Mukti Pani Filters (Freedom Water Filters) for Bangladesh and West

advertisement

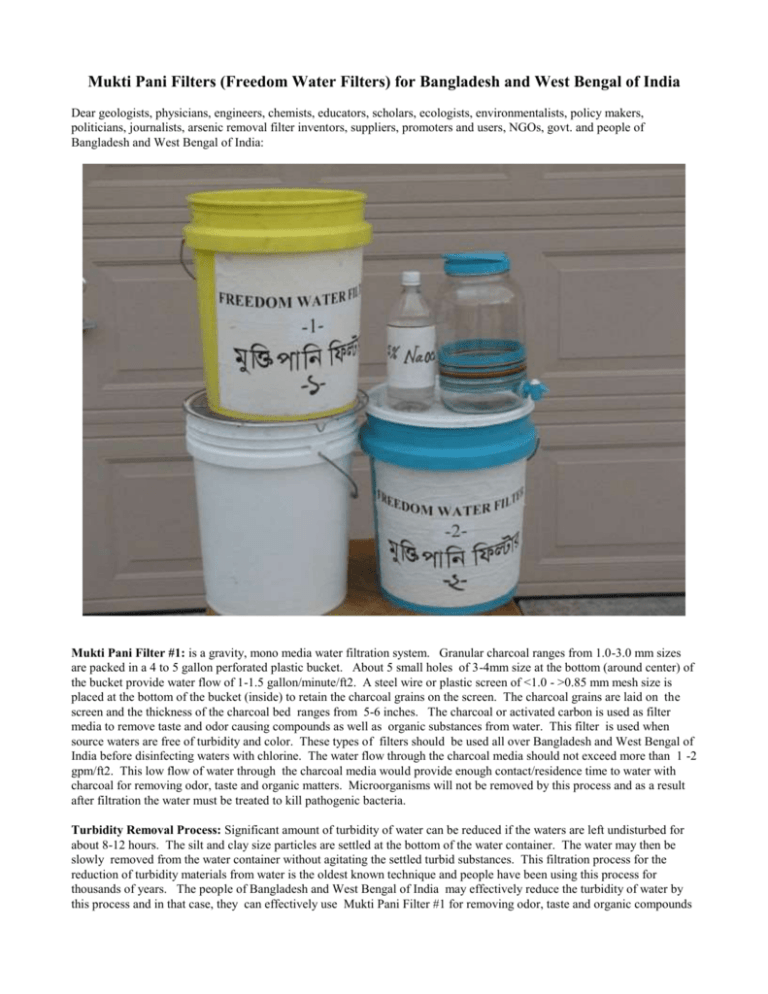

Mukti Pani Filters (Freedom Water Filters) for Bangladesh and West Bengal of India Dear geologists, physicians, engineers, chemists, educators, scholars, ecologists, environmentalists, policy makers, politicians, journalists, arsenic removal filter inventors, suppliers, promoters and users, NGOs, govt. and people of Bangladesh and West Bengal of India: Mukti Pani Filter #1: is a gravity, mono media water filtration system. Granular charcoal ranges from 1.0-3.0 mm sizes are packed in a 4 to 5 gallon perforated plastic bucket. About 5 small holes of 3-4mm size at the bottom (around center) of the bucket provide water flow of 1-1.5 gallon/minute/ft2. A steel wire or plastic screen of <1.0 - >0.85 mm mesh size is placed at the bottom of the bucket (inside) to retain the charcoal grains on the screen. The charcoal grains are laid on the screen and the thickness of the charcoal bed ranges from 5-6 inches. The charcoal or activated carbon is used as filter media to remove taste and odor causing compounds as well as organic substances from water. This filter is used when source waters are free of turbidity and color. These types of filters should be used all over Bangladesh and West Bengal of India before disinfecting waters with chlorine. The water flow through the charcoal media should not exceed more than 1 -2 gpm/ft2. This low flow of water through the charcoal media would provide enough contact/residence time to water with charcoal for removing odor, taste and organic matters. Microorganisms will not be removed by this process and as a result after filtration the water must be treated to kill pathogenic bacteria. Turbidity Removal Process: Significant amount of turbidity of water can be reduced if the waters are left undisturbed for about 8-12 hours. The silt and clay size particles are settled at the bottom of the water container. The water may then be slowly removed from the water container without agitating the settled turbid substances. This filtration process for the reduction of turbidity materials from water is the oldest known technique and people have been using this process for thousands of years. The people of Bangladesh and West Bengal of India may effectively reduce the turbidity of water by this process and in that case, they can effectively use Mukti Pani Filter #1 for removing odor, taste and organic compounds from waters. Mukti Pani Filter #2: is a dual media gravity filtration system and consists of three layers of gravel, sand and charcoal packed in a 6 gallon of plastic bucket. About 10-15 small holes of 4-5mm size at the bottom (around center) of the bucket provide a flow of water of 1-1.5 gallon/minute/ft2. The bottom layer consists of gravel, the sizes of the gravel ranges from 1.0-50.0 mm and the gravel layer is placed on a screen of <1.0->0.85 mm of mesh. The thickness of the gravel layer ranges from 2.0-3 inches. The middle layer consists of a mixture of conventional sand (40%) and coarse sand (60%). The size of the conventional sand ranges from 0.5-0.6 mm and the size of the coarse sand ranges from 0.7-3.0 mm. The sand layer is placed on a screen of <0.5->0.45 mm mesh on top of the gravel layer. The thickness of the sand layer ranges from 3-4 inches. The top layer consists of charcoal grains of 1.0-3.0 mm in size. The charcoal layer is placed on a screen of <1.0->0.85 mm mesh and placed on top of the sand layer. The thickness of the charcoal layer ranges from 4-5 inches. This is also a slow filtration system and is good for low turbidity water. The flow rate of water through these filter media should not exceed more than 2.0 gpm/ft2. When the filter media are clogged with turbidity materials, each media can be washed with clean water and reused again. Other Fiter media: Anthracite coal and activated carbon can be used in place of charcoal. Hard brick chips of gravel size can be used in place of gravel. Steel, aluminum, or earthen based containers may be used as a filter container. Screen media: Wire screen, plastic screen., nylon screen, stainless steel screen etc. Disinfection of water: In developed countries, pathogenic organisms in water that cause various types of diseases such as cholera, typhoid, dysentery, diarrhea etc. are no longer