1. Culture of shrimps in pens

advertisement

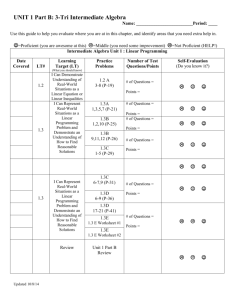

Culture of shrimps in pens Culture of shrimps in pens Training manual for Rekawa fishing community By Dr. S.C.Jayamanne Mr. Upul Liyanage Acknowledgement This booklet was produced for the benefit of the fishing community of Rekawa Fisheries Foundation who are participating in the production of P. monodon in pens in collaboration with NARA and NAQDA under AECI sponsored AIDA Project. The authors wish to acknowledge the financial support given by AIDA and AECI to fulfill this requirement. The authors also wish to acknowledge the efforts of Hon. Felix Perera the Minister of Fisheries and Aquatic Resources, Mr. Gila Director of AIDA, Ms. Priyadarshini Jayawardena the consul of Spain in Sri Lanka and Mr. K.Haputantri the Chairman of NARA, who geared this project in to reality. Encouragement and moral support given by Ms. Avelina Lopez, the consultant of the project and Mr. Ventura Rodriguez, the coordinator of the project are also highly appreciated. Culture of shrimps in pens Table of contents 1. Culture of shrimps in pens .................................. 3 1.1 Introduction .................................................. 3 1.1.1.What is pen culture? .............................. 3 1.1.2. Species used for pen culture, the world scene 3 1.1.3 Sri Lankan Experience .......................... 3 2. Site selection criteria .......................................... 3 2.1. Suitability of site for erecting pen .............. 4 3. Site preparation ................................................... 4 4. Construction of pens ........................................... 5 4.1 Materials required: ....................................... 5 4.2 Pen wall quality requirements ...................... 5 4.3 Selection of wall material ............................. 5 4.4 Height of the pen .......................................... 5 4.5 Quantity of various materials required ......... 6 4.6 Installation of pen ......................................... 6 5. Seeds for stocking............................................... 7 5.1 Quality testing and selection of post larvae for stocking 5.1.1 Gross examination ................................. 7 5.1.2 Microscopic examination ...................... 7 5.1.3. Salinity stress test ................................. 8 5.1.4 Vibrio examination ................................ 9 5.1.5 PCR testing ............................................ 9 5.2 Harvesting and transportation of PL............. 9 6. Rearing Post Larvae in Hapas .......................... 10 7. Transferring seed to grow-out pens .................. 10 8. Maintenance of pen during grow out period .... 11 8.1. Pests ........................................................... 11 8.2. Water quality requirement of P. monodon 11 8.2.1.Salinity ................................................. 12 8.2.2 Temperature ......................................... 12 8.2.3 pH ........................................................ 12 8.2.4 Calcium/Alkalinity .............................. 12 8.2.5 Ammonia ............................................. 12 8.2.6 Nitrite ................................................... 12 8.2.7 Hydrogen sulfide ................................. 12 8.3. Maintenance of water quality in pens ........ 13 9. Monitoring water quality and growth ............... 13 10. Harvesting....................................................... 13 11. Advantages of pen culture .............................. 13 11.1. Effective use of space .............................. 13 11.2. Safety from predators .............................. 14 11.3. Easy harvesting ........................................ 14 11.4. Availability of natural food ..................... 14 12. Disadvantages: ................................................ 14 12.1. High demand for Oxygen ........................ 14 12.2. Pollution .................................................. 14 12.3. Rapid spread of diseases .......................... 14 12.4. Poaching .................................................. 14 12.5 Conflicts with other users ......................... 14 7 Culture of shrimps in pens 13. CONCLUSION .................................................. 14 14. Bibliography ................................................... 15 1. Culture of shrimps in pens 1.1 Introduction 1.1.1. What is pen culture? A Pen is defined as “a fixed enclosure in which the bottom is the bed of the water body” (SEAFDEC/IDRC International workshop on Cage and Pen culture, 1979 (Philippines) - Proceedings Summary Report, P. 20). Shrimp pen culture has been initiated in Killar, Tamilnadu, India in 1982 and became popular as an aquaculture method for development of livelihood in rural communities and has been practiced in countries in Asia pacific. Pens are generally installed in shallow waters and are distinguished from Cages because the pens use natural bottom of the site instead of netting. 