Non-Electronic Oxygen Concentrator Test

advertisement

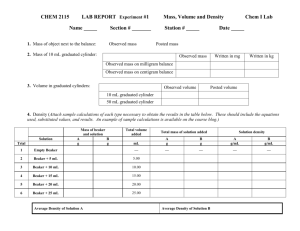

Non-Electronic Oxygen Concentrator Test April 21, 2008 Non-Electronic Oxygen Concentrator Test BME 262: Design for the Developing World Matthew Burke Andrew Dang Geoffrey Southmayd Table of Contents 1 Abstract ................................................................................................................1 2 Background ...........................................................................................................2 3 Completed Work ...................................................................................................4 3.1 3.2 3.3 3.4 4 4.1 4.2 4.3 Pressure/Volume Measurement of Dissolved O2 Concentration ..............................................5 Temperature Measurement of O2 Concentration ............................................................................7 Spectroscopic Measurement of O2 Concentration ...........................................................................9 Final Design: Combustion Rate Measurement of O2 Concentration...................................... 10 Future Work ........................................................................................................ 18 Improve Gas Container ............................................................................................................................ 18 Improve Seal Between Container and Test Surface ..................................................................... 18 Binary Test .................................................................................................................................................... 19 5 Schedule ............................................................................................................. 20 6 Budget ................................................................................................................ 21 6.1 6.2 7 7.1 7.2 Prototyping Budget ................................................................................................................................... 21 Bulk Manufacturing Budget ................................................................................................................... 21 Facilities and Personnel ....................................................................................... 22 Facilities ......................................................................................................................................................... 22 Personnel....................................................................................................................................................... 22 8 Bibliography ........................................................................................................ 23 9 Appendix ............................................................................................................ 25 9.1 9.2 9.3 9.4 9.5 9.6 Intellectual Property and Literature Analysis................................................................................ 25 Standards Analysis .................................................................................................................................... 33 Regulatory Analysis .................................................................................................................................. 35 Specifications ............................................................................................................................................... 39 Experimental Data & Look-Up Table ................................................................................................. 40 Parts List, Instructions, and Pictograms ........................................................................................... 41 Non-Electronic Oxygen Concentrator Test April 21, 2008 1 Abstract Oxygen is considered an important prophylactic and life-saving aid for medical patients when administered during procedures requiring anesthesia, as well as during patient recovery. In the developing world, hospitals often struggle to provide oxygen to their patients due to a lack of funding. In addition to these financial problems, delivering oxygen in cylinders is challenging due to poor road systems in developing countries. As a result, supplying developing world hospitals with oxygen in cylinders remains difficult. The use of oxygen concentrators has provided some relief to the problem of delivering oxygen cylinders to developing world hospitals. Concentrators provide an in-house method of producing oxygen from ambient air. This occurs by passing compressed air over nitrogen-absorbing zeolite crystals, which increases the concentration of oxygen in the compressed air. With repeated use, however, these oxygen concentrators become less accurate, but the cost of maintenance is often too great for the hospital to afford, and as a result, the device may provide patients with oxygen at undesired concentrations. Most often, problems with the concentrator are only observed once a patient becomes hypoxic. A test is needed to verify that the concentrator is delivering oxygen at the desired concentration. We plan to design a non-electronic device for measuring the oxygen levels delivered from concentrators in developing world hospitals. The device will utilize an important property of oxygen: combustion is accelerated in the presence of oxygen gas. Specifically, the device will allow the user to measure the rate of burning of a paper match and with that data “look up” the percentage of oxygen present in the air outputted by the concentrator in question. The device is simple to assemble and use, and a kit will be provided to hospitals to ensure that results can be standardized. Maintenance for the device will occur in the hospital using resources readily available to technicians and doctors. To reduce cost below existing oxygen concentration tests, the accuracy of the reported output to the user was decreased to indicate only clinically relevant concentration intervals. However, under test conditions we were able to achieve prediction accuracy of ±5%. We believe that the resulting device provides a maintainable, reliable, and cost effective method of testing hospital oxygen concentrators in the developing world. 1 Non-Electronic Oxygen Concentrator Test April 21, 2008 2 Background The need for an inexpensive yet reliable method to measure oxygen concentration is the basis for our project. Such a method is required because oxygen concentrators used in developing countries are assumed to deliver 90-95% concentrated oxygen, when many times the actual concentration is much less. As an example, Bill Teninty states that on a recent trip to Indonesia, he tested what a hospital there called a “new” oxygen concentrator and the output he measured was 29-30.5% oxygen, well below the necessary level. (Teninty, 2008) Mission hospitals in developing countries have used oxygen concentrators since the 1980s. (Teninty, 2008) The devices are used in developing world hospitals primarily because oxygen cylinders are too expensive and require too much management (e.g. cylinder refill and replacement) to be affordable (Perrelet, 2004). Instead of using cylinders as a source of pre-concentrated oxygen, oxygen concentrators work by passing compressed atmospheric air through one of two canisters containing zeolite granules. The higher pressure inherent in the compressed air of the canister causes nitrogen to bind to zeolite granules in the filtering canister, allowing output of product with higher oxygen concentration. The pressure is then returned to normal in the first canister, and flow of compressed air is switched into the second canister. Returning the pressure to normal in the first canister allows the bound nitrogen to unbind from the zeolite granules, while the second canister goes through the same process with the compressed air as described before. A constant supply of concentrated oxygen can thus be delivered by continuously cycling the flow of compressed air between the two canisters. (Eltringham, 1992) The World Health Organization has provided specifications for oxygen concentrators used in developing countries. However, the proper performance of concentrators depends on a steady supply of electricity and required maintenance that many rural hospitals lack. (Dyke, 1994) As evidenced by Teninty’s visit to Indonesia, a faulty concentrator was unknowingly assumed as working properly. Therefore, an inexpensive, reliable test of oxygen concentration would decrease the chances that a poorly performing concentrator is used for patient care. Numerous technologies currently exist for measuring oxygen concentration. The zirconia oxygen sensor is used in many industries to measure oxygen concentrations in gas and liquid mixtures. The zirconia electrolyte used in this type of sensor becomes conductive to oxygen ions at high temperatures—300°C-600°C. Higher concentrations of oxygen correspond to greater charge flow, which can be measured as a voltage (Hradek, 1991). Oxygen can be measured chemically using Azide-Winkler titration. This method uses a series of corrosive reagents such as manganese sulfate, sulfuric acid, and 2 Non-Electronic Oxygen Concentrator Test April 21, 2008 sodium thiosulfate, to titrate a liquid containing dissolved oxygen, thereby measuring oxygen concentration. (Chapter 4…, 2007) Electrodes are also used to measure oxygen concentration. The Clark method utilizes the reduction of oxygen at platinum electrodes to generate current and measure oxygen concentration. The electrode is constructed using a thin, organic membrane to cover a layer of electrolyte and a cathode-anode pair that have a fixed voltage, allowing only oxygen to be reduced. (Clark, 2003) Oxygen concentration can also be measured optically. An optical fiber oxygen sensor utilizes a chemical film that covers the tip of an optical fiber. The film is photoluminescent, and its emissions are quenched when exposed to oxygen. Less luminescence means more oxygen is present. (Rosenzweig, 1995) The paramagnetic oxygen sensor is yet another method of measuring oxygen concentration. This device uses a dumbbell-shaped vessel filled with inert gas that is suspended on a platinum wire in a non-uniform magnetic field. As oxygen is passed through the system, oxygen molecules move towards the stronger section of the magnetic field, resulting in a displacement of the dumbbell that corresponds to the oxygen concentration. (Alpha Omega, 2006). Though there are many technologies available, none have been successfully implemented as a cheap, reliable method for testing oxygen concentrator levels in a developing world hospital. The current project seeks find a solution to that problem. 