a problem due to proper water protection, treatment and monitoring. Boiling water is expensive but very effective process known for centuries for killing pathogenic bacteria in water. There are several chemical disinfectants are being used today for water treatment of which chlorine disinfection is simple, inexpensive and very effective. Chlorination is the oldest method of continuous disinfection for public water supplies. There are two theories regarding chlorine disinfection mechanism. One theory views that the vigorous action of chlorine against the bacterial cell destroys bacteria. The other theory is that the organisms die of starvation because the toxic nature of chlorine inactivates enzymes which empower microorganisms to use their food supply. Both Calcium Hypochlorite and Sodium Hypochlorite are being extensively used for treatment of potable water. The chemical reactions of hypochlorites with water are as follows: Calcium Hypochlorite Reaction: Ca(OCl)2 + 2H20------> 2HOCl + Ca(OH)2 Sodium Hypochlorite Reaction: NaOCl + H20 -----------> HOCl + Na(OH) Chlorine Treatment Dosage: In USA most health organizations recommend potable water to be treated with either Calcium Hypochlorite or Sodium Hypochlorite with a concentration range from 1-4 ppm. In Bangladesh and West Bengal the same dosage can be effectively used for disinfecting water. The following chlorine dosage chart for 5% Sodium Hypochlorite (unscented) can be conveniently used for desired dosage. Quantity (gal.) 1000 500 200 100 50 25 10 5 1- PPM 3.0 oz 2.0 oz 1.0 tbsp 2.0 tsp 1.0 tsp 0.5 tsp 0.25 tsp 0.25 2-PPM 5.5 oz 3.25 oz 2.25 tbsp 4.5 tsp 2.25 tsp 1.13 tsp 0.55 tsp 0.45 tsp 3-PPM 8.0 oz 4.5 oz 3.5 tbsp 7.0 tsp 3.5 tsp 1.75 tsp 0.90 tsp 0.65 tsp 4-PPM 10.5 oz 5.75 oz 4.75 tbsp 9.5 tsp 4.75 tsp 2.40 tsp 1.20 tsp 0.80 tsp 5-PPM 13 oz 7.0 oz 6.0 tbsp 12 tsp 6.0 tsp 3.0 tsp 1.5 tsp 1.0 tsp Besides, the above chart, the following formula can also be used to calculate the amount of clorox/hypochlorites (or other bleach containing 5.25% Sodium Hypochlorite) necessary to produce a given dosage in a known volume of water: b=VC(2.44 X 10-3 or VC/410. Where b = ounces of bleach V = volume of water in gallons C = desired dosage in ppm 410 is the concentration produced by one ounce of clorox in one gallon of water. Example: add 3 ppm to 1200 gallons. b = 3 X 1200/410 = 8.78 oz. 1 oz = 2 tbsp (tbsp-tablespoon) 1 tbsp = 3 tsp (tsp-teaspoon) The filtered water should be stored in a clean and tightly covered plastic container or other corrosion resistant container for proper disinfection of water. A required amount of hypochlorite for desired concentration can be calculated from the above chart. (Example: add 4 ppm concentration to 100 gallons, the amount of hypochlorite is 9.5 tsp.). After adding hypochlorite solution, the treated water needs to be thoroughly mixed. The container should be properly covered and let stand for 30-60 minutes. After that the cover should be removed to release the chlorine gas. The treated water is now safe and ready for consumption. If the disinfected water strongly smells, the water should be aerated by pouring it from one container to another to remove smell and taste. The smell and the taste can also be removed by uncovering the container and letting water stand for 3-4 hours before consumption. If granular Calcium Hypochlorite is used , then a stock solution needs to be prepared by following manufacturer's instruction. The above chart and formula can be used for the calculation of desired amount of hypochlorites. Precautions: Before disinfection, water must be filtered first. Because the reaction of chlorine with organic matter present in unfiltered water may produce Trihalomethanes (THMs) which are known carcinogens. Therefore,water must not be disinfected with chlorine before filtration of water. Disinfection of Filter media: The filter media should be washed once a month with 4-5 gallons of water with at least 100 ppm concentration of clorox bleach. The holes of the bucket should be plugged or the bucket filter should be placed in a bigger flat container. The bleach mixed water should be poured into filter media and let stand the solution for an hour and then drain the bleach water and rinse the filter media 2-3 times with clean water. This cleaning process will kill any bacteria developed