Course Text Unit III

advertisement

TAKEOFF FUNDAMENTALS

Takeoff is a critical flight phase, one which constitutes only about one percent of total flight time, but

which results in about to 1/5 (20%). of all accidents. In high performance, high speed airplanes, such

accidents routinely involve serious damage and often result in fatalities. (Landing is an equally brief, even

more critical flight phase, where about 1/4 (25%) of all accidents occur.)

We will examine five factors which affect three important takeoff parameters. The three takeoff

parameters are:

1.

2.

3.

Takeoff distance X (distance covered from brake release to liftoff).

Take off time t (elapsed time from brake release to liftoff).

Takeoff speed V (liftoff speed).

The five factors are:

1. Changes in Gross Weight.

2. Changes in Density Altitude.

3. Changes in Temperature.

4. Runway Wind Changes.

5. Variation of Runway Slope from Horizontal.

We also give a real world example of how to compute takeoff distance using a takeoff performance chart

for a single engine high performance Navy jet airplane. Finally, we briefly discuss the importance of a

takeoff acceleration check and the hazard associated with premature rotation.

1. Theoretical Effects of Changes in Gross Weight, Density Altitude, Wind,

and Runway Slope on Liftoff Speed, Takeoff Distance, and Takeoff Time

During takeoff, thrust overcomes drag and tire friction forces to accelerate the airplane. We first examine

equations which allow predicting takeoff roll, speed, and time changes when gross weight, density altitude,

temperature, runway slope, or the headwind component changes

An increase in gross weight, temperature, or runway upslope, or a decrease in density altitude or headwind

component, causes an increase in one or more of takeoff speed, distance, and time. Sometimes the increase

can be drastic, especially when rising temperatures and higher takeoff elevations (density altitudes) lead to

significantly lower air density.

For example, later we will discuss a single engine jet airplane whose takeoff roll (at fixed gross weight)

increases from 2500’ to 10500’ when runway temperature rises from 0 o to 40o C, pressure altitude

decreases from sea level to 2000’, and headwind decreases from 25 kts to 0 kts. This is an increase of

420% in takeoff distance.

Implications of Equations for Rectilinear Motion. From basic physics, we know that

VF2 = VI2 + 2aX, and

VF = VI + at,

where VI and VF respectively are initial and final velocity in ft/sec; a is acceleration in ft/sec 2, assumed to

be constant (a naïve but useful assumption); X is distance traversed in feet; and t is time in seconds.

Applied to airplane takeoff, VF is liftoff velocity, VI = 0, X is takeoff roll, and we have

VF2 = 2aX, and VF = at, or

X = VF2 / 2a, and t = VF / a.

Rogers’s AS310 Notes, Part III: Page 1

These equations tell us that:

Takeoff roll X is directly proportional to the square of liftoff speed and inversely proportional

to acceleration:

X V2 / a.

Takeoff time t is directly proportional to liftoff speed and inversely proportional to

acceleration.

t V / a.

Suppose a change in some factor such as gross weight or density altitude causes a change in liftoff speed

and aircraft takeoff acceleration. Let X1, t1, and V1 be takeoff parameters associated with the initial

situation, and X2, t2 and V2 be parameters associated with the new situation. Then from the foregoing we

may conclude:

X 2 V22 a 1

t

V a

, and 2 2 1

X 1 V12 a 2

t 1 V1 a 2

Note: since these identities involve ratios, we may use airspeed in knots without bothering to convert to

ft/sec. Also, since we assume constant acceleration in both cases (when actually acceleration decreases

significantly during the takeoff roll), the error introduced is not as great as one might expect.

Effect of Changes in Gross Weight. Suppose gross weight changes from W1 to W2. Then, as we already

know, respective liftoff speeds V1 and V2 are given by

V2 / V1 = (W2 / W1), or V22 / V12 = W2 / W1.

Also, from F = m a = (W/g) a, we see that at takeoff thrust F, acceleration is inversely proportional to gross

weight. We may conclude that the respective accelerations a 1 and a2 corresponding W1 and W2 are given

a

W

by 1 2 . (The equation says the acceleration is inversely proportional to weight.) Thus

a 2 W1

2

X 2 V22 a 1 W2 W2 W2

t

V a

, and 2 2 1

X1 V12 a 2 W1 W1 W1

t 1 V1 a 2

W2 W2 W2

W1 W1 W1

3/ 2

.

That is:

V2 = V1 (W2 / W1).

X2 = X1 (W2 / W1)2.

t2 = t1 (W2 / W1)3/2.

Expressed in English, these equations say that if takeoff gross weight changes from W 1 to W2:

Liftoff speed changes as the square root of (W 2 / W1).

Takeoff roll changes as the square of (W2 / W1).

Takeoff time changes as (W2 / W1) raised to the 3/2 = 1.5 power.

Rogers’s AS310 Notes, Part III: Page 2

Effect of Changes in Field Elevation (Jet or Normally Aspirated Prop). Suppose density ratio

corresponding to field elevation changes from 1 to 2. Then, as we already know, respective liftoff speeds

V1 and V2 are given by

V2 / V1 = (1 / 2), or V22 / V12 = 1 / 2.

Also, from F = m a = (W/g) a, we see that at takeoff gross weight W, acceleration is directly proportional to

thrust F. Assuming thrust is proportional to density ratio for a jet or normally aspirated prop aircraft, we

a

may write 1 1 . (The equation says that acceleration is inversely proportional to density ratio.) Thus

a 2 2

2

X 2 V22 a 1 1 1 1

t

V a

1 1 1

, and 2 2 1

2

X1 V1 a 2 2 2 2

t 1 V1 a 2

2 2 2

That is, for a turbojet or normally aspirated reciprocating prop airplane:

3/ 2

.

V2 = V1 (1 / 2).

X2 = X1 (1 / 2)2.

t2 = t1 (1 / 2)1.5.

Expressed in English, these equations say that if density ratio changes from 1 to 2:

Liftoff speed changes as the square root of (1 / 2).

Takeoff roll changes as the square of (1 / 2).

Takeoff time changes as (1 / 2) raised to the 1.5 power.

Effect of Temperature Change at Fixed Pressure Altitude (Jet or Normally Aspirated Prop). Air

density is a function of pressure and temperature, as implied by the well-known relation = / . That is,

for a fixed pressure altitude (fixed field elevation and altimeter setting), 1 / . Thus the equations

given previously for density altitude change may be rewritten to reflect change in temperature at fixed

static pressure as follows:

V2 = V1 (2 / 1).

X2 = X1 (2 / 1)2.

t2 = t1 (2 / 1)1.5.

Recall that temperature ratio must be calculated using absolute temperatures. Let TA represent absolute

temperature, with TA0 denoting SL temperature in a standard atmosphere. (To calculate TA, add 273 to

temperature in degrees Celsius, or 460 to temperature in degrees Fahrenheit.) Then 2 = TA2 / TA0, and 1

= TA1 / TA0, so 2 / 1 = TA2 / TA1. Thus the above equations may be rewritten:

V2 = V1 (TA2 / TA1).

X2 = X1 (TA2 / TA1)2.

t2 = t1 (TA2 / TA1)1.5.

Expressed in English, these equations say that if absolute temperature changes from TA1 to TA2:

Liftoff speed changes as the square root of (TA2 / TA1).

Takeoff roll changes as the square of (TA2 / TA1).

Takeoff time changes as (TA2 / TA1) raised to the 1.5 power.

Rogers’s AS310 Notes, Part III: Page 3

Effect of Headwind. The effect of a headwind component on takeoff is to decrease the ground speed of

the aircraft at liftoff. An excellent illustration of this phenomenon is the “ground” speed and airspeed of a

jet airplane being launched from an aircraft carrier. The captain accelerates the ship and turns it into the

existing sea wind to get about 35 KTS of wind across the deck. Then an airplane which flies off the bow at

150 KIAS is only moving 150 – 35 = 115 KTS relative to the deck of the ship. That is, the catapult only

has to accelerate the plane to 115 KTS in the space of 200’, not 150 KTS. (Note: there have been a few

launches of jet airplanes from aircraft carriers at anchor, and these rarities are celebrated events in Naval

Aviation lore, with the pilots involved accorded significant bragging rights.)

Let VW be the wind component parallel the runway, with a positive value denoting a headwind, and a

negative value denoting a tailwind. We may conclude that

V2 = V 1 – VW

with acceleration unchanged (i.e., a1 = a2). Thus

X 2 V22 a 1 V1 VW

X1 V12 a 2 V1

2

V

1 W

V1

2

V VW

V

t

V a

, and 2 2 1 1

1 W .

t 1 V1 a 2

V1

V1

That is:

V2 = V 1 – VW .

X2 = X1 (1 - VW / V1)2.

t2 = t1 (1 - VW / V1).

Expressed in English, these equations say that if takeoff gross weight changes from W 1 to W2:

Liftoff ground speed changes by the headwind component V W.

Takeoff roll changes as the square of (1 - VW / V1)2.

Takeoff time changes as (1 - VW / V1).

Note: the decrease/increase in takeoff roll due to headwind/tailwind also applies to landing rollouts.