3 Non-Electronic Oxygen Concentrator Test April 21, 2008 3 Completed Work Three design alternatives were explored with the goal of arriving at the most effective and practical. Because of the nature of the problem—oxygen is an odorless, colorless gas—we focused our search on exploiting a measureable property of oxygen, or on an interaction between oxygen and another substance. Our end goal was to create a simple, novel method for indirectly measuring oxygen concentration in an air sample of unknown quality. There are several properties of oxygen that we believed might prove useful in its measurement. The following design matrix evaluates the merits of several oxygen measurement techniques that take advantage of properties including paramagnetism, combustion, solubility, and chemical reaction. They are examined based on five design goals important to the success of this project: reliability, ease of use, ease of maintenance, cost, and performance. Alternatives Spectral Flame Burn Rate Flame Temp. Fluorescence w/ Aerogel Fluorescenece w/ Fiber Optics Dissolved O2 Volume Tube Pressure Titration Paramagnetism Reaction w/ NO Reliability (100) 5/500 8/700 6/600 8/800 Maintenance (100) 8/800 8/800 8/800 4/400 Goals Ease of Use (80) 9/720 8/640 9/720 5/400 8/800 6/600 6/480 5/200 7/140 2220 7/700 9/900 10/800 6/240 6/120 2760 7/700 8/800 9/900 7/700 9/900 4/400 6/600 4/400 9/720 4/320 7/560 4/320 5/200 3/120 3/120 3/120 7/140 8/160 9/180 8/160 2660 1800 2360 1700 Cost (40) 9/360 9/360 8/320 3/40 Performance (20) 4/80 6/120 5/100 7/140 Total 2460 2620 2540 1780 Table 1: Design Matrix Based on their individual scores, we chose to pursue flame analysis (which includes both burn rate and spectral/temperature analysis), and dissolved O2 analysis. Testing was performed on these alternatives, and it was found that only the burn rate analysis yielded promising results. The results of testing for each alternative will be discussed in brief before a detailed analysis of the final design choice is presented. 4 Non-Electronic Oxygen Concentrator Test April 21, 2008 3.1 Pressure/Volume Measurement of Dissolved O2 Concentration This proposed method of measuring oxygen concentration relied on the physical properties of liquids and gases and the ideal gas law for determining concentration given pressure and volume. It depends on the following hypothesis: for higher oxygen concentrations, more gas will dissolve in water because oxygen has a higher solubility in water than the other gases that comprise room air. Oxygen is bubbled through a fixed quantity of water (H2O) for a fixed period of time. Both of these parameters (volume of water and bubbling time) were investigated during testing to find the optimal combination. We found that due to the time consuming process of boiling water, using smaller quantities was more practical. The operating procedure will be as follows: 1. Fill Erlenmeyer flask with specified amount of water. 2. Bubble oxygen through water for specified period of time. 3. Stopper flask and connect output tube running from Erlenmeyer flask to eudiometer. 4. Engage heat source and bring water to a boil. 5. Read off volume from eudiometer when water reaches a boil (i.e. the solubility of oxygen is considered zero). Experimental Set-Up: Figure 1: Complete set-up for volume measurement method 5 Non-Electronic Oxygen Concentrator Test April 21, 2008 3.1.2 Testing Results Investigation of Bubbling Time: Trial 1 Bubbling Time (air only) Trial 2 Trial 3 None 30 sec 5 min 74 74 74 200 200 200 66 59.6 65 Initial Water Temp. (C) Water Volume (mL) Volume of Gas Released (mL) Table 2: Investigation of Bubbling Time Data for Room Air (21% O2) As can be seen by the results shown in Table 2, there does not appear to be any relationship between boiling time and the amount of gas released during boiling for room air. Trial 1 Bubbling Time (100% O2) Initial Water Temp. (C) Water Volume (mL) Volume of Gas Released (mL) Trial 2 Trial 3 None 2 sec 30 sec 65 65 65 200 200 200 26 66 60 Table 3: Investigation of Bubbling Time Data for 100% O2 In this experiment, there appeared to be an encouraging result in Trial 1. Ideally, with no bubbling, the gas released should be much less than that released when bubbling is applied. However, this result was not replicated and was determined to be an anomaly. There was no significant difference between Trials 2 and 3 when bubbling time was increased from 2 seconds to 30 seconds, which implies that the water is becoming saturated with oxygen very quickly (i.e. < 2 sec). If this is indeed the case, this method may not be practical for clinical use because it will be impossible to achieve a gradient of dissolved oxygen for different gaseous concentrations. Because it is known that solubility of oxygen in water increases as the water temperature approaches 0°C, we investigated whether decreasing the temperature of the water before bubbling would affect our results. However, decreasing the temperature to 1°C had no effect on the volume of gas released during boiling. This 6 Non-Electronic Oxygen Concentrator Test April 21, 2008 is an indication that the boiling method may not be indicative of dissolved oxygen content at all. Investigation of Oxygen Concentration: Trial 1 O2 Concentration Bubbling Time Water Volume (mL) Volume of Gas Released (mL) Trial 2 Trial 3 21% 21% 100% 30 sec 30 sec 30 sec 200 200 200 59 59.6 60 Table 4: Investigation of Oxygen Concentration Data This phase of testing was designed to determine whether we could distinguish between room air (21% oxygen) and 100% oxygen, the largest range we would need to differentiate using this method. Unfortunately, there appeared to be no difference in the volume of gas released when using 100% oxygen as compared to room air. This is another indication that this method may not be reliable and in fact impractical in achieving our design goals. In conclusion, there may be many factors that inhibited successful implementation of this idea, but regardless, the pressure/volume method of measuring oxygen concentration was deemed a failure due to lack of repeatability. 3.2 Temperature Measurement of O2 Concentration Oxygen supports combustion, and changes the characteristics of a flame depending on its concentration in air (i.e. color of the flame, intensity of burning). For this method, we were interested in investigating the adiabatic flame temperature of a fuel at constant pressure. Adiabatic flame temperature is the temperature achieved during combustion of a fuel with no heat transfer or changes in kinetic or potential energy. (Engineering Toolbox, 2005) Other characteristics of a flame were also analyzed in later experiments, such as spectral band emission, flame size, and flame shape. 3.2.1 Testing Results The first step in the flame experiments was determining what type of fuel source(s) to use to generate a flame. Cotton, newspaper, wood on a match stick, and natural gas (from a research lab) were investigated for ability to generate measurable flames. Both cotton and newspaper did not produce measurable flames when ignited with a grill lighter. Instead, they both “cindered” as they burned, therefore we decided not to use cotton and newspaper as fuel sources. We considered using a 7 Non-Electronic Oxygen Concentrator Test April 21, 2008 gas source (natural gas from lab, butane, propane) but professionals (anesthesiologist at Duke Hospital, an M.D. /Ph.D. in a Duke research lab, and the lab manager in the Physics Department at Duke University) recommended against testing gas-fueled flames (e.g. Bunsen burner) with 100% oxygen due to safety concerns. Temperature (near or in the flame): PROPOSED IDEA: By using an infrared thermometer and a closed environment, a correlation could be determined between adiabatic flame temperature and oxygen concentration. TESTING RESULTS: The infrared thermometer used was a Sixth Sense LaserTemp100 IR thermometer with a range of -58 to 932F. The IR thermometer measures surface temperature of whatever object the mounted laser is pointed at. We attempted to measure the temperature of a match flame (Diamond brand matches), but found that the flame was too small and fluctuated too rapidly to get an accurate reading. We did not test a Bunsen burner flame (natural gas fuel) because of multiple warnings from professionals about the dangers of using 100% oxygen with flames from any sort of gas burner. Because of the inaccuracies and inherent danger, we concluded that flame temperature analysis would not be a suitable method for measuring oxygen concentration. Figure 2: Measurement of Flame Temperature using IR Thermometer 8 Non-Electronic Oxygen Concentrator Test April 21, 2008 3.3 Spectroscopic Measurement of O2 Concentration Because oxygen accelerates combustion, we hypothesized that the increased presence of oxygen might also alter the spectral bands of a flame. 