in filter media. Why we should not use arsenic filters for removing arsenic from groundwater in Bangladesh and West Bengal: The geological, hydrological, hydro-geological and socio-economic conditions in Bangladesh and West Bengal of India are not suitable for taking care of arsenic sludge. The improper disposal of arsenic sludge will recontaminate air, soil, sediment, water resources, agricultural resources, ecosystem and the environment. This means that using arsenic removal filters and improper disposal of arsenic sludge will create more pollution and contamination problems and as a result this process should be stopped immediately. What should we do about the indiscriminately disposed arsenic sludge on the ground, ponds, rivers etc? Those scientists and organizations who have been promoting arsenic removal filters and who have suggested and recommended improper disposal of arsenic sludge from the arsenic removal filters and water treatment plants on the ground, rivers, ponds etc. should immediately take necessary steps to map the disposal sites, determine the quantity of disposed sludge and the extent of sludges in the environment on their own expense. They should also collect disposed sludge from the rivers, ponds and other disposal sites and dispose off them properly. Why should we use Mukti Pani Filters or other Filters similar to Mukti Pani Filters? In 1998, in our article “Arsenic Disaster in Bangladesh-An Urgent Call to Save a Nation” we stated that “One or more of the following measures should be implemented, depending on cost effectiveness, availability and ease of water distribution. 1. 2. 1. Extraction and distribution of arsenic free groundwater from deep aquifers. 2. Removal of contaminants in water at existing well sites. 3. Collect, filter, and chlorinate rain or surface water.” 3. We still strongly believe that the measure #3 is the only and most effective solution to the arsenic disaster in Bangladesh and West Bengal. These filters and chlorination process effectively remove turbidity, organic materials from surface waters and rain waters, and kill pathogenic bacteria. Thus these type of filters do not create any pollution and contamination problems. Presently pathogenic organisms in water that cause various types of diseases such as cholera, typhoid, dysentery, diarrhea etc. are no longer a problem due to proper treatment of water. Chlorination is inexpensive, environmentally friendly and safe method for the disinfection of waters. This method for the disinfection of water has been using effectively all over the world. Therefore, filtration and disinfection of surface water with chlorine appears to be the most simple and best solution to the arsenic disaster in Bangladesh and West Bengal of India. How soon we can make available the “filtration and chlorination” method to the people of Bangladesh and West Bengal? These filters can be made at a cost of $4.00-5.00 in Bangladesh and West Bengal of India. One of the potential group of people that can quickly and effectively help to build water filter similar to Mukti Pani Filters are teachers and students of high Schools, colleges and Madrasas. Expatriate Bangladeshi and West Bengal, and local people of each thana/upazila may donate a small amount of money to each school/Madrasa for making filters by students and teachers , and for the preparation of hypochlorite solutions for disinfecting water. Local govt. and non govt. health specialists may also work with these group of people for building & distributing filters to the needy. Each filter can be shared by several families of a village. Those who can afford the purchase, can ask this group to make one for them at a reasonable price. This “students and teachers water filtration project” will create awareness about the danger of arsenic poisoning, danger of improper disposal of arsenic sludge, safe water etc. at a faster rate within entire area of Bengal delta, and it will help them to protect the people of Bangladesh and West Bengal of India from arsenic disaster. In Bangladesh and West Bengal of India, the filtration and chlorination of arsenic free surface water should be implemented as soon as possible. Respectfully, Meer Husain,P.G. Professional Geologist Kansas Dept. of Health & Environment And Adjunct Faculty Cowley County Community College Wichita, Kansas, USA.