pressure must equal 760 mm Hg at some temperature below 80°C. This temperature, the boiling point of the mixture, can be calculated from known values of the vapor pressure of the separate liquids at that temperature. Vapor pressures found for water and benzene in the range 50 to 80°C are plotted in the figure to the right. The dotted line cuts the two curves at points where the sum of the vapor pressures is 760 mm Hg; hence this temperature is the boiling point of the mixture (69.3°C). Practical use can sometimes be made of the fact that many water-insoluble liquids and solids behave as benzene does when mixed with water, volatilizing at temperatures below their boiling points. Thus naphthalene, a solid, boils at 218°C but distills with water at a temperature below 100°C. Since naphthalene is not very volatile, considerable water is 1 Winter 2009 CH241L PCC Sylvania Tristan Jenkins required to entrain it, and the conventional way of conducting the distillation is to pass steam into a boiling flask containing naphthalene and water. The process is called steam distillation. With more volatile compounds, or with a small amount of material, the substance can be heated with water in a sample distillation flask and the steam generate in situ: Some high-boiling substances decompose before the boiling point is reached and, if impure, cannot be purified by ordinary distillation. However, they can be freed from contaminating substances by steam distillation at a lower temperature, at which they are stable. Steam distillation also offers the advantage of selectivity, since some water-insoluble substances are volatile with steam an others are not, and some volatilize so very slowly that sharp separation is possible The technique is useful in processing natural oils and resins, which can be separated into steam-volatile and non-steam-volatile fractions. It is useful for recovery of a non-steam-volatile solid from its solution in a high-boiling solvent such as nitrobenzene, boiling point 210°C; all traces of the solvent can be eliminated and the temperature can be kept low. The boiling point remains constant during a steam distillation as long as adequate amounts of both water and the organic component are present to saturate the vapor space. Determination of the boiling point and correction for any deviation from normal atmospheric pressure permit calculation of the amount of water required for distillation of a given amount of organic substance. According to Dalton's law, the molecular proportion of the two components in the distillate is equal to the ratio of their vapor pressures p in the boiling mixture; the more volatile component contributes the greater number of molecules to the vapor phase. Thus, Moles of Water p water Moles of substance p substance The vapor pressure of water pwater at the boiling temperature in question can be found by interpolation of the data in the table below, and that of the organic substance is, of course, equal to 760 – pwater. Vapor Pressure of Water in Millimeters of Mercury (mm Hg) t(°C) 60 61 62 63 64 65 66 67 68 69 p(mm Hg) 149.3 156.4 163.8 171.4 179.3 187.5 196.1 205.0 214.2 223.7 t(°C) 70 71 72 73 74 75 76 77 78 79 p(mm Hg) t(°C) 233.7 243.9 254.6 265.7 277.2 289.1 301.4 314.1 327.3 341.0 80 81 82 83 84 85 86 87 88 89 p(mm Hg) t(°C) 355.1 369.7 384.9 400.6 416.8 433.6 450.9 468.7 487.1 506.1 90 91 92 93 94 95 96 97 98 99 p(mm Hg) 525.8 546.0 567.0 588.6 610.9 633.9 657.6 682.1 707.3 733.2 Hence the weight of water required per gram of substance is given by the expression: 2 Winter 2009 CH241L PCC Sylvania Tristan Jenkins Weight of water per gram of substance 18 p water MW of substance (760 - p water) From the data given in the figure above for benzene-water, the fact that the mixture boils at 69.3°C, and the molecular weight 78.11 for benzene, the water required for steam distillation of 1 g of benzene is only 18 x 227/(78.11 x (760-227)) = 0.098 g. Nitrobenzene (bp 210°C, MW 123. 11) steam distills at 99°C and requires 4.0 g of water per gram. The low molecular weight of water makes water a favorable liquid for two-phase distillation of organic compounds. On a small scale, steam is generated in the flask that contains the substance to be steam distilled by simply boiling a mixture of water and the immiscible substance. Background of Limonene Lemongrass is a perennial fast-growing aromatic grass, growing to about 1 meter (3 feet) high with long, thin leaves. Originally growing wild in India, it produces a network of roots and rootlets that rapidly exhaust the soil. In India it is known as 'choomana poolu' and is also referred to as 'Indian Verbena' or 'Indian Melissa oil'. In Ayurvedic medicine Lemongrass is used to help bring down fevers and treat infectious illnesses. It is a valuable ingredient in perfumes and citrus-type soaps and is also an insect deterrent. The main chemical components of Lemongrass oil are: Citral, Farnesol, Nerol, Citronellal and Myrcene. All are examples of a very large group of natural products called terpenes. They are responsible for the characteristic odors of plants such as eucalyptus, pine, mint, peppermint, and lemon. The odors of camphor, menthol, lavender, rose, and hundreds of other fragrances are due to terpenes, which have 10 carbon atoms with double bonds or rings and aldehyde, ketone, or alcohol functional groups. In nature these terpenes all arise from a common precursor, isopentenyl pyrophosphate. At one time they were thought