3.3.1 Testing Results Spectral/optical bands: PROPOSED IDEA: The spectral band emission of a flame is like a fingerprint that changes depending on the substances being combusted. In this case, visual analysis of spectral bands from a flame (using a prism to separate wavelengths) would be correlated with different oxygen concentration. TESTING RESULTS: Three different methods were used in the attempt to generate spectral bands from a match’s flame. The first was an equilateral prism placed in between the flame and a white background wall in a dark room. Spectral bands were not observed at all with this method. The second method used was the creation of a “homemade” spectroscope crafted out of a narrow cookie box, paper, tape, and diffraction grating film. Spectral bands were observed in the device when the slit of the device was pointed at a bright and steady light source, such as a fluorescent light bulb, which indicated that the device was working. However, when the device was used with a match flame, spectral bands were not observed. This is most likely because the flame’s intensity was not strong enough to produce bands in the device. Figure 3: Homemade Spectroscope To see if lack of viewable spectral bands was a problem with the device itself, an analog spectroscope was borrowed from the Physics Department at Duke University. Once again, the analog spectroscope produced spectral bands when viewing white light, from a fluorescent bulb, but no bands were viewed when observing the flame from a match. We concluded from these results that spectral band observation of flames would not be a viable method for measuring oxygen concentration. 9 Non-Electronic Oxygen Concentrator Test April 21, 2008 3.4 Final Design: Combustion Rate Measurement of O2 Concentration The final method of measuring oxygen concentration investigated was to analyze the burn rate of a match exposed to air from a concentrator. A container of known volume (in this case a 250 mL glass beaker) is filled underwater with air from the concentrator—water is used to ensure that air from the concentrator fills the entire volume of the container without mixing with room air. A match is placed in a small piece of putty to secure it upright on the test surface. The beaker is covered on the open end with aluminum foil and a small hole is cut in the center to allow placement over the match. As the beaker is moved down over the match, a timer is started. The method depends on measuring the time it takes for a flame traveling along the length of a match to either: reach the bottom of the match, or to cease forward progress along the match. Our design is not a completely closed system, so we cannot measure the time it takes for the flame to extinguish. This is because once the oxygen inside the container is depleted, the flame “sucks in” room air through small gaps between the container and the test surface, causing the match to cinder for a prolonged period before finally extinguishing completely. The time is recorded and the length that the flame burned along the match is measured. This procedure is repeated five times to eliminate random error, and the times/lengths are averaged. Finally, a look-up table is utilized to read off the oxygen concentration from the average burn time and average burn length. The testing process for this design will be discussed in detail later in this section. 3.4.1 First Attempt: Wood Matches and Open-Ended Beaker The first attempt at predicting oxygen concentration with burn rate analysis utilized similar materials, but was not as reliable as the final design. Rather than covering the mouth of the beaker with foil, it was left open. And, instead of using putty to secure the match, a metal spring clip was employed. We performed 50 trials each at oxygen concentrations of 100%, 80%, 60%, 40%, and 21%. It is important to note that during testing, we did not have access to pre-mixed gas at intermediate concentrations. We procured an oxygen cylinder that contained 100% oxygen, and used a basic algebraic formula to calculate how much pure oxygen needed to be combined with room air to create gas containing 80%, 60%, and 40% oxygen. 0.21(V x) x P 100 V In the relation above, P is the desired oxygen percentage; V is the volume of the container (250 mL beaker for our tests); and x is the volume of pure 100% oxygen needed. Generally, we solved this equation for x at the percentages we desired for the known volume of the beaker. The data for this experimental setup is summarized in Table 6, and the plot in Figure 4 shows the analytical fit to the data as well as 99% confidence intervals calculated based on the standard deviation. 10 Non-Electronic Oxygen Concentrator Test April 21, 2008 Oxygen Percentage 100% 80% 60% 40% 21% Average Rate (cm/s) 2.02 1.23 0.70 0.37 0.12 Standard Deviation 0.18 0.11 0.10 0.01 0.01 99% Confidence Interval 0.15 0.09 0.08 0.01 0.01 Table 6: Results of Testing with Method 1 Figure 4: Power Law Fit of Testing Data with Method 1 The plot above shows a power law fit with an R2 of 0.996, which is very high. The confidence bars confirm that this method does indeed allow discrimination of oxygen percentages that differ by 20%. Although the data presented above appear promising, it was determined through blind trials (using people unfamiliar with the procedure) that the open-mouth beaker introduces too much error for the method to be effective. In other words, there was a sharp learning curve for individuals performing the test that greatly decreased their accuracy. Specifically, the method assumes that some volume of oxygen will be lost out the bottom of the beaker in each trial. However, it also assumes that this volume will be constant for each tester. It became clear that a method that depends so strongly on human error for its function was not a viable option. Further, we discovered that wooden matches are not manufactured to be the same size and shape. Some matchsticks were thicker than others, which affects the burn 11 Non-Electronic Oxygen Concentrator Test April 21, 2008 rate—a fact that serves to compound the human error described before. Also, match composition varies between matches as well. Wood that contains more pitch (resin) burns at a faster rate than wood with less. Therefore, we found it difficult to standardize our results across all wood matches of the same brand, let alone all wood matches. 3.2 Second Attempt: Covered Beaker and Wooden Dowels An alternative method was needed. We attempted to solve the gas leakage problem by covering the open end of the beaker with aluminum foil and cutting a small hole for the match to fit through. This greatly decreased the amount of gas that escaped from the beaker in our trials. Unfortunately, the system worked almost too well. The wooden matches flashed completely into flame in well under a second—too short a time to be measured. This occurred at concentrations of both 100% and 80%, effectively preventing us from achieving our specification of ±20% accuracy. Recognizing that the aluminum foil provided optimal retention of gas and was much easier to use than the previous setup, we attempted to find a material that would burn slow enough to be measured when exposed to high oxygen concentrations. Cylindrical wooden dowels were chosen (r = .3 mm, h = 5 mm) as the next test material. These did indeed burn slow enough to be practical. However, a similar problem was encountered as with wood matches. The grain and composition of the dowels varied greatly from piece to piece. Reproducible results were thus not attainable. 3.3 Third Attempt: Covered Beaker and Paper Matches Paper matches were avoided in original testing because we assumed they would yield less consistent results than wood matches. However, further testing proved this assumption incorrect. In fact, paper matches were more reliable than wood for several reasons. First, they are completely manufactured, so each match is identical to every other match (brand dependent). Second, we found that although wood matches burned too quickly under 100% oxygen with a covered container, paper matches did not. Rather, paper matches burned at a measurable rate of approximately two seconds under these conditions. Finally, paper matches are even cheaper than wood matches, costing only $1.44 for 1500 matches. These three observations made paper matches the material of choice for our final design. Testing was performed in much the same way as in the first attempt— however, due to the very consistent results we obtained after 25 trials for lower concentrations (as opposed to the 50 performed before), we determined that additional trials were not necessary. Table 7 summarizes the results from this round of testing. Notice that the standard deviations of the averages are extremely small. This implies that taking the average of five trials as the measured burn rate 12 Non-Electronic Oxygen Concentrator Test April 21, 2008 effectively eliminates whatever inherent error remains in the method. complete data tables can be found in Appendix 9.5. Oxygen Percentage 100% 80% 60% 40% 21% Average Rate (cm/s) 1.48 0.87 0.46 0.28 0.10 Standard Deviation 0.04 0.05 0.01 0.01 0.01 99% Confidence Interval 0.02 0.03 0.01 0.00 0.00 The Table 7: Results of Testing with Final Method Figure 5 below shows the exponential fit to the burn rate data. A correlation coefficient of 0.981 indicates a good fit. The error bars are too small to be visible on the plot, which is an indication of how accurate this method is from trial to trial. Figure 5: Exponential Fit of Burn Rate Data - Final Method In order to construct a look-up table for easy use by hospital technicians without access to scientific calculators, we back-solved the fit to yield concentration in the following manner, where x is oxygen concentration and y is the measured burn rate. y 0.061e 3.264x ln y 3.264 x ln( 0.061) x 0.306 ln y 0.857 13 Non-Electronic Oxygen Concentrator Test April 21, 2008 The following provides a detailed description of the testing procedure followed to obtain the plot above. 