Note: Let (x, y) be a point on the curve depicted in Figure 7.1. Then y / 100 = x2 if x 0.0, and y / 100 = x2 if x < 0. That is, the curve is parabolic, but this fact is obscured by different x and y scales. Also,

numbers on the x-axis are decimal fractions of the takeoff (or landing) speed, while numbers on the y-axis

are percentage changes in takeoff or landing distance, i.e., decimal fractions multiplied by 100.

Effect of Runway Slope or Gradient. The gradient G of a slope is just its rise over its run, expressed as a

decimal fraction.

Let the Cartesian x-axis lie tangent to the earth’s surface, so that the y-axis is perpendicular to the earth.

Then for a runway that has a non-zero gradient (upslope or downslope), the gradient is just y / x, as

illustrated below.

y

W

x

W cos

W sin W (RG)

Rogers’s AS310 Notes, Part III: Page 4

As illustrated in the above figure, for an upslope, there is an additional weight component W sin which

thrust must overcome, effectively decreasing thrust (the accelerating force) on takeoff. (If y is negative,

the runway has a downslope, and thrust is increased by W sin ).

Since the sin tan for small , we may write sin tan = y / x = RG, where RG is runway

gradient, so the additional force to be overcome is just W sin W tan = W (y / x) =W (RG). That

is, a runway gradient changes effective takeoff thrust of an aircraft by W (RG), where W is takeoff gross

weight. RG must be expressed as a decimal fraction, as is conventional. A positive value for RG denotes

an upslope, and a negative value indicates a downslope. If the runway gradient is positive (uphill),

effective thrust is decreased by W (RG); otherwise (downhill or negative gradient) effective thrust is

increased by W (RG).

Let RT/W be the thrust to weight ratio for takeoff thrust. For example, if an airplane weighs 20,000# and

has 9,000# takeoff thrust, RT/W = 9,000 / 20000 = 0.45. RT/W for high performance jet fighters often

approaches 0.75, while RT/W for an airliner might be well below 0.5. Of course, W RT/W gives takeoff

thrust in pounds for an airplane at gross weight W. For example, if W = 300,000# and RT/W = 0.20, then

takeoff thrust is just W RT/W = 300,000# (0.20) = 60,000#.

Since takeoff thrust is W RT/W, a runway gradient of RG causes effective takeoff thrust (T R)1 = W RT/W to

become (TR)2 = W RT/W - W (RG) = W (RT/W – RG), with both RT/W and RG expressed as decimal

fractions. That is,

(TR)1 / (TR)2 = W RT/W / W (RT/W – RG) = RT/W / (RT/W – RG).

Now recall the relationships that express takeoff distance and time ratios. In the case of a runway gradient,

liftoff velocity does not change since gross weight does not change. However, acceleration is changed by a

factor of (TR)1 / (TR)2, since takeoff thrust TR = F = (W/g) a, with W/g constant. That is, V 2 = V1, W2 = W1,

and a1 /a2 = (TR)1 / (TR)2 = RT/W / (RT/W – RG). Thus:

RT/W

RT/W

RT/W

RT/W

X 2 V22 a 1 V12

t

V a

V

2

2

, and 2 2 1 2

X1 V1 a 2 V1 R T / W RG R T / W RG

t 1 V1 a 2 V1 R T / W RG R T / W RG

To sum up, for runway gradient RG expressed as a decimal fraction (with a negative RG meaning a

downslope):

V2 = V1.

X2 = X1 [RT/W / (RT/W – RG)].

t2 = t1 [RT/W / (RT/W – RG)].

Expressed in English, these equations say that for runway gradient RG and thrust to weight ratio RT/W:

Liftoff speed remains unchanged.

Takeoff roll and takeoff time change proportional to the ratio RT/W / (RT/W – RG).

Important note: runway slope affects takeoff distance significantly more in an airplane with low thrustweigh ratio (such as an airliner) than in an airplane with high thrust-weight ratio (such as a jet fighter taking

off with combat thrust.) This is because the ratio RT/W / (RT/W – RG), for fixed RG, becomes larger as RT/W

becomes smaller.

Rogers’s AS310 Notes, Part III: Page 5

Summary of Theoretical Effects of Gross Weight, Elevation, Temperature, Wind, and Runway Slope

Changes. The foregoing results are summarized in the following table. Remember that the results for

elevation and temperature changes apply to jets and normally aspirated props, but not to supercharged

props. Also, neither one of these two results takes into account the very significant change in jet engine

thrust as temperature and/or air density change. As a result, these two equations do not predict takeoff

parameter changes as accurately as the other three.

Gross Weight:

W1 W2

Density Ratio:

1 2

Temperature:

TA1 TA2

Headwind:

VW

R/W Grad: RG &

T-W Ratio: RT/W

Liftoff (Ground) Speed

Takeoff Roll

Takeoff Time

V2 = V1 (W2 / W1)

X2 = X1 (W2 / W1)2

t2 = t1 (W2 / W1)3/2

V2 = V1 (1 / 2)

X2 = X1 (1 / 2)2

t2 = t1 (1 / 2)3/2

V2 = V1 (TA2 / TA1)

X2 = X1 (TA2 / TA1)2

t2 = t1 (TA2 / TA1)3/2

V2 = V 1 – VW

X2 = X1 (1 - VW / V1)2

t2 = t1 (1 - VW / V1)

V2 = V 1

X2 = X1 [RT/W / (RT/W – RG)]

t2 = t1 [RT/W / (RT/W – RG)]

Takeoff performance “rules of thumb” may be adduced from the above equations.. It is easy to verify their

validity from the equations. [I have put hints in brackets to help you see how to do this.]

A 21% increase in gross weight results in a 10% increase in liftoff speed [1.1 = 1.21]

A 10% increase in gross weight gives

1. a 5% increase in takeoff speed [1.1 1.05]

2. a 21% increase in takeoff distance [(1.1)2 = 1.21]

3. a 15% increase in takeoff time [(1.1)1.5 1.15]

A headwind of 10% of liftoff speed (e.g. 15 kts for 150 kt liftoff) gives

1. a 19% reduction in takeoff distance [(1 - .1)2 = 0.81]

2. a 10% reduction in takeoff time [ (1 – 0.1) = 0.9]

3. a 10% reduction in liftoff ground speed [obvious]

A tailwind of 10% of liftoff speed (e.g. 15 kts for 150 kt liftoff) gives

1. a 21% increase in takeoff distance [(1 + .1) 2 = 1.21]

2. a 10% increase in takeoff time [ (1 + 0.1) = 1.10]

3. a 10% increase in liftoff ground speed [obvious]

Shifting from a 10% headwind to a 10% tailwind (as above) increases

1. takeoff distance by about 40% [19 + 21 = 40]

2. takeoff time and liftoff ground speed by 20% [10 + 10 = 20]

Factors Ignored by Foregoing Ratio Estimations. Several important factors are not taken into

consideration by the theoretical approach above, which assumes constant acceleration on takeoff:

1.

2.

3.

4.

5.

6.

The net accelerating force (Thrust – Drag– Friction) is not constant.

Thrust drops during the runway roll for a jet engine because the air velocity at the engine

intake increases faster than at the engine exhaust point.

Parasite drag increases as a function of V2.

After rotation, induced drag increases due to increased AOA.

As lift develops, normal force on tires decreases, decreasing friction.

As a consequence of 1-5 above, takeoff acceleration is not constant, although we assumed it is

constant.

Rogers’s AS310 Notes, Part III: Page 6

Figures 7.3 and graphs typical takeoff thrust, drag, friction, and net acceleration forces vs. airspeed for a

B767. Figure 7.4 uses the net acceleration force of Figure 7.3 to graph typical B767 takeoff acceleration

vs. airspeed.

Figure 7.3. Changes to Thrust, Drag, and Friction Forces during B767 Takeoff Roll

Figure 7.4. B767 Takeoff Acceleration Profile

Inaccuracies occur when one assumes constant acceleration during takeoff roll computation. In our

equations, these inaccuracies are smaller because ratios are used to estimate changes in takeoff time,

distance, and speed as factors such as gross weight, density, temperature, and pressure change.

Rogers’s AS310 Notes, Part III: Page 7

2. Example Problems

Weight Change: An airliner at 200,000# gross takes 32 seconds and 4000’ to get airborne at 140 KTAS.

At 300,000# gross with other conditions unchanged, find takeoff time, speed, and distance.

t2 = t1 (W2 / W1)1.5 = 32 (300,000 / 200,000)3/2 = 32 (1.5)1.5 = 58.78775382 sec

V2 = V1 (W2 / W1) = 140 (300,000 / 200,000) = 140 1.5 = 171 KTAS

X2 = X1 (W2 / W1)2 = 4000 (300,000 / 200,000)2 = 4000 (1.5)2 = 9000.0000000 feet

Elevation Change. An airliner at SL on a standard day takes 32 seconds and 4000’ to get airborne at 140

KTAS. At 7000’ elevation with other conditions unchanged, find takeoff time, speed, and distance.

