Assay of reproducible methods for crispiness

advertisement

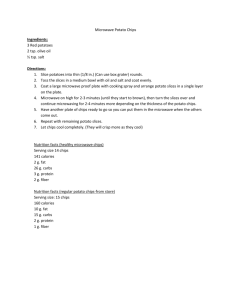

Assay of reproducible methods for crispiness evaluation of potato chips By Akhilesh Pandey In Guidance of Dr. Elena Castell Dr. Rosana Moreira 1 Abstract The reproducible method to analyze textural properties of potato chips was done by comparing ball probe results with two settings of guillotine probe. The results were obtained from texture analysis of Frito-Lays® brand potato chips through TA-XT2i texture analyzer. These results were interpreted by SPSS software to check the variability in data. The results showed high difference from each other due to testing methods. These differences were plotted in form of Force-Distance graph for further analysis. The best method was found by changing the gap between the guillotine probe to emulate it with the three point bend rig. The gap was set with the help of trial and error method to obtain the minimal difference between any two replications. This led to better results than any other methods lessening the variability in each replication. The numbers of multiple peaks due to high variability in ball probe were highly reduced in this method. Therefore the three-point bend rig emulation by guillotine probe was verified as the most suitable method for textural analysis of potato chips. 2 Introduction During the recent few decades numerous evaluation methods and instrumentation has been developed for analysis of mechanical properties of biological materials. Numerous researches have been conducted to produce better quality and to perform quantification of properties like crispiness, hardness, fracturability etc. These basic properties were being related with the processing parameters such as color, moisture content and various unit operations such as blanching, steeping, slicing, frying time. The prior need was to correlate the various quality attributes to the mechanical properties of the food products in order to evaluate the shelf life, stackability, mouthfeel; which serve as major factors in overall product quality. The basic concept behind all these parameters is very vast and difficult to quantify as well to evaluate it. Current researchers continuously thrive for achieving consistency in there data to make superior reproducibility of there results. Many methods have been evolved for qualitative analysis of potato chips lately, with the help of R&D carried out by universities and companies like Frito-Lays®. These methods emphasize on use of a reproducible technique to give consistency in results for evaluation of quality attributes of the final product. In the following experimental analysis of crispiness of potato chips the results were dually analyzed with the use of rupture test with the help of guillotine and ball probe. The basic objective was to achieve reliability and consistency in the results obtained. The principle of the test was to calculate the force required to fracture and break the potato chips as the measure of crispiness and brittleness. The surface irregularity of the chips inhibited the similarity in results of 3 two different samples of chips. This is the major problem in evaluation of the potato chips and to obtain reproducibility in the acquired results. Since potato chips also contain blisters due to frying operations thus making it have higher variability in the texture analysis results. This is due to the fact that no two potato chips are similar to each other in shape and size. The second objective of the experimental analysis was to determine the best method for evaluation of crispiness and brittleness in potato chips. The analysis was to be done by use of two different probes namely Guillotine and Ball probe to see the least variations in the results. Altogether a statistical analysis of the data was required to help in elucidating the results obtained and to provide a result with minimum variability. The method evolved slowly and was practiced as three point bending method that is generally used for evaluation of a sample through snapping test. This method had been used recently in fewer researches for textural analysis of processed food materials. Recently the method has been utilized for testing shelf-life, crispiness and staling of potato chips. 