1. Place a dime-sized amount of adhesive putty in a mound on the table. 2. Cover the mouth of a 250 mL beaker with foil. Tape around the edges of the foil to keep it sealed and secure. Cut a small hole in the center of the foil approximately 1 – 2 cm in diameter. The hole should be able to fit over the match and mound of putty. 3. Stick a paper match about 2 mm into the putty so that it is standing upright. If testing 21% oxygen (room air): fill the beaker with water and then completely empty it to fill the entire volume with room air, then skip to step 5. If testing oxygen concentrations from 40-100%: submerge the 250 ml beaker under water. Invert the beaker, and then fill it as follows: a. 100% oxygen: fill the entire beaker with gas from the 100% oxygen cylinder. b. 80%: fill the beaker to 187ml with 100% oxygen and allow room air to bubble in the remaining gas volume. c. 60%: fill the beaker to 125ml with 100% oxygen and allow room air to bubble in the remaining gas volume. d. 40%: fill the beaker to 60ml with 100% oxygen and allow room air to bubble in the remaining gas volume. 4. Carefully remove the beaker from the water after sliding a piece of aluminum foil over the hole in the mouth of the beaker to keep most of the gas from leaking out. If following from steps 3b, 3c, or 3d, the rest of the beaker is filled with room air (assumed 21% oxygen) by carefully letting water drain out. 5. Bring the beaker over near the match while maintaining the foil seal. 6. Have a 2nd person light the match. 7. After the initial flare up from the sulfur on the match head, quickly place the beaker over the top of the match. Slide the beaker directly from the foil to the flame with as little upward vertical movement as possible (vertical movement causes gas to leak out of the beaker). 8. The 2nd person begins timing once the beaker has been set down. Stop the timer when the flame reaches the bottom of the match or when the flame stops its progress moving down the match. 9. Measure and record the distance burned as well as time to burn along the match. 14 Non-Electronic Oxygen Concentrator Test April 21, 2008 10. Repeat steps 1-9 for 25 times for each oxygen concentration. 11. For each oxygen concentration level dataset, calculate the burn rate for each trial (divide burn length by burn time) and then find the average of each set of five trials. Standard deviation and 99% confidence interval were calculated from the averaged data. The total average combustion rate for each oxygen concentration level can be plotted and fitted to form a rateconcentration curve and equation. 3.4 Unknown Concentrations and Blind Trials The final phase of testing performed was to recruit volunteers unfamiliar with the test procedure and determine whether or not they could replicate our results. Some trials were performed on pure 100% oxygen, however in others, volunteers were instructed to fill the beaker to a specified volume with oxygen and the rest with room air (this produced unknown intermediate concentrations). The following table summarizes the results obtained by eight teams of two volunteers. Table 8: Results of Blind Trials 15 Non-Electronic Oxygen Concentrator Test April 21, 2008 Volunteers were able to predict oxygen concentrations (using our previously determined exponential fit) with an average error of ±5%, well within our original specification. The results presented in Table 8 are encouraging; they demonstrate that users of this test can learn the technique within five trials and still predict very accurately the concentration of oxygen in an unknown sample of gas. A detailed parts list for our testing and instructions for the end-user are included in Appendix 9.6. Also included is a pictogram version of the instruction manual to be used by non-English speaking individuals or as a supplement to the written instructions. 3.5 Limitations There are several limitations to the design described above. First, although efforts were made to seal the bottom of the beaker with foil, some leakage inevitably occurs when removing the beaker from the water. The process of filling the container underwater seems to be the simplest method of reducing contamination by room air and ensuring that as much of the gas inside the container during testing as possible came out of the concentrator. We experimented with filling the beaker out of water. Since we knew the flow rate of oxygen out of the cylinder, we could estimate how long the gas needed to be running to completely fill the beaker. However, because oxygen is odorless and colorless, there is no way to tell when the container is entirely full. Worse, pure oxygen will not usually totally displace the room air that was originally inside the beaker—some mixing will occur. Second, because of the presence of water on the container after it is removed, there were a few instances of drips coming into contact with the match and/or flame. This usually invalidated the trial in question, but was observed rarely enough (1 in 25 trials) that it was not deemed a major issue. Third, there is a slight learning curve that comes with this method. However, because the final measurement is taken from the average of five trials, and because users learned the technique in less than five trials during our experiments, the effect of this should be negligible. Further, because we saw such good accuracy (5%) and our specification was for 20%, there is some room for human error before the test fails. Fourth, since the table was developed for the specific setup we developed, some materials must always remain constant. For this reason, our device will be sent to developing world hospitals in kit form. The kit will include enough matches for 150 tests (1500 matches), a 250 mL glass beaker as a container, and 12 sticks of adhesive putty. The rest of the materials (tape, bucket, foil, watch) should be locally 16 Non-Electronic Oxygen Concentrator Test April 21, 2008 available. Any digital watch or analog watch with a timer can be substituted for the stopwatch used during testing. The final limitation that we foresee is a general misinterpretation of instructions by the user. This would become especially likely if the user does not speak English and must rely on the pictogram instruction manual. While the procedure is relatively simple in and of itself, the user must understand when to start and stop the timer— otherwise the method loses its efficacy. Difficulty in understanding that the user must stop the timer when forward progress ceases or the flame reaches the end of the match, rather than when it extinguishes, may occur. Future work may be helpful in eliminating this and other sources of error. 3.6 Summary and Conclusions This project achieved all of the goals set for it at the beginning of the semester. Namely, it met every design specification and provided performance far beyond what was initially expected (see Appendix 9.4). Our hope is that others take up this concept and work with it in the pursuit of our ultimate goal: impact. Because there is no previous solution to the oxygen concentrator performance problem we investigated, we believe this design has the potential to become widely utilized in hospitals throughout the developing world. Ultimately, it may even save lives. As graduating college seniors we are excited to have participated in creating a device with such potential. Finally, we wish to extend ourselves as resources to others working with our idea. Please feel free to contact any of us to ask specific questions about our work. 17 Non-Electronic Oxygen Concentrator Test April 21, 2008 4 Future Work Although the proposed design successfully meets the desired design specifications for the project, improvements to the design could still be made. Such improvements may involve choosing a different container in place of the 250 ml beaker, or finding a new method of sealing the system while the match is burning. It may also be useful to simplify the test to provide only basic high/low oxygen concentration information. 4.1 Improve Gas Container The use of a 250 ml beaker was useful for prototype testing, since a graduated container was needed to mix different oxygen concentrations for data collection. In the developing world, however, there will be no need for gas mixing, since the gas emitted from the concentrator is already mixed to some (unknown) oxygen concentration. Thus, a non-graduated container, such as a glass cup, may provide a more inexpensive alternative to the beaker. Glass Coca-Cola bottles, or even clear glass beer bottles, might be especially useful substitutes. These containers are readily available in the developing world, and would provide cheaper, more easily replaceable alternatives to the glass beaker. In addition, the small mouth of the Coke or wine bottle would eliminate the need for aluminum foil to cover the opening, since there would be only minimal area for gas to escape. In addition, bottles with volumes larger than 250 ml could be used so that the match would burn longer before depleting the available oxygen. This would eliminate the often-difficult task of deciding when the forward progress of the flame down the match has stopped, since more flames will be able to reach the bottom of the match. The choice of a new container will require additional testing to develop a new calibration curve to fit the data. 4.2 Improve Seal Between Container and Test Surface As the match burns inside the beaker, it draws in room air in an attempt to continue combustion in the increasingly hypoxic environment of the container. As a result of this addition of 21% oxygen, the burn rate of the match decreases. Our model attempts to correct for this occurrence by stopping the timer when burn progress down the match ceases, and not when the match is extinguished. This error could be eliminated, however, by creating a tight seal around the base of the beaker to ensure a closed system during trials. This would allow for timing until the match goes out completely, which is far easier to determine. A seal could be established by pressing the beaker down into a ring of putty circling the match, or by placing the beaker into a shallow pan of water below an elevated 18 Non-Electronic Oxygen Concentrator Test April 21, 2008 match. This procedural change would likely improve the accuracy of the test drastically, but due to time constraints, was not investigated in this analysis. 