Transient pressure in long wellbores

advertisement

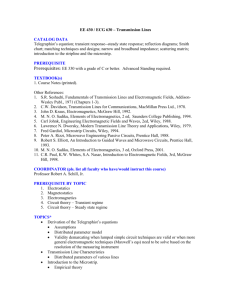

Transient pressure in long wellbores Pål Skalle Department of Petroleum Engineering and Applied Geophysics, NTNU, Trondheim, Norway pal.skalle@ntnu.no Tommy Toverud Department of Petroleum Engineering and Applied Geophysics, NTNU, Trondheim, Norway ttoveru@hotmail.com Abstract Drilling of long oil wells introduces a “new” challenge; after pump start the generated pump pressure, i.e. the hydraulic fiction resistance in the circulation system, needs a transient period of several minutes before it reaches the steady state pressure. A theoretical model to estimate the transient pressure was developed, on basis of classical water hammer theory (pressureincrease due to sudden valve closure in a flowing pipe line). The model was compared with observed transient periods in long wellbores, and the model and fitted well with observations. This knowledge is important when analyzing pressure testing and other sudden pressure change-situations. The transient pressure behavior masks the true pressure during the transient period. 1. Introduction To drill oil wells longer than 5 km are becoming more common now a day, being drilled from fixed platforms at a central location in a geological basin. A new problem accompanying long wells is the long transient time necessary for the pump pressure or stand pipe pressure (SPP) to reach its steady state level after a change in flow rate has occurred. During the transient time period the wellbore pressure is therefore unknown. A common approach to this problem by the operator has been to wait until steady state has been reached before resuming to the ongoing operation. Transient behavior has so far not been an important problem in drilling operations. In relatively short wellbores (< 3000 mMD), the transient period is negligible, and therefore not a practical problem. In long wells the accumulative transient time may become substantial. Each change in mud pump flow rate represents a transient situation. Frictional pressure arise with arising flow rate, resulting in pressure increments or pressure pulses being transmitted both downstream and upstream. The upstream pulse is resulting from friction pressure gradually being built up by increasing hydraulic friction further down the line. Frictional pressure reflected from positions far away from the flow inlet, like from bit nozzles and from the annulus, is dissipating and distorted. It takes time for it to restore to its true, steady state level. Transient behavior in long wells will mask the true characteristics of a wide range of pressure events. Such events are wellbore kicks, breathing events, pressure testing, down linking of pressure signals and downhole wellbore restrictions (pack off). Wellbore restrictions tend to increase in frequency when the well changes from short, vertical to long, inclined path. A pack off will lead to pressure build-up below the point of restriction. Due to transient behavior such an event is not seen sufficiently early at the surface. In the meantime, before it is detected, it may build up to an extent that leads to fractures in the uncased formation below. Rigs equipped with downhole pressure transducers are better off, since only part of the transient behavior is taking place in the annulus. But even with downhole recorders installed we need to understand the physics of transient pressure in order to interpret and counteract correctly. 2. Pressure behavior in long wells Information on pressure transients in long wellbore was scarce. Pressure transient behavior is in most SPE publications related to pressure behavior in the reservoir, described by the diffusivity equation. None of the publications have taken the length of the wellbore itself into consideration, although Rbearvi & Tiab [1] indicate that the length of the horizontal wells have effect on the pressure response during pressure drawdown tests. One interesting and successful application of waterhammer involves overcoming mechanical friction during coiled tubing drill CTD in horizontal wells. Mechanical friction increases with length of wellbore. Castaneda, Schneider and Brunskill [2] describes a tool positioned in the bottom hole assembly (BHA), which, when a valve is suddenly closed, creates an additional pressure pulse, its magnitude depending on the fluid flow rate and valveclosing time. A well-known classical water hammer problem is taking place while shutting-in