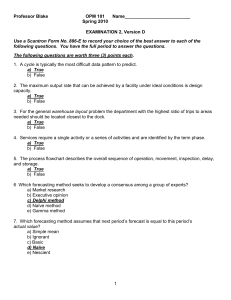

EXAMINATION 1, Version A

advertisement

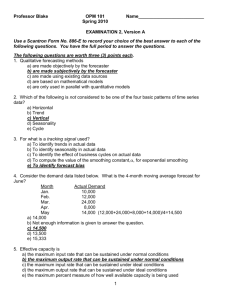

Professor Blake OPM 101 Name__________________________ Spring 2009 EXAMINATION 2, Version A Use a Scantron Form No. 886-E to record your choice of the best answer to each of the following questions. You have the full period to answer the questions. The following questions are worth three (3) points each. 1. JIT considers waste anything that a) Fits in a waste basket b) Reduces production capacity c) Has been discarded d) Cannot be recycled e) Does not add value 2. Which of the following is characteristic of the JIT philosophy? a) Inventories are an asset b) Lot sizes are optimized by formula c) Tolerate some scrap d) Elimination of waste e) Rigidity 3. Three basic elements work together to complete a JIT system: just-in-time manufacturing, total quality management, and a) Quality circles b) Pull production c) Minimizing inventory d) Respect for people e) Full utilization of capacity 4. Which is typically the most difficult data pattern to predict? a) Horizontal b) Trend c) Level d) Seasonality e) Cycle 5. What is the mean absolute deviation of the following forecasts? Month Actual Sales Forecast Abs. Deviation Jan. 614 600 14 Feb. 480 480 0 Mar. 500 550 50 Apr. 500 600 100 a) 3174 164 b) 164 c) 41 MAD: 164÷4=41 d) 136 e) -34 6. The maximum output rate that can be achieved by a facility under ideal conditions is _________________. a) utilization b) design capacity c) effective capacity d) ultimate capacity e) temporary capacity 1 Professor Blake OPM 101 Name__________________________ Spring 2009 7. Long-term capacity requirements are identified on the basis of ________________________________. a) the current trend of the economy b) the expected lifetime of the facility c) demographic factors d) forecasts of future demand e) future political events 8. Service organizations such as restaurants, movie theaters, and banks focus on locating near ____________. a) suppliers b) roads c) intersections d) their customers e) potential workers 9. The load-distance model frequently utilizes points using only north-south and east-west movements. a) curvilinear b) Euclidean c) rectilinear d) direct e) vertical distance, which is the shortest distance between two 10. A job shop is most likely to use which layout type? a) inverted b) hybrid c) process d) fixed position e) product 11. Building construction is an example of which layout type? a) inverted b) hybrid c) process d) fixed position e) product 12. What is the term for the number of units we wish to produce over a specific period of time? a) job flow b) output rate c) cycle time d) output flow e) flow time 13. What is the longest task in a process called? a) obstruction b) bottleneck c) blockade d) hindrance e) constrainer 14. What occurs when a customer decides not to enter the waiting line? a) balking b) walking c) reneging d) vacillating e) jockeying 2 Professor Blake OPM 101 Name__________________________ Spring 2009 15. Customers generally consider which of the following priority rules to be the fairest? a) quickest service requirements first b) longest service requirements first c) first-come, first-served d) best customers first e) highest profit customer first 16. What is the approach to job design which involves an increase in responsibility for work planning and/or inspection? a) job enlargement b) job rotation c) job enrichment d) job involvement e) job enhancement 17. The time is the time it should take a qualified operator, working at a sustainable pace and using the appropriate tools and process, to do the job. a) performance b) observed c) normal d) standard e) ideal 18. When performing a time study, the analyst converts the observed time into the time an "average" worker would require working at an acceptable pace by using which of the following? a) allowance factor b) mean time modulation c) methods analysis d) performance rating factor e) analysis of efficiency 19. By focusing on value-added processes, JIT is able to achieve high-volume production of high-quality, low-cost products. a) True b) False 20. Forecasts are more accurate for individual items than for groups or families of items. a) True b) False 21. Capacity planning is complicated by the fact that capacity is usually purchased in chunks, rather than smooth increments. a) True b) False 22. In product layouts, the material moves continuously and uniformly through a series of