4.3 Binary Test It is possible that oxygen concentrators experience all-or-nothing failure; that is, the concentration of oxygen emitted immediately drops from the desired value towards 21%, rather than slowly declining over time. Instant failure could be due to the zeolite crystals becoming wet due to excess humidity, for instance. In this case, a test would only be necessary to distinguish between extreme high and low oxygen concentrations. The proposed design could easily be simplified to provide this binary concentration determination. Observed burn rates in room air and 100% O2 differ by a factor of almost 15, and so a rough estimate of concentration could be obtained simply by watching the match burn. Rather than calculating burn rate and using a lookup table to determine concentration, the medical technician could simply check whether the match burns the length of the match within a certain amount of time (say, 3 seconds). Implementing such a test would require a detailed analysis of most common failure mechanisms of standard oxygen concentrators. 19 Non-Electronic Oxygen Concentrator Test April 21, 2008 5 Schedule The following design schedule (Figure 11) was followed as closely as possible, with small modifications being made as the process progressed. Figure 6: Design Schedule 20 Non-Electronic Oxygen Concentrator Test April 21, 2008 6 Budget 6.1 Prototyping Budget The prototyping budget outlines the cost of building three (3) working prototypes of our design. The following lists the costs incurred to build three prototypes of the combustion rate measurement device. 250 mL Bomex Beaker (3): $7.80 Adhesive Putty (3 1-cm pieces): $0.38 Diamond Matches (30): $0.03 Aluminum Foil (3 ft2): $0.09 Electrical Tape (3 ft): $0.03 12” Ruler (3): $1.50 Plastic Bucket (3): $6.00 o TOTAL: $15.83 Therefore, a single prototype device costs roughly $5.27, well under our original specification of $100.00. This budget does not take into consideration the cost of a stopwatch. This is because a stopwatch is extremely expensive compared to all the other materials used ($12.99 each). Ideally, the user would own a watch capable of tracking times on the order of several seconds (digital, or analog with a timer). If not, they should be able to find a co-worker who does. If it is deemed during production that a stopwatch should be included in the kit, the cost of production will increase significantly but still fall well below our specification. 6.2 Bulk Manufacturing Budget The bulk-manufacturing budget estimates the cost of producing 500 units of each device. Labor costs are neglected, as no pre-assembly is required to use our device. These budgets were calculated assuming a 20% discount on materials for bulk orders. Further, this budget only takes into account items to be included in the “kit” that will be distributed to hospitals. Locally available items are thus not included in the bulk-manufacturing budget below. 250 mL Bomex Beaker: $2.60 Adhesive Putty (12 sticks): $5.97 Diamond Matches (1500): $1.44 o TOTAL: $10.01 Approximate cost of 500 kits: $4,004.00 Miscellaneous items in both budgets such as travel, consultants, facilities, etc., were found to be negligible. 21 Non-Electronic Oxygen Concentrator Test April 21, 2008 7 Facilities and Personnel 7.1 Facilities 7.2 Duke Engineering BME 261/262 design labs Table saw, band saw, CAD, PIC, computers, other available/purchased equipment and tools as needed Duke University Hospital: access to oxygen concentrators and/or compressed air. Duke Chemistry Department Lab: use to build prototype Personnel Client: Bill Teninty International Aid: Medical Equipment Training Manager Faculty advisor: Dr. Robert Malkin BME 261/262 design class professor and project advisor Expert Consultants: Richard Buck; UNC Biochemistry Department Erno Lindner; University of Memphis University Contacts Dr. Allan Shang, M.D. Duke University Dept. of Anesthesia. Dr. Keita Ikeda, Ph.D. Duke University Dept. of Anesthesia, Research. Project team members: Matt Burke; Andrew Dang; Geoff Southmayd; matthew.burke@duke.edu andrew.dang@duke.edu geoffrey.southmayd@duke.edu This team would like to acknowledge Dr. Ikeda for allowing us access to his lab, and Dr. Shang for providing us oxygen—without which this project would have been impossible. We would also like to thank Dr. Malkin for his support and guidance throughout the project, and for sharing his vision of designing for the developing world with us. 22 Non-Electronic Oxygen Concentrator Test April 21, 2008 8 Bibliography Abbasi, Hamid A. and Rue, David M. “Method for measuring concentrations of gases and vapors using controlled flames.” U.S. Patent 6780378. 24 Aug 2004. Air Liquide. (2007). Gas Encyclopedia. Retrieved February 4, 2008, from Air Liquide: http://encyclopedia.airliquide.com/Encyclopedia.asp?GasID=48 American Chemical Society. (1999). Division of Chemical Education. Retrieved February 4, 2008, from Reaction of Nitrogen Monoxide with Oxygen to form Nitric Acid: http://jchemed.chem.wisc.edu/JCeSoft/CCA/CCA3/MAIN/RAINN1O2/PAGE1.HTM Aquatic Ecosystems, Inc. (2007). Self-Priming Manual Siphon Pump. Retrieved February 21, 2008, from http://www.aquaticeco.com/index.cfm/fuseaction/product.detail/iid/8835/cid/21 60 Bales, R., & Conklin, M. (n.d.). University of Arizona. Retrieved February 4, 2008, from The Hach Dissolved Oxygen Kit: http://www.hwr.arizona.edu/globe/Hydro/kit_chem/hachdo.html Blackie, J., Wu, P., & Naveh, D. (1999). Membrane Oxygenation of Mammalian Cell Culture Fermenters Using Dupont Teflon AF-2400 Tubing. In A. Bernard, B. Griffiths, W. Noe, & F. Wurm, Animal Cell Technology: Products from Cells, Cells as Products (pp. 299-302). Lugano, Switzerland: Kluwer Academic Publishers. “Chapter 4 - From the Field to the Lab: How to Measure Dissolved Oxygen”. A Citizen's Guide to Understanding and Monitoring Lakes and Streams. 23 May 2007. http://www.ecy.wa.gov/programs/wq/plants/management/joysmanual/4oxygen. html. 4 Feb. 2008. Dow Corning. (2008). Rubber Physical and Chemical Properties. Retrieved February 20, 2008, from http://www.dowcorning.com/content/rubber/rubberprop/rubber_perm.asp Dwyer Instruments, Inc. (2005). Measurement of Pressure with a Manometer. Retrieved February 18, 2008, from http://www.dwyerinst.com/htdocs/pressure/ManometerIntroduction.cfm Dyke, T., Brown, N. “Hypoxia in childhood pneumonia: better detection and more oxygen needed in developing countries.” BMJ (1994) 308:119-20. http://www.bmj.com/cgi/content/full/308/6921/119. Educate-yourself.org. (2006). Educate Yourself. Retrieved February 4, 2008, from Ozone's Reaction with Common Chemicals: http://educateyourself.org/ozone/ozonereactionswithcommonchemicals29sep06.shtml#acids 23 Non-Electronic Oxygen Concentrator Test April 21, 2008 Engineering Toolbox. (2005). Adiabatic Flame Temperature. Retrieved February 5, 2008, from The Engineering Toolbox: http://www.engineeringtoolbox.com/adiabatic-flame-temperature-d_996.html Elert, Glenn. “Melting Point of Glass.” 2002. http://hypertextbook.com/facts/2002/SaiLee.shtml. 22 Feb. 2008. Eltringham, Roger. “The Oxygen Concentrator.” Update in Anaesthesia (1992)1,6. http://www.nda.ox.ac.uk/wfsa/html/u01/u01_009.htm. Hradek, Richard W., Myers, William P., Alftine, David N., Cao, Tuan. “Oxygen concentrator with pressure booster and oxygen concentration monitoring.” U.S. Patent 5071453. 10 December 1991. “Jet Engine.” Avarneg Inc. 2007. http://www.madehow.com/Volume-1/JetEngine.html. 22 Feb. 2008. “Leland C. Clark.” The Hebrew University of Jerusalem, Institute of Chemistry. 17 May 2003. http://chem.ch.huji.ac.il/history/clark_leland.htm. 4 Feb. 2008. “MatWeb: Material Property Data.” 2008. http://www.matweb.com/search/PropertySearch.aspx. 22 Feb. 2008 “Oxygen Sensor Types.” Alpha Omega Instruments. 2006. http://www.aoicorp.com/additional_information/oxygen_sensor_types/. 4 Feb. 2008. Omega Engineering Technical Reference. (2007). Pressure Gauges. Retrieved February 20, 2008, from http://www.omega.com/prodinfo/pressuregauges.html Perrelet, A., et. al. “The oxygen concentrator: an appropriate technology for treating hypoxaemic children in developing countries.” International Journal of Tuberculosis and Lung Disease (2004) 8, 9:1138-1141. Pressure Measurement by Manometer. (n.d.). Retrieved February 19, 2008, from http://www.it.iitb.ac.in/vweb/engr/civil/fluid_mech/section2/manometers.htm Rosenzweig Z. and Kopelman R. “Development of a Submicrometer Optical Fiber Oxygen Sensor.” Anal. Chem. (1995) 67: 2650-2654. Teninty, B. (2008, January 29). The Need for an Oxygen Concentration Test in Developing Countries. T. Myers Magic. (n.d.). Squeeze Pumps. Retrieved February 22, 2008, from http://www.tmyers.com/pump/squeeze.html Volland, Walt. “Spectroscopy: Element Identification and Emission Spectra.” 31 Mar. 2005. http://www.800mainstreet.com/spect/emission-flame-exp.html. 22 Feb. 2008. 