18th European Symposium on Computer Aided Process Engineering – ESCAPE 18

Bertrand Braunschweig and Xavier Joulia (Editors)

© 2008 Elsevier B.V./Ltd. All rights reserved.

Thermochemical Multi-phase Models Applying the

Constrained Gibbs Energy Method

Risto Pajarre, Peter Blomberg, Pertti Koukkari

VTT, Process Chemistry, P.O. Box 1000 FIN-02044 VTT, Finland; risto.pajarre@vtt.fi

Abstract

Computation of chemical equilibria in multiphase systems by Gibbs free energy

minimization under constraints set by the material balance has increasing interest in

many application fields, including materials technology, metallurgy and chemical

engineering. The results are utilised in multi-phase equilibrium studies or as parts of

equilibrium-based process simulation. Yet, there exist a number of practical problems

where the chemical system is influenced by other constraining factors such as surface

energy or electrochemical charge transport. For such systems, an extended Gibbs energy

method has been applied. In the new method, the potential energy is introduced to the

Gibbs energy calculation as a Legendre transformed work term divided into substance

specific contributions. The additional constraint potential is then represented by a

supplementary undetermined Lagrange multiplier.

In addition, upper bounds on the amounts of products can be set, which then limit the

maximum extents of selected spontaneous chemical reactions in terms of affinity. The

range of Gibbs energy calculations can then be extended to new intricate systems.

Example models based on free energy minimisation have been made e.g. for surface and

interfacial systems, where the surface, interfacial or adsorbed atomic or molecular

layers are modeled as separate phases. In an analogous fashion the partitioning effect of

a semi-permeable membrane in a two-compartment aqueous system can be modeled. In

such system the large ions, not permeable through the membrane, cause an uneven

charge distribution of ionic species between the two compartments. In this case, the

electrochemical potential difference between the two aqueous phases becomes

calculated for the multi-component system. The calculated results are consistent with

the Donnan equilibrium theory; however the multi-phase system may also include the

gas phase and several precipitating phases, which extends the applicability of the new

method. Finally, similar constraints can also be set to extents of reaction advancements,

allowing usage of Gibbs energy calculations in dynamic reaction rate controlled

systems.

Keywords: Gibbs energy calculation, multi-phase chemistry, surface tension, ion

exchange, reaction rate

1. Theory

When additional energy or work terms affect the Gibbs free energy, [G = G(T,p,nk)] it is

customary to transform the total differential of the Gibbs function to read as follows

(Alberty 2001):

N

dG SdT Vdp k dnk

k 1

F dx

i

i

i

(1)

R. Pajarre et al.

2

where S denotes the entropy and V the volume of the system, μk = μk(T, p, nk) is the

chemical potential of the species (k), T is temperature, p is pressure and nk refers to

mole amounts of chemical substances. The last term (Fidxi) refers to additional

generalised work effects.

The Gibbs energy minimisation requires the use of the chemical potentials μk (partial

molar Gibbs energies) of the constituents of the system. If additional work terms are not

included, the multi-phase chemical equilibrium is solved with the mass balance

constraints as the necessary subsidiary conditions. Yet, in many physical circumstances

the potentials appear constrained also by other typically work-related factors. Then,

immaterial constraints for chemical potentials can be applied together with the mass

balance relations in a multi-phase Gibbs energy minimisation software. The additional

conditions arise from a work or energy effect or they are due to a pre-defined affinity or

extent of reaction. In the Gibbs energy minimisation performed by the Lagrange method

the new constraints are set with additional Lagrangian multipliers (Koukkari, Pajarre

2006a). They assume the same mathematical form as the mass balance conditions, but

with a zero molar mass for the new components. The equations governing the chemical

potentials and their respective constraints in the multi-phase system become as follows:

k

N

a

k 1

kj

l

a

j

(k 1,2,...N )

(2)

nk j 0 ( j 1,2, l )

(3)

j 1

kj

where N is number of different chemical constituents as formed from l system

components by means of the conservation matrix akj. The πj’s represent the chemical

potentials of the components in the system (Koukkari, Pajarre 2006a; Perez-Cisneros et

al. 2007) and equation (3) includes in addition to the mass balance constraints the

necessary immaterial conditions, such as electroneutrality, conservation of surface area,

metastability of a given constituent etc.. Equations (2) and (3) can then be used to solve

for the unknowns (nk, πj). For equilibrium problems, the Gibbs energy minimisation

with given input amounts and the system temperature and pressure is sufficient to solve

for the constraint potential and system composition. In non-equilibrium systems, an

external algorithm of e.g. reaction kinetics can furthermore be necessary to set the

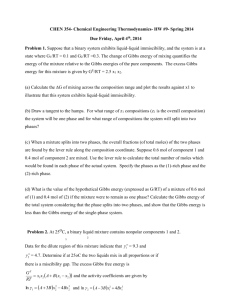

extent of change (Koukkari, Pajarre 2006b). In Table 1 some examples of the

constraints and their respective conjugate potentials have been listed.

