njc11_publication_5[^]

advertisement

![njc11_publication_5[^]](http://s3.studylib.net/store/data/007532969_2-ff6421894f41b36268cd0fda71f4367d-768x994.png)

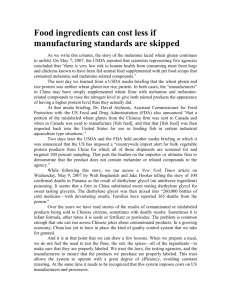

National Journal of Chemistry,2007, Volume 27,483-490 المجلد السابع والعشرون-7002-المجلة القطرية للكيمياء Improved Mechanical Properties of New Melamine Prepared Resins Saja S. Jabbar Al-Taweel Haider A. Jamel Laith S. Jassim College of Science College of Education College of Education University of Al – Qadissia (NJC) (Receivedon 3/12/2006) (Accepted for publication on 10/7 /2007) Abstract The melamine resin has a good chemical properties against alcoholic and water solutions but it has a very long time of reaction and curing. The period of reaction by could be rapid the reaction between urea – melamine to improve the functionality and adhesion then improve the mechanical property of melamine resin only . Five mass ratios of urea to melamine (U:M) and melamine to formaldehyde (M:F) were prepared as (2:50,4:50,6:50,8:50,10:50) (1:9,2:8,3:7,4:6,5:5) gm/gm at different operation conditions of temperature (20-110oC ), mass ratio (1-10) , and time of reaction ( 1-3 hrs). by using a design reaction system of nitrogen and reflux. The drying system was applied to the prepared adhesives and then check the optimum conditions of preparation on the testing properties . The results indicated that optimum mass ratio which gave an optimum mechanical properties is 6:50 (U:M) , and 3:7 (M:F). The impact load is 9 J/cm for (U:M) and 12 J/cm (M:F), compression load is 0.5 kN/Cm (M:U), 0.8 kN/Cm (M:F), tensile load 42 dyne /cm (M:U) and 97 dyne /cm (M:F),and bending load of 2.3 mm and 2.2 mm for (M:U) and respectively (M:F). 483 National Journal of Chemistry,2007, Volume 27,483-490 المجلد السابع والعشرون-7002-المجلة القطرية للكيمياء الخالصة إن الصق الميالمين يمتلك خواص كيمياوية جيدد ددد الملاليدل الكلوليدة والرطوبدة لكدن يمتلدك زمدن إضددداو طويددل لمددن الممكددن تلدديرل وتدددبين التوابددل لددين اليوريددا والميالمدين مددن اجددل تلسددين الددر .وااللتصاق وليما بعد تلسين الخواص الميكاضيكية لالصق الميالمين ) U:M وزضيد د د م د ددن اليوري د ددا إلد د د الميالم د ددين وزضيد ددة مد ددن الميالمد ددين ال د د الوورمالدي ايد ددد خلط د ددا خلطد ددا تطلي د ددق خمد د د ت د ددن لد د د لد د د ا البلد د د ) وخم د د10:50 ،8:50 ،6:50 ،4:50 ، 2:50 )110oC ( بضددد وددروغ تشددميلية مختلوددة للتلدددير محددل درجددة الل درار1:9,2:8,3:7,4:6,5:5)(M:F) تدن تطليددق ضودان تجويد. ) و لددك باسدتخدان مضوومددة توابدل مصدممة ل د ا المدر3 -1hr وزمدن توابدل خاص ل ل اللواصق الملدر حن يتبع لك التأكد من محالية الوروغ المسدتخدمة بلد الخدواص الملسدضة ( تمتلددك خ دواصM:F)(3:7)( وU:M) ) 6:50 الضتدداال إن الخ دواص الميكاضيكيددة للخلطددة خد د د د د د د د د د دواص االضد د د د د د د د د د ددما، بحلت د لي د (12J/cm)(M:F)متتالي د د د د د د د د د ددة لخد د د د د د د د د د دواص الص د د د د د د د د د دددمة (M:U)(42dyne/Cm) خد د د د د د د د د دواص الش د د د د د د د د ددد،(M:F)(0.8kN/cm)،(M:U)(0.5kN/cm)بض د د د د د د د د ددد .(M:F) ( لد2.2mm) ( وM:U) ( لد2.3mm) ( ومعامل اضلضاء بضد97dyne/cm)(M:F)و Introduction Industrial adhesive containing producible melamine–formaldehyde steps of hydroxymethyllation, low PH (MF) water soluble resin of melamine–formaldehyde through four and urea -formaldehyde (UF) cross linking condensation have been used for over fifty years rearrangement reaction (7) Mark was where this types of adhesive are improved the adhesion between the provided in liquid or and are composed fibers (whether they are wet or dry) by of monomeric and oligomeric species using the excess of formaldehyde to containing functionality melamine with about 3 mole F/1 mole including amino , methylol , and alkoxy M where 2 mole bound into colloid and species , to form a three dimensional 1 mole free .On the other hand pick polymer adhesive films (1-4). Vaughn Study the application of both urea and and co-workers (5) have evaluated a formaldehyde with melamine in molded new commercially MF and verified its structure. enhanced reactive reactivity high PH lower The properties of urea-melamine temperture cure response, other workers of thermoset structure give unique (6) try to design a reaction mixture of combination