Safety Information Sheet for Recipients of Cultures/Microorganisms

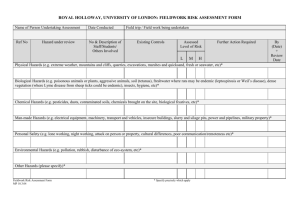

advertisement

EEU UR RO OPPEEA AN NB BIIO OLLO OG GIIC CA ALL R REESSO OU UR RC CEE C CEEN NTTR REESS N NEETTW WO OR RK K IIN NFFO OR RM MA ATTIIO ON NR REESSO OU UR RC CEE Health and Safety Requirements Introduction A Culture Collection should assess the hazards and risks that staff may be exposed to during their work and assign specific responsibilities to individuals to ensure a safe working environment. The Culture Collection management holds the responsibility for the safety of all staff, visitors and hired contractors on the collection site. Staff managers are responsible for the health and safety of the staff they supervise and are required to assess the risk each individual is exposed to in carrying out the tasks assigned. They must also ensure that adequate facilities are available to carry out this work safely. Information transfer to staff on hazards and risks should be provided via safety booklets, appropriate training, safety data sheets, codes of practice and risk assessments on all procedures and duties. Document issue records, risk assessment and training records should be kept for all members of staff and lodged in personnel files. Mechanisms should be in place to ensure that management and staff kept aware of new legislation. Work place and workstations should be inspected regularly. Emergency procedures for major accidents or incidents must be in place. These include fire evacuation procedures, contact procedures for first aiders, emergency procedures for out of hours working, emergency action with liquid nitrogen and chemical spillage. Health and Safety Records There are several health and safety records that are required by law and others that should be kept to facilitate health and safety management. The main records are: Accident book Chemicals in use Fire drill reports Inspection reports Maintenance records Minutes of First Aiders meetings Minutes of safety meetings Personal health records Personal risk assessments Procedural risk assessments Safety data sheets Staff training records Contacts for Emergency Use A Culture Collection should provide information to staff for contacts in case of an emergency such as internal first aid (list of First Aiders) and external provisions, e.g. medical doctor, hospital, other medical aid, emergency services. Additionally, information on building service utilities for cut off in an emergency should be provided, e.g. location of main electricity 1 switches, location of water stop-valves, location of gas stop-valves. An employer should provide First aid boxes for emergency use. Specific Hazards A Culture Collection must have documented procedures for all its activities. An alphabetical list (not exhaustive) of areas to be covered related to biohazards, chemical and technical hazards is given below: Accident reports Allergic reactions Autoclaves Biological hazards Carcinogens Centrifuges Chemicals Sterile work cabinets Cleaner’s safety guidelines Disinfectants Disposal of contaminated materials and wastes Electrical safety Fire Glass Hand tools Hazard groups and containment levels Infection Laboratory practice Laboratory coats and other personal protective equipment (PPE) Ladders Lifting and carrying Liquid nitrogen Microbial toxins Office safety Opening cultures and ampoules Opening parcels Personal protective equipment (PPE) Security Solvents Sterilisation Tidiness Transport of cultures within buildings Visitor’s safety guidelines Visual Display Units (VDU's) Workplace maintenance and repair Risk Assessment A Culture Collection should carry out risk assessments on all its activities. The categories of risk assessment should include: The management is responsible for the health and safety of staff whilst they are carrying out tasks on their behalf. Therefore it must ensure that a suitable and adequate risk assessment of the set task has been carried out and that the staff member has been made aware of the hazards and risks involved and that they have the relevant information and skills to carry it out. A risk assessment must identify the hazards, the potential to cause harm, the degree of harm (consequences of exposure) and the likelihood of exposure. There must be 2 recommendations for safe procedures and actions needed for improving safety where necessary. Hazards: National regulations governing the control of hazardous substances may require the containment of such substances or the reduction of possible exposure to as far below maximum exposure limits or occupational exposure standards as is reasonably practicable. More toxic materials should be replaced with less toxic ones where possible. Safety data sheets must be obtained and risk assessments carried out before chemicals are brought onto site. The risk assessment should include procedures for adequate handling, storage, use and disposal of the hazardous material. Personal health: An individual member of staff may have a wide range of duties involving several hazardous materials. It is extremely important that all their tasks are considered taking into account any synergistic effects. A personal risk assessment form is completed as a written record on the safety aspects of the reportee's tasks. This is reviewed whenever there are major changes to the duties performed and during staff appraisal