Thermochemical Multi-phase Models Applying the Constrained Gibbs Energy Method

Table 1. Examples of constraint potentials in the Gibbs free energy method

System

Constraint

Conjugate potential

Examples

Chemical

equilibrium

systems

Mass balance

Chemical potential of system

components

Multi-phase

chemical

equilibria

N

a

k 1

Systems with

surface/interface

equilibria

kj

nk b j

Surface area

Ns

Ak nks A

j

G k

b j a kj

Surface energy per unit area

(A0)

area

k 1

Electrochemical

multi-phase

systems

Charge neutrality

N

z k nk 0

Electric potential energy per

mole of charge

q

k 1

Rate-controlled

complex

systems

Reacted amount

from the extent of

reaction

N

a

k 1

kr

n k bri

G

A0

barea

G

F

bq

Affinity of chemical reactions

r

i

G

G

Affi

bri i

Phase diagrams

Interface

compositions

Nanoparticle

phase diagrams

Membrane

systems

fibre and pulp

suspensions

Metastable

phases or

constituents;

Non-equilibrium

chemical

reactors

akj = element of conservation matrix ; N = nr. of constituents. ; bj = molar amount of

component jth component, b(X) = molar amount of component ‘X’ (b(area) = A/A0)

πi = Chemical potential of ith component ; π(X) = Chemical potential of component ‘X’

A = total surface area; Ak = molar surface area ; = surface tension; A0 = constant with

dimensions of m2/mol (numerical value arbitrary)

zk = charge number of species ; F = Faraday const. ; = electric potential difference

between phases

Affi = Affinity of ith reaction

2. Example cases

2.1. Surface energy of mixtures

Surface energy can appear as an additional term in the Gibbs energy function of a multicomponent system. Assuming a flat, monomolecular surface layer where each

constituent of the surface phase occupies a characteristic molar surface area Ak, the

Gibbs energy can be written as:

3

R. Pajarre et al.

4

G kb nkb ks nks Ak nks

k

k

(4)

k

where supersrcipts b and s refer to bulk and surface respectively. At equilibrium, the

total surface area (A) is constant and the immaterial constraint corresponding equation

(3) can be written as presented in Table 1. (Pajarre et al. 2006). With this and material

balance constraints formulated in such a way, that a minor amount of the surface phase

will appear, the surface tension can be solved by min(G) calculation as a conjugate

potential, together with the chemical potentials of the bulk and surface phases.. The

molar surface areas and surface energies of pure substances are needed for the standard

chemical potentials of the surface constituents:

k0, s k0 Ak k

(5)

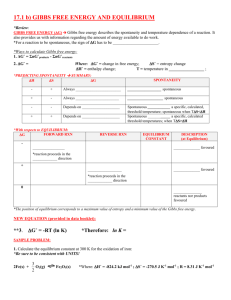

It follows that the composition and surface tension of a mixture can be solved by Gibbs

energy minimisation when the initial amounts, the molar surface areas and surface

tensions of pure substances and the excess energy functions are given as input data. In

Fig. 1 the method has been applied to a binary water-ethanol system.

Surface tension (N/m)

0.08

0.07

0.06

0.05

0.04

0.03

0.02

0

0.2

0.4

0.6

0.8

1

x(C2H5OH) bulk

Figure 1. Surface tension of a water-ethanol system.

2.2. Donnan potential and salt solubilities in pulp suspensions

The concept of ion-exchanging (Donnan) equilibrium has been conventionally used to

characterize electrolyte interactions with cellulose fibres (Towers, Scallan 1996).

Because of its simplicity it is an attractive approach to modelling of fibre-ion

interactions. The aqueous solvent in the pulp system is divided between two subvolumes: The volume of water surrounding the fibres and the volume of water inside

the fibre walls. The amount of water enclosed by the fibre walls depends on the type of

pulp and to some extent the chemical composition of the suspension liquid, typical

values being around 1-1.5 l/kg of dry weight. This value can be measured and is then

regarded as constant. Pulp contains fiber-bound acidic groups that can dissociate giving

the fibre an anionic charge. The amount of these groups, as well as their dissociation

constants can be quantified with standard potentiometric methods, and thus, the

respective G-values for Gibbs energy calculations are accessible.

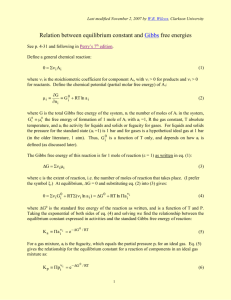

A basic Donnan model however, is insufficient to deal several practical problems that

deal with dissolution and precipitation equilibria. These may involve carbonaceous and

other salts as well as the effect of gaseous pH-agents, such as carbon dioxide and

chlorine dioxide. Thence, a multi-phase approach based on the Gibbs free energy

Thermochemical Multi-phase Models Applying the Constrained Gibbs Energy Method

minimisation was developed, where the Donnan theory for ion exchange between two

aqueous phases was incorporated to a multi-phase Gibbs’ian system. (Koukkari et al.

2002). The necessary constraint is electroneutrality in both aqueous phases, and the

electrochemical potential difference becomes solved formally as another Lagrange

coefficient as presented in Table 1. This approach also enables the use of a more

elaborate ionic interaction models, such as that of Pitzer, instead of the ideal solution

assumption. Model curve in Fig. 2 has been calculated assuming just one acidic group

(pKa=4) as reported by Towers and Scallan.

