Procedures for Handling of Saxitoxin

advertisement

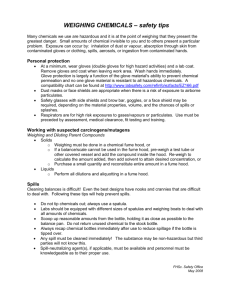

Standard Operating Procedure (SOP) for Saxitoxin University of California, Irvine Purpose This SOP describes the techniques and procedures for safe and proper handling, storage and preparation for experimental use, and disposal of Saxitoxin. Minimum Personal Protective Equipment (PPE) Non-permeable nitrile or latex gloves Disposable long-sleeved lab coat Safety glasses or goggles May be necessary to wear N-95 respirator when handling stock powder When handling toxins that are percutaneous hazards (irritants, necrotic to tissue, or extremely toxic by dermal exposure), select gloves that are known to be impervious to the toxin. Consider both the toxin and the diluent when selecting gloves or other protective clothing. If infectious agents and toxins are used in an experimental system, consider both when selecting protective clothing and equipment. Respiratory protection may be required if aerosols may be generated and it is not possible to use containment equipment or other engineering controls. Placarding When toxins are in use, the room should be posted to indicate “Toxins in Use-Authorized Personnel Only”. Any special entry requirements should be posted on the entrance(s) to the room. Only personnel whose presence is required should be permitted in the room while toxins are in use. Procedures for Handling of Saxitoxin Inspect the containers for damage during shipment. If damaged contact the vendor immediately, and decontaminate and dispose of the shipment immediately. If the vials were not damaged excess packing materials may be disposed in the regular trash. Log in the select agent shipment on the select agent inventory sheet. All packages containing select agents should be opened in a fume hood, glove box or ducted biosafety cabinet. Notify the sender within 24 hours of receipt of the toxin. Maintain a copy of the completed EA-101 form for lab records and fax copy to the Biosafety Officer at (949) 824-3383. All high-risk operations should be conducted with two knowledgeable individuals present. Each must be familiar with the applicable procedures, maintain visual contact with the other, and be ready to assist in the event of an accident. If the Saxitoxin is received as a powder, place a pad on the inside of the fume hood, glove box or ducted biosafety cabinet in order to minimize the spread of contamination during the weighing process. Ensure the fume hood, glove box, or ducted Biosafety cabinet is working properly with an inward airflow prior to initiating work. All work should be performed within the operationally effective zone of the fume hood or biosafety cabinet. When handling dry forms of the powder that are electrostatic, do not wear gloves (such as latex) that generate static electricity. Use a glove bag within a fume hood or biological safety cabinet, a glove box or class III biosafety cabinet. If you are aliquoting samples, place an absorbent pad on the bottom of the fume hood or ducted biosafety cabinet in order to contain any potential spills. Ensure the fume hood, glove box, or ducted Biosafety cabinet is working properly with an inward airflow prior to initiating work. All work should be performed within the operationally effective zone of the fume hood or biosafety cabinet. Resuspend the toxin by extremely careful and slow titration, rinsing down the walls of the tube in the process. Avoiding foaming and aerosolization. Aliquot 5 mls of 10% bleach solution into a 50 ml conical tube and place the open tube in the tube rack. This tube will serve as a waste receptacle for contaminated pipet tips. When vacuum lines are used with systems containing toxins, they should be protected by a HEPA filter to prevent entry of the toxin into the lines. Sink drains should be similarly protected when water aspirators are used. Place the toxin vials in an unbreakable, clean secondary storage container and transfer to storage at the appropriate temperature. Decontaminate the exterior surfaces of all materials leaving the biosafety cabinet, including the closed aliquot tubes with a 10% bleach solution. Decontaminate all work surfaces with a 10% bleach solution. Until the fume hood, glove box or ducted biosafety cabinet is decontaminated, the equipment should be posted to indicate that toxins are in use, and access to the equipment and apparatus is restricted to authorized personnel. Toxins should be transported only in leak-proof secondary containers. Standard sharps must not be used with Saxitoxin unless specifically approved by Environmental Health and Safety. If it is absolutely necessary to use sharps with Saxitoxin, sharps with engineering controls must be used. Engineering Controls Engineering controls such as fume hoods and biological safety cabinets must be used as primary containment in order to limit personnel exposure to Select Agents. Engineering controls must be inspected in order to ensure efficient removal of hazard, and must have a visual indication of airflow, and alarms to indicate that airflow has fallen below acceptable standards. Notification of laboratory personnel must be made prior to any maintenance that will impact the capture velocity of ventilation systems. Local exhaust ventilation systems including laboratory-type chemical fume hoods and biosafety cabinets must be certified upon installation, after maintenance and annually