1.1.2. Species used for pen culture, the world scene Pen culture has been practiced in many countries of the world and wide variety of fish and shellfish has been cultured. Both marine and freshwater species were used in pen culture. Yellow tail (Seriola quinqueradiata), red sea bream (Pagrus major), file fish (Monacanthus cinhifer) and rock fish (Sebastes marmoratus) in Japan (Fujiya, 1979) plaice (Pleuronectes platessa) in Europe (Milne, 1979a). sea bream (Chrysophrys aurata in France) Salmon (Salmo salar) in Norway (Milne, 1979a, b; Moller, 1979), Pompano (Trachynotus carolinus in United States of America and Milk fish in Philippines (Guerrero and Soesanto, 1982) are some examples of finfish cultured in the world. Penaeus indicus, P. monodon (Reyntjens, 1989) P. semisulcatus, (Karim,1985) Macrobrachium rosenbergii and Scylla serrata are the shellfish species used in pen culture. 1.1.3. Sri Lankan Experience Sri Lanka’s experience in pen culture is limited to milk fish (Chanos chanos) culture in Bolgoda Lagoon and Penaeus indicus culture in Chilaw and Negombo Lagoons. Further expansion failed due to slow growth and low market demand for the species cultured. 2. Site selection criteria Marine and brackishwater areas such as shallow lagoons, sheltered and other inter-tidal and sub-littoral coastal areas are generally suitable for pen culture. A site which is suitable for the species selected as well as the requirements for erecting the pen has to be considered. Factors to be considered regarding Species Success of the pen culture system would depend on the understanding the optimal requirements of the species. Optimal conditions of the following factors for the species to be cultured have to be considered for selecting the site. The table below indicates the factors to be considered and the optimal ranges apply to Penaeus monodon. Parameter Optimal Range Culture of shrimps in pens Dissolved Oxygen pH Salinity Temperature NH3 Turbidity 4-7 mg/l 7.5-8.7 15-25 psu 28 – 31oC < 25 mg/l 30-40 cm Table 1. Water quality parameters suitable for Penaeus monodon culture The temperature, oxygen requirement, water quality (pollution) feeding and crowding are closely related. The optimal stocking of prawns in an enclosure is dependant on the availability of oxygen, the rate of oxygen demand of feed remains and excreta (increase of B.O.D). Oxygen content is also as well recognized related to temperature and salinity. The abundance of other organisms (plankton, benthos) within the pen also would deplete oxygen. Since temperatures and O2 demand of fish are high in summer the oxygen lack problem will be acute then a good circulation of water through the enclosure. Pollution of the pen area depends on the factors such as stocking density, species, their size, feeding ration and feeding rate. Therefore, these factors have to be considered carefully before initiation of culture. It would be better to use extensive culture where stocking density is low and the pollution by feeding is absent. Since the waters around the enclosure are rich in nutrients algae and mussels also grow well attached to the framework and nets of the enclosure. Fouling makes the net heavier, increases the drag in current and prevents the exchange of water in the pen. Thus, knowledge on the species composition of the planktons and other invertebrates in the site would be an added advantage for site selection. Presence of predators is another factor that should be considered in pen culture. Usually a shallow area is selected for pen culture and it is an area which is accessible for the predators. Birds (herons, gulls and cormorants), Mammal (seals, otters) and larger fish are the major predators in shallow water areas and absence of such predators would be good for pen culture. 2.1. Suitability of site for erecting pen As stated before, enclosure culture is practiced in the intertidal and sublittoral areas in the brackish and marine waters and in the shallow freshwater bodies in areas closer to the shore. Primarily the hydrography of the waters (water temperature, salinity, oxygen content, water currents, pollution levels etc.) and their seasonal variations has to be known. As the salinity is an important factor in Penaeus monodon culture salinity has to be controlled. Rainfall data of the area during previous 10-25 years would also be useful. 3. Site preparation Site selected should be cleared of all kinds of debris and leveled to some extent. Stones and rocks which could damage the harvesting nets should be removed. Predatory fish and crustaceans should be removed from the pen. The small fish varieties which can compete for natural food should be removed using a seine net, scoop net or cast net. Culture of shrimps in pens 4. Construction of pens 4.1 Materials required: 1. Pen wall – Plastic knotless mesh screen with 2-3 mm stretched mesh 2. Poles to support pen wall – Wooden/ Bamboo poles of 2 m height and 8-10 cm diameter (Poles of Ceriops tagal which can be grown in the area easily could be used if grown especially for this purpose would be ideal). 