7000 = 0.81064

t2 = t1 (σ1 / σ 2)1.5 = 32 (1.0 / 0.81064)1.5 = 43.84377434 sec

V2 = V1 (σ1 / σ 2) = 140 1.0 / 0.81064) = 155.4941378 KIAS

X2 = X1 (σ1 / σ 2)2 = 4000 (1.0 / 0.81064)2 = 6087.008832 feet

Temperature Change. A jet fighter at SL takes 30 seconds and 4100’ to get airborne at 150 KTAS on a

day when the temperature is 0o C. If the temperature increases to 40o C with other conditions unchanged,

find takeoff time, speed, and distance.

TA2 = (40 + 273) = 313; TA1 = (0 + 273)

t2 = t1 (TA2 / TA1)1.5 = 30 (313 / 273)1.5 = 36.82932768 sec

V2 = V1 (TA2 / TA1) = 150 313 / 273) = 160.6135215w KIAS

X2 = X1 TA2 / TA12)2 = 4100 (313 / 273)2 = 5389.844633 feet

Wind Change. An airliner under no wind conditions takes 32 seconds and 4000’ to get airborne at 140

KTAS. Then with 30 KT headwind and other conditions unchanged, find takeoff time, speed, and distance.

t2 = t1 (1 – VW/V1) = 32 (1 – 30/140) = 25.14285714 sec

V2 = V1 - VW) = 140 - 30 = 110 KTAS

X2 = X1 (1 – Vw / V1)2 = 4000 (1 – 30/140)2 = 2469.38755 feet

If there is 25 KTS of tailwind, then takeoff time, ground speed and distance are

t2 = t1 (1 – VW/V1) = 32 (1 – (-25)/140) = 37.71428573 sec

V2 = V1 - VW) = 140 - (-25) = 165 KTAS

X2 = X1 (1 – Vw / V1)2 = 4000 (1 – (-25)/140)2 = 5556.122452 feet

Note that the liftoff speed IAS is not affected by headwind or tailwind; only the ground speed is changed.

Sometimes a chart (or table) is used to determine the percent change in takeoff or landing distances for a

given headwind or tailwind. An example of such a chart is given in Figure 7.1.

Rogers’s AS310 Notes, Part III: Page 8

Figure 7.1. Effect of Headwind / Tailwind Components on Takeoff and Landing Distance.

Previous Wind Change Problem Solved Graphically. An airliner under no wind conditions takes 32

seconds and 4000’ to get airborne at 140 KTAS. Then with 30 KTS headwind and other conditions

unchanged, find takeoff time, distance. Also find the takeoff distance for a 25 KT tailwind.

30/140 = 0.21 (rounded) is the fractional relation of wind speed to liftoff speed. From the origin, proceed

left on the x-axis to 0.21, then down to intersect the curve. Read 38% decrease in takeoff distance on the yaxis. 4000 – 0.38 (4000) = 2480 feet. This compares to 2469 feet computed by the equation.

-25/140 = -18% (rounded).is the fractional relation of wind speed to liftoff speed. From the origin, proceed

right on the x-axis to 0.18, then up to intersect the curve. Read 39% increase in the takeoff distance on the

y-axis. 1.39 (4000) = 5560 feet. This compares to 5556 feet computed by the equation.

Rogers’s AS310 Notes, Part III: Page 9

Runway Slope. A 300,000# airliner with 90,000# takeoff thrust takes 32 seconds and 4000’ to get airborne

at 140 KTAS on a level runway. With other conditions unchanged, find takeoff time and distance with a

runway upslope of 2% and a runway downslope of 5%.

Thrust-weight ratio RT/W = 90,000/300,000 = 0.30.

With a 2% upslope, (RG = 0.02:

t2 = t1 [RT/W / (RT/W – RG)] = 32 [0.3 / (0.3 – 0.02)] = 34.28571427 sec

X2 = X1 [RT/W / (RT/W – RG)] = 4000 [0.3 / (0.3 – 0.02)] = 4285.714284 feet

Liftoff speed remains 140 KTAS.

With a 5% downslope, (RG = -0.05):

t2 = t1 [RT/W / (RT/W – RG)] = 32 [0.3 / (0.3 + 0.05))] =27.42857143 sec

X2 = X1 [RT/W / (RT/W – RG)] = 4000 [0.3 / (0.3 + 0.05)] = 3428.571428 feet

Liftoff speed remains 140 KTAS.

Rogers’s AS310 Notes, Part III: Page 10

3. Real World Takeoff Distance Example

In contrast to our theoretical models, real world empirical data is used to construct takeoff charts which

pilots (or computers) typically use to compute takeoff distance for given gross weight, temperature, density

altitude, and headwind/tailwind component.

Navy RF8 Crusader Takeoff Distance Chart. The Takeoff Distance Chart for a U.S. Navy RF8

Crusader (Photo Reconnaissance version) using military power (as opposed to combat power, or

afterburner) is given on the next page. While the F8 is an older supersonic aircraft (capable of exceeding

Mach 1.8 and still being flown off ship by the French Navy as of November 1999), the methodology used

to compute takeoff distance is typical and not outdated. To use the chart:

1.

2.

3.

4.

5.

6.

Determine runway ambient temperature and headwind (or tailwind) component, field pressure

altitude, and gross weight.

At the lower left part of the chart, locate temperature on the vertical scale, and proceed

horizontally left to intersect the appropriate curved pressure altitude line, interpolating as

required.

From this first intersection point, proceed vertically up to intersect the appropriate straight

gross weight lines in the upper left part of the chart, interpolating as required.

From this second intersection point, proceed horizontally to the right to intersect the vertical

zero wind component line in the upper right part of the chart.

From this third intersection point, proceed parallel the curved headwind/tailwind lines until

intersecting the vertical line corresponding to headwind (or tailwind) component.

From this fourth intersection point, proceed horizontally to the right to read takeoff distance.

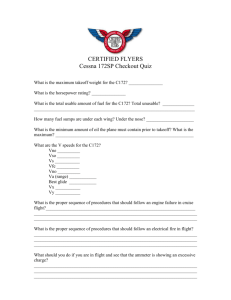

Practice Calculations: Determine takeoff roll for 0o C, 25 kts of headwind, SL pressure altitude, and

28,000# gross. Also determine takeoff roll at the same gross weight for 40 o C, calm wind, 2000’ pressure

altitude.

The following table contains information extracted from the F8 Takeoff Chart. It answers the two

problems posed above, and also compares actual takeoff distances to theoretical takeoff distances computed

using previously derived equations. The distance “errors” using the equations are not always small,

suggesting that the model used to formulate the equations may be somewhat naïve for predicting F8

Crusader takeoff performance. This is most noticeable in density/temperature changes, where the models

do not take account of resultant, often large changes in jet thrust.

Note: Very wide variations in takeoff roll depending on takeoff conditions are reflected in the table. In

particular, changes in pressure altitude and ambient temperature cause large changes in takeoff roll. The

table figures should alert you to the fact that accurate takeoff performance calculations are crucial to flight

safety when operating jet aircraft.

Runway Conditions

28000#, 40o C, 0 kts HWind, 2000 PA

28000#, 0o C, 0 kts HWind, 0 PA

28000#, 40o C, 0 kts HWind, 0 PA

28000#, 0o C, 0 kts HWind, 2000 PA

28000#, 0o C, 25 kts HWind, 0 PA

28000#, 40o C, 25 kts HWind, 2000 PA

24000#, 0o C, 0kts HWind, 2000 PA

24000#, 0o C, 0 kts HWind, 0 PA

24000#, 0o C, 0 kts HWind, 4000 PA

Chart Roll (ft)

10500

4100

8800

4900

2850

8000

3600

2800

3900

Theoretical Takeoff Roll (ft)

% Diff

4100 (313 / 273)2 = 5389

4100 (1.0 / 0.9428)2 = 4612

4100 (1 – 25/150)2 = 2847

10500 (1 – 25/154.5)2 =7376

4900 (24,000 / 28.000)2 = 3600

4100 (24,000 / 28.000)2 = 3012

2800 (1.0 / 0.8881)2 = 3550

-38.8%

-5.3 %

0%

-7.8%

0%

+7.5 %

-9.1 %

Rogers’s AS310 Notes, Part III: Page 11

Rogers’s AS310 Notes, Part III: Page 12

4. Importance of Acceleration Check; Premature Rotation Hazard

Takeoff Acceleration Check. Our theoretical approach to determining relative takeoff time, distance, and

liftoff speed gives useful approximations. Moreover, as we have seen, available heavy aircraft performance

data allow determining takeoff parameters much more accurately using charts and graphs based on this

data.

However, one point is abundantly clear. If the aircraft is not accelerating normally, no calculated takeoff

roll or refusal speed is helpful. That is, you calculate your go / no go speed of say 105 kts to allow you to

stop on the remaining runway when rejecting a takeoff at or below that speed. However, this refusal speed

is based on the assumption that your airplane is accelerating normally. Suppose the 105 kts speed is based

on having 4000’ remaining when you initiate the abort. If your aircraft isn’t accelerating normally, you

may not reach 105 kts until there are only 3500’ of runway remaining, and if you abort at 105 kts, you’re

likely to run off the end of the runway (hopefully at low enough speed to avoid serious damage).

