HSLA Steels – From “Bumper Component Welding State-of-the

advertisement

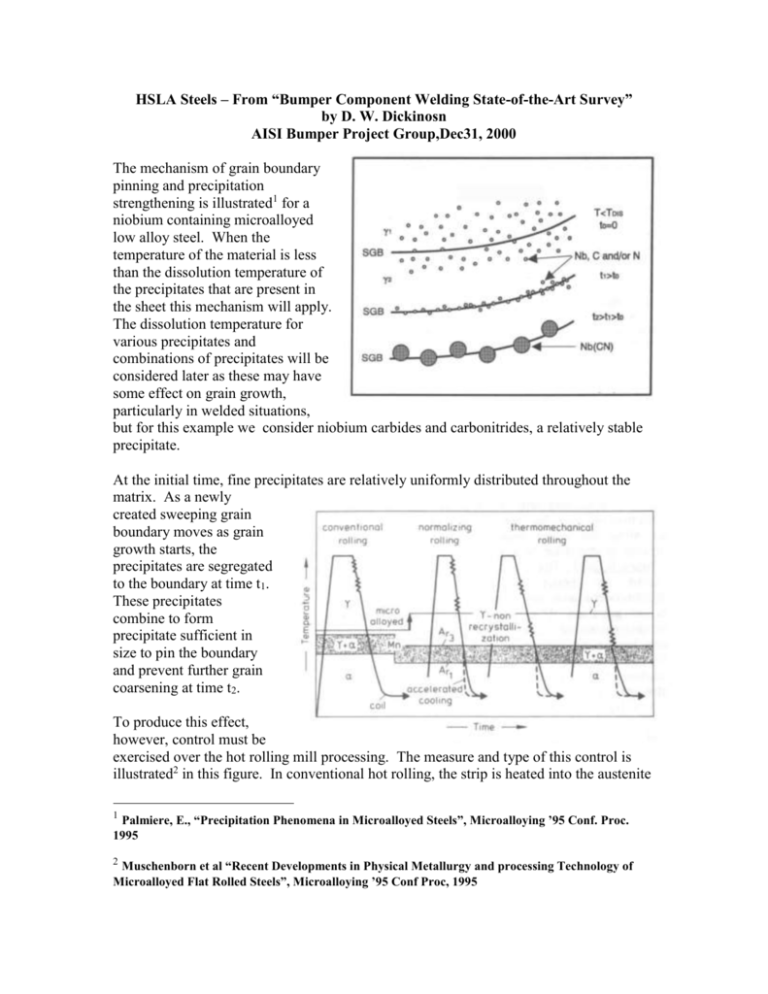

HSLA Steels – From “Bumper Component Welding State-of-the-Art Survey” by D. W. Dickinosn AISI Bumper Project Group,Dec31, 2000 The mechanism of grain boundary pinning and precipitation strengthening is illustrated1 for a niobium containing microalloyed low alloy steel. When the temperature of the material is less than the dissolution temperature of the precipitates that are present in the sheet this mechanism will apply. The dissolution temperature for various precipitates and combinations of precipitates will be considered later as these may have some effect on grain growth, particularly in welded situations, but for this example we consider niobium carbides and carbonitrides, a relatively stable precipitate. At the initial time, fine precipitates are relatively uniformly distributed throughout the matrix. As a newly created sweeping grain boundary moves as grain growth starts, the precipitates are segregated to the boundary at time t1. These precipitates combine to form precipitate sufficient in size to pin the boundary and prevent further grain coarsening at time t2. To produce this effect, however, control must be exercised over the hot rolling mill processing. The measure and type of this control is illustrated2 in this figure. In conventional hot rolling, the strip is heated into the austenite 1 Palmiere, E., “Precipitation Phenomena in Microalloyed Steels”, Microalloying ’95 Conf. Proc. 1995 2 Muschenborn et al “Recent Developments in Physical Metallurgy and processing Technology of Microalloyed Flat Rolled Steels”, Microalloying ’95 Conf Proc, 1995 region as illustrated in the diagram to the far left. Rolling deformation takes place fully while the material is in the austenite phase and conventional dynamic recrystalization occurs. When micoalloying elements are added to the strip, the temperature for nonrecryataliztion and grain growth raises, and the two phase temperature range over which ferrite and austenite are stable is lowered. This opens a processing window in which controlled rolling practice can occur as illustrated in the three rolling temperature curves on the right. In normalized rolling, all deformation occurs at relatively high temperatures, but for thermomechanical controlled rolling the deformation takes place within this temperature-processing window. This results in the grain strengthening described above. As previously mentioned, the stability of the precipitate has an effect on the properties obtain and on the welding response of that material. The solubility product of several precipitates as a function of temperature is presented in this figure. From these curves we can see that the most stable precipitate is TiN and it remains stable to very high temperatures. On the other hand, the least stable is VC. Thus the rolling window mentioned above will be over a larger temperature range for the TiN micoralloyed product. Other factors such as total strength and weldability also needs to be considered, however, when selecting microalloy addition routes. In addition to the precipitate type, the strain during rolling and the temperature at which that strain occurs must also be considered. The compound combination3 of these factors is illustrated in the diagram presented below. 