Exam 3-solution

advertisement

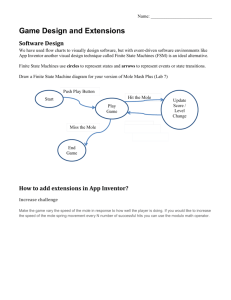

CHEN 2800- Prof. Ring Fundamentals of Process Engineering Name:____Solution____________________ Final Exam Open Book and Open Notes Exam Score Problem 1 ______/15 Problem 2 ______/30 Problem 3 ______/30 Problem 4 ______/25 Total ______________/100 1 CHEN 2800- Prof. Ring Fundamentals of Process Engineering Name:____Solution____________________ Problem 1: (15 Points) In homework problem 17.19, (P. 535 of text), you were given moist air at 25C, 100 kPa, and a dew point of 16C, and were asked to calculate the temperature to which the air must be cooled to condense 50% of the initial water at a constant pressure of 100 kPa. Redo that problem by allowing the pressure to increase until 50% of the initial water has condensed keeping the temperature constant at 25C. Use the following Antoine constants in your calculation: B log10 P A C T where T is temperature (K), P* is vapor pressure (bar), A=4.65430, B=1435.264, C=-64.848, for the temperature range is 255.8-373 K. Report your answer in kPa. A 4.65430 B 1435.264 K To 273.15 K C 64.848 K A P'( T) 1 bar 10 B P1 100 kPa C T y water1 P'( 16 K To ) 1.801 kPa half water is removed from Air so exit air is given by y water2 P2 y water1 P'( 25 K To ) 2 P2 2 P'( 25 K To ) y water1 353.081 kPa 2 P'( 16 K To ) P1 0.018 CHEN 2800- Prof. Ring Fundamentals of Process Engineering Name:____Solution____________________ Problem 2: (30 points) Sea water is desalinized by reverse osmosis using the scheme pictured below with the data given in the figure. Please determine the answers to the following questions. a) Determine the flow rate of waste brine (W) in kg/h. b) Determine the flow rate of desalinized water (D) in kg/h. c) Determine the flow rate of recycle ( R ) in kg/h. Recycle ( R ) 4.0%NaCl Reverse Osmosis Unit Feed Sea Water 1000 kg/h 3.1% NaCl (D) Desalinized Water Product 500 ppm NaCl 3 (W) Waste Brine 5.25% NaCl CHEN 2800- Prof. Ring Fundamentals of Process Engineering Name:____Solution____________________ 4 CHEN 2800- Prof. Ring Fundamentals of Process Engineering Name:____Solution____________________ Problem 3: (30 points) A pelletized mixture of Fe2O3 (hematite) and carbon at 298ºK is reacted with oxygen at 298ºK to produce CO2(g) and Fe(l) by the following reaction sequence: 1) C(s) + ½ O2(g) CO 2) ½ Fe2O3 (s) + 3/2 CO Fe(s) + 3/2 CO2 ΔHrxn = -12.399 kJ/gmole Oxygen is fed to the reactor with 0% excess. The reactor operates at 1900K a temperature just above the melting point of iron (Fe). The product gasses are separated from the liquid Fe product in the separator which also operates adiabatically above the Fe melting point at 1900ºK. As the plant engineer you are required to determine what to do with the heat wasted in the product gas stream. If the exit gas is cooled to 600ºK in a heat exchanger (Qex) and this heat used to superheat the inlet oxygen, how much cooling (QR) would be required for the reactor per mole of Fe(l) produced? 