Figure 7.7. Distance vs. Velocity Acceleration Check

Figure 7.8. Distance vs. Time Acceleration Check

Again, heavy aircraft have performance charts to allow you to determine how fast you should be going

after a given takeoff roll distance. However, such calculations can be done to a fairly good degree of

accuracy using the charts shown in Figure 7.7, based on data for the B767. (Figure 7.8 is a similar figure

for takeoff time as opposed to distance.) Recall that V is velocity, X distance, a acceleration, and t time.

Both these figures depict plots which are parabolic in shape, based on following observation:

VF2 = 2a and VF = at.

Thus X VF2 and VF t,

so X t2.

Rogers’s AS310 Notes, Part III: Page 13

Example Calculation. Suppose rotation speed is 150 KTAS, and rotation roll and rotation time have been

determined to be 8000’ and 45 seconds respectively. Using Figures 7.7 and 7.8, determine predicted roll

and elapsed time when 75 KTAS is achieved.

75 KTAS is 75/150 = 0.5 of your takeoff speed, so from Figure 7.7 you should have covered 0.22 of your

takeoff roll, or 0.22 (8000’) = or 1760’. Note that this is less than ¼ of the total takeoff roll. From Figure

7.8, about 0.45 of the takeoff time should have elapsed, or 0.45 (45) = 20.25 seconds. That is, it takes close

to half of the rotation time but only about 1/5 of the rotation roll to get to half your rotation speed.

You can conclude that early decisions about takeoff abort are necessary. Once you get going fast, you’re

eating up runway like a roadrunner. This implies that unless a runway is extraordinarily long, you must

make an early takeoff commitment in term of runway behind you. Figures 7.7 and 7.8 tell you that when

you have used up half your takeoff roll, you’ve achieved about 73% (almost ¾) of your liftoff velocity and

used up about 70% of your takeoff time. Things happen very rapidly in the last half of the takeoff roll, and

there is no room for indecision during a time when an incorrect response to an emergency can lead to

quick and certain disaster.

Early Rotation Hazard. From Figure 7.4, we see that drag (it’s induced drag) increases significantly once

takeoff rotation starts. Thus early rotation adds additional drag to an aircraft, lengthening takeoff roll.

Another (and contrary hazard) is that you may get airborne prematurely, which can lead to serious

problems. First of all, you’re flying in ground effect, and in some airplanes a very high AOA creates so

much drag that you can’t fly through the high drag region to the front side of the thrust curve. This can be

very hairy if there are obstacles off the end of the runway. Second, you are flying near the stall speed, so

control may be difficult.

Exemplum. I flew in the reserves with a former Blue Angel Hal who was #5 for the Blues when they were

still operating Grumman F11 Tigers. At that time at least, #5 and #6 did individual high performance

takeoffs during air shows. At Andrews AFB during a show, Hal hit a bump in the active runway just at

rotation speed, got airborne prematurely (with the gear coming up), then settled back on the runway and

skidded to a stop on the remaining runway in front of a very surprised crowd. Fortunately, the aircraft

remained on the hard surface, there was no fire, and no one got hurt. But the pilot was severely

embarrassed, and with a little less luck, he could also have been severely dead. By the way, I also know

another Navy pilot Pete who did the same thing in an F8, and he was an Instructor Pilot in the F8 RAG

(Replacement Air Group), a squadron that transitioned Naval Aviators into the Crusader. Hal and Pete

were two of the Navy’s best. Moral: it’s obvious that even the best of us can make foolish mistakes, so

strive to be well-informed and diligent about safety if you want to have a long, happy flying career

unmarred by mishaps.

Rogers’s AS310 Notes, Part III: Page 14

LARGE COMMERCIAL AIRCRAFT TAKEOFF

Rules and Regulations

takeoff anomaly – an undesirable event which occurs during takeoff; e.g., engine failure, tire or

wheel problem, cockpit warning indication, bird strike, &c. After a takeoff anomaly, a decision to

continue or abort the takeoff must be made.

VMC – minimum control speed due to asymmetrical thrust with one engine inoperative. This

speed is subdivided into:

VMCG – minimum control speed during takeoff ground roll with the nose wheel still on the ground.

VMCA – minimum control speed in the air or on the ground with the nose wheel off the ground

after rotation for takeoff.

1.

2.

all engine minimum unstuck speed VMU – slowest airspeed where the airplane can be forced off

the ground with all engines operating. At this speed, the airplane will fly in ground effect but stall

out of ground effect and the settle back toward the ground.

engine out minimum unstuck speed Vmu – slowest airspeed where the airplane can be forced off

the ground with one engine inoperative. Observations immediately above apply.

VXSE – best angle of climb airspeed with one engine inoperative. 180 kts is typical for a large

swept wing jet transport airplane.

VYSE – best rate of climb airspeed with one engine inoperative. 200 kts is not atypical for a large

swept wing jet transport airplane.

climb gradient – altitude gain divided by horizontal distance covered expressed as a percent. A

climb angle of 45o corresponds to a 100% climb gradient. If it takes 4000’ along the ground to

gain 50’ of altitude, the climb gradients is (50 / 4000) 100 = 1.25%.

adequate climb capability – capability to achieve a specified critical engine out climb gradient

depending on the total number of engines on the airplane. Requirements for various takeoff

segments (defined later) are given below.

takeoff safety speed V2 – the speed after takeoff that gives an adequate climb angle (adequate

climb capability) from 35’ AGL to 400’ AGL with an engine inoperative. For large swept wing

jet transport airplanes (but not for light twins), V2 is typically less than VXSE or VYSE. V2 must be

at least 1.2 VS (1.15 VS for some airplanes) for takeoff flaps setting, and at least 1.10 V MCA.

takeoff decision speed V1 – the airspeed at which a decision must have been made to abort or

continue after a takeoff anomaly, especially an engine failure. Below V 1, an abort is feasible; after

V1, takeoff must be continued unless the ability of the airplane to fly is seriously in doubt. For

safety considerations, V1 VMCG, since at and after V1, the airplane is committed to take off.

rotation speed VR –speed at which rotation for takeoff commences. VR must allow V2 airspeed

and 35’ AGL altitude to be reached by runway end if takeoff is continued after a takeoff anomaly.

For safety considerations, VR 1.10 VMU, VR 1.05 Vmu, and VR V1 (use limit which gives the

highest VR).

target pitch angle – the desired pitch angle at liftoff.

specified rotation rate – a takeoff rotation of 3o pitch angle per second is used to attain target

pitch angle.

Rogers’s AS310 Notes, Part III: Page 15

Takeoff Segments

Dirty Configuration

Segment A

Segment B Segment C

Segment D

Clean Configuration

Segment E

Extended Runway

Figure 8.1. Takeoff Profile Segments.

Takeoff Climb Segments. As illustrated in Figure 8.1, the takeoff profile is usually divided into five

segments. For ease of discussion, we have labeled these segments A through E on the figure. Such labels

are not conventional, and are used here for convenience only. The conventional naming of these segments

is somewhat confusing (which is typical of FARs and information derived from FARs). For instance,

Segment C (the third segment sequentially) is often called Segment 2. Also the Segments C and D (the

third and fourth segments sequentially) are sometimes grouped together:

Segment A: ground roll from release of brakes to liftoff. Occurs totally on the ground.

Segment B (1st Segment): from liftoff to 35’ AGL and V2. Called the 1st segment since it is

the first airborne segment. Adequate climb capability in this segment requires

1. a 0.5% climb gradient (5’ altitude per 1000’ of horizontal distance) with 3 out of 4

engines operating.

2. a 0.3% climb gradient (3’ altitude per 1000’ of horizontal distance) with 2 out of 3

engines operating.

3. a positive climb rate with 1 out of two 2 engines operating.

Segment C (2nd Segment): from 35’ AGL to 400’ AGL. V2 is maintained during this segment,

called the 2nd segment, since it is the second airborne segment. Adequate climb capability in

this segment requires

1. a 3.0% climb gradient (30’ altitude per 1000’ of horizontal distance) with 3 out of 4

engines operating.

2. a 2.7% climb gradient (27’ altitude per 1000’ of horizontal distance) with 2 out of 3

engines operating.

3. a 2.4% climb gradient (24’ altitude per 1000’ of horizontal distance)with 1 out of

two 2 engines operating.

Segment D (Acceleration Segment; sometimes subdivided into 3 rd and 4th Segments): segment

where airplane accelerates from V2 to 1.25 Vs (clean) at 400’ AGL. The 3rd Segment ends

when flaps are retracted. The 4th segment ends when the first throttle reduction occurs.

Segment E (Final Segment; also sometimes called the 5 th Segment): clean configuration climb

from 400’ AGL to 1500’ AGL at a speed no lower than 1.25 V s. Adequate climb capability in

this segment requires:

1. a 1.7% climb gradient (17’ altitude per 1000’ of horizontal distance) with 3 out of 4

engines operating.

2. a 1.5% climb gradient (15’ altitude per 1000’ of horizontal distance) with 2 out of 3

engines operating.

3. a 1.2% climb gradient (12’ altitude per 1000’ of horizontal distance) with 1 out of 2

engines operating.

