ARTICLES DF

advertisement

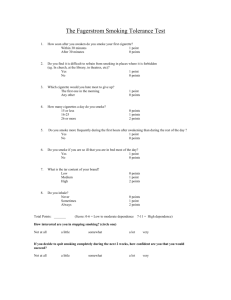

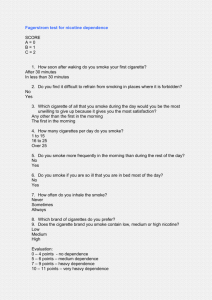

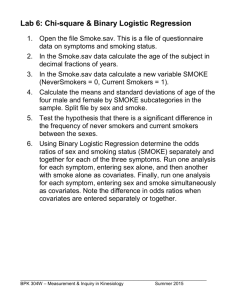

FRA28-- EN- ------ 20030916 --- --- PROJET DEFENCE AND CIVIL SAFETY DIRECTORATE CIVIL DEFENCE AND RISK PREVENTION SUB-DIRECTORATE Paris, dated Fire regulations and public risk office DDSC/SDDCPR/DDSC6/GO/N° Contact: Bernard Nouvier Tel.: + 33 1.56.04.75 87 Fax: + 33 1.56.04.76.00 Email: bernard.nouvier@interieur.gouv.fr ORDER OF approving provisions supplementing and amending the safety regulations to counter the outbreak of fire and panic in establishments open to the public (smoke clearance) The Minister for the Interior, Public Safety and Local Freedoms, Having regard to Directive 98/34/EC of the European Parliament and the Council of 22 June 1998 laying down a procedure for the provision of information in the field of technical standards and regulations and of rules on Information Society services, and in particular Notification No. Having regard to the Construction and Residential Dwellings Code, and in particular Article R 123-12 thereof; Having regard to the Order of 25 June 1980, amended, approving general provisions for safety regulations to counter the outbreak of fire and panic in establishments open to the public; Having regard to the opinion of the standing sub-committee of the Central Safety Commission; Hereby orders: Article 1: The amendments and additions made to the provisions of the safety regulations to counter the outbreak of fire and panic in establishments open to the public appended to this Order are approved. Article 2: The provisions of this Order enter into force three months after the date of its publication. Article 3: This Order will be published in the Official Journal of the French Republic. Done in Paris, on For the Minister for the Interior, Public Safety and Local Freedoms The Director of Civil Defence and Safety Senior Defence Official APPENDIX TO THE ORDER OF ARTICLES DF Article DF 1 Purpose of smoke clearance The purpose of smoke clearance is to extract some of the smoke and combustion gases present at the start of a fire in order to keep the escape routes provided for public use passable. Smoke clearance can also help to: - limit the spread of the fire, - facilitate the work of the emergency services. Article DF 2 Documents to be submitted In accordance with Article GE 2 (paragraph 2), the following documents must be submitted: - a plan showing: - the locations of smoke extraction and air inlet units, - the layout of ventilation networks, - the location of smoke extraction fans, - the location of controls. - an explanatory note detailing the technical characteristics of the various pieces of equipment. Article DF 3 Principles of smoke clearance 1. Smoke clearance can take place either naturally or mechanically using one of the following methods: - by clearing the space that is to be kept passable by forcing in fresh air and extracting smoke; - by a difference in air pressure between the area to be protected and the area in which the fire has occurred, with the pressure in the latter being lower; - or by a combination of these two methods. 2. While the public is still present and if a category A fire safety system (FSS) is being used, smoke clearance must be activated before automatic water extinguishers are put into operation in buildings with such a system. 3. Mechanical smoke clearance systems must be powered by a backup electrical feed (BEF) complying with French Standard NF S 61-940. However, where the particular provisions covering each type of establishment do not require an electrogenic group, the following systems may be powered directly from the main distribution panel of the building or establishment, subject to the conditions of Article EL14: - mechanical smoke clearance systems in first- and second-category establishments where the total power of the motors of the extraction fans in the two smoke clearance zones with the strictest requirements is less than10 kW; - mechanical smoke clearance systems in third- and fourth-category establishments. Where an electrogenic group is required or is present, the power required for smoke clearance must allow power to be supplied to the extraction and draught motors of the two smoke clearance zones with the strictest requirements. 4. Where a permanent or temporary pneumatic backup feed (PBF) is used to supply power to natural smoke clearance systems, the energy reserve of the safety source must be sufficient to render safe the two smoke clearance zones with the strictest requirements. 5. When smoke clearance starts, all mechanical ventilation apart from controlled mechanical ventilation (CMV) must be interrupted in the area concerned, unless it is being used for smoke clearance. Ventilation is interrupted by switching off the fans, which is done: - from the fire safety centraliser, using the smoke clearance control for the smoke clearance zone in question, in the case of a category A or B FSS; - from a control located close to or within the local smoke clearance control, in the case of a category C, D or E FSS. Where comfort ventilation has to be maintained, the interruption is achieved by closing the remote-control valves of the compartment in question. Article DF 4 Application 1. The provisions of this chapter apply to the types of establishments referred to in Title II, Book II of the safety regulations. They relate to: - the protection of stairs from smoke or clearing smoke from them, - the smoke clearance of corridors, - the smoke clearance of compartments, - the smoke clearance of rooms. Where appropriate, these provisions are specified in more detail in the specific provisions applying to each type of establishment. The technical instruction on smoke clearance in establishments open to the public describes the various smoke clearance options. 2. Engineering solutions for smoke clearance may be used, and must be covered by a note from a body recognised as competent by the Ministry of the Interior on advice from the Central Safety Commission. Having obtained the approval of the local safety sub-committee dealing with the outbreak of fire and panic, this note will specify the following parameters for the hypotheses and scenarios on which it is based: - the models and calculation codes used, - the evaluation criteria, - conclusions on the evaluation criteria. The documents relevant to the engineering solution for smoke clearance used and to this note must be present in the safety dossier referred to in Article GE2 of the regulations. 3. The equipment employed in the design of the smoke clearance system must comply with the texts and standards in force, particularly those relating to the fire safety systems referred to in Article MS 53. Moreover, the following equipment: - ventilators, - shutters, - controls, - relay boxes, must bear the NF [French standard] mark Article DF 5 Smoke clearance from stairs 1. In order to restrict or prevent smoke entering enclosed stairs, smoke clearance from these structures can take the form of natural clearance or increasing the air pressure in them relative to the adjacent area(s). Mechanical smoke extraction is not permitted. 2. Smoke clearance of non-enclosed stairs is not required if smoke clearance is not compulsory in the areas with which they communicate directly (floors, rooms, corridors etc.). If smoke clearance is carried out in these areas, the stairs must be separated from the floors below by means of smoke curtains and smoke clearance must be carried out at the top of the stairs via the area with which it communicates. 3. Smoke clearance is not required for stairs serving at most two floors below ground level. 4. Smoke clearance or protection from smoke is required for stairs serving more than two floors below ground level. This requirement does not apply to stairs serving car parks. Article DF 6 Smoke clearance of enclosed corridors and halls accessible to the public 1. In order to restrict or prevent smoke entering enclosed corridors, smoke clearance from these structures can take the form of natural or mechanical clearance. However, smoke clearance is required only in the following situations: - corridors with a total length above 30 metres; - corridors served by overpressurised stairs; - corridors serving bedrooms; - corridors in basements. 2. In accordance with Article CO 34 paragraph 1, halls are regarded as corridors. They are subject to the same smoke clearance requirements as rooms if: - smoke clearance is required for the corridors on that floor, - they cover an area of over 300 m2. 3. Under exceptional circumstances corridors can be overpressurised provided that smoke clearance is possible in all rooms served by these corridors. Smoke clearance is carried out at the same time only in the room in which the fire occurred. Article DF 7 Smoke clearance of rooms accessible to the public 1. Smoke clearance is carried out in basement rooms of over 100 m2, ground floor and upper floor rooms of over 300 m2 and in rooms of over 100 m2 that have no opening to the outside (door or window). This smoke clearance can take the form of natural or mechanical draught. 