the well in on a kick (Jardine et. al. [3]). They showed that so-called hard shut-in (meaning no extra built-in delay) results in negligible additional pressure below the BOP. This is explained by the long time typically spent on closing the annular preventer followed by closing the choke. Figure 2: Observed transient period after pump start vs. measured depth in the 9.5 “wellbore section. The data point at 7 000 mMD (4 min. transient time) represents the data set where the model was initially tested. The aforesaid pressure transient was studied in the 9.5 inch well section. Figure 1 presents a typical example of a transient behavior after turning the pump on and up in order to resume the drilling operation. Mu d pum SPP p SPP Mud pit Drill pipe 10:00 10:10 10:20 Annulus geometry MFI In this paper we will model two typical pump boundary conditions; a) turning pump on and b) increasing pump rate from an initial constant value. We have recorded transient pressure behavior as a function of wellbore length. The data are presented in Figure 2. Only the last part of the transient period is included, the one occurring after the constant pump rate has been reached, as indicated by the vertical line on the time scale in Figure 1. At two selected depths the model input geometry and rheology have been collected and presented in Figure 3. These data will later be used as input to the model. unit data Wellbore geometry: Drill string length Bit size m in 7 000 9½ More details in Appendix HWDP Figure 1: Surface pressure response (SPP, in green) in a 7000 mMD long well after turning on pump mud flow (MFI, in red) at 10:11. At 10:12:45 it is ramped up to 1750 lpm over a period of 44 seconds. After steady pump rate is reached (at 10:13:30), marked by vertical bar) it takes 4 minutes until a steady state pressure is reached (at 10:17:30). At 10:18:00 an RPM-increase leads to an additionally SPP increase (Statoil [4]). Data type Bit nozzles Drilling fluid parameters: n (flow index) K MW Pas-n kg/l 0.51 2.44 1.48 Steady state perational paramters: Pump flow rate Pump pressure Transient time l/min bar min 1 750 177 4.0 DC Figure 3: Principle drawing of a wellbore (left). Specific wellbore data includes specification of geometry, drilling fluid and some operational data. 3. The model Transient flow is often used synonymously with waterhammer, although the latter term is customarily restricted to water. Solving the equation of motion (momentum) and of continuity leads to equation of pulse wave propagation, caused by disturbances of the steady state flow. Steady flow is a special case of unsteady flow, which the unsteady flow must satisfy. 3.1. Introducing the model A simplified flow system is first used to introduce the transient behavior. The unsteady momentum equation is applied to a control volume of a pipe section as shown in Figure 4, where the hydraulic friction in the pipe is simulated by means of a valve. A positive displacement pump is equipped with pulsation dampeners. While running at constant rate it delivers a constant flow velocity v0, independent of pressure. When the flow velocity is changed by v, the change in flow velocity is spreading downstream at the speed of a pressure pulse, a. (a - v0)t pulse rA(v0 + v)2 v0+v -a rA(a-v0)V + rAgH v0 rAv02 Figure 4: Restricting the flow in the pipe by hydraulic friction, illustrated as a valve, results in change of momentum in the control volume (free after Wylie and Streeter [5]). The velocity change v is accompanied by an additional hydraulic friction, expressed as a head change H, which results in a momentum change of rgH. The impulse of the higher pressure travels upstream at the wave speed of a, but at an absolute speed of a-v0-v. This is a reversed sequence of what is taking place in a classical water hammer problem in which the valve closure results in increased head, H, accompanied by a velocity change v. However, the drill string model and the transient effects will be identical. Applying the momentum equation to the control volume in Figure 4, results in equation (1), after neglecting second order terms of v2 and v0. H = - a v/g (1 + v0/a) ≈ - a v/g (1) By assuming the friction valve was really a valve, a full closure of the friction valve would result in v = - v0, and H would become: H = a v0/g. Latter assumption demonstrates the classical water hammer phenomenon. During upstart of the pump and increasing the flow rate linearly by equal increments of v the relationship between all velocity