Rogers’s AS310 Notes, Part III: Page 16

Verbal Description of Flight Operation in Each Section. We will describe aircraft / flight crew behavior

during takeoff segments A – E, under the assumption that an engine failure occurs at or after V 1.

Segment A (ground roll): The aircraft is cleared onto the runway with flaps set for takeoff.

All pertinent speeds – V1, VR, and V2 in particular – are foremost in the minds of the flight

crew. After normal runup and brake release at takeoff thrust, if an engine failure or other

serious takeoff anomaly occurs before V1, an abort is initiated. The pilot not handling the

controls calls out V1 about 5 kts before the go / no go speed is reached, and calls out V R at

rotation speed. Starting at VR, the target pitch angle is achieved using the specified rotation

rate of 3o /sec. Shortly thereafter the aircraft lifts off the runway and Segment A ends. After

V1, the aircraft cannot be stopped without overrunning the end of the runway. Essentially, a

commitment to take off exists, and an abort after V1 should be attempted only when the ability

of the airplane to fly is seriously in doubt. (For example, an explosion or fire causes extensive

damage to wing, tail assembly, or control surfaces.) If the captain initiates an abort at or after

V1, he or she is essentially saying that it is safer to run off the end of the runway at high speed

than to attempt to fly the airplane. A number of serious accidents have been precipitated

when inadvisable aborts after V1 were attempted. If you have already reached V1, it’s far too

late to abort and stay on the runway. It has been shown that initiating an abort even a second

or two after V1 can cause the aircraft to overrun the runway at speeds of 70 – 100 kts.

Remember that the airplane is full of fuel, and that if the fuel tanks rupture, the chances of a

catastrophic fire are great. Also, sudden stops from high speeds due to collision with

obstacles are not very well tolerated by the human body, and the flight crew is in the cockpit

section, which ordinarily impacts off-runway obstacles first.

Segment B (1st Segment). After an engine failure, timely gear retraction will help cut down

drag and make the airplane easier to fly. However, first priority is controlling the airplane

during the asymmetrical thrust situation. Also, gear should not be retracted until it is clear

that the airplane will not settle back onto the runway. If required, firewall thrust is applied

after the engine failure. With gear coming up and a positive climb rate established, the

aircraft (presumably) crosses the upwind end of the runway at V 2 and 35’ AGL or higher.

Flaps are still down as Segment B ends over the end of the runway.

Segment C (2nd Segment). The aircraft continues climb straight-ahead at V2 to 400’ AGL, at

which point Segment C ends. Flaps are still down, and takeoff power is maintained. Landing

gear is retracted. If you get to this point and the aircraft is firmly under control, things are

looking pretty good. Most catastrophic takeoff accidents have already occurred before the

end of Segment C.

Segment D (Acceleration Segment; 3rd and 4th Segment): The aircraft accelerates at 400’ AGL

and flaps are retracted. The 3rd Segment ends. Acceleration continues to attain an airspeed at

least 1.25 VS for the clean configuration. A power reduction to max continuous thrust occurs.

The 4th Segment ends. Segment D is concluded. If you get to this point, everything is

probably going to be OK. The people in the cabin will think the Captain is a hero once the

plane is back on the ground and they get a chance to calm down and reflect a little bit on what

has happened.

Segment E (5th Segment): In the clean configuration at or above 1.25 V S, the airplane climbs

straight ahead to 1500’. Segment E ends. At this point, the flight crew can assess the existing

emergency more fully and decide on a plan of action. For engine failure, it’s obvious that an

immediate landing is desirable, but first you have to get down to max landing weight by

dumping fuel, and many pilots will want to be even lighter than that if the reduction can be

done expeditiously.

Rogers’s AS310 Notes, Part III: Page 17

Balanced Field Length

Review of Important Definitions. As before, we assume failure of a critical engine after the airplane is

committed to takeoff (V V1).

Factors affecting V2, the takeoff safety speed for adequate climb from 35’ to 400’ AGL with

asymmetrical thrust:

1. V2 1.2 VS in the takeoff configuration, to preclude inadvertent stall.

2. V2 1.1 VMCA, to preclude inadvertent loss of control.

3. Ordinarily, V2 is significantly lower than VX, which is typically in the 180-220 kts

range for jet transports. Accelerating to VX with an engine out might require that

significant time be spent at low altitude. However, V2 must be high enough to allow

adequate climb capability with a critical engine out, as previously defined.

4. It follows that the largest of {1.2 VS, 1.1 VMCA, V for adequate climb capability}

applies.

Factors affecting rotation speed VR:

1. VR 1.10 VMU (minimum unstuck speed), or VR 1.05 Vmu (engine out minimum

unstuck speed) to avoid getting airborne at a speed where the airplane probably will

not fly out of ground effect. (The presumption here is that this restriction ensures V R

VS in the takeoff configuration.)

2. VR 1.05 VMCA, to preclude inadvertent loss of control.

3. It follows that the largest of {1.10 VMU, 1.05 Vmu, 1.05 VMCA} applies.

4. VR V1, refusal speed, for safety reasons. Abort after rotate is a risky undertaking.

Factors affecting V1, the decision or go / no-go speed:

1. V1 VR, as explained above.

2. V1 VMCG, to avoid loss of control while still on the runway.

3. V1 must be fast enough to allow reaching 35’ AGL and V2 at or before the end of the

runway. This allows avoiding ground obstacles.

4. V1 must be slow enough to allow stopping the airplane on the remaining runway if

an abort is initiated.

The foregoing restrictions are summarized in the following table:

Speed

V2

VR

V1

Restrictions

max (1.2 VS, 1.1 VMCA, Vadequate climb)

max (1.10 VMU, 1.05 Vmu, 1.05VMCA); VR V1

V1 VR; V1 1.05 VMCG; V1 allows climb to 35’

AGL and / or stopping on remaining runway.

Accelerate-Go and Accelerate-Stop Distances: The following are FAR definitions.

accelerate-go distance – distance an airplane uses to accelerate to V1, experience a critical

engine failure, then continue accelerating, lift off, and achieve an altitude of 35’ AGL.

accelerate-stop distance – distance an airplane uses to accelerate to V1, then decelerate to a

stop using only brakes and spoilers (Assumes an engine has failed, making reverse thrust

unusable or inadvisable: reverse thrust is permitted on a wet runway in some cases).

The figure shown below (a recreation of Figure 9.1 in the text) plots accelerate-go and accelerate-stop

distances for values of V1 between 0 and 150 kts. Accelerate-stop distance increases as V1 increases, since

more runway is used in the accelerate phase, and the decelerate phase begins from a higher speed.

Accelerate-go distance decreases as V1 increases, since the engine failure occurs later in the takeoff roll,

hence the airplane is subject to full power for a greater portion of the takeoff.

Rogers’s AS310 Notes, Part III: Page 18

14

Distance in Feet / 1000

12

accelerate-stop

10

8

6

4

accelerate-go

2

0

0

50

100

Decision Speed V1 (KIAS)

150

Figure 9.1 (Redrawn). Accelerate-Stop and Accelerate-Go Distance vs Decision Speed.

We will discuss shortly the effect of gross weight, density altitude, and configuration changes on

accelerate-stop and accelerate-go distances. Other factors which can affect these distances include runway

slope, runway conditions, and reduced thrust settings used in thrust derated takeoffs.

Balanced Field Length. Balanced field length is the runway length where, for a given gross weight,

elevation, and takeoff configuration, accelerate-stop distance and accelerate-go distance are the same.

Since takeoff from a short runway requires optimal performance, we assume takeoff flaps are set to give

such performance. Any change from optimal flap setting for existing conditions will increase balanced

field length and V1. The graph is based on existing conditions (gross weight, temperature, wind, &c.).

In Figure 9.1, balanced field length is 6000’, and corresponds to a go / no-go speed V1 of about 130-135

KIAS. For this particular aircraft on a 6000’ runway at existing ambient conditions:

1.

2.

3.

4.

if an engine failure occurs prior to V1, the aircraft will have adequate runway remaining to

stop when an abort is initiated.

If an engine failure occurs at or above V1, the aircraft will achieve 35’AGL by the end of the

runway if the takeoff is continued.

if an abort is initiated after V1, the aircraft will overrun the runway.

if an engine failure occurs prior to V1 and takeoff is continued, the aircraft will not achieve

35’ AGL by the end of the runway. (In fact, it might not get airborne at all, if the engine

failure occurred at a very low speed!).

It is easy to draw three important conclusions from Figure 9.1 and the above observations:

1.

An airplane should never attempt to depart from a runway shorter than the balanced field

length for its particular gross weight, elevation, and takeoff configuration, since

a decision to abort just below V1 will result in runway overrun.

a decision to continue just above V1 will result in achieving less than 35’ AGL by the

end of the runway.

2.

If V1 is changed from the V1 corresponding to balanced field length, the runway length to

depart safely increases, since

when V1 decreases, accelerate-go distance increases, and takeoff commitment occurs

at V1.

When V1 increases, accelerate-stop distance increases, and a commitment to abort

exists below V1.

3.