2. Where the specific provisions applicable to each type of establishment permit communication between up to three floors, the area thus created is regarded as a single room for the purposes of smoke clearance where the total surface area of the floors accessible to the public is greater than 300 m² . Article DF 8 Smoke clearance of compartments Smoke clearance of compartments as defined in Article CO 25, where they are permitted by the specific provisions applicable to each type of establishment, is carried out as follows: - if the compartment has full-height partitions (from floor to ceiling), smoke clearance is carried out of corridors of any length and of rooms as defined in Article DF 7; - if the compartment is of open-plan design, or has partitions that do not run the full height of the compartment, smoke clearance of the total area is carried out in accordance with the provisions specified for rooms. Article DF 9 Maintenance and operation Competent staff must periodically carry out the following operations: - maintenance of safety sources in accordance with the provisions of Article EL 18; - routine maintenance of mechanical and electrical components in accordance with the manufacturer's instructions; - maintenance of the safety system in accordance with the provisions of Article MS 68 and the manufacturer's instructions. Operating and maintenance rules are laid down in Article MS 69 and French standard NF S 61-933. Article DF 10 Technical inspections 1. Smoke clearance systems must be inspected as described in Articles GE 6 to GE 8. 2. Inspections are performed once a year and cover: - the operation of manual and automatic controls; - the operation of smoke clearance shutters, ventilators and openings; - the closure of mobile compartmentalisation elements which are involved in smoke clearance; - the shutdown of comfort ventilation referred to in Article DF 3 paragraph 5; - the operation of smoke clearance fans; - the pressure, flow and speed measurements in the case of mechanical smoke clearance. TECHNICAL INSTRUCTION 246. 1. Purpose Chapter IV, Title 1, Book II of the safety regulations of 25 June 1980 lays down the purpose, principles and obligations regarding smoke clearance in establishments open to the public. Where appropriate, these provisions are specified in more detail in the specific provisions applying to each type of establishment. The purpose of this instruction is to specify the implementation rules for the said smoke clearance by describing the solutions whereby: - stairs can be protected from smoke, or smoke clearance carried out in them; - smoke clearance can be carried out in corridors; - smoke clearance can be carried out in rooms accessible to the public. Smoke clearance solutions must be mutually compatible. This instruction does not rule out the option of adapting smoke clearance solutions described in chapters 3 to 7, provided that equivalent results are obtained and in particular that: - satisfactory clearance of the zone in question is achieved, - stratification and natural movement of smoke is not impeded. 2. Terminology The following definitions apply to this instruction: Smoke ventilator: smoke and heat evacuation device built into a structural element separating the inside of the building from the outside. This structural element shall have an angle of 30° or more from the vertical. Geometric area of a ventilator: opening area measured in the plane defined by the area of the opening at the point where it comes into contact with the structure of the ventilator. No restriction is applied for the area occupied by controls, slats or other obstructions. Ventilation coefficient: ratio of the effective flow, measured under specific conditions, to the theoretical flow of the ventilator (Vc).This coefficient takes account of blockages in the ventilator such as controls, slats, crosspieces etc. and the effect of side winds. Useful area of a ventilator: the geometric area multiplied by the ventilation coefficient. Façade smoke clearance opening: smoke and heat evacuation device or air inlet device built into a structural element separating the inside of the building from the outside. This structural element shall have an angle of 30° or more from the vertical. Geometric area of the smoke clearance opening: area freed by the opening at the level of the frame when it is in the open position. Free area of an opening: real area of airflow, less than or equal to the geometric opening area, taking account of any obstacles (opening mechanisms, grids, etc.) provided that the opening can open to an angle of at least 60° in the case of tipping openings (which are raised or lowered towards the inside or outside, horizontally or vertically) or pivoting openings (which pivot horizontally or vertically). In the case of sliding openings, the free area is the area freed by the sliding part. Calculated free area of an opening: free area obtained by applying the criteria of sheet VIII of French standard NF S 61-937. The vertical area between the upper part of the opening in the open position and the ceiling must be at least equal to the flat area between the opening and the frame, otherwise this vertical area is regarded as a flat area. The lateral triangles cannot be taken into consideration if there is a lateral obstacle at a distance less than half the height of the opening or if the space between openings is less than that same distance. This area is limited to the geometric area of the opening (fig. l). Useful area of an opening: area determined after testing and taking account of any deformation caused by a rise in temperature. However, until such time as a test method has been defined, the useful area will be obtained by applying a coefficient of 0.5 to the free area (or calculated free area) of the opening. Vent: orifice of an air inlet or smoke outlet conduit normally closed by a shutter. Geometric area of a vent: area freed by the shutter at the level of the frame when it is in the open position. Free area of a vent: real area of airflow, less than or equal to the geometric opening area, taking account of any obstacles (opening mechanisms, grids, etc.) Shutter: remotely-controlled closing device placed on the right of a smoke clearance vent served by a ventilation conduit. 3. Provisions relating to natural smoke clearance 3.1. Operating principles Natural draught smoke clearance is achieved by the natural evacuation of smoke and intake of air communicating either directly or by conduits with the outside and arranged in such a way as to ensure satisfactory clearance of the area in question. 3.2. Smoke extraction Smoke extraction is achieved by: - façade openings; - ventilators; - or vents. No opening may have any dimension less than 0.20 m. 3.3. Air intake Air intake is achieved by: - façade openings; - doors of rooms where smoke clearance is to be achieved that give on to the outside or onto areas which can be well ventilated; - non-enclosed stairs; - or vents. No opening may have any dimension less than 0.20 m. Mechanical air intake is permitted under exceptional circumstances but only in association with ventilator extraction. The fans must comply with the conditions laid down in paragraph 4.7 and the airflow to the vents must not exceed 5 m/s. 3.4. Features of conduits 3.4.1. Conduits must comply with the following provisions: - their cross-section must be at least equal to the free area of the vents which they serve on each floor; - the ratio of the largest to the smallest dimension of their cross-section must be less than or equal to 2. 3.4.2. Vertical extraction conduits can have up to two bends of not more than 20 degrees from the vertical. The length of horizontal storey joints of extraction conduits must not exceed 2 m unless the flow is shown to be adequate. This is demonstrated by calculating the flow when the smoke temperature is 70°C, the outside temperature is +15°C and there is no wind. 3.4.3. The conduits must be made of M0 or A2 s2 d0 category materials and fireproof for 15 minutes. Air intake conduits are ventilation conduits and if they cross other rooms their crossing fireproof capacity must be equal to the fireproof capacity of the room's walls. Smoke extraction conduits are smoke clearance conduits and are tested by an internal fire. Their fire resistance action must last for at least as long as the fireproof capacity of the wall which they cross. These requirements can be met by the duct in which they are housed provided that nothing else is housed within this duct and that the duct is equally as fire-resistant as the walls which are crossed. 3.5. Siting smoke extraction and air intake devices 3.5.1. Where possible, air intake and smoke extraction devices must be sited taking account of the direction of the prevailing winds. Smoke extraction devices must be sited in such a way that no structural element or fitting impedes the removal of smoke. 3.5.2. The outlets of ventilators and extraction conduits must be outside the covered parts for which particular protection is required under Article CO 7. Furthermore, these outlets must be located at least 4 metres in a horizontal orientation from structural openings of other buildings. If it is not possible to respect these distances, all measures (such as the construction of a canopy roof, for example) shall be taken to prevent fire spreading. 3.5.3. The distance between the outlets of ventilators and natural smoke clearance conduits from obstacles higher than themselves must be at least equal to the height of the obstacles. However, the maximum height requirement is set at 8 metres. 3.5.4. Exterior fresh air inlets may not be located in an area likely to become smokelogged. 3.6. Features of smoke clearance devices 3.6.1. Smoke clearance ventilators, shutters and openings must comply with French standard NF S 61 -937. 