Brenda Coleman

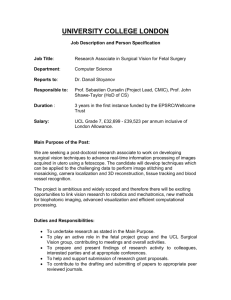

advertisement

4500 Worth Street Philadelphia, PA 19124 Phone: 215.948-9285 Ext 104 Fax: 215.948-9284 Email: CharlesM@manufacturingonline.org Web: www.manufacturingonline.org Mark E. S. Overall, twenty three years of experience in various supervisory/managerial roles and technical positions. Involving leadership of working crews, responsibility for equipment, timesheets, ordering of materials, scheduling, liaisons with project directors, inventories, organizing and maintaining files and records, multi-tasking, meeting deadlines, and multiple other duties. Numerous years spent maintaining, operating, and repairing many different types of technical equipment and machinery, with particular expertise in mechanics. Also years spent using technical instrumentation such as in surveying and the operating room (surgical instruments and equipment). Years spent supervising various workers and crews in various positions and managing case files and maintaining numerous types of records. EDUCATION: MILITARY Diploma, Academy of Health and Science 300FlO(GMO) General Medical Orientation (Medic) Diploma, Academy of Health and Science 30191DlO Operating Room Specialists (Surgical Technician) Diploma, Academy of Health and Science 30191GlO Behavioral Science Specialists (Psychologist/counselor) CIVILIAN Diploma, Bridgeton High School Other - Trade certs. Or qualifications MILITARY EXPERIENCE: US Army, Honorable discharge, E-4/Spc, 1992 US National Guard, Honorable Discharge E-4/Spc 2001 4500 Worth Street Philadelphia, PA 19124 Phone: 215.948-9285 Ext 104 Fax: 215.948-9284 Email: CharlesM@manufacturingonline.org Web: www.manufacturingonline.org PROFESSIONAL CERTIFICATIONS: *OSHA Health and Safety *OSHA 30 Hr Construction Industry Outreach Training *OSHA Safety Management *US Army Corps of Engineers – Construction Quality Management for Contractors *ECATTS - Environmental Compliance Assessment, Training, and Tracking System All Pennsylvania, all New Jersey, and all military installations (every course) *Green Living Certification *Fundamentals of Business Management – Certificate of Mastery *Diploma in Project Management *Intro to ISO 9001:2008 *OSHA Construction: (certs) Introduction to OSHA Personal Protective Equipment Safe Material Handling Scaffolding Safety Stair and Ladder Safety Fall Protection Excavation Safety Electrical Safety Crane Safety Hand and Power Tool Safety Other Certifications: Machine Guarding Hazard Communications Walking and Working Surfaces Flammable and Combustible Liquids Bloodborne Pathogens Exit Routes, Emergency Action Plans, Fire Prevention Plans, and Protection Adult/Child/Infant CPR, AED, and First Aid US Army Drug and Rehabilitation Training 5H-F4/302-F4(INDIV) counseling US Army Drug and Rehabilitation Training 5H-F5/302-F5(GROUP) counseling Advanced New Miner Training Surface and Underground Recent Trends in Stimulant Abuse, Treatment, and Relapse OSHA Lift Truck Operator (Forklift all types) All certifications available upon request. 4500 Worth Street Philadelphia, PA 19124 Phone: 215.948-9285 Ext 104 Fax: 215.948-9284 Email: CharlesM@manufacturingonline.org Web: www.manufacturingonline.org EXPERIENCE: CIVILIAN TURTLE ASSOCIATES, LLC; Superintendent/QC Manager: July 2010 – June 2011 In charge of Punch list repair work with Ujima Ministries. Also Superintendant and Quality Control Manager for all projects at Colts Neck: Naval Weapon Station Earl; Responsibilities putting together and submitting all submittals, writing all prevention plans, building proposals, finding and contracting subcontractors, dealt with all communications between contracting officers for government and our Company, was Super and Quality control on site when projects started and ran them til closeout. Made sure all materials and work to be done met specs, Supervised many workers, did production reports and quality assurance reports daily and many other types of paperwork, inspected all materials and work, onsite inspection of work to be done and chart drafting of cost breakdowns for materials and manpower, Held many safety and precon meetings. Performed all these same duties periodically at other sites also. Also performed many Project Manager duties. SEABROOK BROTHERS AND SONS; Freezer Leader: Nov. 2008 - June 2010 Working supervisor in large freezer warehouse. Duties included organizing, maintaining, consolidating, and constant inventory of approximately twenty million plus pounds of product. Supervision of other workers also supervise product coming in and going out on daily basis to and from many different locations. In charge of continuous replenishment of product to attached production floor. Also operated lift truck for movement of product and loading and unloading trucks. Maintained various types of records and paperwork. BLUE MOUNTAIN ENGINEERING; Crew leader, Surveyor: Jan. 2006 - June 2008 Ran crew of two to four men on daily basis surveying at various locations to include above and underground at coal mines. Tracked down gas wells for CNX Gas. Surveyed property lines and found property