3. Side poles – to give additional strength and support to poles of pen wall 4. 4-5 mm thick foot rope. High density polyethylene (HDPE) rope locally available is ideal. This may have to be weighed down using weights or chain depending on the current velocity. 5. 3-5 mm thick head rope, HDPE rope 6. HDPE twine of 0.75-1 mm thickness for tying, lacing etc.; coir ropes can also be used for this purpose but may have to be replaced regularly. 4.2 Pen wall quality requirements The walls of the pen must be small to retain small-sized shrimp but big enough to allow free flow of water without easily permitting silt deposits or algal growth and should last long enough to enable the shrimp to grow to marketable size. Resistant to salt water and sun and to crab cuts. Strong enough to withstand the stretching tension and wind and wave actions. Cheap and locally available. Easy to handle and transport so that construction, installation on soft or firm bottoms, repair, maintenance and removal are easy. 4.3 Selection of wall material Plastic mesh wire will be selected as probable screening material for pen walls. The possibility of using bamboo split and other local material was ruled out, considering the lengthy procedures involved in procurement procedures and cost of labour and transport. Knotless, plastic wire mesh with a mesh size of 2-3 mm will be used as pen wall. 4.4 Height of the pen Height of the pen is an important factor to be considered as part of the wall will be driven into the mud prevents the cultured shrimp from burrowing out, and fish such as eels, catfish, etc., from burrowing into the pen. The depth to which the pen should be driven in to mud depends on the nature of the bottom. If the bottom is soft mud the wall should be embedded deeper in to the mud. It is safer to drive the pen wall at least 0.3 -0.5 m into the mud. The height of the pen then can be calculated as Culture of shrimps in pens Hp= H + D + F HP = height of the pen, H = height embedded, D=the depth of water at highest high tide and F= free board above water (appx. 0.3-0.5) Usually a height of 1.5 – 2.0 m is adequate for a pen constructed in a shallow area. Fig.1 Design of a fish pen wall as defined by LLDA (from Alferez, 1982) 4.5 Quantity of various materials required Quantities of various materials required for a 0.5 ha (100 m x 50 m) rectangular pen will be as follows. Material required Quantity Knotless plastic webbing (10 mm mesh) 2 m height x 300 m length Bamboo/ wooden posts 9-10 cm diameter at 150 Numbers (Appx) base end, 3.5 m long Horizontal bars, 4-5 cm diameter at 600 m (Appx.) base/reepers HDPE ropes 32 rolls Coir Ropes 6 -10 kg Foot rope HDPE, 4-5 mm diameter 500 m HDPE twine 1 mm thickness 1 kg Metal furrower for inserting pen webbing to 01 number ground Table 2. Quantities of materials required 4.6 Installation of pen The webbing which comes in 50 lengths has to be tied to the poles using HDPE ropes. Bottom line and upper line has to be tied to the poles with thick HDPE ropes and the middle part can be tied with thinner HDPE ropes. It is advantages to make loops with the HDPE rope of the bottom line at regular intervals so that the loop could be driven into mud preventing escape of prawns. The bottom part of the webbing has to be dug at least 30-50 cm deep into the ground. After finishing tying of the web into the poles horizontal bars will have to be tied at a height of approximately 0.75 m to reinforce the pen. Culture of shrimps in pens Fig. 2. A milkfish pen, showing nursery, rearing area and warehouse (from Alferez, 1982). 5. Seeds for stocking Many hatcheries are available in the northwestern province of Sri Lanka and hatchery produced fry could be obtained easily. The farmers could use following methods to test the quality of the hatchery produced post larvae. The quality of the post larvae is important since heavy mortalities will occur if weak post larvae were obtained. Quality testing methods are indicated below and these methods are generally followed by hatcheries when on demand. Fig.3 Post larvae ready for market 5.1 Quality testing and selection of post larvae for stocking The PL quality assessment involves five main areas: gross examination, microscopic examination, salinity stress test, vibrio examination and PCR testing. The samples have to be submitted to a competent laboratory for testing vibrio and PCR screening. Laboratories at NARA provide facilities for both these tests and PCR screening is available in some hatcheries it self. 5.1.1 Gross examination This involves examination of the size and physical behavior of the post larvae. A sample of post larvae should be measured to see