3.6.2. Manual controls must allow ventilators, openings or shutters to be opened in the smoke clearance zone in question (floor, room, section, compartment, corridor or part of corridor affected). Where smoke extraction and air intake are brought about by means of a activated safety device (ASD), they must be opened simultaneously from the same unit that houses the control device. Where dedicated pneumatic backup feed (PBF) control devices are used for smoke clearance in a section larger than 500 m2, it must be possible to activate these by a single manual operation on a safety unit. Where single-use PSF control devices connected to the "opening and closing" networks are used, it must be possible to switch them to 'stand-by' and 'reset' mode without handling the cartridges after opening or closing them (automatic-purge systems). When a category A or B FSS is in use, the manual controls must be activated from the fire safety centraliser (FSC) that complies with French standard NF S 61-934. When a category C, D or E FSS is in use, the manual controls must be given from the alarm control unit (ACU), manual control group unit (MCGU) or manual control unit (MCU) complying with French standard NF S 61-938. MCUs must be located close to the main entrance to the area(s) concerned. 3.6.3. Where required by regulatory provisions, smoke clearance of the smoke clearance zone (SCZ) must be activated automatically by the fire detection system installed in the relevant area. This automatic activation is backed up by the manual controls of the centralised manual control unit (CMCU) of the FSC. Automatic activation of the smoke clearance devices of the other parts of the building served by the same smoke clearance network is neutralised until the original cause of the fire has been dealt with. However, it must be possible to activate smoke clearance of the other parts of the building manually from the CMCU. 3.6.4. In normal operation, it must be possible to reset (close) the ventilators, openings or shutters from the ground of the smoke clearance zone or room, in the case of rooms divided into various sections. 3.7. Features of vents and shutters 3.7.1. Vents must be closed by flame-resistant shutters in the case of air intake vents and by fireproof shutters in the case of smoke extraction vents, and their resistance to fire must be at least equal to that of the conduits. These shutters are closed when in the inactive position. However, no fire-resistance requirements apply to shunt conduits. Conduits serving only one floor are not required to have shutters; if they do, the shutters are not subject to any fire resistance requirements. 3.7. 2. The ratio of the largest to the smallest dimension of a vent must be less than or equal to 2. 3.8. Features of ventilators The features specified below for ventilators are defined with reference to future European standards. They apply as from the end of the transition period laid down in the orders referred to in Article 1 of Order 92-647 (amended) on the suitability for use of construction products dealing with these materials. In the meantime, the provisions of Article GN 14 apply. Ventilators shall be of reliability class Re 300 (300 safety cycles). Dual-function ventilators used to provide comfort ventilation undergo 10,000 opening in ventilation position tests. The snow overload classification is SL 250 (25 daN/ m2) for altitudes of 400 m or less and SL 500 (50 daN/ m2) for altitudes over 400 m and less than or equal to 800 m. However, the SL 0 class may be used if the region in which the ventilator is to be sited is not likely to experience snowfall or if design features prevent snow accumulating (such as an angle of > 45° between the slope of the ventilator and the roof slope, or a snow-bearing device for sliding lock paddle devices). At altitudes above 800 m, class SL 500 ventilators must be used and installed with design features preventing the accumulation of snow. Ventilators shall be of ambient temperature class T00 (0°C) and heat exposure class B 300 30. (300° for 30 minutes) 3.9. Windows and doors used for smoke clearance Doors used to provide a natural intake of air can be activated directly. In addition, in some rooms the windows can be opened by directly activating their manipulation device where this is provided for by the specific provisions. These devices are not ASDs as defined by NF S 61 -937. 4. Provisions relating to mechanical smoke clearance 4.1. Operating principle 4.1.1. Mechanical draught smoke clearance takes the form of mechanical smoke extraction and natural or mechanical air intake arranged in such a way as to ensure that the area in question is cleared. The relative air pressure of the areas to be protected from smoke can be increased as an additional measure. 4.1.2.If a room is permanently ventilation (air renewal, heating or air conditioning), its ventilation system may be used for smoke clearance if it meets the provisions of this chapter. The fan network may contain sound traps or filters under the conditions laid down in Articles CH 32 and CH 38. 4.2. Smoke extraction Smoke is extracted by vents connected to an extraction ventilator. 4.3. Air intake 4.3.1. Mechanical air intake is provided by vents connected to a draught fan. 4.3.2. Natural air intake is provided by: - façade openings; - the doors of rooms from which smoke is to be cleared giving on to the outside or onto areas which can be well ventilated; - non-enclosed stairs; - or vents. 4.4. Features of conduits Natural air intake conduits must have the features described in paragraph 3.4. Mechanical extraction conduits and air intake conduits must have the features described in paragraph 3.4.3. They must also be sufficiently airtight. To this end their total leakage rate must not exceed 20% of the rate required on the most unfavourable floor. Collective extraction conduits must be underpressurised. 4.5. Siting of smoke extraction and air intake units Smoke extraction and air intake units are sited in accordance with the provisions laid down in paragraphs 3.5.1.,3.5.2 and 3.5.4 for natural draught smoke clearance. 4.6. Vents and shutters 4.6.1. The speed at which air reaches the air intake units must not exceed 5 m/s. The dimensions of natural air intakes must be proportional to the total extraction flow rate. Mechanical air intake units must have a flow rate of around 0.6 times the extraction flow rate. 4.6.2. These vents are fitted with shutters that are closed in the inactive position and that meet the provisions laid down in paragraph 3.7.1. 4.7. Features of fans 4.7.1. The dimensions of draught and extraction fans must be proportional to the features of the network they serve and to a flow rate equal to the nominal flow rate plus the tolerable flow rate (around 20%). The flow rates defined in this technical instruction are measured at ambient temperature. The fans must be controlled by a relay box complying with French standard NF S 61.937. 4.7.2. Extraction fans and their connections with the conduits must operate reliably for one hour in the presence of smoke at 400°C, or must be classified F400 90. The connection between the extraction fans and the conduit must be made of M0 or A2 s2 d0 category material. These requirements do not apply to draught fans. 4.7.3. The 'open' or 'closed' status of the fan section switch must be reported to the control room or a place which is normally under supervision. This requirement is met by the relay box. 4.7.4. The supply lines feeding the smoke clearance fans must comply with the provisions laid down in Articles EL. 4.7.5. The extraction fans must be installed either outside the building or in a technical room separated from the adjacent areas by walls that are fireproof for one hour. The entrance door will be fireproof for 30 minutes and fitted with a door closer. The ventilation of the room will be compatible with the operation of the various materials contained within it. 4.8. Controls Controls must be constructed in accordance with the provisions laid down in paragraph 3.6 for natural draught smoke clearance. They must also ensure that the fans are activated, with a delay time of no more than 30 seconds to allow ASDs (shutters and doors) to be activated for smoke clearance and compartmentalisation of the smoke clearance zone. 4.9. Stopping the fan French standard NF S 61-932, paragraph 8.4.3, requires each smoke clearance fan to be capable of being stopped from the location where its manual safety mode control is located. Access level II (as defined in French standard NF S 61-931) is required to obtain this function. 5. Solutions applicable to enclosed stairs 5.1. Smoke clearance by natural clearance Natural clearance of a staircase is achieved by opening a ventilator with a geometric area of 1 m2 or a smoke clearance opening of an identical free area in the upper part of the stairwell and an air intake as defined in paragraph 3.3 of an equal area in the lower part of the stairwell (fig. 2). The control for this smoke clearance system is located at the bottom level of the stairwell. In normal operation, it must be possible to reset (close) it from the bottom level of the stairwell or from the last landing. If the air intake is provided by a door, this is not an ASD in smoke clearance terms. When under exceptional circumstances natural smoke clearance is impossible, the air pressure on the stairs must be increased by mechanical draught, which must be accompanied by smoke clearance of the area in direct communication with the stairs. The increase in pressure must be carried out at the same time as the smoke clearance of that area, and activated by the smoke clearance control. (fig. 3) The difference in pressure must be between 20 and 80 Pa with all the doors leading off the stairs closed. The flow rate must be such as to ensure that air travels at 0.5 metres per second or faster through the door giving on to the floor where the fire is burning, the doors of the other floors remaining closed. 