Paper - College of Earth and Mineral Sciences

advertisement

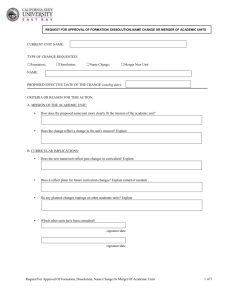

Igor Faoro Pressure solution around two cylindrical rods in contact 1 -6 Pressure solution around two cylindrical rods in contact By using the Femlab program, we introduce and study a finite element model capable to describe the rate of mass diffusion due to a progressive compaction of two infinitely long cylindrical quartz grains, that are subjected to a constant normal stress uniformly distributed along their diametric section area. We investigate the dissolution process up to the reaching of the plastic deformation state of the mineral and we display its behavior as a function of time. 1. Introduction In recent works it has been shown that the evolution of the mechanical and transport proprieties of rocks containing fractures at a variety of scales is strongly influenced both by the mechanical effects of crack formation, dilation, and closure, and their interaction with chemical effects of stress-mediated dissolution and precipitation. Specifically, these effects seem to be rather common either in microcracks [e.g, Tenthorey et all., 2003] or faults [Tadokoro and Ando, 2002; Yasuhara et al., 2005]. Many data are current available at high temperatures in granite [Moore et al., 1994], at lower temperatures in tuff [Lin et al.,1997] and at high and low temperatures in composite aggregates of quartz [Elias and Hajash, 1992], halite [Gratier, 1993], calcite [Zhang et al., 1994] and albite [Hajash et al.,1998] [e.g, Zoback and Byerlee, 1975; Siddqi et al., 2001] . On the contrary, there is only a few number of studies on fractures [Moore et al., 1994; Lin et al., 1997; Durham et al.,2001; Polak et al.,2003; Yasuhara et al., 2004], that can account for the changes in the transport parameters resulting when a fracture is subjected to pressure solution by circulating hydrothermal fluids. Main reason for this is due to the fact that the phenomenon of pressure solution in fractures is not well defined as for the case of granular aggregates [Weyl, 1959; Coble,1963; Rutter, 1976; Raj, 1982; Tada et al., 1987], where it represents a dominant mechanism for the deformation and the compaction within the upper earth crust [Palciauskas and Domenico,1989; Stephenson et al., 1992]. In this paper we aim to study the mass dissolution process due to the pressure solution that occurs between the fracture’s walls. To this aim, we introduce a punctual and simplified two dimensional model, that is independent from the temperature of the circulating fluid, where we consider only twin cylindrical quartz rods in contact that are subjected to a constant normal compressive stress acting along their diametric cross section (see figure 1). Figure 1. Schematic of the geometry model configuration. 2. Governing equations The rate of compaction and the final steady configuration for the two quartz Igor Faoro Pressure solution around two cylindrical rods in contact rods in the model are obtained by using the following formula: G u G 2 u 0 (1 ) y (1) here is thePoisson coefficient, G denotes the modulus of rigidity and u represents the displacement . As it will be clarified in the following, in our treatment only two dimensions (x,y) are relevant. The rate of mass diffusion equation is given by: M K * 2 -6 example a spherical shape for the grains is adopted. In order to analyze the problem in two dimensions, we assume to neglect the strengths, and the relative deformations in the z direction produced by the load. As a result, the cylindrical grains must be considered as infinitely long. Furthermore due to symmetry argument, only the quarter part of the all system has been evaluated. (See figure 2.) (2) where M denotes the dissolution mass rate, K is the dissolution rate constant and is mean value of the stress. Notice that Eq. (2) provides a link between the structural-mechanical problem and the diffusion one. Indeed, it allows to obtain the dissolution mass rate as a function either of the flow rate or of the amount of strengths between the contact boundaries of the rods. The rate of diffusion along the x direction is given by: c 2c D 2 t x (3) where D is the diffusion coefficient. 