4 Literature Review The work carried out in the texture analysis of the potato chips is at its primitive level and more is to be achieved in this area to find better alternatives for measuring crispiness, hardness like variables of the complex shaped objects like potato chips. The major problem with reproducibility of the results obtained from texture analysis of potato chips is due to the shape irregularity of the chips. Therefore a method must be devised to ensure consistency in the results. In last few decades very few research papers have been published correlating various qualitative properties of potato chips to textural properties of the chips. In this paper they are being listed in a chronological order as published in different Journals. A very basic level of rupture testing of potato chips for textural analysis using a ball probe was also done by (C.Granda, R.Moreira 2005) in her thesis Acrylamide content of potato chips. The work carried out was similar to other cylindrical probe of 0.203 cm in diameter and a cylindrical base with an outside diameter of 25.5 cm and a hole of 19 mm was used in a bite compression test with a probe velocity of 10 mm/s. Kawas (2000) used a similar procedure to measure texture of tortilla chips: a ¼ inch ball probe traveled at a downward velocity of 0.1 mm/s until it broke the sample; the sample was located on an 18 mm diameter hollow cylindrical base. Fracturability was determined as the first peak of the force vs. distance curve. Garayo (2001) used a rupture test on fried potato chips. He used the same approach used by Kawas (2000); hardness of the chips was determined by finding the maximum force at compression (Steffe, 1996). 5 One of the most important researches was carried out named Mechanical properties of fried crust (Isabel Lima, R. Paul Singh ; 2001) at UC Davis; used both ball probe for the puncture testing of potato chips and guillotine type three point bending probe for snapping test. In this paper restructured potato model system was fried in canola oil for 5, 10, or 15 min at 170, 180, or 190oC and tested in a Dynamic Mechanical Analyzer. Selected mechanical properties were measured using puncture and three-point bending cells. Forces involved in puncture were a combination of tension, compression, and shear, while the three-point bend test studied the crust flexural properties. Therefore evaluating, the effect of frying time and multiple temperatures on the textural properties of the potato chips. In other researches various quality attributes such as effect of time and storage condition on Rheological properties of Masa for corn tortillas( Rosana Moreira, Elena Castell, Bootsrapa Limanond 1999) conducted test for evaluating the textural properties of corn masa. A similar research paper named Textural properties of Baked tortilla chips (Ahmed Kayacier, Rakesh Singh, 1999) was conducted to analyze changes in texture with multiple baking temperatures). The conclusion of this paper said that the force required to break the sample was higher for samples with higher work values. Three point bending using Instron punch was utilized for comparing the textural properties of potato chips by assay of changes in moisture content and sorption/ desorption, Thickness of potato chips, position of slice within potato tuber, frying time, temperature and potato specific gravity effects were deeply studied in the paper 6 named reproducible texture analysis of potato chips (S. Segnini, P. Dejmek and R Oste, 1999). Materials and Methods Sample Procurement The sample used was Frito Lays® brand classic potato chips procured at a rate of $3.50 per bag cost. These were the biggest possible bags of basic potato chips available by the company. The biggest bag was utilized due to the fact that more number of chips had shape irregularity. Only the samples with even and desired shape were presorted for the test to minimize variability in the results. The nominal thickness of the chips was around 1.6 mm. During every change in measurement or other day of test a new bag of potato chips was utilized so as to minimize variability in results due to moisture absorption. The chips were claimed to have no trans fats and fried in 100% sunflower oil. The seasoning on the chips was salt as claimed by company. Sample Preparation Once the potato chips bag was opened the chips were sorted out according to the shape and size. The check was done for any irregularities and to utilize the chips with very less blisters in the surface due to frying operation. Normally any brokens and cracked or fissured chips were discarded. The sample was ensured to have a straighter shape rather than a curved one. Also the thickness was checked to match the nominal thickness of other samples. This was done to provide consistency in the results and minimize the variability. 7 Instrument and its setup The apparatus utilized was: TA-XT2i Texture Analyzer Texture Technologies Corp, NY This equipment basically detects the force applied on its arm when a probe is used to compress/extend or rupture a product. In this project it was the main unit for determining the textural properties of potato chips under various settings. Fig 1.TA-XT2i Equipment Source: (Texture Tech. Inc) The main methodology was to use two different settings in the primary calculation by using the following probes: TA- 8 1/4“ diameter ball, stainless steel This probe was previously utilized in various other researches of textural analysis of various materials. It has been used for rupture test in which a ball shaped dong ruptures the potato chips surface by compressive force placed over a cylindrical cavity. One of similar analysis is presented in the literature review (C. Granda, R. Moreira 2005) Fig 2.The Ball probe setup Source(Texture tech Inc.). 