6. Solutions applicable to enclosed corridors 6.1. Smoke clearance by natural clearance Natural smoke clearance of enclosed corridors must take place under the conditions laid down in paragraph 3, in accordance with the following rules: - air intake and smoke extraction devices are alternated, either staggered or in a straight line, and sited in accordance with the location of risks. There are at least as many air intake devices as extraction devices. The horizontal distance between an air intake device and a smoke extraction device, measured in line with the axis of travel, may not exceed 10 m (when the devices are placed in a straight line) or 7 m (when they are not placed in a straight line). Where one smoke extraction vent is served by two air intake vents, the distances between the vents shall be broadly similar (fig. 4); - all doors of rooms accessible to the public that are not located between an air intake device and a smoke extraction device must not be more than 5 m of one such device; - each air intake and smoke extraction device have a minimum free area of 10 dm2 per completed corridor passage unit (complete PU rounded up to the nearest value); - the top of the air intake vents must be no more than 1 m above the floor, and shall ideally be located near to the intersection doors and the stair access doors; - the bottom of the smoke extraction vents must be at least 1.80 m above the floor and be entirely within the upper third of the corridor; - extraction vents may be replaced by ventilators or façade smoke clearance openings with a geometric area equal to the free area of the vents. Their controls must comply with the provisions of paragraph 3.6.2. - it is not permitted for several corridors or sections of corridors on a single floor to be served by the same network unless they constitute a single smoke clearance zone. 6.2 Mechanical smoke clearance Mechanical smoke clearance of enclosed corridors must be achieved as described below under the conditions laid down in paragraph 4: - air intake and smoke extraction vents are alternated, either staggered or in a straight line, and sited in accordance with the location of risks; - the horizontal distance between an air intake device and a smoke extraction device, measured in line with the axis of travel, may not exceed 15 m (when the devices are placed in a straight line) or 10 m (when they are not placed in a straight line). Where one smoke extraction vent is served by two air intake vents, the distances between the vents shall be broadly similar ; - all doors of rooms accessible to the public that are not located between an air intake device and a smoke extraction device must not be more than 5 m of one such device; - the top of the air intake vents must be no more than 1 m above the floor, and shall ideally be located near to the intersection doors and the stair access doors. If openings are used to provide air intake, the free area of these openings taken into consideration must be in the lower half of the room; - the bottom of the smoke extraction vents must be at least 1.80 m above the floor and be entirely within the upper third of the corridor; - all sections of corridors located between a smoke extraction vent and an air intake vent must be cleared by an extraction flow of at least 0.5 m³/s per completed corridor passage unit (complete PU rounded up to the nearest value); however, the total extraction flow in a corridor (or part of a corridor in the case of corridors with intersections) shall not exceed 8 m3/s) (fig. 6); - when the smoke clearance system is in operation, the difference in pressure between the stairwell and the corridor from which smoke is being cleared must not exceed 80 Pa with all the doors to the stairs closed; - it is not permitted for several corridors or sections of corridors on a single floor to be served by the same network (conduits and fans) unless they constitute a single smoke clearance zone 7. Solutions applicable to rooms with public access 7.1. Natural smoke clearance of rooms 7.1.1. Terminology The concepts 'useful smoke extraction area' and 'smoke clearance section' are used when discussing natural smoke clearance of rooms. The following definitions apply (fig.7): Smoke curtain: vertical separating element placed underneath the roof or ceiling to prevent smoke and combustion gases drifting sideways. Smoke curtains may be penetrated by pipework or appliances with the necessary tolerance for play. Smoke clearance section: free area between the floor and the ceiling or roof and within the smoke curtains. Surface area of a smoke clearance section: surface area obtained by horizontal projection of the volume of the section. Reference height (H): arithmetic mean of the heights of the highest and lowest points of the roof, ceiling or suspended ceiling measured from the upper surface of the floor. The suspended ceiling is ignored if more than 50% of it allows free passage and if no more than 50% of the space between the roof and the suspended ceiling is occupied. The smallest dimension of the orifices in the suspended ceiling is 5 mm. (fig. 8 and 9) Smoke-free height (SFH): height of the zone located below the smoke curtains, or in the absence of a curtain below the layer of smoke and compatible with use of the room. Thickness of the smoke layer (TSL): difference between the reference height and the smoke-free height. 7.1.2 Smoke clearance sections and smoke curtains Room smoke clearance systems must comply with the following rules, in addition to the provisions relating to natural smoke clearance defined in paragraph 3: - rooms with a surface area of over 2,000 m2 or that are more than 60 m long are divided into smoke clearance sections that are as evenly sized as possible, with a maximum surface area of 1,600 m2. The length of each section may not exceed 60 m. Ideally the minimum surface area of these sections shall be 1,000 m². Sections are divided by smoke curtains or by the configuration of the room and the roof, - the lower edge of the curtain is normally horizontal. However, where the slope of the roofs and ceilings exceeds 30°, smoke curtains must not impede the natural flow of smoke but rather channel it towards the ventilators. If the curtains run parallel to the slope, their smallest height will be regarded as the thickness of the smoke layer (fig. 10). Furthermore, smoke curtains must impede the movement of smoke towards chutes connecting various floors unless these chutes are involved in smoke clearance. Smoke curtains are made up of: - structural elements (roofs, beams, doors), - permanently installed rigid or flexible screens with 15 minutes or DH 30 fire resistance and made of Ml or B s3 d0 category material, - or mobile (ASD) rigid or flexible screens with 15 minutes or DH 30 fire resistance and made of Ml or B s3 d0 category material. The smoke-free height is at least equal to half the reference height; it is always higher than the door lintel and never lower than 1.80 m. The thickness of the smoke layer is at least equal to: - 25% of the reference height (H) where this is less than or equal to 8 m, - 2 m where the reference height is greater than 8 m. However, this thickness can be reduced in order to respect minimum smoke-free heights. This reduction means that the smoke extraction area must be increased and the rate of α (see appendix) must be calculated. Smoke curtains are not required for rooms with a reference height above 8 m and where the largest dimension does not exceed 60 m. In this case, the rate α is calculated with a smoke thickness layer of one metre. 7.1.3 Siting smoke extraction devices No point in a section whose roof or ceiling slope is less than or equal to 10% may be more than four times the reference height away from a smoke extraction device in a horizontal direction (up to a maximum distance of 30 metres). At least one smoke extraction device must be provided per 300 m2 of surface area. In sections whose roof or ceiling slope is greater than 10%, smoke extraction devices must be sited as high up as possible, and their central point may not be below the building's reference height. Where a roof has two opposing panes (with the exception of double-ridged roofs), ventilators must be sited evenly on each pane. 7.1.4. Calculating the useful area of smoke extraction devices needed to clear smoke from a room The areas taken into consideration for smoke extraction must be located in the smokelogged zone. The areas taken into consideration for the air intake devices must be located in the smoke-free zone. The distribution of the air intake devices must ensure that the room is properly cleared. 1) Rooms with a surface area of up to 1,000 square metres For smoke clearance of a room up to 1,000 m2, the useful area of the smoke extraction devices must correspond to one two-hundredth of the surface area of the room measured in horizontal projection. However, this area can be limited to the value of the useful area calculated using the table in the appendix for a room of 1,000 m2 with the same reference height and smoke thickness. The total free area of air intake devices in a room must be at least equal to the geometric area of the smoke extraction devices in that room. Where specific provisions require a smoke clearance system for a room with a surface area of less than 300 m2, a window can be regarded as an air intake and/or smoke extraction vent; the free area taken into consideration for smoke extraction must be in the upper half of the room and more than 1.80 m from the floor. The free area taken into consideration for air intake must be outside the zone defined above for smoke extraction. 