their size distribution, swimming activity, feeding, colour etc. Looking at the size one can determine the age of post larvae. For example a 15 days old post larva is of a total length of 11-12 mm. Colour of healthy larvae is clear dark. The weal larvae will have red/white colour. Healthy post larvae swim actively and show full guts. If you tapped gently on the bowl of PL they jump. 5.1.2 Microscopic examination Culture of shrimps in pens Microscopic examination could be performed if the farmer is not satisfied of the results of gross examination. For this a sample of 20–30 PL are randomly selected and examined at 40 x magnification. The Table 3 indicates the criteria used for determination of health of post larvae. Hepatopancreas (HP): Gut condition Fouling (protozoans, bacteria or dirt) Deformity (moulting problems, necrosis) Muscle to gut ratio (muscle:gut) (in the 6th abdominal segment) Scoring criteria full and dark with lipid vacuoles partially dark and full with some vacuoles light, empty, no vacuoles full, with vacuoles and peristalsis vacuoles and peristalsis empty, no vacuoles or peristalsis no fouling medium fouling heavy fouling none sligh heavy muscle 75 percent of width muscle 50–75 percent of width muscle <50 percent of width None few many score Final score 10 5 0 10 5 0 10 5 0 10 5 0 10 5 0 MBV (malachite 10 green-stained smear 5 of HP looking for 0 occlusion bodies): Table 3. Criteria for selection of healthy larvae Scoring: The maximum score is 60 points, and the pass mark is usually set at 50 points (depending on PL availability). Any batch with more than three zero scores fails, regardless of the overall score. 5.1.3. Salinity stress test In this procedure PL are subjected to sudden change of salinity. The PL are moved to a beaker (1L), which contains sample of water from the PL tank diluted to 50% (1:1) with clean freshwater (drinking water). About 100-300 PL are subjected to this treatment and after 3 h, the numbers of PL that are still active or that move when prodded with a needle are counted and the result expressed as a percentage. The Culture of shrimps in pens good quality PL will have a score >75 percent and fails if below this score. The test is usually performed only on 12 or more days old PL. 5.1.4 Vibrio examination This is done to check for potentially harmful Vibrio spp. in the PL and the farmers can take a sample of PL to a reputed laboratory to perform this test. 5.1.5 PCR testing PCR testing is a common and compulsory practice in Sri Lanka and there are private laboratories in Chilaw area which perform this test. However, the government laboratory at NARA is also performing this test and farmers can get the samples test at any of these laboratories depending on their convenience and cost involved. This test will help to reduce the risk of crop loss due to White Spot Disease should therefore be conducted on each batch of PL stocked. However, an experienced farmer can judge the quality of PL even without performing above tests. PCR screening is strictly recommended for buying PL. 5.2 Harvesting and transportation of PL Harvesting and transporting is important for PL as this is the time that they are exposed to stress. Hence it is necessary to carry out this process so ensuring that PL will have minimal stress. The PL could be acclimated at the hatchery to the expected salinity of the grow-out place. When stocking in pens the water temperature and salinity psu of the lagoon environment should be checked and the PL should be acclimatized to the lagoon water salinity. This will ensure minimum stress as the PL can be provided with enough oxygen while acclimatizing to the expected salinity at the hatchery. Salinity adjustments should be done gradually adding freshwater to achieve a salinity change of <3 psu/h from 30 to 20 psu but should be reduced to<1 psu/h from 20 to 10 psu and <0.5 psu/h from 10 to 5 psu. Harvesting of PL should be done on the day of transportation. Until such time the PL should be held in tanks containing clean, disinfected and filtered seawater with aeration (or preferably oxygenation). Then the temperature should be decreased gradually (by adding bagged ice) until the desired transport temperature is reached. Decreasing the temperature should be done very slowly and it may take 30–40 min to reduce temperature from 28–30oC to 23 oC. Water salinity should be the same as the water in the larval rearing tanks (which should have already been adjusted to that found in the target ponds). Counting of PL can then be started. Counting is started by placing a scoop of PL in a basin. Then they should be counted manually and the number required can be estimated. Temperature reduction is required during transportation to lower the metabolic rate of the PL. When the temperature is reduced the PL will use less oxygen, excrete less waste and remain calm during transportation. The temperature used