24 Non-Electronic Oxygen Concentrator Test April 21, 2008 9 Appendix 9.1 Intellectual Property and Literature Analysis 9.1.1 Patent Search Patent Title: Oxygen detecting composition Number: 6,703,245 Date: March 9, 2004 The oxygen detecting composition described in this patent has the ability to change color depending on the availability of oxygen. This could be utilized as a quick test of oxygen concentration if the color change could be set at a certain threshold of oxygen concentration. Patent Title: Method for measuring concentrations of gases and vapors using controlled flames Number: 6,780,378 Date: Aug 24, 2004 This patent describes a method of measuring select spectral bands emitted from a controlled flame to determine the concentration of certain gases and vapors. Application of this technology to calculate oxygen concentration is mentioned in the patent. Adapting this technology could provide a novel method of measuring concentration. Patent Title: Optical paramagnetic/diamagnetic gas sensor Number: 4,875,357 Date: Oct 24, 1989 The apparatus described utilizes the paramagnetic nature of certain gases to cause a dislocation in a movable element as they are passed through a magnetized chamber. Greater dislocation is correlated to greater concentration of tested gas. This technology is a potential means of measuring oxygen concentration, since oxygen is a paramagnetic gas. 25 Non-Electronic Oxygen Concentrator Test April 21, 2008 Patent Title: Oxygen indicator Number: 5,358,876 Date: Oct 25, 1994 This patent describes the use of an organic compound, acid, and a dye to test the presence of without water and in the presence of light. If this method could be adapted in some way to indicate degree of oxygen content, it would prove useful to the proposed project. Patent Title: Device and method for determining oxygen concentration and pressure in gases Number: 5,885,843 Date: March 23, 1999 This patent describes a novel approach to photoluminescence-based oxygen concentration detection. A silica aerogel diffusive medium allows oxygencontaining gas to diffuse easily through the porous network and quench photoluminescent material infused into the aerogel. This process provides an option for oxygen concentration detection in the current project. Patent Title: Method and sensor for measuring oxygen concentration Number: 5,043,286 Date: December 14, 1988 This patent describes a method for measuring oxygen concentration in a fluid. A plastic film containing a luminescent substance that is quenched in the presence of oxygen is exposed to the test fluid. The film is subjected to irradiation by light that is strongly absorbed by the luminescent substance, and the time-dependent emission intensity is measured. The luminescent substances used are metallo derivatives of partially or fully fluorinated porphyrins. Although the actual mechanism of luminescence and quenching is non-electronic, this method would most likely require an electronic transducer to be effective, making it difficult to apply to this project. Patent Title: Method and arrangement for measuring the concentration of gases Number: 4,003,707 Date: January 18, 1977 In this method for measuring the concentration of a gas, an indicator generates light signals corresponding to the concentration of gases in a sample to be measured. The apparatus includes a light transmissive surface upon which a beam of monochromatic light is directed. The indicator reacts when illuminated by the 26 Non-Electronic Oxygen Concentrator Test April 21, 2008 incident light and has a resulting color characteristic that will show the concentration of gases in the mixture. This apparatus seems too complicated for our application, but the technology is useful in thinking about the problem. Patent Title: Dissolved oxygen measurement instrument Number: 4,330,385 Date: May 18, 1982 This patent describes an instrument for indirectly measuring the concentration of dissolved oxygen in a liquid. Entrapped air is continuously circulated through the enclosure and bubbled through the liquid. A sensor measures the oxygen concentration of the air after it is bubbled through the liquid, which provides an indirect measurement of the amount of oxygen that dissolved in the liquid. The same type of design may be useful for our purposes, although the sensing element in this case is electronic. Patent Title: Ozone/ultraviolet water purifier Number: 4,141,830 Date: February 27, 1979 This patent describes a method of purifying water by irradiating air with ultraviolet light to convert some of the oxygen to ozone, and then bubbling this ozonated air through water to purify it. This method may be useful for creating ozone and dissolving it in a liquid should we choose to pursue that design concept. Patent Title: Method for Measuring Oxygen Concentration Number: 4,810,655 Date: March 7, 1989 This patent uses luminescent emission to determine oxygen concentration from a test fluid. This fluid is passed over an oxygen-permeable matrix containing phosphorescent molecules that fluoresce in response to a particular wavelength of light. By measuring the change in intensity due to the addition of the test fluid to the matrix, the oxygen concentration can be determined. This could provide a method of testing the oxygen concentrators in a developing world hospital, if we could find a reliable and inexpensive method of measuring fluorescence. 27 Non-Electronic Oxygen Concentrator Test April 21, 2008 Patent Title: Ozone Generating Device Number: 4,857,277 Date: August 15, 1989 Ozone is generated by exposing ambient air to ultraviolet (UV) radiation. The device has been designed with a series of two 90° bends to allow for airflow through the system without exposing the user to any harmful UV radiation. This patent would be useful as a method for safely creating ozone from the gas delivered by the concentrator. The added reactivity of this ozone-rich gas could then be measured to estimate the concentration of oxygen in the original sample. Patent Title: Direct Readout Dissolved Gas Number: 4,702,102 Date: October 27, 1987 This patent measures the percentage of gas dissolved in some liquid solvent. The device includes a gas-permeable tube that is sealed on one end and has a pressure sensor on the other. When the tube is immersed in the liquid, gas will either be released or absorbed as the pressure inside the tube equilibrates to the external aqueous environment. The resulting change in the pressure gage can then be used to determine the percentage of gas dissolved in the liquid. This process would be useful if we chose to bubble the gas from the concentrator through a solution before measuring its concentration. Patent Title: Colorimetric Oxygen Detection Number: 3,545,930 Date: December 1970 This patent describes a method of determining the amount of oxygen in a sample by reacting the gas with bis(cyclopentadienyl)titanium chloride, and observing a color change in response to oxygen. This method could serve as an oxygen indicator test, which could easily be read, like pH paper, by technicians in developing hospitals. Patent Title: Oxygen Monitoring Device and Method Number: 4,677,078 Date: June 30, 1987 This patent uses a manganese tertiary phosphine polymer film that experiences a change in color intensity with varying oxygen levels. It provides measurements “over an indefinite period of time and at a minimal cost.” This could potentially provide a cost efficient oxygen sensor, although the ease of obtaining the necessary film in a developing country may be a problem. 28 Non-Electronic Oxygen Concentrator Test April 21, 2008 9.1.2 Literature Search Last name of 1st author: Broenkow Title: Colorimetric Determination of Dissolved Oxygen at Low Concentrations Journal: Limnology and Oceanography Year Published: 1969 This journal article details a non-electronic, chemical means of measuring amount of dissolved oxygen. The requirement of this method is that the dissolved oxygen is at a low concentration. Our project could follow this path if we develop a means of dissolving sampled air into a liquid and determine the amount of dissolved oxygen in liquid as an indirect measure of oxygen concentration in the sample air. Last name of 1st author: Perrelet Title: The oxygen concentrator: an appropriate technology for treating hypoxaemic children in developing countries Journal: The International Journal of Tuberculosis and Lung Disease Year Published: 2004 This article details a study of oxygen concentrator use by patients and personnel in Ndioum Hospital, Senegal. The article is useful in providing insight and examples of how patients and personnel potentially handle oxygen concentrator equipment. The design of our project can take this behavior into account, particularly in terms of structurally designing our project to be user and/or patient friendly. Last name of 1st author: Eaton Title: A novel colorimetric oxygen sensor: dye redox chemistry in a thin polymer film Journal: Sensors and Actuators Year Published: 2002 The approach outlined in this article uses a redox reaction of 2,6dichloroindophenol, fructose, and base in a thin ethyl cellulose polymer film that is colorless when there is a lack of oxygen. In the presence of oxygen, color changes to a strong blue. The intensity of the color is stated to show “reasonable linearity” with increasing partial pressures of oxygen, thereby making this a potential method to implement in detecting oxygen concentration in our project. 