2) Rooms with a surface area greater than 1,000 square metres The useful area of smoke extraction devices is determined by the type of operation (which affects the area of the fire) in the light of the reference height (H) and the thickness of the smoke layer (TSL). This area is calculated by multiplying the surface area of each section by a rate α (as a percentage); it can never be less than that calculated for a 1,000 m2 section. A table of values for this rate α and the two formulae which can be used to calculate it are given in the appendix. If the roof (or suspended ceiling) of a section is horizontal but of uneven height, the useful area is calculated for each section, taking the height of the highest part of the section as the reference height. The useful area of the extraction devices located in the other parts is corrected under the conditions laid down in point 3 of this paragraph (fig. 12). In rooms containing only one section, the total free area of the air intake devices must be at least equal to the total geometric area of the smoke extraction devices. In the case of rooms divided into several sections, air intake may come via the peripheral sections. The free area of the air intake devices must be at least equal to the sum of the geometric areas of the smoke extraction devices of the two sections requiring the largest useful extraction areas. 3) Correction of useful smoke extraction areas for rooms larger than 1,000 square metres The useful area of a ventilator must be decreased or increased by applying an efficiency coefficient depending on whether the ventilator is located below or above the reference height (fig. 13). In the latter case, the length of any vertical connecting conduits is limited to 10 hydraulic diameters unless a greater length is justified by calculation. (Hydraulic diameter = 4 x cross-section of the conduit / perimeter of the conduit). This efficiency coefficient (e) depends on the thickness of the smoke layer (TSL) and the difference in the height (ΔH) (positive or negative) at which the ventilator is sited compared to the reference height, worked out as follows: e = (l+ΔH/TSL) 1/2 The same efficiency coefficient applies to the useful area of extraction vents. For façade openings, this efficiency coefficient applies to the useful area of the opening located in the smokelogged zone; the value ΔH represents the difference in level between the reference height and the average of the highest and lowest points of the part of the opening located in the smokelogged zone. When the only smoke clearance devices in a room are façade openings located at the same height, this correction serves no purpose if the average of the highest and lowest points is regarded as the reference height (Fig 15). 7.1.5. Smoke clearance of spaces created by communication between up to three floors Smoke extraction devices must be perpendicular to the communication chutes. No smoke curtain may impede the flow of smoke towards these chutes. The useful area of the smoke extraction devices is calculated, for the lowest floor, using the same rules as those laid down for rooms with an area of more than 1,000 square metres, with the coefficient α being determined for the total height of the space thus created and the smoke thickness tolerated on the highest floor (fig.16). 7.2. Mechanical smoke clearance of rooms 7.2.1 Smoke clearance sections and smoke curtains Where mechanical draught smoke clearance is used in rooms accessible to the public, it must be carried out under the following conditions: - the rooms are divided into sections under the same conditions as for natural smoke clearance (paragraph 7.1.2); - the height of smoke curtains must be at least equal to: - 25% of the reference height where this is less than or equal to 8 m, - 2 m where the reference height is greater than 8 m. - smoke curtains are not required for rooms with a reference height above 8 m and where the largest dimension does not exceed 60 m: in this case, the extraction flow rate is calculated for the entire space. 7.2.2 Siting extraction vents No point in a section whose roof or ceiling slope is less than 10% may be more than four times the average height below the ceiling away from a smoke extraction device in a horizontal direction. The ground surface area served by a vent may not have an elongated form; the length to width ratio of this area may not exceed 2. In sections whose roof or ceiling slope is greater than 10%, smoke extraction devices must be sited as high up as possible. 7.2.3 Flow rate calculation rules The hourly extraction rate is at least 12 times the volume of the section. The maximum extraction rate is 3 m3/s for 100 m2. It is never less than 1.5 m3/s per room, except in the case of waiting rooms as defined in Article AS 4. One fan can serve up to the total number of vents in two sections; in this situation its flow rate can be reduced to that required for the largest section. Air intake is provided either mechanically or naturally, and may come from the peripheral sections. 7.2.4. Smoke clearance of spaces created by communication between up to three floors Mechanical smoke clearance is calculated on the basis of the flow rates recommended in paragraph 7.2.3. and relate to: - the total space, with smoke extraction vents sited perpendicular to the communication chutes and no smoke curtain impeding the flow of smoke, - or each floor, with the floors being insulated from the common chute by smoke curtains. 7.2.5. Mechanical smoke clearance system shared by several rooms a) Smoke clearance may be carried out for two rooms on the same floor separated by fire-resistant walls by means of a single mechanical smoke clearance system. The minimum flow rate must be equal to or greater than the flow rate corresponding to the smoke clearance of the larger of these rooms. The smoke clearance network must respect the fire-retardant insulation between the rooms. b) Smoke clearance may be carried out for several rooms on the same floor separated by fire-resistant walls by means of a single mechanical smoke clearance system. The minimum flow rate must be equal to or greater than the flow rate corresponding to the simultaneous smoke clearance of the two largest rooms. The smoke clearance network must respect the fire-retardant insulation between the rooms. c) Where a smoke clearance system serves several floors, the smoke clearance flow rate is calculated for the largest floor. d) The air intake devices in each room comply with paragraph 7.2.3. 7.3. Compatibility between natural and mechanical smoke clearance The use of natural smoke clearance systems and mechanical smoke clearance in different ZFs of a single establishment is permitted. The mechanical smoke clearance system must never be activated if it does not operate to clear smoke from the ZF where the fire has occurred. 8. Rules on engineering smoke clearance solutions Engineering solutions may be used as an alternative to the quantitative rules laid down in chapters 3 to 7 to determine the features of the smoke clearance systems. These features must be such as to allow the smoke clearance objectives laid down in Article DF1 of the safety regulations to be met. For example, routes are considered practicable if the following conditions are met: - the smoke-free height is sufficient (this height is at least equal to half the reference height, is always higher than the door lintel and is never lower than 1.80 m); - the heat flow reaching people is bearable. This engineering solution must allow the evolution of smoke-related phenomena to be simulated and controlled by natural and/or mechanical ventilation smoke clearance systems. It must include: - a detailed presentation of all the hypotheses, parameters and quantitative data used, - the conduct of simulations showing adequate smoke control for some clearly defined values of the quantitative parameters relating to the smoke clearance systems used in these simulations. - a presentation of the simulation results and conclusions as to the efficacy of the recommended smoke clearance systems. Finally, the features of the smoke clearance system not taken into consideration in the engineering solution (particularly the features of the materials used) must comply with the provisions recommended in chapters 3 to 7. The competent authorities may require on-site tests to be performed to validate the features of the chosen smoke clearance systems. APPENDIX Determination of the useful opening area of a ventilator or smoke clearance system (Application of paragraph 7.1.4 point 2 relating to rooms larger than 1,000 square metres) Where chapters of specific provisions for different types of establishment require smoke clearance, the rooms for which smoke clearance is required are classified as follows, taking account of the likely size of the seat of a fire: Class 1 Facilities for the elderly and disabled; Concert halls, conference halls, meeting rooms, rooms for associations, rooms used by residents' associations, rooms used to show films, auditoria with a stage area that can be insulated; Restaurants, cafés, bars and other catering outlets; Hotels, guest-houses, bed and breakfast operations; Communal areas of flats; Amusement arcades; Educational establishments; Medical establishments; Religious establishments; Public- and private-sector offices, banks; Indoor sporting establishments; Museums. Class 2 Auditoria with integrated