equipment reference - Subcommittee on Maintenance

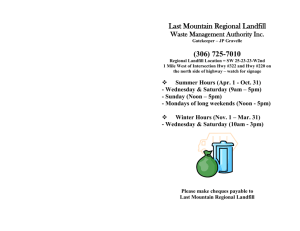

advertisement