melamine and additive to give rapid low which are un matched by any other temperture cross linking by the using plastic raw material in the same price alcoholic , range making it ideal for wide range of ethanol , and butanol (6). Developed application practically in domestic field such as and and methanol 484 of molded properties National Journal of Chemistry,2007, Volume 27,483-490 المجلد السابع والعشرون-7002-المجلة القطرية للكيمياء (1-3) .A new development melamine melamine resin to resistance water by the addition properties (5) .The reaction between of urea resin (4) others are used urea to melamine and urea is (6) : improve the flexural strength and other mechanical of H 2C H 2N N CH2 N NH 2 N N CH 2 H 2C + N HCHO N N N NH 2 N CH2 H 2C Figure: A The Aim of Present Work: The aim of this to improve the Procedure: chemical and mechanical properties of melamine resin by the use of Urea, The raw materials are applied to formaldehyde and other very cheep a design section system of (1L) three additive material. neck end with reflux and under inert ambient by nitrogen flow rate where the Experimental Part: basis of adhesive such as urea and Materials: melamine was reacted as the reaction 1. Melamine of white standard indicated in theoretical section (fig A). grade general powder Five mass ratio of mixing supplied by BDH Company. applied 2. Flower (commercially). to the reaction system continuous stirred tank reactor (CSTR) 3. Urea (Industrial). until the temperature of reaction reach 4. Formaldehyde liquid (37%) (110ºC) let stay for concentration. (1: 5) half hours then applied the very cheep 5. Wood available (cut pieces) at additive hardener of flower and other a specified dimensions. material 485 to quick solidified the National Journal of Chemistry,2007, Volume 27,483-490 المجلد السابع والعشرون-7002-المجلة القطرية للكيمياء produced adhesive film between two cured the crosslink adhesives by heat , sheets of wood , then this film joints where table (1) indicate the experiments cured at (150ºC) for (1 hr) in order to mixtures applied to the plywood joints. Table (1): Experimental mixtures used in this work No. of Exp. Melamine (g) Formaldehyde(g) Urea(g) 2 2 1 50:9 50:8 50:7 50:6 50:5 1 2 3 4 5 2 4 6 8 10 1 1 2 3 4 5 Ratio F/M Ratio U/M 1:9 2:8 3:7 4:6 5:5 2:50 4:50 6:50 8:50 10:50 Properties: 1. 3. Procedure: It could notice the below term: Impact, Mechanical properties : The mechanical properties of Bending, Compression were Tensile applied A. use clean wood sheet in order and to to the adjust the functionality occurred. prepared specimen according to the B. Good stirring for reaction procedure of ASTM : mixture in order to homogenate (i). Impact Test: the reaction. By charpy impact tester C. enough time for reaction and according to (ISo-179). crosslinking of structure. (ii). Bending Test: By applied three points Results and Discussion: bending test, due to (ASTM-D790). Mechanical - adhesion properties: (iii). Tensile Test: A. Impact Test (J/cm): By Zweigle tester due to Figure (1) show the effect of (D-560) ASTM. urea resin on the impact load of new (iv). Compression Test: melamine prepared film, the impact load By Hydraulic piston type resistance increased with increasing the due to slandered (ASTM-D695). amount of urea used and the melamine 2. Chemical Properties: To check the chemical resistance of above adhesive, the resistance to moisture and chemical solutions were applied (8, 9). bonding reason (M:U). This may be attributed to the reason indicated by the reason indicated by Skeist (10). 486 المجلد السابع والعشرون-7002-المجلة القطرية للكيمياء National Journal of Chemistry,2007, Volume 27,483-490 Figure (2) indicates that the bonding resin and resistance to distortion resistance to impact load is increased load , where the resistance to distortion with increasing the additive of melamine is increased with increasing of melamine bonding resin until reach optimum bonding resin until reach the optimum mixing value at 3:7 (M:F) (12 J/cm) the value (97 dyne/cm) at 3:7 (M:F) this continuous addition of melamine bound may be into collide adhesive film, increase the indicated (8). functionality D. Compression Test KN/cm: between adhesive