298ºK O2(g) Qex C(s) Fe2O3(s) 298ºK Reactor Separator 600ºK Fe(l) 1900ºK QR Data for Problem: Heat of Formation Hf º (kJ/mole) O2(g) 0 N2(g) 0 CO(g) -110.599 CO2(g) -393.798 Fe2O3(s) -824.8 Fe(l) Fe(s) 0 C(s) 0 CO2(g) 1900ºK Heat Capacity (J/(mole ºK)) 34.8 32.8 34.0 55.3 42.5 40.2 24.5 8.5 5 Melting Point Heat of Fusion (ºK) (kJ/gmole) 1838ºK 83.3 1809ºK >2300ºK 18.8 - CHEN 2800- Prof. Ring Fundamentals of Process Engineering Name:____Solution____________________ Data for Problem Cp_O2 34.8 J Cp_CO 34.0 mole K J Cp_CO2 55.3 mole K Heat of Formation Data J mole K Δ Hrxn_1 26.416 CO Cp_Fe2O3 42.5 Cp_C 8.5 J mole K Cp_Fe_liq 40.5 J Cp_Fe_s 24.5 mole K mole K mole kJ Hf_CO2 393.798 mole kJ Hf_CO 110.599 mole Δ Hrxn_2 3/2C(s) + 3/4 O2(g) 3/2 CO 2) ½ Fe2 O3 (s) + 3/2 CO Fe(s) + 3/2 CO2 Fe2O3 197 3 2 94.057 3 2 3 2 1 kJ Hreactants Hf_Fe2O3 412.4 2 mole Tf 298 K Cp_Fe_s d t Δ Hf_Fe_liq H 2 f_CO2 3 600 K 298 K kcal mole 393.798 824.8 1 mol 1 mol kJ kJ kcal mole 1 kcal 3 kcal 1 197 26.416 mole 12.399 mol kJ mole 2 2 ΔHºrxn = + 18.8 kJ/gmole overall reaction is exothermic 1 kJ Hf_CO2 Hf_Fe_s Hf_Fe2O3 178.297 mole 2 Hproducts 1 kcal mole ΔHºrxn = -12.87 kJ/gmole Overall Enthalpy Balance 0=Q+W-ΔH using (eq. 25.6) ΔH=Hproducts(Tout)-ΔHreactants(Tin)+ΔHrxn(298K) based upon overall reaction stoichiometry, outlet conditions and T.ref=298K 94.057 ΔHºrxn = 3/2*(-110.51 kJ/gmole) 3) Fe(s) Fe(l) 3/2C(s) + 3/4 O 2(g) +½ Fe2 O3 (s) Fe(l) + 3/2 CO 2 2 kJ Reaction heat 1) 3 1 mol kJ Hf_Fe2O3 824.8 mole Solution Basis: 1 mole Fe(l) Product at 1900K set T.ref = 298K Perform an overall MB and EB. Δ Hrxn_298 CO2 kJ Hf_Fe_s 0 mole Tf 1900 K kJ 110.599 J To 298 K mole K Δ Hf_Fe_liq 18.8 J kcal mole 1900 K Tf Cp_Fe_liq d t ... 507.597 kJ mole Cp_CO2 d t kJ QR Hproducts Hreactants Δ Hrxn_298 273.494 mole Reaction is exothermic so cooling is required Answer: QR=273.494 kJ 6 94.057 94.057 kcal 1 197 kcal 0 kJ 178.297 1 kJ 2 mole mole mol mole kcal 1 197 kcal 18.8 kJ 159.497 1 kJ 2 mole mole mol mole CHEN 2800- Prof. Ring Fundamentals of Process Engineering Name:____Solution____________________ Problem 4 (25 points) Potassium hydroxide is commonly produced from KCl by electrolysis. The process is sketched below. All concentrations are percent by weight. a) What is the fractional conversion of KCl to KOH? b) How many kilograms of chlorine gas is produced per kilogram of product? c) How many kilograms water must be evaporated in the evaporator per kilogram of product? Cl2 KCl Dissolve 30% KCl Solution H2 Electrolysis H2O Evaporation water Product 50% KOH 7%KCl 43% H2O Data for problem Mole Weight KCl 74.56 KOH 56.11 Cl2 70.91 H2 2.01 H2O 18.01 7 CHEN 2800- Prof. Ring Fundamentals of Process Engineering Name:____Solution____________________ Reaction 1 KCl + H2O --> KOH + 1/2 H2 + 1/2 Cl2 Basis 0.3 kg KCl fed and 0.7 kg water fed 0.3 kg M wKCl xKCl 0.3 kg MwKCl F 0.3 kg MwKCl 0.7 kg 0.094 xH2O 1 xKCl MwH2O 0.7 kg 42.891 mol MwH2O Use Basis 1 kg of product to determine the mole fractions for KOH and KCl in product only 0.5 kg M wKOH y KOH 0.5 kg 0.07 kg 0.43 kg Mw MwKCl MwH2O KOH 0.264 0.07 kg y KCl M wKCl 0.5 kg 0.07 kg 0.43 kg Mw MwKCl MwH2O KOH 0.028 y H2O 1 y KOH y KCl Overall mole balance on K 0.5 kg 0.07 kg M wKOH M w KCl F x P KCl 0.5 kg 0.07 kg 0.43 kg 0.5 kg 0.07 kg 0.43 kg Mw Mw Mw Mw Mw Mw KOH KCl H2O KOH KCl H2O 0.5 kg 0.07 kg MwKOH MwKCl F x P KCl 0.5 kg 0.07 kg 0.43 kg Mw Mw Mw KOH KCl H2O P F xKCl 0.5 kg 0.07 kg MwKOH MwKCl 0.5 kg 0.07 kg 0.43 kg Mw MwKCl MwH2O KOH Product flow rate 13.777 mol Wgt of Product Stream WP P y KOH MwKOH y KCl MwKCl y H2O MwH2O 0.408 kg R y KOH P 3.64 mol FractionalConversion M Cl2 1 2 Moles reacted in reaction 1 y KOH P xKCl F 0.905 Answer y KOH P M Cl2 MwCl2 0.129 kg M Cl2 MwCl2 WP Wgt Cl2 produced Answer 0.316 Overall Mole Balance on Water In-Out-reacted=0 xH2O F P y H2O 1 E 1 R 0 E F xH2O R P y H2O 25.474 mol E MwH2O 0.459 kg E MwH2O WP 1.123 Moles water evaporated weight of water evaporated Answer 8