The balanced field length concept ordinarily should be used to determine decision speed V1.

Rogers’s AS310 Notes, Part III: Page 19

Effect on Balanced Field Length of Changes in Gross Weight, Density Altitude, and Runway Slope

The table below recapitulates earlier results on takeoff speeds and distances.

Gross Weight:

W1 W2

Density Ratio:

1 2

R/W Grad: RG &

T-W Ratio: RT/W

Liftoff (Gnd) Speed

Takeoff Roll

Takeoff Time

V2 = V1 (W2 / W1)

X2 = X1 (W2 / W1)2

t2 = t1 (W2 / W1)3/2

V2 = V1 (1 / 2)

X2 = X1 (1 / 2)2

t2 = t1 (1 / 2)3/2

V2 = V 1

X2 = X1 [RT/W / (RT/W – RG)]

t2 = t1 [RT/W / (RT/W – RG)]

From the table, we can immediately conclude that increases in gross weight or takeoff elevation cause an

increase in both accelerate-stop and accelerate go distance. As a consequence, balanced field V 1 also

increases.

accelerate-stop distance increases because a higher TAS must be achieved to takeoff, because

takeoff acceleration decreases and takeoff distance increases, and because stopping from a

higher velocity requires more runway.

accelerate-go distance increases because a higher TAS must be achieved to takeoff, because

takeoff acceleration decreases and takeoff distance increases, and because reaching V 2 and

35’ AGL takes a longer distance due to decreased acceleration.

balanced field V1 increases because both accelerate-go and accelerate-stop distances increase.

VR and V2 also increase due to increases in TAS proportional to (W2 / W1) or (1 / 2).

These ideas are reflected in the figure shown below. Balanced field V 2 has increased something like 8-10

KIAS, and balanced field length has increased from 6000’ to about 7700’. Since IAS to takeoff has

increased, VR will also increase.

14

Distance in Feet / 1000

12

accelerate-stop

10

8

6

4

accelerate-go

2

0

0

50

100

Decision Speed V1 (KIAS)

150

The table at the top of the page also reflects the fact that runway upslope slope reduces effective takeoff

thrust without changing liftoff velocity. Thus V2 also remain constant. However, accelerate-go distance

will increase because it takes longer to reach V1, VR, and V2 and 35’ AGL. Predicting the effect on

accelerate-stop distance is more problematic, because after engine failure an upslope actually decreases

stop distance somewhat. On the other hand, it takes longer to reach the stop point with an upslope. The

overall effect of runway slope is to increase balanced field length and V 1. VR theoretically remains

constant, though some carriers increase speed slightly to compensate for reduced acceleration after rotation

due to increased induced drag.

Rogers’s AS310 Notes, Part III: Page 20

Effect of Reduced Thrust on Balanced Field Length and V1. Derated (reduced thrust) takeoffs where

feasible are routinely used by air carriers to prolong engine life. It is straightforward to see that reducing

thrust increases balanced field length and V1. Reducing thrust

increases takeoff distance and the distance required after liftoff to reach V 2 and 35’ AGL, thus

increasing accelerate-go.

ncreases distance required to reach V1 (but not to stop from V1), thus increasing accelerate-stop

distance.

Derated takeoffs are possible only when actual runway length significantly exceeds balanced field length

for full takeoff thrust.

Effect of Runway Conditions on Balanced Field Length and V1.

slippery runway – a slippery runway is one where poor braking action (rain, freezing rain, very

light ice or packed snow) increases accelerate-stop distance but not accelerate-go distance. An

increase in balanced field length will occur as a result. V1 must be decreased to allow a greater

abort rollout. VR and V2 remain unchanged.

cluttered runway – a cluttered runway is one where precipitation on the runway increases

accelerate-go distance but not accelerate-stop distance. Balanced field length will increase, as will

V1, because it takes longer to achieve a ground speed compatible with reaching V 2 and 35’ AGL

by the end of the runway. This definition is pretty much academic. Most cluttered runways are

also slippery. Such a runway is called a “slippery-cluttered” runway.

Summary of Changes to Balanced Field Length. The following graph summarizes effect on balanced

field length and V1 of weight , elevation, and runway slope increases; and of slippery/cluttered runways.

Note that all increases increase balanced field length, and that all changes except slippery runway increase

V1.

distance

stop wt, el, derate

upslope, slippery,

stop dry

Slip/clut

Clutter

slippery

dry

go wt, el, derate

upslope, cluttered

true airspeed

Slippery

Dry

Slip/clut

clutter

go dry

Rogers’s AS310 Notes, Part III: Page 21

Effect of Stopway on Accelerate-Stop Distance. A stopway is a paved runway extension, at least as wide

as the runway itself, able to support the weight of an airplane running onto it, as for example during an

aborted takeoff. Since it is not used for landing, a stopway need not be as strong as the runway itself, hence

is cheaper to construct. Of course, obstructions are prohibited in a stopway. Figure 9.14 depicts a typical

stopway.

Figure 9.14. A Typical Stopway.

Stopway length may be added to runway length in calclulating accelerate-stop distance and V1. Quite

obviously, the presence of a stopway will enable V1 to be increased beyond what it would be for runway

length alone, i.e., beyond balanced field length V1. Figure 9.15 illustrates this idea.

Figure 9.15. Accelerate-Stop Distance Including a Stopway.

Effect of Clearway on Accelerate-Go Distance. A clearway is an unpaved unobstructed area at the end

of the runway which is under control of the airport. It must extend at least 250’ to either side of the

centerline, and must have a gradient no larger than 1.25%. There is no requirement that a clearway be

paved. Threshold lights no higher than 26 inches are the only objects which may be located in a clearway.

Figure 9.16 depicts a typical clearway. Note that nothing prohibits a paved clearway with adequate load

bearing capability from functioning as a stopway.

Rogers’s AS310 Notes, Part III: Page 22

Figure 9.16. A Typical Clearway.

In calculating accelerate-go distance, up to one-half of the distance from liftoff to 35’ AGL may be over a

clearway. The presence of a clearway will increase an airplanes maximum allowable takeoff gross weight

over what it would be if the clearway did not exist. Figure 9.17 illustrates this idea.

Figure 9.17. Accelerate-Go Distance Including a Clearway.

Effect of Stopway / Clearway on Balanced Field. If a clearway is used to extend accelerate-go distance,

or a stopway is used to extend accelerate-stop distance, then the airplane is not taking off from a balanced

field.

Rogers’s AS310 Notes, Part III: Page 23

Some Important Additional Definitions. The following definitions address additional FAR restrictions

on allowable minimum runway length for takeoff. No airplane may attempt a takeoff on a runway that is

shorter than FAR Takeoff Field Length, as defined below. All definitions are for ambient conditions; i.e.,

different conditions lead to different absolute lengths in feet when applying the following definitions.

All-Engine Takeoff Distance – the distance from the start of takeoff roll to V2 and 35’ AGL

with all engines operating.

All-Engine Takeoff Field Length – 115% of all-engine takeoff distance. (See Figure 9.18)

FAR Takeoff Field Length – the larger of

1. Balanced Field Length; or

2. All-Engine Takeoff Field Length.

Note that FAR Takeoff Field Length can be limited by takeoff roll distance or by minimum climb gradient

restrictions. That is, an airplane must be capable of getting airborne in a distance that allows significant

runway still in front of it. Once airborne, it must be capable of meeting all FAR climb restrictions for

normal flight and for flight with an engine out. In essence, the airplane can be takeoff roll limited or climb

limited. This distinction is discussed further in the next section.

Figure 9.18. All Engine Takeoff Field Length

Rogers’s AS310 Notes, Part III: Page 24

B767 ALLOWABLE GROSS TAKEOFF WEIGHT, V1, V2, AND VR

Note that the calculations discussed in Chapter 13 are for the B737, and should be ignored. We will

explain how to determine B767 maximum allowable takeoff gross weight at full takeoff thrust, and the

corresponding V1, VR, and V2. (Thrust derated takeoffs are not discussed.) The procedure is conceptually

simple but somewhat elaborate in the details:

1.

2.

Determine maximum takeoff gross using various Takeoff Performance Charts.

Using maximum takeoff gross, find V1, VR, and V2 from the Takeoff Speeds Chart.

Factors Which Influence Allowable Takeoff Gross. Takeoff performance charts for the B767 allow

determining different potential maximum allowable takeoff gross weights for the active runway, as follows:

Takeoff Performance Field Limit—maximum gross takeoff weight which allows the

airplane to comply with FAR Takeoff Field Length, which is the larger of balanced field

length and all engine takeoff field length (115% of all engine takeoff distance).

Takeoff Performance Obstacle Limit—maximum gross weight which allows the airplane to

clear all obstacles by a minimum of 35’ vertically, assuming that the critical engine has failed.

Runway Contamination—slush or standing water, when present, will affect acceleration and

stop distances and hence decrease both the Field Limit and the Obstacle Limit gross weights.

Takeoff Performance Climb Limit—maximum gross weight which allows the airplane to

meet all FAR climb gradient requirements.