and stocking density of PL will depend upon the duration of the transportation. Typically no temperature reduction is required if the hatchery is within one hour of the farm. Temperature should be reduced to 26–28 oC for transportation times of 1–3 h, 25–26 oC for 3–12 h. PL can be transported either in large, aerated tanks or packed into plastic bags, usually held inside polystyrene and/or cardboard boxes. In either case the container should be filled with filtered seawater (at the same salinity as in the larval tanks) chilled to the desired temperature. New, already washed activated carbon (1 g/litre) can be added to absorb any ammonia produced by the PL and tris-HCL buffer can be added at 100 mg/litre to stabilize pH. It is advisable to provide live Artemia nauplii to if the transportation takes more than 4 h to prevent cannibalism during transportation. Culture of shrimps in pens Stocking density of PL15 should not exceed 500 PL/litre. Transportation in the early morning or during the night time is preferred as the temperature rise in the PL container will not rise during such times. 6. Rearing Post Larvae in Hapas Hatchery produced prawn larvae are too delicate to be stocked in the pens directly. Therefore the post larvae (PL20) have to be stocked in Hapas for a period of 1 month or more until they acclimatize to the environment. Hapas are cage like structures installed inside the pen (see figure 4) could be made using mosquito netting or a mesh with similar mesh size. Fig.4. Hapa net installed in shallow water Size of the Hapa cages could be of any size convenient to the farmer but usually hapas of 10 m x 3 m x 1.5 m, 10 m x 4 m x 1.5 m and 15 m x 4 m x 1.5 m could be used. Mesh sizes of the screens should be approximately 1.6 mm. The hapa cages could be fixed in the water with vertical posts as shown in the figure 4. The cage bottom is in close contact with the bottom so that the mud is acting as a natural substratum to the shrimp. A weight preferably a stone or some bricks wrapped in polyethylene paper are placed at various points to keep the bottom from floating up. Keeping bundles of sea grasses or weeds will be advantages for the shrimps since it provides shelter to the baby shrimp besides presenting substrata for the growth of periphytic food organisms. Sea grasses such as Halophila, Halodule and filamentous algae such as Chaetomorpha, and Enteromorpha provide good substratum for the baby shrimps. Shrimps could be stocked at a density ranging from 20-40/ L in the hapa net. During the period where shrimps are kept in hapa cage they should be fed with appropriate feed. Commercial feed available for shrimp farms could be used at the specified rates for this purpose. Feeding five times daily is advised for best results. When the shrimps attain a size of 30 mm they are ready to be stocked in the pen. 7. Transferring seed to grow-out pens Transferring of post larvae in to the pen is easy as the hapas are already installed inside the pen. One side of the cage could be untied and shrimps could be allowed to move in to the pen passively. This will reduce the stress caused by handling shrimps. It is also possible to collect the juveniles by crowding all the juveniles to one side of the hapa and then catching them with a hand net and transferring in to the pen. This will give the farmer an opportunity for counting the numbers and determination of survival during the rearing period in the hapa cages. Stocking density of 2-5 per m2 is advisable if extensive culture system is used for pen culture. However, it is possible to increase the stocking density if the feeding is Culture of shrimps in pens administered during the grow out period. Feeding shrimps four times daily is advisable in grow out phase. 8. Maintenance of pen during grow out period The farmer may encounter following problems during the grow out period. Lifting of pen walls due to strong winds and currents Holes in the nets Fouling of poles and nets by barnacles Clogging of nets preventing water exchange Rotting of poles Lifting of pen walls and holes appearing in the net may cause total loss of a promising crop. Therefore, the farmer should take close watch on the net wall. Crabs may cut holes in the net if the net is nylon but they cannot harm the plastic netting materials. Net walls have to be cleaned regularly to maintain water exchange and remove fouling organisms, clogged material etc. Rotting of poles may be expected if the poles provided are not durable. If this occurred the rotten poles have to be replaced immediately. As recorded by Tammenna, poles seemed more durable than bamboo poles as latter gets water logged and attacked by wood borers. 