The Oink Report - Rensselaer Swine Services, PC

Rensselaer Swine Services, P.C.

The Oink Report

210 East Wood Road, Rensselaer, IN 47978

Phone: 219-866-6465 Fax: 219-866-3431 Toll free #: 877-866-7675 www.rssvet.com

Tom Gillespie, DVM, Diplomate, ABVP E-mail: tom.gillespie@rssvet.com

Amy Carroll, DVM E-mail: amy.carroll@rssvet.com

Staff: Melanie, Paula, Denise and Jodi

Volume 36 August, 2005

Introducing Draxxin – A New

Swine Antibiotic!

Although available in

Europe for a year, Pfizer Animal

Health has just launched Draxxin in the United States in August.

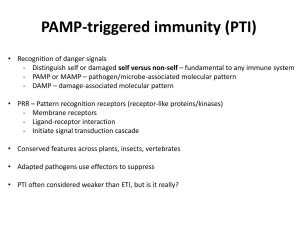

Draxxin is tulathromycin, a member of the new triamilide class of antibiotics. Draxxin is positioned to be a top-notch drug for treating complex swine respiratory disease. It is labeled for treatment of APP, Pasteurella multocida , Bordetella and HPS. Although not currently labeled for

Mycoplasma treatment in the US, studies have also shown very good efficacy against hefty Mycoplasma challenges.

Draxxin is a single-dose treatment with a lowvolume dosage. It is administered IM at a dose of 1 cc/88 lbs and has a 5 day slaughter withdraw. This drug preferentially distributes quickly to lung tissue and remains there at high concentrations for several days, as seen in the following graph. Therefore, pigs do not need to be re-treated with Draxxin as is the case with all other antibiotics (excluding Excede).

Another unique feature of Draxxin is that this drug accumulates in the body’s immune cells. The immune cells travel to the site of active bacterial infections, therefore taking the “drug to the bug.” With the higher drug concentration at the site of infection, the bacteria are killed more effectively. This tissue targeting hypothesis is depicted below.

Bacteria

Immune cells

Draxxin

(tulathromycin)

1.

Immune cells accumulate tulathromycin, migrate to infection sites and release drug via normal transport processes.

2.

Many Gram-negative pathogens secrete cytolysins or leukotoxins.

3.

Cytolysins can lyse tulathromycin-loaded immune cells, thus enhancing drug release.

4.

High local tulathromycin concentrations are delivered to the vicinity of target bacteria within the infection site.

We are very excited about the release of this new drug and are eager to try it. Please contact us for further information.

Cytolysins and leukotoxins

2005 Midwest Pork

Conference

Just a reminder that the 2005 annual Midwest Pork Conference is coming up on August 31 at the

Sheraton Hotel at Keystone at the Crossing in

Indianapolis. Registration is only $49.95 for the first person and $25 for each additional person from the same farm or company. There will be talks focusing on health issues, marketing & economics and legal/regulatory issues. Dr. Tom will be a featured speaker discussing PRRS control. Check out the full agenda and register on-line at www.midwestpork.com

.

Another meeting reminder – our annual client appreciation meeting will be September 13, starting at

3:30 at the Jasper County Fairgrounds in Rensselaer.

We have many educational speakers lined up for the afternoon and a pork loin dinner at 6:00, with entertainment to follow. Please bring your staff and families and come join us for this meeting! The following is a list of the speakers for the afternoon – you can definitely find a topic to interest you!

Dr. Allan Schinckel, Purdue University –

Getting the most for your money from Paylean and minimizing finisher variation.

Dr. Teddi Wolff, Alpharma Animal Health –

Impacts of Aureomycin usage in PRRS and

Mycoplasma breaks.

Dr. Mike Kuhn, Pfizer Animal Health–

Introduction of Draxxin, a new swine antibiotic.

Dr. Brad Lawrence, Boehringer Ingelheim –

Fine-tuning performance near weaning

Dr. Amy Carroll, Rensselaer Swine Services –

Ventilation basics – how do your pigs feel?

Judy Loven, Purdue University – Practical rodent control for swine barns

Dr. Brad Thacker, Intervet – Managing breeding flows – how to fit in the holdover sows.

Paul Groenewegan, Alltech – Using chelated

minerals in swine rations

Dr. Greg Stevenson, Purdue University –

Update on the PMWS situation within the swine industry.

Dr. Annamaria Castiglia-Zanello, Dupont –

Practical on-farm disinfectant solutions.

Research Update on Trailer Disinfection

With the ever-increasing importance of biosecurity in the swine industry, there has been much research focused on effective decontamination of transport equipment recently. In studies conducted by

Dr. Scott Dee at the University of Minnesota, it has been determined that under normal drying conditions,

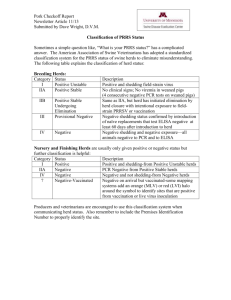

Synergize, Virkon S and BioSentry 904 have excellent efficacy against PRRS virus. Disinfection with

Synergize resulted in no positive PRRS PCR results after 60 minutes, while the same results were obtained with Virkon S and BioSentry 904 after 90 minutes. It is very important to remember to provide adequate contact time (at least 2 hours), regardless of which disinfectant you are using.

