Supporting information MOFs-templated formation of porous CuO

advertisement

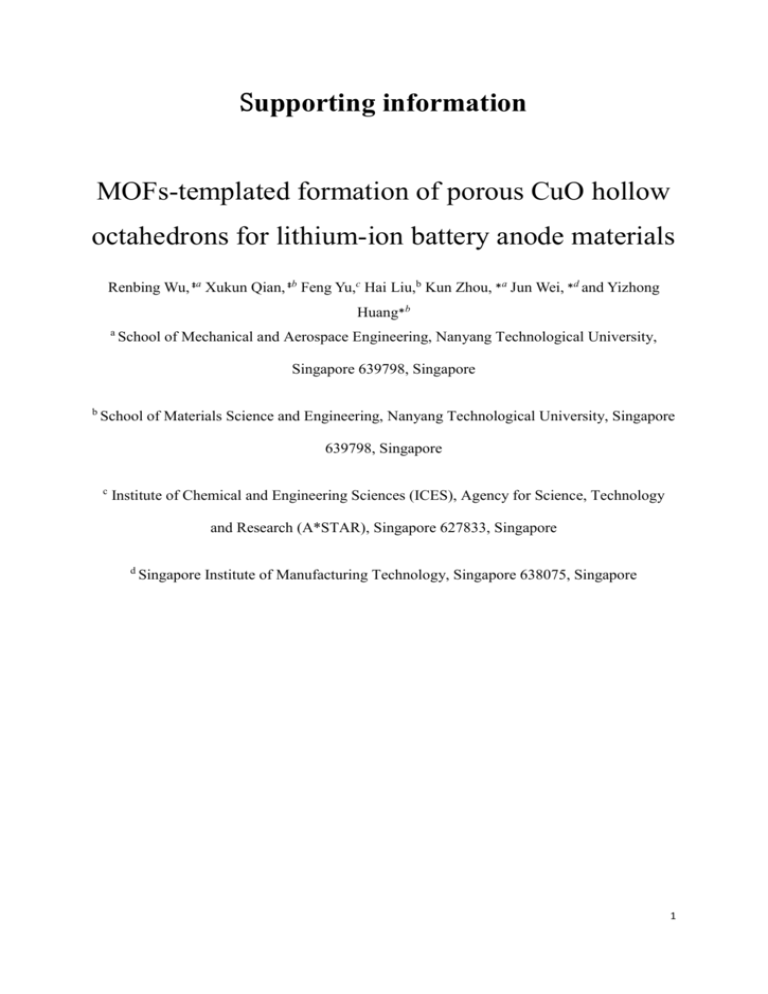

Supporting information MOFs-templated formation of porous CuO hollow octahedrons for lithium-ion battery anode materials Renbing Wu, ‡a Xukun Qian, ‡b Feng Yu,c Hai Liu,b Kun Zhou, *a Jun Wei, *d and Yizhong Huang*b a School of Mechanical and Aerospace Engineering, Nanyang Technological University, Singapore 639798, Singapore b School of Materials Science and Engineering, Nanyang Technological University, Singapore 639798, Singapore c Institute of Chemical and Engineering Sciences (ICES), Agency for Science, Technology and Research (A*STAR), Singapore 627833, Singapore d Singapore Institute of Manufacturing Technology, Singapore 638075, Singapore 1 S1 Experimental details Synthesis of Cu-btc MOFs. All chemicals were of analytical grade and used without further purification. In a typical procedure, 1.82 g copper nitrate (Cu(NO3)2·3H2O) and 0.875 g benzene-1,3,5-tricarboxylic acid (C6H3(COOH)3) were dissolved in a 50 ml absolute methanol under ultrasonication, respectively. After that, the copper nitrate solution was transferred into the tricarboxylic acid solution. The mixture solution was kept at room temperature for 2 h until MOF precipitation finished. The precipitation was retrieved by centrifugation and washed with methanol for two times. At last, the blue powder of Cu-btc MOFs was dried in vacuum at room temperature. Preparation of the CuO hollow octahedrons. At first, a glass vessel containing the powder of Cu-btc MOFs was placed in a tube furnace. Before being heated, the furnace tube was flushed twice by high-purity nitrogen gas to remove oxygen. The furnace was then heated to 300 °C at a rate of 10 °C min-1 and maintained at this temperature for 30 min under nitrogen gas flow. After that, the nitrogen gas flowing was switched off and the furnace was still kept at this temperature for another 60 min in flowing air. Finally, the product was taken out and it was found that the color changed from blue to black. Materials Characterization. The crystal phase of the prepared samples was characterized by X-ray powder diffractometer (Bruker D8 Advance) with Cu Kα radiation (λ=1.5406 Å). Morphological features and internal structures of the samples were studied using field emission scanning electron microscope (FESEM, JEOL JSM-7600F) and transmission electron microscope (HRTEM, JEOL JEM-2100F), respectively. The thermogravimetric analysis (TGA) was carried out by using a Shimadzu-60 thermoa-nalyzer under air flow at 10 °C min-1 from room temperature to 600 °C. The nitrogen adsorption-desorption isotherm was measured using a Quantachrome Instruments Autosorb AS-6B equipment. 