stage areas containing props made of M0 or Ml materials; Multi-purpose rooms; Clubs; Dance halls or discotheques. Class 3 Auditoria with integrated stage areas containing props made of M2 materials or M3 wood; Retail outlets, shopping centres and their walkways; Libraries, record offices and archive reading rooms; Exhibition rooms and halls. Table of rates (as percentages) used to determine the useful opening area of a ventilator or smoke clearance system Values of α for smoke layer thicknesses or for average floor-to-ceiling heights that differ from those in the table are obtained by liner interpolation (working from the thickness of the smoke layer) or by calculation using the two formula given below. Extrapolation is not permitted. Average floor-to- Smoke-free ceiling height (m) height (m) Thickness of the Rate α as a percentage smoke layer (m) Class 1 Class 2 Class 3 2.50 2.00 0.50 0.23 0.33 0.47 3.00 2.25 2.00 0.75 1.00 0.23 0.17 0.32 0.23 0.46 0.33 3.50 2.65 2.50 2.00 0.85 1.00 1.50 0.27 0.23 0.14 0.39 0.33 0.19 0.55 0.46 0.27 4.00 3.00 2.50 2.00 1.00 1.50 2.00 0.30 0.19 0.12 0.43 0.27 0.17 0.61 0.38 0.23 4.50 3.40 3.00 2.50 2.25 1.10 1.50 2.00 2.25 0.35 0.25 0.16 0.13 0.49 0.35 0.23 0.19 0.70 0.50 0.33 0.26 5.00 3.75 3.50 3.00 2.50 1.25 1.50 2.00 2.50 0.38 0.31 0.21 0.15 0.54 0.44 0.30 0.21 0.76 0.63 0.43 0.29 5.50 4.15 4.00 3.50 3.00 2.75 1.35 1.50 2.00 2.50 2.75 0.43 0.38 0.27 0.19 0.16 0.60 0.54 0.38 0.27 0.23 0.85 0.76 0.54 0.38 0.32 6.00 4.50 4.00 3.50 3.00 1.50 2.00 2.50 3.00 0.46 0.33 0.24 0.18 0.64 0.47 0.34 0.25 0.91 0.66 0.48 0.35 6.50 4.90 4.50 4.00 3.50 3.25 1.60 2.00 2.50 3.00 3.25 0.50 0.39 0.30 0.22 0.19 0.71 0.56 0.42 0.31 0.27 1.00 0.79 0.59 0.44 0.38 7.00 5.25 5.00 4.50 4.00 3.50 1.75 2.00 2.50 3.00 3.50 0.53 0.46 0.35 0.27 0.20 0.75 0.65 0.50 0.38 0.29 1.06 0.92 0.71 0.54 0.41 7.50 5.65 5.50 5.00 4.50 4.00 3.75 1.85 2.00 2.50 3.00 3.50 3.75 0.58 0.53 0.41 0.32 0.25 0.22 0.82 0.75 0.59 0.46 0.35 0.31 1.16 1.07 0.83 0.64 0.50 0.44 Average floor-to- Smoke-free ceiling height (m) height (m) Thickness of the Rate α as a percentage smoke layer (m) Class 1 Class 2 Class 3 8.00 6.00 5.50 5.00 4.50 4.00 2.00 2.50 3.00 3.50 4.00 0.61 0.48 0.38 0.30 0.23 0.86 0.67 0.53 0.42 0.33 1.22 0.95 0.76 0.60 0.47 8.50 6.50 6.00 5.50 5.00 4.50 4.25 2.00 2.50 3.00 3.50 4.00 4.25 0.69 0.54 0.44 0.35 0.28 0.25 0.97 0.77 0.62 0.49 0.39 0.35 1.37 1.09 0.87 0.70 0.56 0.50 9.00 7.00 6.50 6.00 5.50 5.00 4.50 2.00 2.50 3.00 3.50 4.00 4.50 0.85 0.61 0.50 0.40 0.33 0.26 1.08 0.87 0.70 0.57 0.46 0.37 1.53 1.23 0.99 0.81 0.65 0.53 9.50 7.50 7.00 6.50 6.00 5.50 5.00 4.75 2.00 2.50 3.00 3.50 4.00 4.50 4.75 0.95 0.76 0.56 0.46 0.38 0.31 0.28 1.20 0.97 0.79 0.65 0.53 0.44 0.39 1.70 1.37 1.12 0.92 0.75 0.62 0.56 10.00 8.00 7.50 7.00 6.50 6.00 5.50 5.00 2.00 2.50 3.00 3.50 4.00 4.50 5.00 1.05 0.85 0.70 0.52 0.43 0.36 0.29 1.32 1.07 0.88 0.73 0.61 0.50 0.41 1.87 1.52 1.25 1.04 0.86 0.71 0.59 10.50 8.50 8.00 7.50 7.00 6.50 6.00 5.50 5.25 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.25 1.16 0.94 0.77 0.64 0.48 0.41 0.34 0.31 1.45 1.18 0.98 0.82 0.69 0.57 0.48 0.43 2.05 1.67 1.39 1.16 0.97 0.81 0.67 0.61 11.00 9.00 8.50 8.00 7.50 7.00 6.50 6.00 5.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 1.27 1.04 0.86 0.72 0.60 0.46 0.38 0.32 1.58 1.30 1.08 0.91 0.77 0.65 0.54 0.46 2.23 1.83 1.53 1.28 1.08 0.91 0.77 0.64 Average floor-to- Smoke-free ceiling height (m) height (m) Thickness of the Rate α as a percentage smoke layer (m) Class 1 Class 2 Class 3 11.50 9.50 9.00 8.50 8.00 7.50 7.00 6.50 6.00 5.75 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 5.75 1.39 1.14 0.95 0.79 0.67 0.57 0.43 0.37 0.34 1.71 1.41 1.18 1.00 0.85 0.72 0.61 0.52 0.48 2.42 2.00 1.67 1.42 1.20 1.02 0.87 0.73 0.67 12.00 10.00 9.50 9.00 8.50 8.00 7.50 7.00 6.50 6.00 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00 1.52 1.25 1.04 0.88 0.74 0.63 0.54 0.41 0.35 2.06 1.53 1.29 1.10 0.94 0.80 0.69 0.58 0.50 2.62 2.17 1.82 1.55 1.32 1.13 0.97 0.83 0.70 12.50 10.50 10.00 9.50 9.00 8.50 8.00 7.50 7.00 6.50 6.25 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00 6.25 1.66 1.36 1.14 0.96 0.82 0.70 0.60 0.51 0.40 0.37 2.22 1.84 1.40 1.19 1.03 0.88 0.76 0.65 0.56 0.52 2.81 2.34 1.98 1.69 1.45 1.25 1.07 0.92 0.79 0.73 13.00 11.00 10.50 10.00 9.50 9.00 8.50 8.00 7.50 7.00 6.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00 6.50 1.80 1.48 1.24 1.05 0.90 0.77 0.66 0.57 0.49 0.38 2.39 1.99 1.68 1.29 1.12 0.97 0.84 0.72 0.63 0.54 3.02 2.52 2.14 1.83 1.58 1.37 1.18 1.02 0.88 0.76 13.50 11.50 11.00 10.50 10.00 9.50 9.00 8.50 8.00 7.50 7.00 6.75 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00 6.50 6.75 1.95 1.61 1.35 1.15 0.99 0.85 0.73 0.63 0.55 0.47 0.39 2.56 2.14 1.81 1.56 1.21 1.05 0.92 0.80 0.69 0.60 0.56 3.23 2.70 2.30 1.98 1.71 1.49 1.30 1.13 0.98 0.85 0.79 Average floor-to- Smoke-free ceiling height (m) height (m) Thickness of the Rate α as a percentage smoke layer (m) Class 1 Class 2 Class 3 14.00 12.00 11.50 11.00 10.50 10.00 9.50 9.00 8.50 8.00 7.50 7.00 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00 6.50 7.00 2.10 1.74 1.47 1.25 1.08 0.93 0.80 0.70 0.61 0.53 0.46 2.75 2.29 1.95 1.68 1.46 1.14 1.00 0.87 0.76 0.67 0.58 3.44 2.89 2.46 2.13 1.85 1.61 1.41 1.24 1.08 0.94 0.82 14.50 12.50 12.00 11.50 11.00 10.50 10.00 9.50 9.00 8.50 8.00 7.50 7.25 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00 6.50 7.00 7.25 2.26 1.88 1.59 1.36 1.17 1.01 0.88 0.77 0.67 0.58 0.51 0.47 2.94 2.46 2.09 1.80 1.57 1.37 1.08 0.95 0.84 0.73 0.64 0.60 3.66 3.08 2.63 2.28 1.99 1.74 1.53 1.35 1.18 1.04 0.91 0.85 15.00 13.00 12.50 12.00 11.50 11.00 10.50 10.00 9.50 9.00 8.50 8.00 7.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00 6.50 7.00 7.50 2.43 2.03 1.72 1.47 1.27 1.10 0.96 0.84 0.73 0.64 0.56 0.49 3.14 2.63 2.24 1.94 1.69 1.48 1.30 1.03 0.91 0.80 0.71 0.62 3.88 3.27 2.81 2.44 2.13 1.88 1.65 1.46 1.29 1.14 1.00 0.88 Calculating rate α Rate α, used to determine the useful area of a ventilator or smoke extraction system, is a function dependent on the area of the fire (Af), the average height below the ceiling (H) and the thickness of the smoke layer (TSL). The figures used for the area of the fire are: - 9 m2 for class 1, - 18 m2 for class 2, - 36 m2 for class 3. If the thickness of the smoke is greater than half the reference height, the calculation is performed for: TSL = H 2 This rate can be calculated according to two formulae. The first, for large fires, is: α1= 0.13 4 Af ( H TSL)3 0.6 16 TSL The second, for small fires, is: α2= 0.043 ( H 1.5 Af TSL)5 / 2 16 TSL The large fire formula is used for all class 3 rooms. The small fire formula is used for class 1 and 2 rooms if the smoke-free height is more than twice the theoretical diameter of the fire (D): D= 4 Af The large fire formula is also used if the smoke-free height is below this figure. SPECIFIC SMOKE CLEARANCE PROVISIONS Article L 30 Scope 1. When calculating the coefficient α as described in the appendix to TI 246, rooms are divided into the following classes in the light of the likely size of the seat of a fire: a) class 1: concert halls, conference halls, meeting rooms, rooms for associations, rooms used to show films, auditoria with a stage area that can be insulated; b) class 2: clubs, auditoria with integrated stage areas containing props made of M0 or Ml materials, multi-purpose rooms; c) class 3: auditoria with integrated stage areas containing props made of M2 materials or M3 wood 2. Smoke clearance controls are not required to be automatic; this also applies to the establishments referred to in the first part of Article L 15 (paragraph 1). Article L 40 Insulation 1. In establishments with a booth serving a room, and by way of derogation from the provisions of Article CO 24 (paragraph 1), no fire resistance requirement applies to the wall separating the booth from the room. However, this wall must be made of non-combustible materials and penetrated only by the openings needed for projection and stage (or special) effects. 2. In establishments with one or more booths serving several rooms, and by way of derogation from the provisions of Article CO 24 (paragraph 1), no fire resistance requirement applies to the walls separating the booths from the rooms if all of the following conditions are met: - a fixed wall element 0.80 metres high complying with Article CO 24 (paragraph 1) and extending to the ceiling is placed above these non-fire-resistant walls; - these walls can be masked by a curtain made from M0 or A2 s2 d0 material (the control of this device must be located in the booth and/or any other permanently staffed point). 3. One of the walls (selected by the operator), possibly separating the booth from a hall or passageway with public access, may comprise glazed components made of safety glass complying with NF B 32-500 and capable of resisting the press of a crowd or protecting by a rail offering the same resistance. 