However, the situation changes considerably when freezing conditions are present. Many pathogens, particularly viruses, are stable for long periods of time at low temperatures. For example, PRRS virus is infective for a week at 39 o F, but it is stable for months at -4 o F. In addition to the enhanced viability of viruses at low temperatures, the efficacy of disinfectants decreases with lower temperatures. When washing trailers or load-outs outdoors in the winter, the residual wash water and disinfectants will freeze, resulting in inadequate decontamination. The importance of drying has long been established, but this is very difficult to accomplish in the winter in the Midwest. However, there has been some very interesting research conducted lately that examines this issue and how we can overcome it.

One option that has been presented and is working quite well is the use of the thermo-assisted drying and decontamination (TADD) system. In this system, trailers are washed and disinfected, then the interior of the trailer is heated to 160 o F and maintained at that temperature for 30 minutes. An infrared thermometer can be used to determine the temperature on the inside of the trailer. Previous research has that PRRS virus cannot survive more than 6-20 minutes at 132 o F. This is the justification for the TADD system protocol of 160 o F for 30 minutes, ensuring adequate killing of any

PRRS virus. This system requires the use of a large heater to heat the inside of the trailer.

Another option that Dr. Scott Dee has worked on is to prevent the disinfectant from freezing after being applied. From studies on various disinfectants at temperatures of approximately 40 o F, it was determined

that Synergize was the most reliable disinfectant for cold weather. Other disinfectants used in this study included

DC&R, Tektrol, Sentramax,

Biophene, Virkon S and Aseptol 2000. At 60 minutes post treatment, Synergize was the only tested disinfectant that yielded no PRRS positive PCR tests from all 12 replicates of the trial. After determining the Synergize was the most efficacious cold-weather disinfectant, Dr. Dee evaluated the efficacy of

Synergize under freezing conditions. For this part of the study, he mixed the

Synergize with either water

(normal situation), a 10% propylene glycol solution or a

40% methanol solution. The propylene glycol and the methanol were added to prevent freezing. All solutions were applied via fumigation and the small model trailers were stored overnight in a -4 o F freezer. The addition of propylene glycol or methanol prevented visible freezing, but the other treatments were frozen within one hour. After the trailers were thawed the next day, they were swabbed and tested for

PRRS virus by PCR and also by the use of sentinel pigs placed in the trailers. There were no positive PRRS PCR swabs, nor any positive sentinel pigs from the trailers treated with Synergize plus propylene glycol or Synergize plus methanol. In the trailers treated with

Synergize mixed with water, positive PRRS PCR results were obtained on 4 out of the 20 replicates and

1 of 4 sentinel pigs became infected with PRRS. These results are summarized in the table below.

20

18

16

14

12

10

8

6

4

2

0

Drying Wash only Synergize

+ 40% methanol

Synergize

+ 10& propylene glycol

# PRC + / 20 # + sentinels / 4

Synergize

+ water

This study clearly demonstrates the importance of adequate disinfectant application, particularly during the winter when we routinely face freezing conditions.

This information can be put to practical use on your farm for all trailers, load-outs, pig carts, etc. that cannot be brought inside to be thoroughly disinfected and dried. We can help you develop a protocol for using the propylene glycol or methanol if you are interested.

Take Care – Use Antibiotics Responsibly

Many of you are likely already aware of the

National Pork Board’s new program to encourage producers to follow specific principles and guidelines to minimize the risk of antibiotic resistance. This is the

Take Care – Use Antibiotics Responsibly program.

The swine industry must show proactive commitment on our part in seriously addressing the issue of antibiotic resistance. The principles of the Take Care program are:

Take appropriate steps to decrease the need for the application of antibiotics.

Assess the advantages and disadvantages of all uses of antibiotics.

Use antibiotics only when they provide measurable benefits.

Complete the PQA program and fully implement the management practices described for responsible use of animal health products into daily operations.

Follow the Take Care Responsible Use

Guidelines.

As we continue to face increasing pressure regarding antibiotic use in agriculture, it is essential to demonstrate that pork producers are doing their part to use antibiotics responsibly. The NPB is asking producers to endorse this program on their farms. Currently, producers supplying over 40% of the pigs marketed in the US have signed endorsements. For more information on this program, follow the Take Care link at www.porkboard.org

or contact one of our veterinarians. We also have endorsement forms available to get your farm signed up as endorsing the

Take Care program.

Intervet Product Availability

Those of you that routinely use

ProSystem RCE know that it has been backordered for quite some time. This product is now available. Please let us know if you need to order some.

On another note, PG-600 is now on backorder and may remain on backorder until November. We have a limited allotment for some or our regular clients. Just continue to check with us on availability this fall. In the mean time, please use this product judiciously until we are able to meet your full needs for

PG-600. We realize that this is a major inconvenience for you, especially at this time of year and we are sorry about the situation.