changes and the resulting head change becomes: a / g v H pump H friction H DP H Bit H Ann (3) The pulse H represents the energy related to the hydraulic friction in the control volume. As soon as the control volume is compressed the next one in the upstream direction will be compressed, travelling back towards the source, compressing the fluid, and stretching the wall a little. When the wave reaches the upstream end, all the upstream fluid is under the extra head, all its momentum has been transformed to elastic energy from kinetic energy, represented by v. The stored compressed and elastic energy will send out a reflection at the pipe end, if not absorbed at the discharge source. SPP v0 + v H H (2) 3.2. Transient flow for viscous fluids The method of analysis of transient flow starts with the basic equations of motion, of continuity, state, and other relationships of the physics involved. The selection of restrictive assumptions dictates the overall approach. We have selected to employ the so called characteristics method as presented by Wylie and Streeter [5] The method converts the two differential equations of motion and the continuity equation into four total partial differential equations, which are integrated to be expressed in terms of finite differences, and finally dividing the flow system into specified time intervals. That simplification is a challenge when pipe sections lengths do not comply with the specific time interval. Nevertheless, one of the many advantages of the characteristics model is that the boundary conditions are easily programmed. Since a general solution to the partial differential equations is not available, the method transforms said equations into four total-differential equations and integrate them to yield finite differences; easily handled numerically. The time step results in finite length intervals, x. Conditions of the pressure pulse are known at the two start points A and B, and are predicted at point P, t seconds later, through equations (4) and (5): HP – HB + B (qP – qB) + R/4 (qB + qP) |qB + qP| = 0 HP – HA – B (qP – qA) – R/4 (qA + qP) |qA + qP| = 0 (5) This is true as long as the pressure wave has not reached the upstream end of the pipe and returned as a reflected wave, i.e. before 2L/seconds has passed. In real cases the reflected wave is small due to attenuation over long distances. The minus sign is used for waves traveling upstream. Here B is the capacitance, B = a/g, A and R is the viscous resistance; R = fx/(2gdA2). Eqn (4) is valid for increasing head in the + x direction (downstream), while eqn. (5) represents increasing head for each reach (x) in the negative x-direction. H and q are typically known at time zero, at which time initial steady-state conditions rule. HP and qP are found through iteration and interpolation rules. The steady state hydraulic friction in all the pipe section and in singularities inside the pipe defines the steady state HGL. At the discharge end the total friction pressure is recorded at the stand pipe pressure gage (SPP), and expressed through eqn. (3): In pipeline flow the velocity is written in terms of discharge. However, the variation of flow is unknown during transient flow. For problems in which the friction term dominates, a second-order approximation is necessary, yielding equation (4) and (5). 3.3. H0 Hydraulic grade line elevation, H The magnitude of the pressure wave reduces due to attenuation as it travels upwards as shown in Figure 5. At its downstream end the friction pressure reaches its full effect quickly. When the pressure pulse travels upstream it slows down the initial fluid velocity, causes storage of volume as liquid becomes compressed, and even strong pipe walls will expands a bit. However, since pressure attenuate, and will continue to rise for a while longer. This delayed increase is called line packing. The pressure is approaching the steady state HGL asymptotically. H0 rise a t the w a ve front f = / (½ rv2) Distance from discharge end Figure 5: At t = 0 the pump is turned on and reaches instantly a constant flow rate v0. At t = L/a seconds later, the fluid front has reached the downstream end. Without attenuation the final head rise H would have been reached at the upstream end 2L/a seconds after pump start. Dotted line represents the real, attenuated head rise. Combining eqn. (6) and (11 ) and solving for frictional pressure results in the Darcy-Weisbach equation: ppipe = f Shear stress can be expressed in terms of