8.1. Pests While installing the pens, many undesirable organisms get trapped inside the pens. Repeated netting with small-mesh cast net, dragnet, gillnet and hand picking before and after stocking may reduce the pest population. Predatory fish and crabs may enter the pen either on their early life stages or through holes in the net. While very young, they only compete with the shrimp for food and space, but later the predatory species will turn to be a direct threat to the shrimp. Therefore it is necessary to control pest populations using fish attracting devices and removal of them using drag nets, cast nets and traps, therefore, should be practiced as a matter of routine. Pests interfere with shrimps either by competing for food and space or by preying on them. Eels Muroene and Congresox, are recorded to be the worst predators in pens and the catfish species Plotosus and Tachysurus. Other species of concern in varying degrees were Lates calcarifer, Johnius, Pomadasys, Polynemus, Elops, Thenaponi, Belone, Epinephelus, Gobids, etc. It was suspected that big-sized eel could find their way into the pens beneath the foot line. Hand-line and hook was found to be the most effective method for catching the eel. Hand picking and spearing helps removal of cat fish and eel. Cast netting, gillnetting and drag netting could be used to remove other fish. Crabs are another nuisance species in pens. They burrow into the mud, cut holes in the nets and compete for food. The crabs could be removed using baited traps. Daily checking was necessary to locate the holes and mend them under water. The work is quite laborious, time-consuming and cumbersome but necessary. 8.2. Water quality requirement of P. monodon Culture of shrimps in pens Water quality is critical for survival, health and growth of prawns, especially in semi-intensive and intensive culture. To maintain good water quality, the physical and chemical properties of water should be kept within certain safe levels, for example, dissolved oxygen supply should be adequate for prawn respiration, and toxic substances generated from the decomposition of organic compounds in the bottom sediment should be prevented or removed. 8.2.1. Salinity P. monodon can tolerate a wide range of salinity, however, high mortality and poor growth rates were found at salinities lower than 10 ppt. The lowest salinity they can tolerate is about 2 ppt. The optimum range of salinity which supports normal growth of P. monodon is between 15-30 ppt. Rapid change in salinity normally causes high mortality of P. monodon. Therefore stocking of P. monodon in the Rekawa Lagoon has to be done during the dry season and avoiding monsoon seasons. 8.2.2 Temperature P. monodon is sensitive to temperature changes in water. When the temperature is below 13 oC or above 33 oC, the prawns would normally develop cramps and die. The range of temperature which supports normal growth of P. monodon is between 28-33 oC. The temperature range in Sri Lanka is suitable for the culture of P. monodon throughout the year. 8.2.3 pH The optimal pH for P. monodon growth is between 8 - 8.5. Low pH can stress the prawn and cause soft shell and poor survival. 8.2.4 Calcium/Alkalinity The calcium content in water is important for moulting and growth of the prawn. After the prawn has shed its cuticle, calcium is required to replace the lost calcium in the cast cuticle and to increase the rate of carapace calcification. Calcium deficiency in water will interrupt these processes resulting in incomplete moulting and heavy mortality. The calcium content in normal brackish water is high and sufficient for P. monodon. 8.2.5 Ammonia Ammonia exists in water in both ionized (NH4+) and unionized (NH3) forms. The unionzed form of Ammonia is considerably toxic to P. monodon. Ammonia concentration is dependent on pH, temperature and salinity. The safe concentration recommended will be 0.15 mg/l NH3-N for postlarvae. 8.2.6 Nitrite Nitrite and nitrate are the products of the oxidation of ammonia by the nitrification process in water. The effect of nitrite on the growth of prawns is largely unknown. Applying a safety factor of 0.1, the safe level of nitrite recommended for P. monodon growth is 1.28 mg/l N02-N. 8.2.7 Hydrogen sulfide Culture of shrimps in pens Bacterial activity on organic materials in sediment under anaerobic condition results in the build-up of anaerobic metabolites particularly hydrogen sulfide. Hydrogen sulfide is highly toxic to organisms such as prawns which disturb the sediment when searching for food or burrow into the sediment to hide from predators. In water, hydrogen sulfide exists in unionised (H2S) and ionised forms (HS- and S-2). The unionised form is toxic. Unionised H2S concentration is dependent on pH, temperature, and salinity. Although hydrogen sulfide is known to be highly toxic to prawns, especially to its larval stages, the acute and chronic effects of H2S on P. monodon is unknown. Chen (1985) recommended a safe level of 0.033 mg/l H2S for P. monodon culture. Some researchers recommended 0.005 mg/l H2S. 8.3. Maintenance of water quality in pens Maintenance of water quality in pens is not possible since the farmers will not have control over the changing environment. However, it is possible to time the stocking and harvesting during the best season and avoid deterioration of water quality and related problems. 