thereafter. Administrative Controls Written Standard operating procedures should be developed for all laboratories possessing, using, transferring or receiving select agents in order to ensure consistently safe work practices are being used. Standard Operating Procedures must be reviewed annually or as necessary to reflect changes to procedures. Standard Laboratory Practices for Guidelines for Work with Toxins of Biological Origin are addressed in the BMBL Appendix I. http://www.cdc.gov/od/ohs/biosfty/bmbl4/b4ai.htm Security Select Agents must be stored in a locked facility within a locked freezer, refrigerator, or cabinet when not in use. An inventory control system should be in place. Access to areas containing toxins should be restricted to those whose work assignments require access. Principal Investigators are responsible for ensuring that all laboratory workers and visitors understand security requirements and are trained and equipped to follow established procedures. Laboratory and animal areas with select agents must be locked at all times. All entries (including entries by visitors, maintenance workers, and others needing one-time or occasional entry) should be recorded by signature in a log book. Only workers required to perform a job should be allowed in laboratory areas, and workers should be allowed only in areas and at hours required to perform their particular job. Access for students, visiting scientists, etc., should be limited to hours when regular employees are present. Access for routine cleaning, maintenance, and repairs should be limited to hours when regular employees are present. The laboratory must be cleared of hazardous materials by EH&S prior to maintenance work or cleaning. Freezers, refrigerators, cabinets, and other containers where stocks of select agents are stored must be locked when they are not in direct view of the workers (e.g., when located in unattended storage areas). Decontamination and Disposal All liquid waste must be decontaminated using a 10% bleach solution for a 30-minute contact time and disposed of down the drain with plenty of water. Dry waste must be placed in double red biohazard bags autoclaved in an autoclave approved for Medical Waste treatment at 121 C for 60 minutes at 18 psi. Any destruction of Select Agents must be witnessed by the RFO. Contaminated and potentially contaminated protective clothing and equipment should be decontaminated using methods known to be effective against the toxin before removal from the laboratory for disposal, cleaning or repair. If decontamination is not possible/practical, materials (e.g. used gloves) should be disposed of as hazardous waste. Materials contaminated with infectious agents as well as toxins should be also be autoclaved or rendered non-infectious before leaving the laboratory. Spill Clean up If a spill occurs outside of the fume hood or ducted biosafety cabinet, notify lab personnel and evacuate immediately. Close the doors as you exit to allow the aerosols to settle. Notify EH&S immediately! Do not re-enter the facility. Personnel decontaminated the spill must wear the minimum PPE of safety goggles, disposable lab coat, double gloves and shoe coverings. Respiratory protection may be necessary based on a risk assessment of the Select Agent. Cover the spill area with absorbent material and cover with 10% bleach solution for a 30minute contact time. Do not splash the material in your face, and attempt to limit exposure. Clean up the material and place in double red biohazard bags. Ventilate the area and wash the spill site again after decontamination is complete. Notify your supervisor and EH&S of the spill immediately at 824-5073. Medical Surveillance Medical surveillance may be required for laboratory personnel based on potential risks of exposure. The PI should determine the need for medical surveillance with the assistance of Environmental Health and Safety. Post-Exposure Management In the event of an exposure to Saxitoxin Immediately call EH&S at 824-5073 or 911 from a Campus Phone. After hours (before 8AM or after 4:30pm) call (714) 456-7890 and request the Infectious Disease Fellow On-Call or go to the nearest hospital emergency room. Symptoms of Saxitoxin Exposure include: Tingling of the tongue and mouth Vertigo or dizziness Weakness Nausea and vomiting Headache Signs of Intoxication include: Flaccid paralysis Respiratory paralysis Convulsions Salivation Muscle twitching Rapid pulse Abdominal pain Treatment should be: No specific antitoxin is available Supportive care Anticipation of progressive ascending paralysis, particularly of the respiratory system Stomach evacuation by the emergency department if ingested Training All personnel possessing, using, transferring, or receiving select agents must have training as to the symptoms of toxin exposure, Post-Exposure Management Protocol, spill cleanup and decontamination, proper use of engineering, administrative and work practice controls and personal protective equipment, and security requirements for select agent possession and use. Personnel must be trained on the Chemical Hygiene Plan and the Select Agent specific Standard Operating Procedures. Training is required before initiation of research involving Select Agents and annually thereafter. For Additional Information Please contact the Biosafety Officer, Ms. Susan Weekly at 824-9888 or sweekly@uci.edu for additional information or assistance.