pressure, the force balance between shear stress and pressure; p /4 d2 = dL, yielding: dh /4L (6) The hydraulic diameter, dh, is equal to d for pipes and to (douter – dinner) for annuli. Drilling fluid is non-Newtonian. Transient flow, which is low at pump start conditions, will experience relatively higher hydraulic friction at low flow velocities. This behavior is taken care of through the selected shear stress model, the Power Law model: n (7) Friction pressure depends largely on the Reynolds number, given by NRe = rvdh / eff (8) Effective viscosity of a power law fluid is given by eff, pipe = [v/d 1/2 rv2 L/dh (12) (3n+1)/4n]n Kd/8v (13) Eqn. (9) and (10) are slightly different from annular flow. Shear stress is considered to be the same in transient flow as if the velocity were steady. Speed of a pressure pulse In very thick-walled, stiff pipes or pipes with large diameters, the acoustic speed of the pressure pulse is: The hydraulic friction term =K Both the empirical constants are related to Power law fluid behavior where a = (log n + 3.93) / 50 and b = (1.75 – log n) / 7. 3.5. (11) F = a NRe-b L = p (10) For turbulent flow the friction factor must be determined experimentally. The Fanning friction factor f is originating from the quotient between shear stress and kinetic pressure: Original steady state grade line v0 3.4. (3n+1)/4n]n L/d For drill pipes and drilling fluids we have selected the Metzner & Reed (Hemeida [6]) correlation: Final steady state HGL Head ppipe = 4 K [v/d Attenuation and line packing (9) At laminar flow (NRe < 1 800) the frictional pressure may be derived theoretically as: a K/r In a drillpipe part of the pulse energy is absorbed by wall streching, and a more realistic expression is (Wylie & Streeter 1978): a ( K / r ) / [1 ( K / E)( D / e)] (15) The term c1 is adjusted for pipe being anchored at its origin only (leading to axial streching): c1 = 1 – /2 (16) In the annulus c1 must instead be adjusted for cased holes: c1 = 2Ee /( Efm D + 2Ecsg e) (17) An important contribution to speed of pulse is the volume fraction of suspended solid particles in the liquid phase. Both K and r are adjusted: K = Kliq /[1 + (Vs/V)(Kliq/Ks -1)] (18) r = rs Vs/V + rliq Vliq/V (19) 4. Testing the model 4.1. Boundary conditions The transient problem is defined by its boundary condtions. For drilling operations the upstream-end boundary conditions is defined by a piston pump with known flow discharge. Head-discharge is ranging from zero to final steady-state level. Pump characteristics behavior during pump start are typically described by Figure 1. Flow output can be expressed by a linearely increasing function: q1 = q0 * t/t1, for t = 0, q = q0, for t = t1, q = q0 (20) 4.2. Model flow chart. The program was coded in Matlab codes. Flow chart of the program is presented in Figure 6. A tricky issue was the determination of the specific time interval. It had to be determined and optimized on basis of number and length of pipe sections (see detail in flow chart). Set values of model constants (mud weight, well length, etc) Start Figure 7: Results of transient pressure build-up of SPP. The data are taken from Figure 3 and Appendix. The drill pipe has been simulated shorter and longer than the base case in Figure 3 (and Appendix). We can state that the model imitate the reality in an acceptable manner. Estimated data Discretize independent variables; Time and MD Discretize dependent variables; q and H Observed data Inital conditions for q and H Boundary conditions for q and H at inlet and outlet no Compute grid point values for q and H between inlet and outlet using equation (4) and (5) Figure 8: Simulation of variable pipe length. Is max time reached? yes Stop Figure 6: Flow chart of program execution. 4.3. Results The result of the case defined in Figure 3 is presented in Figure 7. Our results matched quite well with field observations as shown in Figure 8. 