9. Monitoring water quality and growth Grow out period for P. monodon under extensive culture may vary from 3 months to 4.5 months. During this period water quality inside the pond should be measured to ensure that the water quality is safe for growth of shrimps. Therefore, water quality parameters; Dissolved oxygen (mg/l), pH, temperature (oC) and nutrients (Ammonia, Nitrite, Nitrate, Phosphate) should be monitored at least at weekly intervals. This will give an alarm if the water quality is going to deteriorate or if there is a chance for eutrophication and remedial measures could be adopted avoiding mortality of shrimps. Growth of shrimps should be monitored at least once a month. Sampling of shrimps could be done either by cast netting or using a feeding tray. If feeding is administered in the pen using a feeding tray sampling would be easy. 10. Harvesting Harvesting of pens can be started when the shrimps attained a weight of 25 g. Three gears; cast netting, trapping and drag netting could be used for harvesting the shrimp. Harvesting in the morning during the low tide is more appropriate but not essential. Drag netting is easy at low tides and cast nets could be operated during the high tide. The fishermen in Rekawa are experienced fishermen in cast netting and trapping thus harvesting would not be a problem. Complete harvesting of pen my take 3-7 days, but the fishermen ca employ partial harvesting depending on the market price. Storing harvested shrimp in hapas fixed in water will be advantageous as it is possible to keep them alive until they are marketed. The catch can be brought ashore, graded and sold at a higher price, 11. Advantages of pen culture 11.1. Effective use of space Culture of shrimps in pens The pens are usually small or large but the space covered by the pen is always effectively utilized. A higher production per unit area which may be 4 – 10 times higher than the natural production could be achieved. 11.2. Safety from predators Predators are usually removed from the pen before stocking and predators. Entry of predators in to the pen is also prevented by the design of pen wall thus the shrimps will be safe from the predators. 11.3. Easy harvesting Harvesting shrimps from pens is easier than from the natural waters as they are confined to the pen. 11.4. Availability of natural food The bottom of the pen is the natural bottom and the shrimps will have the advantage of feeding on natural food available in the pen. 12. Disadvantages 12.1. High demand for Oxygen Since the shrimps are stocked in high density compared to that of natural environment they deplete oxygen very fast. A good flow of water through the pen either by natural means or artificial aeration may be necessary for healthy and fast growing of shrimps. 12.2. Pollution Since a large biomass of shrimps are cultured a large quantity of excrements may accumulate in the area and cause a high BOD and also substances such as ammonia and other excreted materials causing pollution. 12.3. Rapid spread of diseases High stocking density in an enclosed area usually supports disease spread very quickly and can cause immense mortality of stock and production decline. 12.4. Poaching Poaching may be a threat to pen culture as the shrimps are in an enclosed area and easy to catch 12.5 Conflicts with other users Pen enclosures can interfere with other fishing activities such as blocking navigational routes and recreational activities, such as swimming, boating etc. 13. Conclusion Culture of shrimps in pens Aquaculture is a most advancing field in the world today. Rural development through aquaculture has received attention and the government promotes the increase in production from natural water bodies. The warm environment of the tropics remains as a major incentive for aquaculture and taking advantage of the existing advanced technologies to increase production will be beneficial for uplifting the living conditions of rural fishing communities of Sri Lanka. This may not be a big challenge if there is a will to change the attitudes, involve sound aquaculture principles and employ better management practices. 14. Bibliography Alferes, N. V. 1982. Fish pen design and construction in: Guerrero, R.D. and V. Soesanto (Prep). Report of the training course on small scale pen and cage culture for finfish. SCS/GEN/82/34, pp. 23–51; FAO/South China Sea Development and Coordination Programme, Manila. Beveridge, M.C.M. 1984. Cage and Pen Fish farming covering capacity models and environmental impact FAO. Fish Tech Pap. 255-13 pp. Reyntjens, D. 1989. Pen culture of shrimp in Chilaw, Sri Lanka. BOBP/WP/60 NARA-AIDA Project 2006-2009