and wood sheets (8). attributed to the reasons Figure (7) shows the effect of melamine B. Bending Test (mm): Figure (3) shows the relation bonding resin on the compressed load applied, the resistance between resistance to distortion load and is amount of melamine bonding resin and melamine bonding resin until reach this relation stated that the distortion is optimum value at 0.5 KN/cm. This increased with increasing amount of the relation is increased due to the reason melamine bonding resin until reach 6:50 above (10). (2.3mm) (M:U) then it failur due to increased with increasing the Figure (8) stated the relation reason stated by Skeist (10). between melamine bonding resin and the Figure (4) indicated that the compressed load, the resistance is resistance to distortion is increased with increased with increasing melamine increasing additive of melamine bonding bonding resin until reach the optimum resin until reach optimum value at 3:7 value (0.8kN/cm) at 3:7 (M:F) then (M:F) (2.2mm) and this agreement with continuous to increase with increasing the result obtained (8). additive ratio, this may be due to reason indicated (8). C. Tensile Test dyne/cm: Figure (5) stated the effect of melamine bonding resin on the distortion Conclusion: load of tensile , the resistance is 1. The adhesive film 6:50 (M:U) decreased with increasing melamine have optimum mechanical bonding resin until reach the value of 42 properties. dyne/cm then it increased this may be 2. The Newer adhesives are cheep sharply due to reason indicated by Skiest and have a good mechanical (10). properties. Figure (6) shows the relation between weight ratio of melamine 487 المجلد السابع والعشرون-7002-المجلة القطرية للكيمياء National Journal of Chemistry,2007, Volume 27,483-490 3.5 3.5 3 2.5 2.5 Impact (KN) Impact (J/cm) Impact (KN) 3 2 2 1.5 1.5 1 1 0.5 0.52 4 2 6 4 8 6 8 10 10 12 12 weight of additives(gm) weight of additives(gm) Figure (1): Additive of (M:U) 16 16 Impact (KN) Impact (J/cm) (KN) Impact 14 14 12 12 10 10 8 6 8 6 1 1 2 3 4 5 2 3 4 5 weight of additives (g) weight of additives (g) 6 6 Figure (2): Additive of (M:F) 3.5 3.5 Bending Load (mm) Bending Load (mm) 3 3 2.5 2.5 2 2 1.5 1.5 1 1 0.5 0.5 2 2 4 4 6 8 10 6 8 10 w eight of additive (gm) w eight of additive (gm) Figure (3): Additive of (M:U) 488 12 12 National Journal of Chemistry,2007, Volume 27,483-490 المجلد السابع والعشرون-7002-المجلة القطرية للكيمياء 2.8 2.8 Bending load (mm) Bending load (mm) 2.5 2.5 2.2 2.2 1.9 1.9 1.6 1.6 1.3 1.3 1 1 1 2 1 3 4 5 2 3 4 5 additive of weights (g) additive of weights (g) 6 6 Figure (4): Additive of (M:F) 125 125 tensile load (dyne) Tensile (dyne/cm) Load tensile load (dyne) 110 110 95 95 80 80 65 65 50 50 35 35 20 20 2 4 2 4 6 8 10 6 8 10 w eight of additives (gm ) w eight of additives (gm ) 12 12 Figure (5): Additive of (M:U) Tensile load (dyne) Tensile Load Tensile load(dyne/cm) (dyne) 135 135 120 120 105 105 90 90 75 75 60 60 1 1 2 3 4 5 2 3 4 5 weight of additives (g) weight ofFi additives (g) gure (6): Additive of (M:F) 489 6 6 المجلد السابع والعشرون-7002-المجلة القطرية للكيمياء National Journal of Chemistry,2007, Volume 27,483-490 compression (KN) Compression (kN/cm) compression (KN) 1.1 1.1 0.9 0.9 0.7 0.7 0.5 0.5 0.3 0.3 0.1 0.1 2 4 2 4 6 6 8 10 10 8 12 12 weight of additives (gm) weight of additives (gm) Figure (7): Additive of (M:U) Compression (KN) Compression (kN/cm) Compression (KN) 1.1 1.1 0.9 0.9 0.7 0.7 0.5 0.5 0.3 0.3 0.1 0.1 1 1 2 2 3 4 5 3 4 5 weight of additives (g) weight of additives (g) 6 6 Figure (8): Additive of (M:F) 7. H.A. Gardener, Paint Testing Manual, 13th Ed, ASTM press Philadelphian, 1972. 8. San Dicge , Plastics , Inc , CA, 2004. 9. Manufacturing and rehabilitation of guard–rall posts using composites for superior performance, thesis by Rakeshk, 2000. 10. A.A.Skiest, Technology of wood bonding, New York, chapter 3-6, 1993. 490 References 1. J.M. Bijeu, Neth, Appl., 1980 , 098 , 7903 . 2. W.H.G.Schoea. Belg.Pat.BE, 1981 , 886, 936 . 3. K.K.Union Showa, JPn. Pat, 1984, 117, 566 . 4. Nissan chem. Industries, Ltd. Japan. Pat. 1984, 59, 195, 562. 5. S.Irving, Hand book of adhesives, 1973. 6. J.Shields, adhesive hand book, 2nd, London, 1976.