3. Formulation Geometry assumption The geometry of the model consists of two cylindrical grains and the pore volume between them. The choice of the cylindrical shape is not casual. Indeed, by using this geometry, it is possible to neglect the void space around the diametric section area of the grains that would be otherwise present if for Figure 2. Schematic of the final geometry model configuration, and boundary numeration The plain strain problem has been solved using the “Structural Mechanics Module /plane strain / non linear static analysis” application provided by the Femlab program. In particular, the expressions necessary in order to define the contact boundary forces and compute the analytical values are (applied for the boundaries 3and 4): Fc t n (en gap) gap 0 (4) e Fc t n exp n gap gap 0 tn (5) (1 2 ) E (6) 2F b2 x2 b2 (7) b 2 F R P here gap denotes the distance between the grain and the base, PB are the contact forces, tn is the input estimate of Igor Faoro Pressure solution around two cylindrical rods in contact the contact force, en represents the penalty stiffness, b is half of the total length, F is the applied load, R denotes the radius of grain, is the Poisson’s coefficient, E is the Young modulus, x is the distance along x-axis. Furthermore we assume that there are no displacements along the x directions, and no load along the y-direction (applied for boundary 1 and 2). The dissolution mass rate is computed manually using equation 2, after calculating the average value The diffusion process is solved by using the ”Comsol Multiphysics / convection and diffusion / diffusion /transient analysis” application; the flux equation reads: DC No Kb(Cb C ) 3 -6 his plasticization limit; after that, no further deformations can occur. Figure 3. Von Mises stress [N/m2] (8) here No is the inward flux, Kb is the mass transfer coefficient and Cb denotes the bulk concentration. 4. Solution The results of the plain strain problem are reported in Figure 3 and Figure 4. The load applied is equal to 10 KN. In particular, in Figure 4 it is also possible to see the final deformation line of the quartz grain at the steady state. The total displacement distribution inside the surface and the development of the surface tractions along the contact boundary between the surface grain and the base are reported respectively in Figure 5 and Figure 6. Specifically, Figure 6 shows that the tensile tensions vary from an initial value equal to 7*108 Pa down to 0 Pa in the first portion of the boundary (see also figure7). This behavior can be explained only by considering that the grain has reached Figure 4. Particular Von Mises stress [N/m2] Figure 5. Total displacement distribution [m] Igor Faoro Pressure solution around two cylindrical rods in contact 4 -6 Figure 8. Concentration [mol/m3] Figure 6. Surface Traction in y-direction [Pa] In Figure 9 we report the complete variation of concentration as a function of time, by assuming an initial concentration equal to 1 [mol/m3] applied on the boundary 3 and 4. Notice that, even from such a small concentration it is possible to understand how small is the contribute due to the mass dissolution compare to the complete diffusion process. Figure 7. Surface Traction in y-direction [Pa], plasticization limit. As it is evident from Figure 6, the mean stress value recorded is 3.5*108 Pa; by considering a unitary quartz grain volume is possible to estimate that the value of the dissolution mass rate is equal to 5.8*10-5[mol/s]. Furthermore by assuming a constant value for the dissolution rate equal to 10-12 [gr/(sPa)], the inward flux and the bulk concentration can be estimated and we find that they are respectively equal to 0.058 [mol/(m2s)] and 3.6*106 [mol/m3] . In Figure 8 we report the diffusion distribution. Figure 9. Concentration [mol/m3] 5. Validation-parametric study The model that we study in the first part simulates the stress and the relative displacements distribution that occurs in all those structural problems where more or less complex elements are subject to particular load configurations. Because of its assumptions it is almost impossible to compare the results we obtained with the ones given in literature. Nevertheless, we can view this model as a first step in order to analyze Igor Faoro Pressure solution around two cylindrical rods in contact 5 -6 all those structural problems in which the plasticization phenomenon need to be investigated. In this respect, some possible applications may be planning studies of tunnels, tubes, circular walls, just to mention a few (see Figure 10) b Figure 10. Schematic plasticization zone for planning . Different results can be obtained by changing the main variables of the model, like for example material characteristics (Young modulus, Poisson modulus, density, stiffness..), loads, and values of relative concentrations. In Figure 11 we