workstations until the product is completed. a) True b) False 23. A single-line service system eliminates jockeying behavior. a) True b) False 24. In a time study, personal time, fatigue, and unavoidable delays (PFD) during the typical work day are accounted for in the allowance factor. a) True b) False 3 Professor Blake OPM 101 Name__________________________ Spring 2009 The following problems are worth ten (10) points each. 1. Hoops, Inc. produces videos on the art of shooting in basketball. The firm has experienced the following demand for the most recent four months. Month Mar. Apr. May June July Demand 10,000 2,000 20,000 30,000 Forecast 8,000 8,800 6,080 11,648 18,988.8, ~18,989 Ft+1 = At + (1-α)Ft FAPR=.4*10,000+.6*8,000=8,800 FMAY=.4*2,000+.6*8,800=6,080 FJUN=.4*20,000+.6*6,080=11,648 FJUL=.4*30,000+.6*11,648=18,988.8 Prepare an exponential smoothing forecast for July, using an value of .40. Initiate the process by assuming that the forecast for March is 8,000 units. 18,988.8 or 18,989 2. Aamedco plans to open a new medical center and is looking for a suitable location. They have narrowed their choice down to three locations, on Oak, Elm, and Ash Streets. They have defined four factors and have assigned weights to these factors as follows: proximity to hospitals (40), customer parking (30), appearance (20), and ease of expansion (10). They then rated the three locations for the four factors, using a scale of one to five. Their ratings are as follows: Oak Location Score Elm Score Ash Score Weight 40 2 80 5 200 3 120 30 5 150 1 30 3 90 20 4 80 2 40 5 100 10 3 30 4 40 1 10 100 340 310 320 (a) Calculate the scores for each location. OAK: 340, ELM: 310, ASH: 320 (b) According to the model which location should they choose? Choose OAK as it has the highest score Factor Proximity to hospitals Customer parking Appearance Ease of expansion 3. The reference desk of a university library receives requests for assistance. Assume that a Poisson probability distribution with a mean rate of 10 requests per hour can be used to describe the arrival pattern and that service times follow the exponential probability distribution, with a mean service rate of 12 requests per hour. λ = 10 requests/hour μ = 12 requests per hour ρ = λ / μ = 10/12 = .833 a) What is the average number of requests that will be waiting for service? LQ = ρ*L L = λ/ μ- λ = 10/12-10 =5 requests LQ = .833 * 5 = 4.17 requests b) What is the average waiting time in minutes before service begins? WQ = ρ*W W = 1/ μ- λ = 1/12-20 = .5 hours or 30 minutes WQ = .833 * .5 = .42 hours or 25 minutes c) What is the average time at the reference desk in minutes (waiting time plus service time)? W = 1/ μ- λ = 1/12-10 = .5 hours or 30 minutes d) Suppose that a “super” librarian can be hired who can handle 16 requests per hour. Now what is the average waiting time in minutes before service begins? λ = 10 requests/hour μ = 16 requests per hour ρ = λ / μ = 10/16 = .625 W = 1/ μ- λ = 1/16-10 = .1666 hours or 10 minutes WQ = ρ*W WQ = .625 * .1666 = .10417 hours or 6.25 minutes 4 Professor Blake OPM 101 Name__________________________ Spring 2009 Formulas--Examination 2 Chapter 7: JIT Kanbans: N DT S N—no. of kanbans, D—demand rate, T—lead time, S—safety stock, C—container size C Chapter 8: Forecasting Naïve: Ft+1 = At At [n – number of periods to be used] n Weighted moving average: Ft 1 C t A t [Ct – weight for period t] Exponential smoothing: Ft 1 αA t 1 αFt or Ft 1 Ft αA t Ft Moving average: Ft 1 Linear regression: Y = a + bx Forecast error: At – Ft MSE b XY n X Y X 2 nX a Y bX 2 (actual forecast)2 n MAD actual forecast n actual forecast Tracking_signal MAD Note: Ft is the forecast and At is the actual in period t Chapter 9: Capacity Planning and Facility Location Utilizationef f ective actual_out put 100% effective_ capacity Utilizationdesign actual_out put 100% ld design_cap acity Chapter 10: Facility Layout available_ time ; C cycle_time output available_ time Output output available_ time Maximum_ou tput minimum_cy cle_time_( bottleneck ) C TM t ; TM theoretica l_min.# workstatio ns; t total_task _time C Efficiency (%) t (100); N number_wor kstations NC Balance_de lay(%) 100% - efficiency Supplement D: Waiting Lines λ ; average_system_utilization μ λ L ; average_# customers_in_system μλ L Q ρL;average_# customers_waiting_in_line ρ W WQ 1 ; average_time_in_system μλ ρW; average_time_in_line Pn (1 ρ)ρn ; probability_n_customers_in_system 5 l d ij ij X c.g. l x l i i i Yc.g. l y l i i i