4. No fire resistance requirement applies to any wall separating the video control room from the auditorium. Any walls made of glazed components and surrounding by a passageway must be made of safety glass complying with NF B 32-500 and capable of resisting the press of a crowd or protecting by a rail offering the same resistance. Article L 62 Smoke clearance of store rooms Smoke clearance is required for store rooms. In the case of natural smoke clearance, the useful area of the smoke extraction devices must be one-fiftieth of the area of the rooms, and the area of air intake devices must be at least as large. In the case of mechanical smoke clearance, the flow rate must be calculated on the basis of paragraph 7.2.3 of 'TI 246. Article L 74 Smoke clearance of the stage house Smoke clearance of the stage house must be natural and in accordance with the provisions of Articles DF 1 to DF 7, DF 9, DF 10 and the following specific provisions: - the useful area of smoke extraction devices and air intake devices must be one-twentieth of the area of the stage floor measured in horizontal projection. Furthermore, the useful area of an opening or ventilator must always be greater than 2 square metres; - in the case of mechanical air intake, the "air renewal" rate must be twelve volumes per hour and the draught speed must not exceed 5 m/s; - the outlets of ventilators and extraction conduits must be outside the covered parts for which particular protection is required under Article CO 7. Furthermore, these outlets must be located at least 8 metres in a horizontal orientation from neighbouring structural openings; - there must be at least two ventilators with broadly similar cross-sections; - façade openings may be permitted under exceptional circumstances provided that they are spread over at least 3 surfaces and that they all have broadly similar cross-sections. No void may be present above or perpendicular to the openings or within 4 metres either side of them. Voids located in a different plane from the opening must be at least 8 metres away; - smoke clearance activation controls must be manual. Each control must operate half the system. They must be located on the floor of the stage, close to an exit, and duplicated by controls outside the stage house. Furthermore, a thermal activator must ensure that the smoke extraction devices are automatically switched on as soon as the temperature in the upper part of the stage house reaches 93°C. Article L 75 Safety equipment controls Safety equipment controls (controls sealing off the stage void, activation, smoke clearance and other valves etc.) must be clearly marked. Where possible, these controls must be located together in an easily accessible and clearly visible place. These controls are independent of the FSS installed in the establishment. Article L 81 Repealed Article M 18 General provisions 1. The rooms are class 3 for the purposes of determining coefficient α as defined in the appendix to TI 246. 2. Smoke clearance of walkways is carried out in the same way as for rooms larger than 1,000 m2 under the conditions defined in paragraph 7 of Technical Instruction 246. 3. Smoke clearance is not required for shops giving onto a walkway that are not covered by Article DF7. Their surface area is not taken into consideration when calculating smoke clearance of the walkway, and no smoke curtain is required between the shop and the walkway. 4. Smoke clearance controls are not required to be automatic. Article M 19 Specific case of interconnecting multi-storey premises 1. In the situations covered by Article M 6 (paragraph 1), the floors of interconnecting multi-storey shops can be regarded as a single space with a surface area of over 1,000 m2. Interconnecting multi-storey walkways as defined in Article M 6 (paragraph 1) are divided into sections no longer than 60 m. Smoke clearance is carried out in the same way as for single spaces with a surface area of over 1000 m2. 2. In all other situations smoke clearance is mechanical on all floors, apart from the top floor where natural smoke clearance is permitted. Article M 54 Smoke clearance of store rooms 1. Smoke clearance of store rooms is carried out in the same way as for rooms less than 1,000 m2 in size, in accordance with Articles DF 7 and M 45. 2. The smoke clearance controls are not required to be automatic. They must form an integral part of the establishment's FSS. Article N 9 Scope 1. The establishments covered by this chapter are class 1 for the purposes of determining coefficient α as defined in the appendix to TI 246. 2. The smoke clearance controls are not required to be automatic. Article O 11 Scope 1. The establishments covered by this chapter are class 1 for the purposes of determining coefficient α as defined in the appendix to TI 246. 2. By way of deviation from Articles DF 4 and DF 6, smoke clearance is not required in corridors leading to bedrooms in the following cases: - the distance between the door of a bedroom (or apartment) and a staircase where smoke clearance is carried out (or a staircase protected from smoke) does not exceed 10 m; - the bedrooms are located in buildings that have no more than one floor above ground level and have façade openings. This provision does not apply to establishments occupied by a larger number of wheelchair users than the number specific in Article GN 8. 3. Doors of rooms accessible to the public giving on to passageways used as escape routes from bedrooms must be fitted with door-closers. 4. Smoke clearance devices in enclosed corridors leading to bedrooms must be connected to the automatic fire detection system in the corridor in question. Article O 12 Repealed Article O 13 Repealed Article P 14 Scope 1. The establishments covered by this chapter are class 2 for the purposes of determining coefficient α as defined in the appendix to TI 246. 2. By way of deviation from Article DF 7, smoke clearance is required in dance halls with mezzanines or incomplete storeys and in basement rooms. 3. By way of deviation from Article DF 5, smoke clearance or smoke protection is required for enclosed stairs leading to basements. 4. By way of deviation from Article DF 6, smoke clearance is required for enclosed corridors that are 5 metres or more in length. 5. Smoke clearance may be required for the rooms referred to in Article P 5 if in the opinion of the safety commission they present fire risks associated with significant calorific (or smoke-generating) potential. 6. If the establishment is fitted with a category A fire safety system, smoke clearance must be activated automatically by the automatic fire detector. Article R 19 Scope 1. The establishments covered by this chapter are class 1 for the purposes of determining coefficient α as defined in the appendix to TI 246. 2. Further to Articles DF 6 and DF 7: - smoke clearance is not required in enclosed corridors in buildings that have no more than one floor above ground level; - smoke clearance in buildings that have more than one floor above ground level and that do not contain any bedrooms may be carried out by means of smoke clearance of all rooms to which the public have access, irrespective of their surface area, except for toilets; - smoke clearance is always required for corridors in basements. 3. Smoke clearance of rooms with a surface area less than 300 m2 may be carried out by means of windows under the conditions laid down in paragraph 3.9 of TI 246. 4. By way of deviation from Article DF 6, smoke clearance is required for all enclosed corridors in buildings that have more than one floor above ground level and that contain bedrooms. 5. In the case of a building fitted with a category A FSS, smoke clearance of corridors of buildings containing bedrooms must be activated automatically from information provided by the fire detectors located in these corridors. Article S 9 Scope 1. The establishments covered by this chapter are class 3 for the purposes of determining coefficient α as defined in the appendix to TI 246. 2. In the case of an establishment fitted with a category A fire safety system covered by Article S 16, smoke clearance must be activated by the automatic fire detector. 3. Smoke clearance under the same conditions as rooms with public access may be carried out for rooms presenting particular risks as defined in Article S 8 with a volume greater than 1000 m³ if in the opinion of the safety commission they present fire risks associated with significant calorific (or smoke-generating) potential. Article S 10 Interconnecting floors These floors are regarded as a single space for the purposes of smoke clearance in the situation covered by Article S 6. Article T 25 Scope 1. The establishments covered by this chapter are class 3 for the purposes of determining coefficient α as defined in the appendix to TI 246. 2. In the case of an establishment fitted with a category A fire safety system covered by Article T 49, smoke clearance must be activated by the automatic fire detector. 3. Smoke clearance may be carried out for the rooms referred to in Article T 13 if in the opinion of the safety commission they present fire risks associated with significant calorific (or smoke-generating) potential. Article T 26 Chutes leading to a hall Smoke clearance is carried out for interconnecting floors as follows under the conditions defined in Article T 14: - smoke clearance can be carried out via the communication chute only for the lowest floor in accordance with the technical instruction on establishments open to the public (paragraph 7.1.5). - smoke clearance for the other floors may not be carried out in this way, but must be carried out under the conditions defined in paragraph 7.2.4 of Technical Instruction 246. Article V 6 Scope By way of deviation from Article DF 7, smoke clearance is required only for: - basement rooms with a surface area greater than 300 m2; - ground floor or upper floor rooms with a surface area greater than 300 m2 and a floor-to-ceiling height of less than 4 metres. The establishments covered by this chapter are class 1 for the purposes of determining coefficient α as defined in the appendix to TI 246. 2. The smoke clearance controls are not required to be automatic. Article W 9 Scope 1. The establishments covered by this chapter are class 1 for the purposes of determining coefficient α as defined in the appendix to TI 246. 