3 DeArdo, “Modern Thermomechanical Processing of Microalloyed Steel” Microalloying ‘95 Conf Proc. 1995 Strain and Ppt’s Control Recrystallization & Grain Size Grain Coarsening Temperature • Increased Hot Deformation Lowers RXN Temp • More Stable Ppt inhibit grain coarsening at higher temps The graph in the upper left hand section of this diagram relates the type of grain deformation that is expected as a function of the deformation strain and the temperature at which this strain occurs. For high deformation temperatures, the resulting grain structure is recrystallized austenite. If an increased amount of deformation occurs, the energy for recrystalization increases and a lower critical temperature will still result in equiaxed-recrystallized grains. In the region of slightly lower deformation temperatures, only partial recrystalization occurs and the resulting structure is partially recrystalized fine grains mixed with elongated somewhat larger worked grains. At low temperatures of deformation, no recrystallization occurs and the grains will be elongated worked grains. For those materials in the intermediate range, the presence of grain boundary pinning precipitates will likewise retard the recrystallization and grain growth as observed in the diagram in the upper right hand side of this figure. The result of these factors is illustrated in the 3 dimensional plot for a carbon, manganese, niobium low alloy steel (similar plots are available for other steel compositions). The results considering all steel combinations show that increasing the hot deformation lowers the recrystallization temperature and that the more stable precipitates inhibit recrystallization and grain coarsening at higher temperatures. Thus the rolling deformation and temperature selection must be made for each precipitate forming alloy composition, thus the term “controlled rolling” unique for each alloy. In summary, the structure present in the controlled rolling practice4 are illustrated in the next figure. With conventional air-cooling after rolling, the resulting structures are represented by the top 3 cooling curves. In normalizing rolling, the deformation takes place in region I (the recrystallization region) and the austenite grains recrystallize with grain size somewhat dependent on precipitate pinning action if stable pinning precipitates are present. With controlled rolling where deformation takes place in region II (the nonrecrystallization region), deformed austenite grains are produced. With controlled rolling where deformation takes place in region III (the austenite plus ferrite region), both deformed austenite and deformed ferrite grains occur. On finish of cooling to room temperatures the final structures are represented by the sketches b’, c’, and d’. The material deformed in the recrystallized region has fairly large ferrite grain size (b’); The material deformed in the non-recrystallized region have finer grain ferrite (c’); and the material deformed in the dual phase region has the retained deformed ferrite with new fine grains of ferrite forming from the deformed austenite. In general, the lower the final deformation temperature, the finer the resulting ferrite grains and the higher the strength of the resulting product. This diagram also represents structures obtained by accelerated cooling from the hot rolling by run-off table accelerated cooling devices. These structures represented by (c’ AC) and (d’AC) show a finer grain structure yet. Tanaka T., “Science and Technology of Hot Rolling Process of Steel”, Microallying ’95 Conf. Proc., 1995 4