Takeoff Performance Tire Speed Limit—maximum gross weight which assures the

airplane’s tires can withstand centripetal stress forces that develop during the takeoff roll. As

weight increases, VLOF increases, placing more stress on the tires during takeoff roll. Tires are

usually rated at 210 or 225 mph, and can sometime limit allowable takeoff gross weight.

Takeoff Performance Brake Energy Limit—a maximum brake energy speed VMBE assures

that the airplane’s brake assemblies can absorb and dissipate heat energy created if an abort is

executed. As gross weight and takeoff/abort speeds increase, brake assembly stress increases,

creating a potential fire hazard due to overheated brakes. Thus V1 must not exceed VMBE.

The allowable takeoff gross weight is just the smallest of the Field Limit Gross, Obstacle Limit Gross,

Climb Limit Gross, and Tire Speed Limit Gross. Once computed, the figure is used to determine V1, VR,

and V2. Then, if the computed V1 exceeds VMBE, the allowable takeoff gross must be reduced, and V1, VR,

and V2 for the new gross weight must be recomputed.

Algorithm for Finding Max Allowable Takeoff Gross Weight and Corresponding V1, VR, and V2.

1.

2.

3.

Find the Field Limit Gross Weight from the Takeoff Performance Field Limit Chart.

Find the Obstacle Limit Gross Weight from the Takeoff Performance Obstacle Limit Chart.

If slush or standing water are contaminating the runway, use the Field Limit and Obstacle

Limit Reduction Chart to reduce the Field Limit and Obstacle Limit Gross Weights.

4. Find the Climb Limit Weight from the Takeoff Performance Climb Limit Chart.

5. Find the Tire Speed Limit Weight from the Takeoff Performance Tire Speed Limit Chart.

6. Find the Max Brake Release Weight, which is the minimum of the Field Limit Weight, the

Obstacle Limit Weight, the Climb Limit Weight, and the Tire Speed Limit Weight.

7. Determine preliminary V1, VR, and V2 from the Takeoff Speeds Chart using Max Brake

Release Weight computed in step 6.

8. If the Max Brake Release Weight is the Climb Limit Weight, the airplane is climb limited. In

that case, use the Improved Takeoff Performance Climb Limit Chart to increase the Max

Brake Release Weight. Preliminary V1, VR, and V2 values will also increase.

9. Use the Brake Energy Limit Chart to determine if preliminary V 1 exceeds VMBE. If it does,

adjust the Max Brake Release Weight downward accordingly. V1, VR, and V2 also decrease.

10. If step 9 lowered the Brake Release Weight, re-enter the Takeoff Speeds Chart with the new

gross weight to determine final V1, VR, and V2. Adjust speeds if aircraft is climb limited.

Rogers’s AS310 Notes, Part III: Page 25

B767 Takeoff Charts may be found in an appendix to Part II of the class text. The title of the appendix is

“Boeing 767 Operations Manual.” Most required charts are reproduced in the class notes.

Determining Takeoff Performance Field Limit (Step 1). This gross weight is determined from the

Takeoff Performance Field Limit Chart. The weight, read on the right vertical scale of the chart,

corresponds to the intersection of two distinct trace lines. This weight must then be incremented if bleed

packs will be off for takeoff, and decremented if engine and wing anti-icing systems will be utilized.

1.

2.

3.

4.

5.

Construct the first trace line:

a. Enter the chart on the lower right horizontal scale with the field (runway) length.

b. Proceed vertically upward to the first reference line.

c. Follow the slanted guide lines to the runway slope on the right vertical scale.

d. Proceed vertically upward to the second reference line.

e. Follow the slanted guide lines to the headwind component on the left vertical scale.

f. Proceed vertically upward to the third reference line.

g. Follow the slanted guide lines to the flap position on the right vertical scale.

h. Proceed vertically upward to the top of the chart.

Construct the second trace line to its intersection with the first trace line:

a. Enter the chart on the lower left horizontal scale with the runway temperature.

b. Proceed vertically upward to the pressure altitude.

c. Proceed horizontally to the right to the vertical reference line.

d. Follow the slanted guide lines to intersect the first trace line.

At the intersection of the second trace line with the first trace line, proceed horizontally to

read the allowable field limit gross weight on the right vertical scale.

If bleed packs will be off for takeoff, add 1100# to the allowable field limit gross weight.

(See note lower left of chart)

If engine and wing anti-ice systems will be on, subtract 3090# from the allowable field limit

gross weight. (See table at lower left of chart.)

Determining Obstacle Performance Limit (Step 2). This gross weight is determined from the Takeoff

Performance Obstacle Limit Chart. Four trace lines must be constructed. Be sure to choose the chart

corresponding to planned takeoff flaps setting. (Only the Flaps-5 chart is included in the notes. The class

text contains both a Flaps-5 and Flaps-15 chart.)

1.

2.

3.

4.

5.

Construct the first trace line:

a. Enter the chart on the lower left horizontal scale with the runway temperature.

b. Follow the slanted pressure altitude lines to the pressure altitude on the lower left

vertical scale.

c. Proceed vertically upward to intersect the flap setting slanted line.

d. Proceed horizontally to the right margin of the chart.

Construct the second trace line to its intersection with the first trace line.

a. Enter the chart on the lower right horizontal scale with the distance to the obstacle.

b. Proceed vertically upward to the horizontal reference line.

c. Follow the slanted lines to an intersection with the first trace line.

Construct the third trace line. From the intersection of the first and second trace lines,

proceed vertically upward to the top of the chart.

Construct the fourth trace line.

a. Enter the chart on the upper left vertical scale with the obstacle height.

b. Proceed horizontally to the right to the vertical reference line.

c. Follow the slanted wind reference lines to the headwind or tailwind component.

d. Proceed vertically to the right of the chart.

At the intersection of the third and fourth trace lines, read obstacle limit gross weight using

the slanted weight lines.

Rogers’s AS310 Notes, Part III: Page 26

Adjusting Field and Obstacle Performance Limit Gross Weights for Runway Contaminants (Step 3).

A slippery runway decreases braking effectiveness, decreasing V 1 and increasing balanced field length. A

cluttered runway decreases acceleration, increasing both V 1 and balanced field length. Use the

Slush/Standing Water Takeoff Chart to decrease allowable field and obstacle performance gross weights.

1.

2.

3.

4.

Enter the chart with the calculated gross weight, pressure altitude, and depth of slush/standing

water.

Read the weight reduction in the appropriate column.

Three levels of linear interpolation will be required to obtain the best safe gross weight. (If

interpolation is not used, always round up to the higher value to achieve a conservative

takeoff gross weight figure. This figure will be less than the “best” gross weight.)

a. Interpolation between two gross weights.

b. Interpolation between 0.25” and 0.5” of slush/water.

c. Interpolation between two pressure altitudes

The weight computed must be subtracted from the gross weight used to enter the chart.

Determining Takeoff Performance Climb Limit (Step 4). This gross weight is determined from the

Takeoff Performance Climb Limit Chart.

1.

2.

3.

4.

5.

6.

7.

Enter the chart on the lower right horizontal scale with the runway temperature.

Proceed vertically upward to intersect the pressure altitude, using the slanted lines to

interpolate.

From the pressure altitude intersection, proceed horizontally left to intersect the vertical

reference line.

From the reference line, use the slanted lines to proceed to the flap position indicated on the

lower left horizontal scale.

From the intersection with the flap position, proceed horizontally to read the climb limit gross

weight on the left vertical scale.

If air conditioning packs will be off, increase calculated gross weight by 3100#. (See note at

lower left of chart.)

If engine and wing anti-ice will be used, decrement the calculated gross weight 3500# for

Flaps 5 takeoff or 3300# for Flaps 15 or Flaps 20 takeoff. (See box at lower left of chart.)

Determining Takeoff Performance Tire Speed Limit Step 5). This gross weight is determined from the

Takeoff Performance Tire Speed Limit Chart. The chart for 225-mph tires is given in the notes.

1.

2.

3.

4.

5.

Enter the chart on the bottom horizontal scale with the runway temperature.

Proceed vertically upward to intersect pressure altitude, using the slanted lines to interpolate.

From the pressure altitude intersection, proceed horizontally to read the flaps 5 tire speed limit

weight on the left vertical scale.

For flaps 15, increase gross weight limit by 26,500#. For flaps 20, increase by 50,300#.

(Notes at bottom of chart.)

For each knot of headwind component, increase weight limit by 2,600#. For each knot of

tailwind, decrease weight limit by 4,300#. (Note at bottom of chart.)

Determining V1, VR, and V2 (Steps 7, 10). Use the Takeoff Speeds Chart and to compute these values.

1.

2.

3.

4.

In the upper left portion of the figure, find the intersection of pressure altitude on the left

vertical scale with runway temperature on the bottom horizontal scale. This intersection falls

in one of five column reference areas of the graph: A, B, C, D, or E.

Enter the table in the flap setting row and column reference column to read V1, VR, and V2

corresponding to the previously computed maximum allowable takeoff gross weight.

Adjust V1 for wind and runway slope by referring to the small table at the upper right of the

figure. Adjustments must not increase V1 beyond VR.

If V1 falls in a shaded area, it may be less than VMCG. In that case, consult the table at the

lower left of the figure to increase V1 to VMCG.