29 Non-Electronic Oxygen Concentrator Test April 21, 2008 Last name of 1st author: Cox Title: Detection of oxygen by fluorescence quenching Journal: Applied Optics Year Published: 1985 This paper details experiments using fluorescence quenching of an aromatic hydrocarbon fluorescent compound in a silicone composite matrix. Measurement of oxygen concentration is shown to be approximately linear when correlated with fluorescence intensity. The paper provides experimental examples and reference data in the case that we decide to use a form of fluorescence quenching methodology in our project design. Last name of 1st author: Chung Title: Measurement of Dissolved Oxygen in Water using Glass-Encapsulated Myoglobin Journal: Analytical Chemistry Year Published: 1995 This paper introduces the concept of using myoglobin, a biological molecule that binds to oxygen, to measure oxygen concentration in a liquid. The absorbance of a deoxyMb-containing gel is measured and was found to change linearly with time and be directly proportional to the concentration of oxygen in the solution. Although developing world hospitals most likely do not have the equipment to measure absorbance easily, it may be possible to develop another method of achieving the same measurement. Last name of 1st author: Evans Title: A Novel Luminescence-Based Colorimetric Oxygen Sensory with a “Traffic Light” Response Journal: Journal of Fluorescence Year Published: 2006 The authors of this paper developed a dual-lumophore oxygen sensor that changes color dramatically depending on oxygen concentration (red, yellow, and green). Their approach enables the simple and quick determination of oxygen concentration in a solution. The sensor requires the use of platinum, which may be too expensive of a material for our application, but nonetheless the technology is very interesting. 30 Non-Electronic Oxygen Concentrator Test April 21, 2008 Last name of 1st author: Hitchman Title: Measurement of Dissolved Oxygen Journal: none (source is a book, 255 pp.) Year Published: 1978 This text discuss the importance of dissolved oxygen measurements, thermodynamic considerations, and the principles of many different kinds of sensing methods including chemical, electrochemical, and polarographic. There is also a detailed discussion of the Winkler method, colorimetry, radiometry, manometry, volumetry, mass spectrometry, thermoconductivity, paramagnetism, and gas chromatography. Solubility tables, convective flow and diffusion, and other useful parameters are listed as well. This resource will provide a fundamental background to the science of oxygen measurement. Last name of 1st author: McEvoy Title: Dissolved oxygen sensor based on fluorescence quenching of oxygen-sensitive ruthenium complexes immobilized in sol–gel-derived porous silica coatings Journal: The Analyst Year Published: 1996 This article describes a fluorescent quenching method similar to ones described in the papers above. However, it uses a ruthenium complex as its indicator molecule and a blue LED as its light source. A photodiode is the measurement instrument. This technique, although it uses some electronics, has applications to be a low-cost, portable tool for measuring oxygen concentration in the developing world. Last name of 1st author: Howie Title: Beyond Good Intentions: Lessons on Equipment Donation from an African Hospital Journal: World Health Organization Year Published: 2007 This article describes modes of failure of a group of oxygen concentrators donated to a Gambian hospital. It provides important insight into how the concentrators malfunction, and discusses how technicians and doctors use these devices in developing world hospitals. 31 Non-Electronic Oxygen Concentrator Test April 21, 2008 Last name of 1st author: Solanki Title: Oxygen Concentrator Malfunction Journal: The Lancet Year Published: 1990 This article is more of a case study documenting the malfunction of an oxygen concentrator being used at home by a 55 year old woman. In this case, a drink had been spilled on the device, causing it begin producing gas with oxygen concentrations below desired levels. The article calls for the need for an “analyzer” that can “warn the patient of poor oxygen concentration.” This article provides an additional example of a malfunction that might occur in the concentrators being used in developing world hospitals. Last name of 1st author: Vanderkooi Title: An Optical Method for Measurement of Dioxygen Concentration Based upon Quenching of Phosphorescence Journal: Journal of Biological Chemistry Year Published: 1987 This article describes the oxygen-dependent quenching of phosphorescence used to determine oxygen concentration. Our design may use a similar method of optical oxygen sensing technology. Last name of 1st author: Zhu Title: Effects of Oxygen Concentration on Combustion of Aluminum in Oxygen/Nitrogen Mixture Streams Journal: Combustion and Flame Year Published: 1998 In this article, the experimenters measure burning rate, temperature, and flame structure of an oxide-coated piece of aluminum placed in a stream of oxygenated air. Their finding show increases Al and AlO emissions with increasing oxygen concentration, as well as increases in the burning rate of the aluminum that were slightly dependent on the amount of oxygen present. 32 Non-Electronic Oxygen Concentrator Test April 21, 2008 9.2 Standards Analysis ISO 7767:1997: Oxygen monitors for monitoring patient breathing mixtures – Safety Requirements Table 9: Standard Analysis Name and # of Standard ISO 7767:1997 Section 6.1 - Oxygen monitors specified for use with flammable anaesthetic agents shall be classified and marked as CATEGORY APG EQUIPMENT and shall comply with the requirements of APG EQUIPMENT in IEC 601-1:1988. ISO 7767:1997 Section 7.2 - Fire Prevention In order to reduce the risk to patients, other persons or the surroundings due to fire, ignitable material, under normal and single fault conditions, shall not, at the same time, be subjected to conditions in which: - the temperature of the material is raised to its minimum ignition temperature, and - an oxidant is present. Why/how we will meet/not meet standard N/A ISO 7767:1997 Section 7.2 - Annex In considering the ignitable material, particular attention should be paid to materials which may accumulate during prolonged use, e.g. airborne particles of paper or cotton. We will test to this standard by collecting potential waste material (e.g. used/burnt match sticks) and attempting to ignite the waste with a match flame to quantify the danger of such waste material. ISO 7767:1997 Section 8.2 – Protection against hazardous output subsection 51.5 – The difference between the mean oxygen reading and the oxygen level shall be within ± 3% (V/V) over the range 15, 21, 40, 60, and 100% Oxygen (V/V) (Balance nitrogen). We will test for ± 20% accuracy instead of ± 3%. We will use a modification of the suggestion stated in the standard: ISO 7767:1997 Section 8.2 - Annex A simple, effective calibration method would be a) place the sensing area in 100% (V/V) oxygen; b) adjust the calibration control so that the oxygen reading is 100% (V/V) oxygen; c) place the sensing area in room air and verify that the oxygen reading is 21% ± 3% (V/V) oxygen. [change ± 3% to ± 20%!] We will NOT meet this standard because the basis of our flame combustion rate test depends on igniting a match using oxygen as the oxidant. 33 Non-Electronic Oxygen Concentrator Test April 21, 2008 ISO 7767:1997 Section 11.3 - Gas leakage and sampling loss ISO 7767:1997 Section 11.3.1 - Requirement: the rate of leakage of a non-diverting oxygen monitor shall not be greater than 20ml/min. We plan to meet this standard. See 11.3.1.1 and 11.3.1.2 of ISO 7767:1997 for testing apparatus and procedure ISO 7767:1997 Section 11.4 - Connections If an oxygen sensor is intended to be connected to the breathing system through a T-piece, the breathing system connection ports of the T-piece shall be 15mm and/or 22mm conical connectors in accordance with ISO-5356-1 or ISO 5356-2. We plan to meet this standard. If we use a Tpiece, we will measure the diameters of our connectors to match the values listed in the standard. 34 Non-Electronic Oxygen Concentrator Test April 21, 2008 9.3 Regulatory Analysis 9.3.1 Device Classification: Classification of this device was made using the classification system developed by the Global Harmonization Taskforce. The device fit the necessary criteria of a Class A device. Table 10: Device Classification Rule # Response Conclusions 1 The device is non-invasive, and does not touch the skin. Rules 2, 3, and 4 do not apply. Class A 2 The device is not intended for channeling or storing fluids or gases. Does not apply 3 It is not intended for modifying biological or chemical composition of fluids before infusion. It does not filter, centrifuge, or exchange gas/heat. Does not apply 4 It does not come into contact with injured skin, nor does it act as a mechanical barrier. Does not apply 5 It is non-invasive Does not apply 6 It is not involved in surgical procedures. Does not apply 7 It is non-invasive and non-surgical in nature. Does not apply 8 It is not implantable and not used for surgery. Does not apply 9 It is not utilized directly in patient care and therapy. It does not administer or exchange energy with the patient. Does not apply 10 It does not supply energy to be absorbed by patient. It will not be used in vivo, will not measure vital signs. Does not apply 11 Does not administer or remove substances from the body Does not apply 35 Non-Electronic Oxygen Concentrator Test April 21, 2008 12 Rules 9, 10, 11 do not apply Class A 13 It does not use ancillary medicinal products. Does not apply 14 It does not incorporate animal cells or tissue. Does not apply 15 Will not be utilized for sterilization of other deices. Does not apply 16 It is not intended for use as a contraceptive. Does not apply 9.3.2 Regulatory Pathways: The regulatory pathways set forth by the Global Harmonization Taskforce (GHTF) are necessary to ensure protection of public health and safety when using this oxygen concentration test, as well as consumer trust in the product. The GHTF regulatory pathway begins with documentation to verify that the device conforms to the Essential Principles of