Synthesis, Determination, and Catalytic Measurement of Ruthenium Indenylidene

Complexes used in Olefin Metathesis

Author: Adam Capriola

CHM 2521 Section 151, Department of Chemistry, Saint Joseph’s University

Date Submitted: April 19, 2010

Abstract

The reaction of RuCl2(PPh3)2, THF, and diphenylpropargyl alcohol under reflux yields

C51H40P2Cl2Ru in 46% yield. 1H NMR spectroscopy of C51H40P2Cl2Ru shows a series of

overlapping peaks at δ 7.3-7.8. C51H40P2Cl2Ru can then react with dichloromethane and

tricyclohexylphosphine to form C51H76Cl2P2Ru. 1H NMR spectroscopy of C51H76Cl2P2Ru yields

the same series of peaks found around δ 7.3-7.8 that C51H40P2Cl2Ru exhibits, along with a faint

series of peaks at δ 1.8-2.1.

31

P NMR spectroscopy of both products shows a single peak around

δ 29.5. This suggests what was believed to be C51H76Cl2P2Ru was actually mostly

C51H40P2Cl2Ru. Catalytic measures of the two synthesized products were inconclusive due to

their similar natures, however, it is expected that C51H76Cl2P2Ru is the better catalyst as it has

bulkier, more readily dissociating substituents.

Introduction

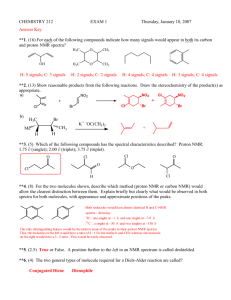

The reaction of RuCl2(PPh3)2 with THF and diphenylpropargyl alcohol under reflux

yields C51H40P2Cl2Ru.1 The reaction specifically takes place in the following manner:

Scheme 1

OH

Ph

Ph

PPh3

Ru PPh3

Cl

PPh3

Cl

THF, Reflux

PPh3

Cl

Ru

Cl

PPh3

Ph

C51H40P2Cl2Ru can then react with dichloromethane and tricyclohexylphosphine to form

C51H76Cl2P2Ru. The reaction occurs in the following manner:

Scheme 2

PPh3

Cl

Ru

Cl

PPh3

Ph

PCy3

CH2Cl2

PCy3

Cl

Ru

Cl

PCy3

Ph

These products be distinguished via 1H and 31 NMR spectroscopy. The 1H NMR spectrum of the

C51H76Cl2P2Ru will yield peaks representative of the newly added cyclo groups, which are

missing in C51H40P2Cl2Ru. The 31P NMR spectra of each product should theoretically each show

1 peak, with the peak of C51H76Cl2P2Ru being downfield from C51H40P2Cl2Ru because of the

lower electron density around the phosphorus.

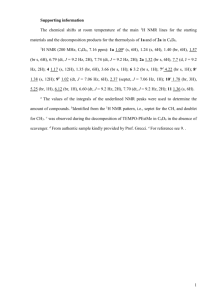

The products from these two reaction are of interest because they are ruthenium alkidene

complexes, which are alternatives to Grubbs’ catalysts and are much less difficult to prepare in

the laboratory.1 These two ruthenium indenylidene complexes can be used as catalysts in ring

closing metathesis. Show below are the balanced reaction and mechanism in which diethyl

diallylmalonate undergoes this process with the aid of a ruthenium catalyst:

Scheme 3

CO2Et

EtO2C

Ru Catalyst

EtO2C

CO2Et

+

H2C CH2

CH2Cl2

Scheme 4

PCy3

Cl

Ru

Cl

PCy3

Ph

EtO2C

CO2Et

EtO2C

+

PCy3

Cl

Ru

Cl

PCy3

Ph

EtO2C

+PCy3

EtO2C

PCy3

Cl

Ru

Cl

Ph

EtO2C

+

EtO2C

PCy3

Cl

Ru

Cl

Ph

EtO2C

EtO2C

Ph

-PCy3

Cl Cl

Ru PCy

EtO2C

3

Cl Cl

Ru PCy

3

EtO2C

EtO2C

PCy3

Cl

Ru

Cl

PCy3

+PCy3

-PCy3

PCy3

Ru

Cl

Cl

+

EtO2C

CO2Et

The relative catalytic rates of the two ruthenium indenylidene complexes can be monitored via

GC/MS. Determination of the starting material and product from this technique can show the

relative percentages of each material within a solution. By comparing the ratio of reagent to

product for each of the ruthenium complexes, it can be determined which is a better catalyst, as

the more efficient catalyst will sport the lower ratio of reagent to product.

