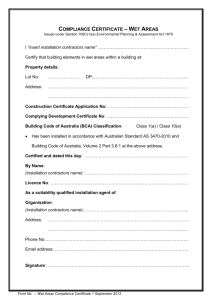

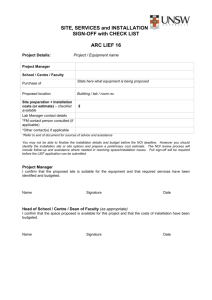

technical specifications

advertisement