5. Problems associated with transient pressure Pressure inside pipes propagates at the speed of sound waves, typically at 1 200 m/s in fluids inside steel pipes. It is therefore common to assume that fluids accelerate homogeneously as a stiff mass. These fast dynamics are much faster than the bandwidth of the MPD control system and are thus neglected in the hydraulic model (Kaasa et. al. [7])). However, in long pipes lines (> 3 000 mMD) including the annulus system, transient flow is exposed to multiple reflections and to attenuation, resulting in a transient period of minutes instead of seconds. Figure 7 demonstrates this clearly. In Figure 9 we have selected a specific location in the annulus to observe how the local transient pressure behaves vs. time. We observe that some reflections are more pronounced than others. observed data could in this well be described by the equation t = c L2. The theoretical increase of transient time vs. well length had a lower exponent than 2. Many closed-in situations and pressure transmission events will be exposed to long transient periods in long wells. This can lead to safety issues and miss-functionality. There is a need to re-visit these events to ensure full interpretations and downhole functionality. References Figure 9: Transient pressure vs. time at 3 500 mMD in the annulus. It takes 11 seconds before the first pressure increase is seen. At 17.5 s a pronounced reflection is coming from the outlet of the annulus and at 25 s a new one from the bit. Pressure In HPHT wells and other wells with narrow pressure window it is difficult to distinguish between breathing, kicking and transient pressure. Figure 10 illustrates how the surface pressure will react to different events after shut-in in long wellbores. Through proper analysis of the closure pressure we may be able to reveal its true response. 1 2 3 4 [1] S. A. Rbeawi and D. Tiab: Transient Pressure Analysis of Horizontal Wells in a Multi-Boundary System. SPE paper 142316 prepared for presentation at the SPE Production and Operations Symposium held in Oklahoma City, Oklahoma, 27-29 March 2011 [2] J.C. Castaneda, C.E. Schneider and D. Brunskill: Coiled Tubing Milling Operations: Successful Application of an Innovative Variable-Water hammer Extended-Reach BHA to Improve End Load Efficiencies of a PDM in Horizontal Wells. SPE paper 143346, prepared for presentation at the SPE/CoTA Coiled Tubing and Well Intervention Conference and Exhibition held in The Woodlands, Texas, 5-6 April 2011 [3] S.I. Jardine, A.B. Johnson, D.B. White and W. Stibbs: Hard or Soft Shut-In: Which Is the Best Approach? SPE/IADC paper 25712 prepared for presentation at the 1993 SPE/IADC Drilling Conference held in Amsterdam, 23-25 February 1993 [4] Statoil ASA: Real-time drilling data from Gullfaks. Statoil Rotvoll, Drilling Section, Trondheim, 2007 [5] E. B. Wylie and V. L. Streeter: Fluid transients. McGrawHill International Book Company, New York, 1978 [6] A. M. Hemeida: Friction factor for yield less fluids in turbulent pipe flow. J of Canadian Petroleum Technology, Vo. 32, No 1, 1993 [7] G.-O. Kaasa, Ø. N. Stamnes, L. Imsland and O. M. Aamo: Simplified hydraulic model used for intelligent estimation of downhole pressure for a managed pressure drilling control system. SPEDC, March 2012 5 6 1. Water or oil kicks from highly permeable zone 2. Gas kick from highly permeable zone 3. Breathing wellbore 4. Kick from low permeable zone 5. Pressure transient 6. Gas rising (by bouyancy) Time Figure 10: Pressure responses for different pressure events after shut-in in long wellbores. 6. Conclusion Transient pressure is a problem only in long wellbores. In 2000 m long wells it takes typically 5-10 seconds for pressure pulses to reach steady state, while in 7000 m long wells it takes typically 4 minutes. The model is based on known water-hammer theory applied to viscous fluids. In long wellbores the transients are caused by increased flow velocity, resulting in increased viscous friction. The friction pressure increase is transmitted back to the source (the pump) in an attenuated manner and therefore taking longer time in long wellbores. Testing of the model gave results that agreed well with field observations. The exponential time increase of the Nomenclature Roman: a A B BHA c1 d e E g H speed of pressure pulse cross sectional area a/g = capacitance bottom hole assembly effect of pipe constraint conditions on pulse speed, dimensionless) diameter wall thickness modulus of elasticity gravitational acceleration pressure head K L n p q R SPP t v v0 V x bulk modulus of elasticity, consistency index in the Power Law model length flow index in the Power Law model pressure fluid flow rate viscous resistance stand pipe pressure time fluid velocity steady state fluid velocity volume axial distance Greek: difference, here also used for transient time r Poisson’s ratio mass density viscous stress Subscrips: A 0 1, 2 csg fm i liq P s tot at point A steady state condition section numbers casing formation inner; section number liquid predicted solids total