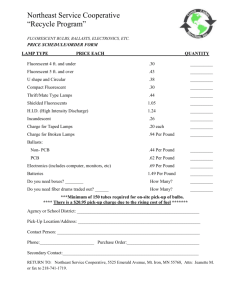

Draft Product Stewardship Fluorescent Lighting Action Plan

advertisement