corners. Also did subdivides and many other types of surveying, Responsible for maintaining and using very delicate instrumentation on a regular basis. Various other duties such as map and blueprint reading, record keeping, and various other duties done on regular basis. BARR EXCAVATION; Crew leader, equipment operator: Sept. 2005 - Dec. 2006 In charge of small crew in doing all the excavating of land of New Housing Development being built. Operated various excavating machinery and equipment such as Track excavators, Bulldozers, Front End Loaders, Rollers, Bobcats, and various others. Responsible for clearing of land, building roads, 4500 Worth Street Philadelphia, PA 19124 Phone: 215.948-9285 Ext 104 Fax: 215.948-9284 Email: CharlesM@manufacturingonline.org Web: www.manufacturingonline.org digging trenches to install (manholes, waterlines, gas lines, and other utilities), and other excavation tasks. Responsibilities also included maintenance of equipment, ordering materials and supplies, reading blueprints, reading blueprints, payroll of my men, and brainstorming with project director. SHELTON SCRAP METAL SVCS; Owner, operator: Jan. 2003 - June 2005 Responsibilities included all phases of the business. Finding and maintaining relationship and customer accounts, buying and maintaining equipment, advertising, scheduling, handling safety precautions, and maintaining pay records. KERBECK BUICK, PONTIAC, GMC; Sales manager: Feb. 2002 - Nov. 2002 Responsibilities included supervising and maintaining numerous open deal files, maintain inventory of incoming and outgoing vehicles, and supervising eight to twelve sales people. Also performed TO's with all sales peoples customers close to deal. Work the numbers and deal with customers and various other managerial duties. VARIOUS AUTOMOBILE DEALERSHIPS; salesman: Aug. 2000 - Jan. 2002 Responsible for meeting and greeting new customers and showing our vehicles, with the prospect of new sales. Maintained open deal folders. FOREST GROVE AUTOBODY; Auto body tech: April 1997- Nov. 1998 Responsible for various stages of auto body repair. Used and maintained wide variety of tools and equipment. MEINEKE MUFFLERS; Exhaust mechanic: Mar. 1996- Jan. 1997 Performed various stages of under car repair and other mechanical repairs. Responsible for written estimates and completion of work, Did torching, welding, and used numerous other tools and equipment in completion of work. A-JACKS AUTO REPAIR; Manager, mechanic: April 1995- Jan. 1996 Performed all phases of auto repair. Responsibilities included writing estimates for customers, completing repairs, maintaining records of repairs, collecting and keeping track of monies collected from customers, ordering supplies and parts from various locations, supervising other mechanics, distribution of work, and payroll for other mechanics. 4500 Worth Street Philadelphia, PA 19124 Phone: 215.948-9285 Ext 104 Fax: 215.948-9284 Email: CharlesM@manufacturingonline.org Web: www.manufacturingonline.org WHEATON TUBE DRAW; packer, pitman, finish operator, line operator: Dec. 1993Feb. 1995 Responsible for production of glass tubing being produced. Running delicate equipment which controlled size (length, diameter, and thickness of tubes being produced which varied from job to job. EXPERIENCE: MILITARY UNITED STATES NATIONAL GUARD; Heavy Mobile Equipment Repairer (Temp. Federal Position with reserve unit):April 1999- July 2000 Responsible for repairing and routine maintenance of all military motorized vehicles with unit to include Hemmits, Tanks, Hummers, Ambulances, etc. Responsible for maintaining proper log records and submitting proper paperwork and request forms. All phase of repairs done and repair tools and equipment used. UNITED STATES ARMY; Medic, Operating Room Specialist, Behavioral Science Specialist, Soldier: May 1987- Nov. 1992 Worked in Operating Room as surgical assistant responsible for setting up surgical table and instruments and handing surgeon proper instruments during surgical procedure while maintaining sterile field. Responsible for studying surgical procedures and patient charts for procedures you are assisting surgeon with next day. When not scrubbing in for procedure responsible for supplying materials and instruments needed during surgery without breaking sterile field. Also responsible for prepping rooms before surgery and cleaning after surgery, Also duties included patient transport to Operating room and auto claving of dirty instruments and putting together surgical packs. Worked in Army (Drug and Alcohol Rehabilitation Center, Community Mental Health, and Social Work Svcs) as psychologists/counselor. Administered hundreds of intake evaluations, facilitated various types of group sessions, performed hundreds of one on one counseling sessions, taught a variety of classes such as stress management, parenting, etc., referred many cases to proper outside resources, started and properly maintained hundreds of case files, and set up resources for patients with special needs leaving hospital (such as home health care, meals on wheels, special transportation needs, etc.).