Donnan potential, V .

0.07

0.06

0.05

0.04

0.03

0.02

0.01

0

-0.01

0

2

4

6

8

10

12

pH

Ca

Mg

Mn

model

Figure 2. The Donnan potential has been calculated as a function of pH and compared to

measured values of the concentration ratios of cationic species Ca2+, Mg2+ and Mn2+ in a pulp

suspension. The open diamond at highest pH value is for Manganese corrected for calculated

precipitation of solid hydroxide.

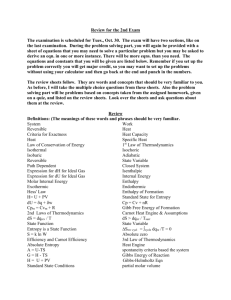

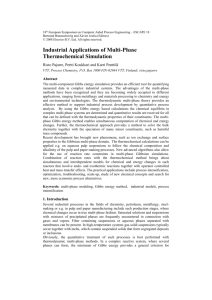

2.3. Affinity of a rate constrained reaction

Analogously with the equilibrium work terms it is possible to constrain the chemical

affinity of selected reactions of a multicomponent system. Thus the Gibbs energy

minimisation can be done for systems where one encounters metastable species or nonequilibrium constituents whose molar amounts are controlled by reaction rates. The

constraining by reaction rates is most practically performed by determining the extent of

a given reaction (r) from the experimental rate data (Koukkari and Niemelä 1997;

Perez-Cisneros et al. 1997). As this can be done incrementally for any reaction with

known reaction kinetics, the extent of reaction can be ‘frozen’ for any instant of time

while the min(G) procedure is performed for the whole system, as presented in Table 1.

The amount of the constraining component remains conserved during the minimisation,

while otherwise the system may reach equilibrium. In terms of affinities of the reactions

one may conclude that the affinity of fast (equilibrium) reactions becomes zero, while

the affinity of the constrained reaction results with a positive (non-zero) value until the

global equilibrium is reached (Fig. 3). Performing these calculations assumes local

chemical equilibrium to be valid for the homogeneous (well-stirred) system (or in

system that can be divided to such parts) and that the chemical relaxation rate is slow

compared with other relaxation times, including local heat exchange. The model results

can be validated by measured laboratory or process data.

5

R. Pajarre et al.

6

Gibbs free energy [kJ]

-1930

-1940

-1950

-1960

140

1

0.8

0.6

0.4

0.2

0

120

100

0

5

-1970

10 15 20 25

Time [ms]

Gibbs energy

-1980

Affinity

80

60

40

Affinity [kJ/mol]

Extent of reaction

-1920

-1990

20

-2000

-2010

0

0

5

10

15

20

25

Time [ms]

Figure 3. The reaction rate controlled oxidation reaction of TiCl 4 in the Ti-O2-Cl2 -system at 1360

C, showing the monotonically decreasing total Gibbs free energy and the affinity of the oxidation

reaction on the same time scale.

3. Conclusion

The constrained Gibbs energy applies to modeling of such systems as the

electrochemical Donnan equilibria in aqueous systems containing semi-permeable

interfaces, phase composition in surface-energy controlled systems and in systems with

affinities controlled by chemical reaction kinetics. The new method has been

successfully applied in calculating distribution coefficients for metal cations together

with pH-values in pulp suspensions, in calculation of surface tension of various

mixtures and in thermochemical process modelling involving chemical reaction rates. It

can be used in assessment of thermodynamic properties, service and design

applications, process scale-up, study of new chemical concepts and search for new,

more economic process alternatives.

References

R. A. Alberty, 2001, Use of Legendre transforms in chemical thermodynamics, Pure Appl.

Chem., 73(8), 1349-1380.

P. Koukkari, J. Niemelä, J, 1997, Time-dependent reactor simulation by stationary state

thermochemistry, Comput. Chem. Eng., 21(3), 245 – 253

P. Koukkari, R. Pajarre, 2006, Calculation of constrained equilibria by Gibbs energy

minimisation, Calphad, 30, 18-26.

P. Koukkari R. Pajarre, 2006, Introducing mechanistic kinetics to the Lagrangian Gibbs energy

calculation, Comput. Chem. Eng., 30(6-7), 1189-1196.

P. Koukkari, R. Pajarre, H. Pakarinen, 2002, Modelling of the ion exchange in pulp suspensions

by Gibbs energy minimisation, J. Solution Chem, 31 627-638.

5 R. Pajarre, P. Koukkari, T. Tanaka, J. Lee, Computing surface tensions of binary and ternary

alloy systems with the Gibbsian method, 2006, Calphad, 30,196-200.

E. Perez-Cisneros, R. Gani, M. L. Michelsen, Reactive Separation Systems. Part I: Computation

of Physical and Chemical Equilibrium, 1997, Chem. Eng. Sci., 52(4), 527-543.

M. Towers, A. M. Scallan, 1996, Predicting the ion-exchange of kraft pulps using Donnan theory,

J. Pulp Pap. Sci., 22, J332 – J337.