8 TA-7K Guillotine block (for TA-90) for snapping test. This probe was used for snapping test to determine crispiness and hardness of the chips through rupture test. Later on it was altered to emulate the three point bending probe. This was done by changing the gap width of the base. Fig 3. The Guillotine probe setup. Source(Texture Tech. Inc.) The instrument is setup according to the setup in Thesis report of Acrylamide in potato chips (Granda 2005) for the setup of ball probe for texture analysis. The guillotine probe was primarily utilized for normal rupturing of the sample. Later on due to inconsistency of the results and by study of more methods guillotine blade was emulated as three point bending test to snap the potato chips. This led to better results with low variability and high consistency. The setting of ball probe was similar to others, in which a spherical probe of ¼ inch in diameter and a cylindrical base with a hole of 19 mm was used in a rupture test with a probe velocity of 10 mm/sec with a total distance of 18 mm for the arm and return distance of 4mm for the ball probe. While similar method parameters were utilized for guillotine probe except the total distance traveled by the probe was 15 mm with same return distance due to bigger size of the probe. 9 The potato chips were kept in a manner such that a plain uniform cross-section part of the chips surface was facing the probe without any blisters. This was ensured for every sample chips tested. There were 10 replications made for each type of the probe setting. Later on the guillotine probe was adjusted in a manner to maximize the gap of the base plate to emulate the three point bend snap test. The formula used for this was taken from (Bruns and Bourne, 1975): [F = (2/3) σ b h2/ L] (1) The flexural strength of the potato chips is the resistance it offers to the probe on bending. The maximum stress caused by bending is calculated by following formula: [σ = 3 F L/b d2] (2) Where, F is snapping force or the maximum force at yield or break (N), σ is the flexural strength (N/m2), b is the width of the sample, h is the height of the sample and L is the length between two supports. 10 d b F h rectangular 3 D circular 3 E = Fa /(4dbh ) 3 3 E = 4Fa /(3dpD ) Fig.4 Calculation of Young modulus for various shaped object in Three point bending test.( Texture profile analysis lecture slide; BAEN 620,spring 2007) The three point bending is basically the method developed for evaluation of crispiness and hardness of a potato chip. The length between two supports was set by trial and error method to find out the minimal difference in the force values of two replications. The trial and error method was practiced because of the lack of calculating method of flexural strength of potato chips in the given time. Therefore this work was recommended in the future researches in the conclusion of the report. 11 Results and Discussion The results were interpreted through the average of all the force and distance obtained in the experiment and the plots were obtained from the test. Further on the statistical analysis was done to determine the variance and the mean force values. The results with the ball probe had very high variability in the results. Similarly difference between the guillotine probe with normal gap and changed gap width were having a difference in its values of force. While the guillotine probe when emulated as a three point bending snap test equipment resulted in least variability of results. Therefore the three point bend test was the best testing method available for the texture analysis of the potato chips. The plots of the three different testing conditions are shown in the next page which is average of 10 replications by using ball probe, Guillotine probe with no alterations and Guillotine probe with changed gap width of the base plate to emulate the three point bending system. A statistical analysis was done with the help of SPSS software to determine the mean, variance and distribution of the force with distance to find out the best method with higher consistency in results. The statistical analysis was cross checked with the graphs obtained by the results in force and distance by texture analysis of potato chips. This was to verify and quantify the variability in the results obtained through by checking the variance with the graphs. A Table was copied from the SPSS results to show the variability and distribution of force in the whole testing procedure as Table 1 on the next page. It was noticed that the mean value had a high difference in the values. 