Safety and Performance for Medial Devices, SG1/N041:2005. The maintaining of a quality management system will be unnecessary, since our manufacturing will be limited initially to 3 individual devices. Thus, manufacturing practices need not be verified. Post-market surveillance is also not needed, since this is beyond the scope of the class. Documentation of adherence to SG1/N041 is contained in the Summary Technical Documentation for Demonstrating Conformity to the Essential Principles of Safety and Performance of Medical Devices (STED). This document is reviewed by the Regulatory Authority (RA) to determine proper compliance. Technical documents may be collected in a Declaration of Conformity, used to ensure compliance with other GHTF regulations. Following this technical documentation, the oxygen test must be registered by the RA before it is able to enter the market. A summary of these steps is shown below in Table 11. Table 11: GHTH Regulatory Pathway for Class “A” Device # Topic Comments 1 Quality Management System Not applicable 2 Post-Market Surveillance Will not be possible. Technical Documentation Prepare STED if requested 36 Non-Electronic Oxygen Concentrator Test April 21, 2008 3 Declaration of Conformity Prepare if requested 4 Registration Provide Regulatory Authority with needed registration information Final completion of meeting regulatory requirements will likely take several months. In addition, registration could also take up to a month to complete. We estimate a period of 4-6 months to complete the regulatory pathway. 9.3.3 FDA Regulations: This oxygen concentration test constitutes an unapproved medical device. The export of such devices outside the United States is governed by Chapter VIII of the Federal Food, Drug, and Cosmetic Act (FD&C Act), primarily in sections 801 and 802. This Act was modified in 1996 by the Public Law 104-134, the Food and Drug Export Reform and Enhancement Act (FDERA), which modified sections 801 and 802 of the original document. The device will be exported under section 801(e)(1) of the FD&C Act, which allows for the export of adulterated medical devices without FDA approval. As a class I medical device, 801 should be sufficient, and section 802 need not be considered. Currently, there are not many other similar oxygen concentration tests, and thus 510(k) marketing clearance may need to be obtained before export. Further research may result in the discovery of a similar concentration test, which would allow for export without marketing clearance. Table 12: FDA Regulatory Pathway for Export of Device # Topic Comments 1 801(e)(1) Requirements Keep documentation showing that device meets requirements to obtain Certificate of Exportability 2 501(k) Clearance No documentation needed if equivalent, FDA-approved devices are found. 3 Section 802 Requirements Not necessary. 4 Foreign Law Ensure device abides by laws of importing country, and that device meets foreign specifications. 5 Export Export Device to Foreign Country 37 Non-Electronic Oxygen Concentrator Test April 21, 2008 Device I classification was determined using the DHHS General Device Classification Questionnaire. The device is not life-sustaining or life-supporting It is not used in preventing the impairment of human health It does not present unreasonable risk of injury to the user Further testing will be needed to support safety estimations. Specifically, the risk of combustion due to the close proximity of flame and compressed oxygen will be explored. 38 Non-Electronic Oxygen Concentrator Test April 21, 2008 9.4 Specifications Design Goals 1. Reliability 2. Ease of Maintenance 3. Ease of Operation Design Feature O2 Concentration Specification ±20% Test Results ±5.08% Status Pass Cost < $100 $17.66 Pass Ease of Use Able to be used by a standard medical technician within 15 minutes of reading instructions Pass Instructions Printed in pictograms Pass Maintenance Able to be maintained by standard medical technician using in-house tools. Only required maintenance: cleaning beaker Pass Reliability < 1% readings more than 20% from actual gas concentration 0% Pass Assembly On site in developing world hospital Only Required Assembly: Cover beaker with foil Pass Speed of Operation Reading obtained in < 20 minutes ~ 10 minutes Pass Electronics None None Pass Dimensions Device should be portable from room to room in a hospital Weight < 20 lbs Pass 2 lbs Pass 39 Non-Electronic Oxygen Concentrator Test April 21, 2008 9.5 Experimental Data & Look-Up Table (See uploaded PDF’s) 40 Non-Electronic Oxygen Concentrator Test April 21, 2008 9.6 Parts List, Instructions, and Pictograms 9.6.1 Parts Part 250 ml beaker Adhesive putty Paper matches (3.3 cm each) Aluminum foil Vinyl electrical tape Stopwatch Ruler Manufacturer Pyrex Office Depot Diamond Reynolds Wrap Tartan Sportline Wescott Item number Product #1000-250 49656 Model 220 Price $4.50 $2 for 2oz. $1.44 for 1500 matches $0.09 for 0.33 m2 $0.95 for 1 roll $12.99 $0.49 250 ml beaker We chose to use a 250 ml beaker because it provided enough volume of oxygen so that the flame could burn long enough to calculate combustion rate. Having a known volume of 250 ml allowed us to standardize the volume of gas tested. The beaker is also made of glass that withstands the flame’s heat while simultaneously allowing visual observation of the flame. Adhesive Putty 41 Non-Electronic Oxygen Concentrator Test April 21, 2008 Adhesive putty is utilized to hold the match steady and vertical during the experiment. Furthermore, putty is flame-resistant and waterproof, two important properties that made it ideal for our experimental procedure. Diamond brand paper matches We decided to use paper matches because when covered by a beaker infused with 100% oxygen, they burned slowly and consistently enough to record burn time. These matches also had consistent length (3.3 cm), allowing for experimental standardization. Aluminum foil A piece of aluminum foil with a small hole in the center was used to cover the mouth of the beaker so that a minimal amount of gas was lost when transferred from the bucket of water to the match. Foil was a good material for this purpose because of its low cost, high availability, and flame-resistant properties. 42 Non-Electronic Oxygen Concentrator Test April 21, 2008 Vinyl Electrical Tape Electrical tape was used to seal the edges of the aluminum foil onto the mouth of the beaker. However, any heavy-duty tape may be substituted for this purpose (duct tape, packing tape). Stopwatch A typical stopwatch was used to measure the time (in seconds) for the flame to burn along the match. In practice, any digital watch or analog watch with a timer may be used. Bucket A typical plastic bucket was used to contain the water used to submerge the beaker. The bucket had a width and depth sufficient to completely submerge the beaker 43 Non-Electronic Oxygen Concentrator Test April 21, 2008 while allowing enough room for handling and to bubble oxygen from a tube through the mouth of the beaker. Ruler A common metric ruler was used to measure the burn distance along the matchstick. 9.6.2 Building Instructions To prepare the beaker, cover the mouth of the beaker completely with a piece of aluminum foil. Roll down or trim the edges of the aluminum foil so that there is enough visibility into the beaker (this is important in order to be able to view the match as it is burning within the beaker). Secure the aluminum foil to the mouth of the beaker by wrapping electrical tape around the edges of the aluminum foil. Cut a hole in the center of the aluminum foil with a diameter large enough to surround a dime-sized mound of sticky-tack (this is the hole where the match and sticky-tack will fit through). 9.6.3 Directions for Use Our device measures oxygen concentration by determining the burn rate of a match when exposed to gas from a concentrator. Procedure for using the device is as follows: 1. Place a dime-sized amount of adhesive putty in a mound on the table. 2. Cover the mouth of a 250 ml beaker with foil. Tape around the edges of the foil to keep it secure. Poke a small hole in the center of the foil. The hole should be able to fit over the match and mound of putty. 3. Stick a paper match 2 mm into the putty so that it is standing upright. Submerge a 250 ml beaker under water. The beaker should be filled as full of water as possible, avoid leaving any air bubbles inside—tap against the side of the bucket and swirl underwater to remove air bubbles. Invert the beaker, and then fill the entire beaker with gas from the oxygen concentrator. 44 Non-Electronic Oxygen Concentrator Test April 21, 2008 4. Carefully remove the beaker from the water after sliding a piece of aluminum foil over the hole in the mouth of the beaker to keep most of the gas from leaking out. 5. Bring the beaker over near the match while maintaining the foil seal. 6. Have a 2nd person light the match. 7. After the initial flare up from the sulfur on the match head, quickly place the beaker over the top of the match. Slide the beaker directly from the foil to the flame with as little vertical movement as possible (vertical movement causes gas to leak out of the beaker). 8. The 2nd person begins timing immediately once the beaker has been set down. Stop the timer when the flame reaches the bottom of the match or when the flame stops its progress moving down the match. Important note: timing must be stopped when forward progress stops, not when the flame extinguishes itself. 9. Measure and record the distance burned and time to burn along the match. 10. Repeat steps 3-9 for 5 trials. Calculate the average distance burned and average burn time for the 5 trials. Look up where these two values intersect on the supplied table to find the approximate oxygen concentration. 9.6.4 Pictogram Instructions (See uploaded PDF) 45