2 Electrochemical Measurements. To fabricate the cathode of a coin cell battery, the sample of CuO octahedron was mixed with acetylene black and polyvinylidene fluoride (PVDF) in a weight ratio of 80:10:10 in N-methyl-2 pyrrolidinone (NMP). The obtained slurry was coated onto Cu foil, dried at 120 °C for 12 h, and then punched into round plates with diameter of 10.0 mm as the cathode electrodes. Finally, the prepared cathode, a Celgard 2400 separator (diameter of 16.0 mm), a lithium anode, electrolyte of 1M LiPF6 in EC-DEC-EMC (1:1:1 vol %), and the other components of the coin-type cell were assembled into a coin cell (CR2032) in an argon filled glove box. The coin cells prepared were examined at various charge-discharge currents between 0.01-3.0 V. Cyclic voltammetry (CV) was collected using an Autolab PGSTAT30 Electrochemical Workstation. Electrochemical impedance spectroscopy (EIS) was performed using Solartron SI 1260 Impedance/Gain-Phase Analyser. The sinusoidal excitation voltage applied to the cells was 10 mV with a frequency range of between 1MHz and 10 mHz. S2 Figure S2 (a) Low- and (b) high-magnified FESEM images of Cu-btc MOFs. 3 S3 Intensity (a.u.) Cu-btc MOFs I II 5 10 15 20 2 (degree) Figure S3. (I) Experimental and (II) simulated XRD patterns of Cu-btc MOFs. S4 100 90 80 Weight (%) 70 60 ~40% 50 40 30 20 10 0 0 100 200 300 400 500 Temperature (℃) 600 700 Figure S4. Thermogravimetric analysis (TGA) curve of as-prepared Cu-btc MOFs under nitrogen atmosphere with a ramp of 10 oC min-1. 4 S5 110 ramp: 10 C/min, in N2 Weight (%) 100 soaking phase 1: at 300 C for 30 min in N2 soaking phase 2: at 300 C for 30 min in air 90 80 70 60 ramp soaking phase 1 50 soaking phase 2 40 30 20 0 20 40 60 80 100 Time (min) Figure S5. Thermogravimetric analysis (TGA) curve of as-prepared Cu-btc MOFs under the heating treatment. 5 S6 Figure S6. (a) Low- and (b) high-magnified FESEM images of products obtained after heating Cu-btc MOFs at 350 oC; (c) low- and (d) high-magnified FESEM images of products obtained after heating Cu-btc MOFs at 400 oC. 6 140 0.035 120 0.030 -1 dV/dD (cm g nm ) -1 0.025 100 0.020 3 3 -1 Volume adsorbed (cm g ) S7 80 60 0.015 0.010 0.005 0.000 0 10 20 30 40 50 Pore diameter (nm) 40 20 adsorption desorption 0 0.0 0.2 0.4 0.6 0.8 1.0 Relative presure (P/P0) Figure S7. N2 adsorption/desorption isotherm curve of the CuO hollow octahedrons with the inset showing the distribution of the pore sizes. S8 800 -Z''im (Ohm) 700 600 500 400 300 200 100 2nd cycles 100th cycles 0 -100 0 100 200 300 400 500 Z' (Ohm) Figure S8. Electrochemical impedance spectra (EIS) of CuO octahedrons after discharge-charge cycles. 7 S9 Figure S9. The TEM image of the electrode after 100 cycles 8