2. Smoke clearance is required for rooms presenting a particular risk covered by Article W 4 with a volume greater than 1,000 m3. 3. The smoke clearance controls are not required to be automatic. Article X 19 Scope 1. The establishments covered by this chapter are class 1 for the purposes of determining coefficient α as defined in the appendix to TI 246. Multi-purpose rooms are class 2 for the purposes of determining coefficient α, other rooms are class 1. 2. Further to Articles DF 6 and DF 7, smoke clearance is only required for: - multi-purpose rooms mainly used for sport covered by Article X 1(paragraph 1); - rooms used for sport: - with a surface area greater than 300 m2 located in the basement; - with a surface area greater than 300 m2 located on the ground floor or upper floor and with a floor-to-ceiling height of less than 4 m. - changing rooms, locker rooms, and rooms used to store equipment with a surface area greater than 100 m2 that do not give on to a sports area. Smoke clearance of rooms with a surface area less than 300 m2 can be carried out by means of windows under the conditions laid down in paragraph 3.9 of TI 246. 3. The smoke clearance controls are not required to be automatic. Article Y 13 Scope The establishments covered by this chapter are class 1 for the purposes of determining coefficient α as defined in the appendix to TI 246. Article Y 14 Interconnecting floors These floors are regarded as a single space for the purposes of smoke clearance in the situation covered by Article Y 5, under the conditions defined either by TI 246 or TI 263. Article J 25 Scope of Articles DF 1. The establishments covered by this chapter are class 1 for the purposes of determining coefficient α as defined in the appendix to TI 246. 2. Smoke clearance of common corridors serving floors open to the public, irrespective of their length and including corridors in compartments bounded by full-height partitions, must be mechanical; this does not apply to common corridors in buildings with no more than one floor above ground level and entrance halls, where natural smoke clearance is permitted. 3. By way of deviation from Article DF 7, rooms covered by Article J 12 (paragraph 4) are subject to the provisions laid down in Article J 12. 4. The controls of smoke clearance devices in rooms, halls, common corridors and compartments must be automatic and must be connected to the fire detection system under the conditions laid down in Article J 36. 5. In accordance with Article DF 3, if the establishment has an electrogenic group the smoke clearance fans must be automatically repowered by this group if the normal power source fails. Article OA 16 Scope 1. Smoke clearance must be carried out in all the collection rooms in accordance with Article DF4. 2. In the case of mechanical smoke clearance, the fans must be automatically repowered by the electrogenic group referred to in Article OA 19 if the normal power source fails. 3. All (design or installation) measures must be taken to prevent devices (openings, ventilators, mechanisms etc.) being blocked by ice. Article REF 13 Stairs 1. By way of deviation from Article CO 52 (paragraph 3), all the stairs leading to the janitor's apartment or upperfloor bedrooms of the refuge must be enclosed top to bottom. 2. The enclosing walls must be of a matching fireproof class to the fire resistance of the building, except for the wall facing outward from the façade, which is only required to meet the provisions laid down in Article REF 9. 3. There must be no more than one access point to the stairs on each floor. The door blocks of the stairwell must be flame-resistant for 30 minutes and fitted with a door closer. 4. The upper end of the stairwell must have a mechanism capable of making a vertical opening of one square metre to the open air. A control located near the stairs on the ground floor must enable its rapid activation. Article EF 9 Smoke clearance 1. Smoke clearance is compulsory in rooms open to the public irrespective of their use if their surface area is equal to or greater than 300 m2 at or above the level of the escape bridge and 100 m2 below the escape bridge. 2. Smoke clearance is compulsory in corridors and stairs leading to bedrooms for public use, including those leading to rooms where the number of disabled people exceeds the threshold laid down in Article 8 of the Order. 3. In accordance with Article DF 4 of the safety regulations, smoke clearance (or smoke protection in the case of stairs) is required in enclosed stairs and corridors in establishments used for dancing or gambling (with the exception of corridors less than five metres long located at or above the level of the escape bridge). Article GA 4 9.2. Smoke clearance Smoke clearance must be carried out as appropriate for the situation in the light of the general principles of the technical instruction dealing with smoke clearance. Article GA 5 7. Smoke clearance The provisions of the technical instruction dealing with smoke clearance do not apply to underground railway stations. Smoke clearance is carried out in underground railway stations as follows: - for single-storey stations: natural or mechanical smoke clearance; - for multi-storey stations: mechanical smoke clearance. 7.1. Natural smoke clearance: The smoke clearance system must contain several communication channels with the air outside the station, separate from the passageways used by passengers, with a total cross-section at least equal to one-fiftieth of the surface area of the sites where smoke clearance is required; these communication channels must not be concentrated in a single zone. The smoke clearance conduits must comply with the following provisions: - their cross-section must be at least equal to the free area of the vents they serve; - the ratio of the largest to the smallest dimension of their cross-section must be less than or equal to 2; - the conduits must be made of non-combustible material or classified Al, and be fire-resistant for 15 minutes. If they cross other rooms, their crossing fireproof capacity must be equal to the fireproof capacity of the outer walls of these rooms. The fire-resistance requirement can be met by the duct in which they are housed provided that nothing else is housed within this duct and that the duct is equally as fire-resistant as the walls which are crossed; - extraction collector conduits, mainly vertical in orientation, can have up to two bends of not more than 20 degrees from the vertical; - The length of horizontal joints of extraction conduits must not exceed 2 m unless the draught is shown to be adequate (calculated for a smoke temperature of 70°C, outside temperature of +15°C and no wind). 7.2. Mechanical smoke clearance Mechanical smoke clearance is carried out in zones defined on a case-by-case basis. The minimum air renewal flow rate in each zone is 15 volumes per hour. Furthermore, each zone must have an independent ventilation system (extraction and draught) so that in the event of a fire air pressure is decreased on the floor where the fire has occurred and increased on the other floors. Smoke clearance fans must operate for one hour in the presence of smoke 400°C or be classified as F400 90. By way of deviation from the provisions of Article DF 3 paragraph 3, these fans must have two independent power sources. A single electrical channel may be used to provide these two independent power sources provided that it: - can operate for one hour in the conditions described in Article EL 3 (paragraph 2a) of the safety regulations referred to in Article GA 1 above; - is protected in such a way that it is not affected by an incident occurring in the other circuits. It can be activated manually or automatically. However, automatic controls must be duplicated by easily accessible and marked manual controls. Mechanical smoke clearance is carried out in passenger corridors containing shops on the basis of a flow rate of one cubic metre per second per 100 square metres of ground surface. TECHNICAL INSTRUCTION 263 On the construction and smoke clearance of interior free spaces in establishments open to the public Note 1. Smoke clearance of chutes leading on to a hall created by the possible interconnection of three floors is carried out in accordance with TI 246 (paragraph 7.1.5 and 7.2.4). Note 2. Interior streets resemble single interior corridors, three-level walkways, or atriums; if smoke clearance is required it is carried out, in the light of the opinion of the competent Safety Commission, under the same conditions as the spaces which they resemble though their architectural features are different. CATEGORY 5 ESTABLISHMENTS ARTICLE PE 11 Passageways 6. e) Smoke clearance of stairwells is carried out in accordance with Article PE 14. ARTICLE PE 14 1. Rooms over 300 m2 on the ground or upper floors and rooms of 100 m2 in the basement must have one or more openings at the top or bottom of the room connected to the outside either directly or via conduits. The useful smoke extraction area must be at least one-two hundredth of the ground area of these rooms. The total free air intake area in a room must be at least equal to the geometric area of the smoke extraction devices in this room. 4 Enclosed stairwells must have a frame or window at the top, with a free area of one square metre, with a mechanism allowing it to be easily opened from the access floor of the establishment. Where this natural smoke clearance system cannot be provided, the air pressure on the stairs is increased under the conditions laid down in Technical Instruction 246.