Rogers’s AS310 Notes, Part III: Page 27

Determining Takeoff Performance Improved Climb Limit (Step 8). Allowable gross takeoff weight is

the minimum of the field limit, obstacle limit, climb limit, and tire speed limit weights. If the climb limit is

smallest, then the airplane is climb limited. A higher V2 gives a higher rate of climb rate. Use the Takeoff

Performance Improved Climb Limit Chart to increase allowable takeoff gross (V2 will also increase). Two

calculations – Field Length Limit and Tire Speed Limit – must occur. The same algorithm works for both:

Compute Field Limit Weight – Climb Limit Weight, or Tire Speed Limit Weight – Climb

Limit Weight, depending on which chart will be used.

2. Enter the chart on the lower horizontal scale with this difference.

3. Proceed vertically upward to intersect the normal climb limit weight line.

4. From the intersection, move horizontally to read gross weight improvement on the left

vertical scale.

5. From the intersection, move horizontally to read V1 increase to the right of the chart.

6. Continue right to intersect vertical reference line.

7. Follow the slanted lines to intersect vertical normal climb limit weight line.

8. From the intersection, move horizontally to read VR and V2 increase on the right vertical

scale.

9. When two climb limit increases have been calculated, add the lesser of the two to the takeoff

performance climb limit gross weight. (V1, VR, and V2 will also increase)

10. The resultant figure gives the maximum allowable gross weight for takeoff.

1.

Determining Takeoff Performance Brake Energy Limit Speed (Step 9). Use the Takeoff Performance

Brake Energy Limit Chart to assure that V1 as calculated above is not greater than the maximum allowable

brake energy limit speed VMBE. If it is greater, reduce allowable takeoff gross and recompute V 1, VR, and

V2.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Enter the chart at the upper left with the pressure altitude on the left vertical scale and

allowable takeoff gross weight on the bottom horizontal scale.

Proceed vertically up from the gross weight and horizontally right from the pressure altitude

to find the intersection of these two lines.

If the intersection falls outside the shaded area, or when operating with a tailwind or using

improved climb gross weight, continue with step 4. Otherwise, V MBE V1, and the

computation is complete.

From the intersection, proceed horizontally right to intersect the runway temperature.

From the intersection with runway temperature, proceed vertically down to intersect

calculated max takeoff gross weight.

From the intersection with gross weight, proceed horizontally to read V MBE on the right

vertical scale.

Adjust VMBE for runway slope, headwind/tailwind, or inoperative anti-skid brake feature, as

indicated in the table at the lower left of the figure.

Follow instructions at bottom of figure for normal takeoff gross weight or improved climb

takeoff gross weight to determine how much the allowable takeoff gross from step 1 must be

reduced.

Using the reduced allowable takeoff gross, determine new values for V 1, VR, and V2. If the

airplane is climb limited, use the Climb Limit Performance Chart to find revised values for

incrementing V1, VR, and V2.

Rogers’s AS310 Notes, Part III: Page 28

Example Calculation Using Algorithm on Pages 23. Suppose the following conditions exist at B767 takeoff:

Runway Length: 12000’

Runway Temperature: 32o F (0o C)

Conditions: 0.25” Standing Water

Anti-Ice: Off

Obstacle: 22000’ from the takeoff end 100’ above lowest point

Pressure Altitude: 4000’

Runway Downslope: 2%

Flap Position: Flaps 5

A/C Packs: On

Wind: 10 kt tailwind

Tires: 225 mph

1.

Takeoff Performance Field Limit: 395,000# – 5,025# = 389,975#.

Takeoff Performance Field Limit Correction for Runway Contamination: 5,025#:

Subtract 5,700# at 380,000# gross. Subtract 4,800# at 400,000# gross.

At 395,000# gross,

395,000 380,000

Subtract 5,700

5,700 4,800 = 5,700 – (0.75) (900) = 5,025#

4000,000 380,000

2.

Takeoff Performance Obstacle Limit: 380,000# - 5,700# = 374,300#.

Takeoff Performance Obstacle Limit Correction for Runway Contamination: 5,700#.

Subtract 5,700# at 380,000# gross.

3.

Takeoff Performance Climb Limit: 373,000#.

4.

Takeoff Performance Tire Speed Limit Weight: 445,000# - 10 (4,300)# = 402,000# (10 kt tailwind).

5.

Maximum Authorized Brake Release Weigh is 373,000#, which is the minimum of:

Final Takeoff Performance Field Limit: 389,975#.

Final Takeoff Performance Obstacle Limit: 374,300#.

Takeoff Performance Climb Limit: 373,000#.

Takeoff Performance Tire Speed Limit: 402,000#.

6.

From Takeoff Speeds Chart, at 373,000# gross and Flaps 5:

Pressure altitude / temperature category is B.

V1 = 157 kts; VR = 160 kts; V2 = 166 kts.

Slope adjustment to V1 is –3 kts, and wind adjustment is –1 kts.

Final V1 = 157 – 3 – 1 = 153 kts. This is well above VMCG of 103 kts.

7.

Airplane is climb limited, so determine Improved Takeoff Climb Performance Limits.

Field Length Limit Improvement: Field Limit Weight – Climb Limit Weight = 389,975# – 373,000# =

16,975#. Climb Weight Improvement: 5,700#. Add 4 kts to V1, and 4 kts to VR and V2.

Tire Speed Limit Improvement: Tire Limit Weight – Climb Limit Weight = 402,000# - 373,000# = 29,000#.

Climb Weight Improvement: 5,800#. Add 4 kts to V1, and 4 kts to VR and V2.

8.

Improved Takeoff Performance Climb Limit: 373,000# + 5,700# = 378,700#.

9.

Add lesser of Field Length (5,700#) and Tire Speed (5,800#) Improvements to takeoff gross.

Improved takeoff max gross is 378,700#.

Add 4 kts to V1, and 4 kts to VR, and V2: V1 = 153 + 4 =157; VR = 160 + 4 = 164; V2 = 166 + 4 = 170.

VMBE from Brake Energy Limit (BEL) Chart: 175 – 8 – 22 = 145 kts.

Decrease 8 kts for 2% downgrade.

Decrease 22 kts for 10 kt tailwind.

V1 = 157 kts and VMBE = 145 kts, so subtract 12 (800) = 9,600# from climb improved weight giving

369,100#. This exceeds actual climb improved weight ,so now apply the VMBE check to 373,000#.

10. Determine Final Takeoff Gross and Corresponding Airspeeds:

Max Takeoff Gross Weight (Climb Limit) = 373,000#. Corresponding V1 = 153, VR = 160, V2= 166.

From BEL Chart, V1 –VMBE = 7, so must subtract 7 (1,800) = 12,600# from Takeoff Gross of 373,000#.

Final Max Takeoff Gross: 373,000 – 12,600 = 360,400#.

From Takeoff Speed Chart, V1 = 154 – 3 – 1 = 150; VR = 157; V2 = 163.

The climb limit gross was increased 5,800# using improved climb performance, then reduced since the improvement

produced a V1 that exceeded VBME. We discovered that no climb improvement was possible. Finally, in fact, the

original Climb Limit Gross of 373,000# was reduced (because of VBME) to 364,000#, and V1 reduced to 150 kts.

Rogers’s AS310 Notes, Part III: Page 29

Step-by-Step Explanation of Solution to Quiz on Preceding Page

1.

Determine the uncorrected field limit gross weight from the Field Limit Chart. Use the Runway Contamination

Table to determine how much weight to subtract from the initial field limit gross. Do the subtraction to determine

the final field limit weight.

2.

Determine the uncorrected obstacle limit gross weight from the Obstacle Limit Chart. Use the Runway

Contamination Table to determine how much weight to subtract from the initial obstacle limit gross. Do the

subtraction to determine the final obstacle limit weight.

3.

Determine the climb limit weight from the Climb Limit Chart.

4.

Determine the tire limit weight from the Tire Limit Chart, being sure to correct for existing tailwind.

5.

Choose the smallest of the four weights found in steps 1-4. This weight is the climb limit weight, and is the

current proposed max gross takeoff weight.

6.

Use the V1, VR, and V2 Table to find each of these speeds for the climb limit weight determined in Step 5. Be sure

to correct V1 for existing down slope and tailwind.

7.

Since the climb limit weight is the lowest weight in step 5, use the Climb Limit Chart to determine two values: a)

how much weight can be added due to excess field length and b) how much weight can be added due to excess tire

speed capacity. Note that adding weight requires an increase in V 1, VR, and V2, and that the increases for both

weight increments can be determined from the Climb Limit Chart.

8.

Add the lower of the two weight increments to the climb limit weight, giving a new and higher proposed max

gross takeoff weight. In this case, the lower increment is the one associated with the field length weight. Increase

V1, VR, and V2 as determined in step 6 by the amount associated with the field length weight increment, as

determined in step 7. The idea here is that the increased V 2 will give FAR acceptable climb gradients at the higher

proposed max gross takeoff weight. You now have a climb improved weight (378,700#) and corresponding V1,

VR, and V2. This weight is the new proposed max gross takeoff weight.