study the model in the case progressive increasing loads (500 N, 1 KN, 10 KN) are applied. This example is particularly interesting because it follows the reaching of the grain plasticization limit during the time. Indeed, starting from an initial total elastic behavior, one can see how the steady plasticization configuration is progressively reached by increasing the load. a c Figure 11. Surface Traction in y-direction [Pa] at load values respective equal to: (a) 500 N,(b) 1 KN, (c) 10 KN. 6. Conclusions In this paper we introduced and discussed a finite element model that can be considered as a preliminary study of the dissolution process caused by the pressure solution between two cylindrical quartz rods that are subjected to a constant normal stress distribution. The reaching of the plasticization behavior by the grain and the relative dissolution mass rate have been investigated. In the future, it could be interesting to study the evolution of this phenomenon when the rock starts to fail, and to investigate how the dissolution mass rate changes as a function both of the temperature and of the circulating fluid. Igor Faoro Pressure solution around two cylindrical rods in contact References Coble,R.L.(1963), A model for boundary diffusion controlled creep in polycrystalline materials, J.Appl.Phys.,34,1679-1682. Durham,W.B.,W.L.Boucrcier, and E.ABurton (2001), Direct observation of reactive flow in a single fracture, Water resour.Res.,37,1-12. Elias,B.P., and A.Hajash (1992), Change in quartz solubility and porosity change due to effective stress: An experimental investigation of pressure solution, Geology, 20,451-454. Gratier,J.P.(1993), experimental pressure solution of halite by an intender tecnique, J.Geophisics.Res.,Lett.,20(15),1647-1650. Hajash,A.,T.D.Carpenter, and T.A. Dewers (199810, Dissolution and time dependent compaction of albite sand: Experiments at 100 C and 260 C in pH-buffered organics acid and distilled water, Tectonophysics,295,93-115. Lin,W.,J.Roberts, W.Glassey, and D.Ruddle (199710,Fracture and matrix permeability at elevated temperatures, paper presented at Workshop on Significant Issues and Available Data, Near-Field/Altered-Zone Coupled Effects Expert Elicitation Project, U.S.Dep. of Energy, San Francisco, Calif.,Nov Moore, D.E., D.A.Lockner and J.A Byerlee (1994), Reduction of the permeability in granite at elevate temperatures, Science, 265 (5178), 1558-1560, 1994 Palciauskas,V.V., and P.A.Domenico (1989), Fluid pressures in deformation porous rocks, Water Resour.Res.,25,203-213. Polak A, Elsworth D, Yasuhara H, Grader AS, Halleck PM Permeability reduction of a natural fracture under net dissolution by hydrothermal fluid Geophysical research letters 30 (20): Art. No. 2020 OCT 16 2003 Raj,R. (1982), Creep in polycrystalline aggregates by matter transport though a liquid fase, J.Geophisics.Res.,87,4731-4739. Rutter,E.H (1976), The kinetics of rock deformation by pressure soltution, Philos. Trans.R.Soc.london,Ser.A, 283 ,203-219. Siddiqi.G. ,B.Evans, G.Dresen, and D.Freund (2001), Effect of semibrittle deformation on transport proprieties of calcite rocks, J. Geophisics.Res.,106,8665-8686. Tada,R.,RMaliva,and R.Siever (1987), Rate laws for water-assisted compaction and stressinduced water-rock interaction in sandstones, Geochic.Cosmochin.Acta,51,2295-2031. Tadokoro,K,and M.Ando (2002), Evidence for rapid fault healing derived from temporal changes in S wave splitting, J.Geophisics.Res., Lett.,29(4),1047,doi:10.1029/2001GL013664. 6 -6 Tenthorey. E.,S.F.Cox, and H.F.Todd (2003), Evolution of strength recovery and permeability during fluid-rock reaction in experimental fault zones, Earth Planet.Sci.Lett.,206,161-172. Weyl, P.K., Pressure solution and force of crystallization – A phenomenological theory. Journal of geophysical research-solid earth .64,2001-2025,1959 Yasuhara H, Elsworth D, Polak A Evolution of permeability in a natural fracture: Significant role of pressure solution Journal of geophysical research-solid earth 109 (B3): Art. No. B03204 MAR 13 2004 Yasuhara H, Marone C, Elsworth D Fault zone restrengthening and frictional healing: The role of pressure solution, Journal of geophysical research-solid earth 110 (B6): Art. No. B06310 JUN 24 2005 Zhang, S., S. Cox and M.Paterson, (1994), The influence of room temperature deformation on porosity and permeability in calcite aggregates, J.Geophisics.Res.,99,761-755 Zoback, M., and J.Byerlee (1975), The effect of microcracks dilatancy on the permeability of Westerly Granite, J.Geophisics.Res.,80,752-755.