to come from the simple diene, isoprene (2-methyl-1,3-butadiene), because the skeletons of terpenes can be dissected into isoprene units, having five carbon atoms arranged as in 2-methy1butane. These isoprene units are almost always arranged in a "head-to-tail fashion." Some Terpenes: CHO OH O Camphor Menthol Citral Limonene 3 Winter 2009 CH241L PCC Sylvania Tristan Jenkins Procedure In the present experiment citral is isolated by steam distillation of lemon grass oil, which is used to make lemongrass tea, a popular drink in Mexico. The distillate contains 90 % citral and 10 % neral, the stereoisomer about the 2,3-bond. Citral is used in a commercial synthesis of Vitamin A. The citral and neral are isolated from the water by shaking the mixture with methyl t-butyl ether (MTBE). The citral dissolves in the MTBE, which is immiscible with water, and the two layers are separated. The MTBE is dried (MTBE also dissolves trace amounts of water) and evaporated to leave citral. If you need to store the citral, keep it in the smallest possible container in a dessicator for later analysis. A. Steam Distillation: Into a 5-mL short-necked round-bottomed flask place a boiling chip, 0.5 mL of lemongrass oil (obtain the mass of the lemongrass oil added), and 3 mL of water. Assemble the apparatus as demonstrated in the lab using a 400-mL beaker for the ice bath. Distill as rapidly as possible, taking care that all the distillate condenses. Using a syringe, inject water dropwise through the septum to keep the volume in the flask constant. Distill into an ice-cooled 15-mL centrifuge tube or a vial until no more oily drops can be detected, about 10 to 12 mL. 1. Record the vapor temperature during the distillation as each 1 mL of distillate is collected. Prepare a computer-generated graph of this data to include in your analysis section (you may have to estimate how many mL you have captured: roughly 20 drops = 1 mL). mL Vapor Temperature ______ ________________ 1 2 3 4 5 mL Vapor Temperature ______ ________________ 6 7 8 9 10 2. In the analysis section comment on how the above data correlates with the theory of steam distillation. (Include the b.p. of pure citral in your answer). B. Extraction of citral (http://orgchem.colorado.edu/hndbksupport/ext/ext.html look on the web for more information on the theory and practice of extraction) Add 2.5 mL of MTBE to the cold distillate in the 15-mL centrifuge tube. Put a cap on the centrifuge tube and shake carefully. The citral will dissolve into the upper ether layer. Draw off most of the ether layer with a Pasteur pipette and place in a clean reaction tube. Extract the ether layer twice more with 1.5 mL portions of MTBE to remove all of the citral. That means: add 1.5 mL MTBE, shake, remove. Repeat. Combine all three of the ether extracts in the reaction tube. To dry (remove all traces of water http://orgchem.colorado.edu/hndbksupport/drying/drying.html) the ether layer, add about 2 mL of saturated sodium chloride solution to the ether in the reaction tube. Stopper the reaction tube (use a septum), shake it, and then remove and discard the aqueous layer. (Note! Before discarding the aqueous layer, make sure it is the aqueous layer! Is it the top or bottom layer? Actually, it is 4 Winter 2009 CH241L PCC Sylvania Tristan Jenkins usually beneficial to keep all layers until you are positive you have the desired product. You would hate to realize that you threw away your product several steps ago). Add a small scoop of anhydrous calcium chloride pellets to the ether in the reaction tube to remove the last traces of water. Stopper the reaction tube again and shake over a period of 5 to 10 minutes. Read about drying agents on the internet. Remove the dry (no water, not “no liquid”) ether layer and place in another clean, dry, and tared (weighed) reaction tube with a boiling stone. Make sure you weigh the reaction tube with the boiling stone added! Add fresh ether (no more than a mL is needed for this) to the reaction tube with the drying agent to transfer all traces of citral. Combine with the ether in the second reaction tube. Evaporate the ether by placing the tube into a warm water bath in the hood. The last traces of ether are removed by connecting the reaction tube directly to the water aspirator. The residue should be a clear, fragrant oil. If it is cloudy, it is wet. Determine the weight of the citral, and calculate the percentage of citral recovered from the lemongrass oil, assuming that the density of citral is the same as that of lemongrass oil (0.89 g/cm3). Transfer the citral to the smallest possible airtight container. Obtain an FTIR and refractive index value. Analysis Include these items in your notebook. 3. Mass of lemon grass oil used. _______________ grams Final yield of purified citral. ________________ grams % Yield _________________% Physical appearance and odor of your product. __________________________________ _______________________________________________________________________ 4. Run an I.R. Spectrum of your purified citral. Indicate on the spectrum the presence of specific absorptions that correspond to specific structural components of citral. Comment below on how the I.R. spectrum might be used to confirm the identity of your product. 5. The index of refraction of my product was _______________________ at _________°C . The index of refraction of pure citral is _____________________ (at same temp as above). (source: ______________________________) 5