12 Table 1: Descriptive analysis through statistical method by SPSS software Type of Probe setup 10 Replications Ball Probe Statistic 20.7503 Mean 95% Confidence Interval for Mean Lower Bound Upper Bound 10 Guillotine probe with altered to Replications emulate three point bending 5% Trimmed Mean Median Variance Std. Deviation Minimum Maximum Range Interquartile Range Skewness Kurtosis Mean 95% Confidence Interval for Mean Lower Bound Upper Bound 10 Guillotine Probe 5% Trimmed Mean Median Variance Std. Deviation Minimum Maximum Range Interquartile Range Skewness Kurtosis Mean Std. Error 1.75611 17.3046 24.1961 10.4711 .2000 3370.725 58.05794 -6.80 298.30 305.10 1.30 2.970 8.166 .074 .148 4.0670 .21775 3.6394 4.4947 3.3911 1.2313 29.114 5.39571 -1.13 22.81 23.94 4.44 1.872 2.540 .099 .197 2.0907 .41270 Replications 95% Confidence Interval for Mean Lower Bound Upper Bound 5% Trimmed Mean Median Variance Std. Deviation Minimum Maximum Range Interquartile Range Skewness Kurtosis 1.2775 2.9039 .8162 .3131 38.833 6.23158 -.72 38.01 38.74 .05 3.971 15.538 .161 .321 13 Average Force vs. Distance Graph for Ball probe 350 300 Average Force (N) 250 200 150 100 50 0 0 2 4 6 8 10 12 14 16 18 20 -50 Average Distance (mm) In the graph above between average force and distance we can notice the multiple peaks formed by the forces acquired from different replications. This resulted in very high inconsistency of the results. Therefore assumption was made that the results cannot be reproduced with higher accuracy. As per the industrial level measurement criteria the results obtained must be reproducible and comparable with other results in such a manner that the value of force show least variability. Therefore in context of Frito-Lays® like chips making company this method will be highly unreliable. In the statistical analysis the variance in the values as seen in table 1 is very high in comparison to the variance in the results of the guillotine probe. Thus dually proving the inconsistency of results obtained from the rupture test conducted through ball probe. 14 Average Force vs. Distance Graph for Guillotine Probe 25 20 Average Force(N) 15 10 5 0 -15 -10 -5 0 5 10 15 -5 Avergage Distance (mm) In the above graph the average values of force are very much consistent and do not show as high variability as the ball probe results. This shows that the results obtained have higher reproducibility between multiple numbers of samples. Similarly in the statistical results the variability in the results is very much lower than that obtained from the ball probe. Thus guillotine blade may serve better in obtaining replicable and consistent results for industrial use. 15 Average Force vs. Distance graph for Guillotine probe 40 35 30 Force(N) 25 20 15 10 5 0 0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 -5 Distance(mm) In the graph above the there are very less number of peaks for fracturability and crispiness making it the best result overall. In the statistical analysis the variance in the values is also minimum. Therefore we can say that; when the guillotine probe was emulated to do the three-point bending test the results were highly consistent. Therefore this method provided very good reproducibility for the potato chips. Normally most of the literature also covers the three point bend test of snapability for various food products to check crispiness and other properties. Thus, making it the most prospective method for use at industrial level to get consistency in results. 16 Conclusion The whole work carried out for devising of best reproducible method was done without any idea of methods used at industrial level for texture analysis of potato chips. During the work it was discovered that the certain way of using the guillotine blade by changing the gap between the base-plate would provide consistent results. Later on to be found as the emulation of Three-point bend rig generally used for checking crispness, fracturability, hardness for industrial use. Therefore it can be said assuredly that the method used by Frito-Lays® involving guillotine like blade probe is the typical three point bending probe setup. This setup was enquired for procurement from Food Technology Corporation as Part number 423-027 and was priced around $ 975 with 10% discount on academic purchases. Future Recommendations The future work must be carried out for: Procurement of correct three-point bend apparatus to get better results. The flexural strength of the potato chips must be calculated by the equation 1 and 2 for further in-depth analysis of the textural properties of potato chips. 17