Network Models: Transportation, Assignment, Shortest Path

advertisement

Chapter 5 Network Models

Examples discussed in this chapter

Example 5.1: Transportation model

Example 5.2: Production and shipment

Assignment model

Example 5.3: Assignment of busing routes model

Example 5.4: Transshipment model

Example 5.5: Shortest path model

Example 5.6: Equipment replacement model

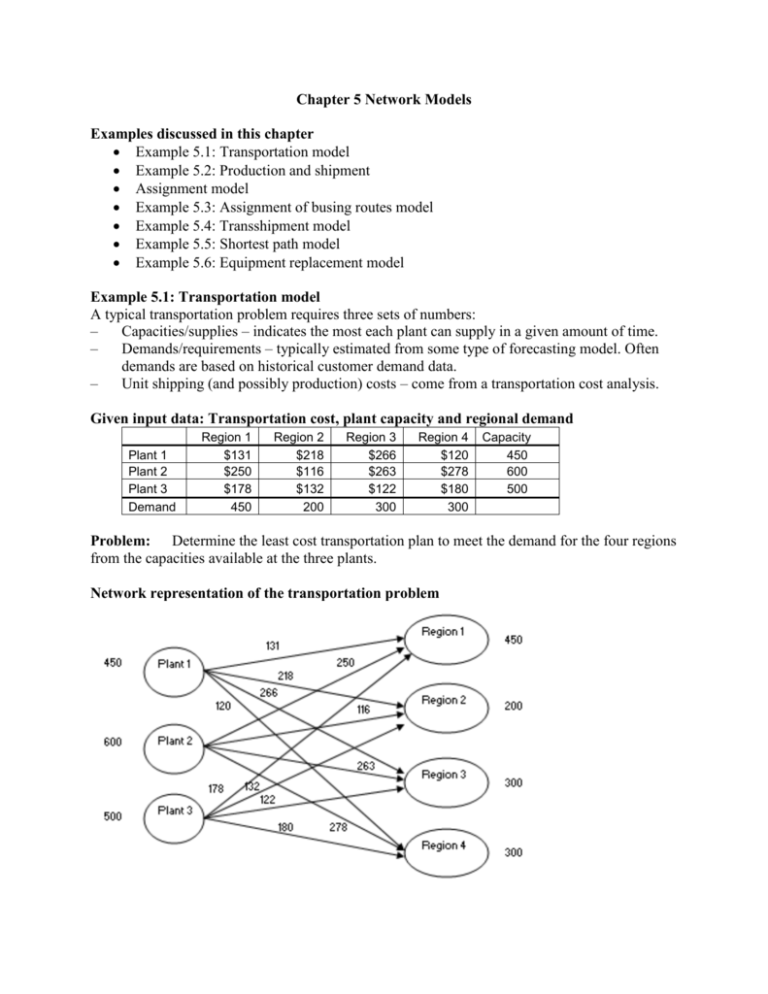

Example 5.1: Transportation model

A typical transportation problem requires three sets of numbers:

–

Capacities/supplies – indicates the most each plant can supply in a given amount of time.

–

Demands/requirements – typically estimated from some type of forecasting model. Often

demands are based on historical customer demand data.

–

Unit shipping (and possibly production) costs – come from a transportation cost analysis.

Given input data: Transportation cost, plant capacity and regional demand

Plant 1

Plant 2

Plant 3

Demand

Region 1

$131

$250

$178

450

Region 2

$218

$116

$132

200

Region 3

$266

$263

$122

300

Region 4

$120

$278

$180

300

Capacity

450

600

500

Problem: Determine the least cost transportation plan to meet the demand for the four regions

from the capacities available at the three plants.

Network representation of the transportation problem

Decision variables: No. of automobiles sent from each plant to each region

Objective function: Minimize cost of transportation

Constraints:

Quantity shipped from a plan cannot exceed capacity

Quantity shipped to a region must meet its demand

Alternative Form of Transportation Model

Setup data as columns and use SUMIF function.

Example 5.2: Transportation model approach for maximizing profit when selling price and

cost of production are given.

Given input data

Table of transportation cost, plant capacity and regional demand as earlier

Selling price at the four regions

Cost of production at the three plants

Tax rate for profit generated at each plant

Problem: Develop a production and transportation plan that maximizes after-tax profit

Decision variables: No. of automobiles sent from each plant to each region

Constraints:

Quantity shipped from a plan cannot exceed capacity

Quantity shipped to a region must meet its demand

Objective function: Maximize after-tax profit

Profit per unit = (Selling price – Production cost – Shipping cost) * (1 – Tax rate)

§ 5.3 Assignment model

Assignment models are used to assign members of one set to members of another set in a least

cost or maximum profit manner. For example, suppose there are 4 jobs are 5 machines. Every

pairing of machine and a job has a given job completion time as below.

Machine

1

2

3

4

5

Job 1

14

2

7

2

5

Job 2

5

12

8

4

5

Job 3

8

6

3

6

4

Job 4

7

5

9

10

8

The problem is to find an assignment of machines to jobs such that the total completion time is

minimized.