procedures. A list of all hazardous substances that could have cumulative effects that the reportee may be exposed to must be kept and updated. An assessment of the amount and frequency of exposure must be made and recorded. Manual handling: A manual handling risk assessment form must be completed for every member of staff. VDU operation: A VDU (Visual Display Unit) workstation assessment must be carried out for all staff who are categorised as VDU users (those who operate a VDU in excess of a defined exposure time, usually one or two hours per day). A trained VDU assessor should carry out this assessment. Workplace: An annual safety inspection by experts outside the Culture Collection is advisable but the day to day assessment of workplace suitability and repair is an internal responsibility. The workplace and individual workstation must be suited to the tasks being carried out and must not place the operator at risk to their health and safety. Equipment: All work equipment must be safe and suitable for the task for which it is being used. Equipment must be inspected regularly and any faults or concerns addressed immediately or before the equipment is next used. Relevant Treaties, Directives and Legislation Treaty/Directive/legislation Requirement Risk Assessment Control of access and distribution Convention on Biological Diversity PIC; MTA European Commission Decision 91/448/EEC of Risk assessment; 29 July 1991 concerning the guidelines for Adequate health and classification referred to in Article 4 of Directive safety practices 90/219/EEC National Heaith and Safety Legislation Risk assessment; Adequate health and Existing BRC protocols Cartagena Protocol to the Convention on Biological Diversity 3 MOSAICC OECD Mandatory Guidance for BRCs OECD Mandatory safety practices European Council Directive 89/391/EEC: Council Directive of 12 June 1989 on the introduction of measures to encourage improvements in the safety and health of workers at work European Council Directive 90/219/EEC of 23 April 1990 on the contained use of genetically modified micro-organisms European Council Directive 90/220/EEC of 23 April 1990 on the deliberate release into the environment of genetically modified organisms European Council Directive 90/679/EEC on the protection of workers from risks related to exposure to biological agents at work (7th individual Directive within the meaning of Article 16 (1) [1997] European Parliament (2000) Directive 2000/54/EC on the protection of workers from risks related to exposure to biological agents at work. OJ No. L262, pp. 2145 of 18.09.2000 Risk assessment; Adequate health and safety practices Guidance for BRCs OECD BRC Mandatory Guidance Risk assessment; Adequate health and safety practices Risk assessment; Adequate health and safety practices Risk assessment; Adequate health and safety practices OECD BRC Mandatory Guidance USEFUL SAFETY REFERENCES Anon (1995) Categorisation of pathogens according to hazard and categories of containment. Fourth edition. Advisory Committee on Dangerous Pathogens (ACDP). London: HMSO. Anon (1996a). COSHH (General ACOP), Control of Carcinogenic substances, Biological Agents: Approved Codes of Practice (1996). London: HSE. Anon (1997a). Safe Biotechnology, Classification of Biological Agents, Bacteria. Berufsgenossenschaft der chemischen Industrie. Merkblatt B 006e, 2/97, ZH 1/346. 69021 Heidelberg: Jedermann-Verlag. Anon (1997b). Safe Biotechnology, Classification of Biological Agents, Fungi. Berufsgenossenschaft der chemischen Industrie. Merkblatt B 007e, 2/97, ZH 1/346. 69021 Heidelberg: Jedermann-Verlag. Collier, L., Balows, A. & Sussman, M. (eds) (1998). Topley and Wilson’s Microbiology and Microbial Infections. 9th edition. London: Arnold. Collins C H (1990). A review. COSHH and the microbiologist. Letters in Applied Microbiology 10, 109-112. Collins C H; Hartley E G; Pilworth R (1974). The prevention of laboratory acquired infection. PHLS Mongraph Series 6. London: HMSO. de Hoog, G.S. (1996) Risk assessment of fungi reported from humans and animals. Mycoses 39, 407-417. Smith, D. (ed.) (1996). Committee on postal, quarantine and safety regulations report 1996, Postal, quarantine and safety regulations: status and concerns. Braunschweig, Germany: World Federation for Culture Collections. pp39. Smith, J.E. & Moss, M.O. (1985). Mycotoxins: Formation, analysis and significance. Chichester, New York: John Wiley. Smith, D., Rohde, C. & Holmes, B. (1999). Handling and distribution of microorganisms and the law. Microbiology Today 26, 14-16 4 Stricoff, R.S. & Walters, D.B. (1995) Handbook of Laboratory Health and Safety, second edition. pp 462. New York: John Wiley & Sons. World Health Organization (1993) Laboratory Biosafety Manual, 2nd ed. (revised; interim guidelines). World Health Organization, Geneva, ISBN 92- 4-154450-3 Web sites ICGEB - http://www.icgeb.trieste.it - biosafety - http://www.icgeb.trieste.it/~bsafesrv/ AHIS - http://www.aphis.org CFSAN - http://vm.cfsan.fda.gov/~mow/chap24.html Belgian Biosafety Server http://biosafety.ihe.be UK site on safety http://hazmat.dot.gov/ Safety Standards the UK ACDP can be found at http://www.hse.gov.uk/foi/openacdp.htm http://www.oecd.org/oecd/pages/home/displaygeneral/0,3380,EN-home-0-nodirectorate-nono-no-0,FF.html WHO - http://www.who.int/homepage - The Biosafety Manual is found at http://www.who.int/emc/biosafety.html 5