Decision variables: Assignment of each machine to each job, 0 = not assigned, 1 = assigned

Objective function: Minimize cost completion time

Constraints:

Only one machine is assigned to a given job

No. of jobs assigned to a given machine does not exceed its capacity

Example 5.3 Assigning busing routes

Some assignments are not allowed, as in Bus Routing example.

Example 3: Minimum cost network flow model

Network flow models are like transportation models except:

Capacity limits for transportation segments (arcs)

Each node has inflows and outflows

Shipment can be bi-directional

Nodes are classified as “supplier”, “demanders”, and “transshipment points”

“Supplier” nodes have capacity available

“Demander” nodes have demand quantity required

“Transshipment point” nodes have no supply and no demand

Graphical representation of problem 5.4 (Page 206)

Shipment costs are given in Table 5.7, page 206.

Input variables:

Decision variables:

Objective function:

Constraints:

Plant capacity, customer demand, arc capacity, shipment cost

Shipment on allowed arcs

Minimize total shipment cost

Flow on each arc <= capacity

Inflow and outflow must be balanced for each node as follows

Supply node: Outflow – Inflow <= available capacity

Demand node: Inflow – Outflow >= demand

Transshipment nodes: Inflow – outflow = 0

Optimal solution in network:

Sensitivity: Counting number of flows at capacity (Use COUNTIF)

Extensions:

Two products on the flow network

Perishable product, i.e. shrinkage in warehouse

Case 1: Two products on the flow network

Changes to the model:

Two columns for arc flow, one for each product

Arc capacity applies to the total flow of two products for each arc

Set up two separate sets of flow balance constraints for each of the two products

Case 2: Product shrinkage in warehouses

Changes to the model:

Assume a certain percentage of the product will be lost in the warehouse. In other words,

only a certain percentage of inflows go out as outflows. For example, if the shrinkage

factor is 90%, only 90% of the inflows will go out as outflows from warehouses; 10%

will be lost in warehouses.

Then, the only the warehouse constraints need to be changed as follows:

Outflows – Shrinkage factor (Inflows) = 0

Example 4: Shortest path model

The problem is to find the shortest path between two points in a network. For example,

what is the shortest path between node 1 and node 10 in the network given in Figure 5.25 in page

214? The distance between each pair of nodes (arc) is given in the network.

This problem is similar to the Minimum cost network flow model discussed earlier, except,

Node 1 is the “Supplier” node with a capacity of 1

Node 10 is the “demander” node with a demand 1

All other nodes are similar to warehouses where inflows must equal outflows

Extension: Equipment Replacement Model

Horizon is 5 years, i.e. 20 quarters

Purchase cost of a new machine is $3530 throughout the 5 years

Maintenance cost is $100 for first quarter, and increases by $65 per quarter for three

years

Salvage value of a machine is $1530 after the first quarter and decreases by $110/quarter

No machine is sold before the end of the first year

Machines remaining unsold at the end of three years are sold off

Objective: Optimal machine replacement strategy for five years

Shortest Path model for machine replacement problem

Nodes: Represent start of each quarter as a node. For a five year horizon we will have 21 nodes,

starting from node 1 representing the start of quarter 1 and node 21 representing the end

of quarter 20 (i.e. end of the fifth year).

Arcs: An arc between node “i” and node “j” represents purchase of a new machine at the

beginning of quarter “i” and selling it off at the beginning of quarter “j”. No arc is

required for the first 3 quarters of the life of the machine as machine are not sold within a

year. Also, no arcs are required past three years as machine not sold till three years are

sold off at the end of three years.

Arc (4,12) = Use the machine from quarter 4 to 11, and at the end of quarter 11 trade it in

for a new machine

Cost of an arc: Cost of arc = Maintenance cost for the duration of the arc – salvage value + Cost

of new machine

Cost of arc (4,12) = Maintenance cost for the first 8 quarters of the life of the machine Salvage value at the end of 8 quarter + Purchase price of a new machine

i.e. = (100 + 165 + 230 + 295 + 360 + 425 + 490 + 555) - (1530 – 7*110) + 3530 = $5390

Example 5: Project Scheduling

A project is defined by (i) a list of activities to be completed, (ii) duration of activity time for each

activity, and (iii) a list of immediate predecessors for each activity.

Activity (Node) Immediate predecessorsImmediate successorsDuration (weeks)

A

None

D, E

7

B

None

C

10

C

B

E

3

D

A

None

12

E

A, C

None

6

Forward scheduling

Earliest start time of a given activity (ES) = Max{Earliest finish time all its predecessors}

Earliest finish time of a given activity (EF) = ES + Duration

Backward scheduling

Latest finish time of a given activity (LF) = Min{Latest start time all its successors}

Latest start time of a given activity (LS) = LF - Duration

Slack of a given activity = LS – ES = LF – EF

An activity with zero slack is a critical activity. A path from start to finish using only critical

activities is called a critical path.

Example 5.7 Building a new room (Page 225)

Crashing the activities

Crashing an activity means reducing the activity time. Given cost of reducing activity time per unit

and a maximum limit for reduction, the task is to determine the least cost crashing to achieve the

desired project completion time.