Experimental

All syntheses were carried out in nitrogen and the reagents and solvents were purchased

from commercial sources and used as received unless otherwise noted. The synthesis of

C51H40P2Cl2Ru (1A), C51H76Cl2P2Ru (1B), and C11H16O4 (2) were based on reports published

previously.1

C51H40P2Cl2Ru (1A). A hot, dry 100 mL 3 neck round bottom flask was obtained from

an oven and connected to it were a cold water condenser, septum, and sidearm stopcock. A gas

inlet was connected to the condenser and a bubbler was connected to the gas inlet. All joints

were greased. A stir bar was placed in the round bottom flask and the apparatus was connected

to a nitrogen source. The condenser was connected to a cold water source. The round bottom

flask was degassed with N2 until cool, at which time RuCl2(PPh3)2 (0.179 g, 1.87 x 10-4 mol),

THF (10 mL), and diphenylpropargyl alcohol (0.080 g, 3.84 x 10-4 mol) were subsequently

added to the reaction vessel. A sand bath was constructed and was used to heat the solution.

The sand bath was set to 80% power and the mixture began to reflux a while later, but THF

began to evaporate over time so the sand bath was turned down to around 40% power and an

additional 30 mL of THF had to be added to the solution during the 2.5 h reflux period. The stir

bar was spun at a moderate speed during this time.

After the reflux period had been completed, the reaction mixture was allowed to cool to

room temperature. The solution was then transferred to a single neck 50 mL round bottom flask

at which time the solution was taken off the N2 supply and was exposed to air for the remainder

of the synthesis. The solvent was removed via rotary evaporation leaving a thick, dark, brownish,

reddish liquor. 1.5 mL dichloromethane was added to the liquor along with 9 mL hexane, which

was slowly pipeted in. A dark red solid was precipitated and filtered using a small fritted funnel

and was washed 3 times with about 2 mL hexane during each rinsing. The solid was vacuum

dried and placed into a pre-weighed vial (9.698 g). The vial was stored in a dessicator for 1

week. The final weight of the vial was 9.767 g. The product was determined to be 1A (0.069g,

7.78 x 10-5 mol, 41.6% yield based on the amount of RuCl2(PPh3)2 used). 1H NMR (CDCl3): δ

7.3-7.8 (6 H, overlapping signal, Ph and indenylidene).

31

P NMR (CDCl3): δ 29.5 (s, Ru-P).

FTIR (ATR) ν 1928 cm-1 (m).

C51H76Cl2P2Ru (1B). A hot, dry 100 mL 3 neck round bottom flask was obtained from

an oven and connected to it were a cold water condenser, septum, and sidearm stopcock. A gas

inlet was connected to the condenser and a bubbler was connected to the gas inlet. A stir bar was

placed in the round bottom flask and the apparatus was connected to a nitrogen source. The

condenser was connected to a cold water source. The round bottom flask was degassed with N2

until cool, at which time 1A (0.050 g, 5.64 x 10-5 mol), dichloromethane (7 mL), and

tricyclohexylphosphine (0.055 g, 1.96 x 10-4 mol) were subsequently added to the reaction vessel.

The mixture was stirred at a moderate speed at room temperature for 1.5 h. 2 mL of additional

dichloromethane was added to the solution during this time as some had evaporated off.

The solution was then transferred to a 50 mL single neck round bottom flask at which

time the solution was taken off the N2 supply and was exposed to air for the remainder of the

synthesis. The solvent was removed via rotary evaporation. The remaining solid was suspended

with 5 mL of hexane. This new solution was stirred at a moderate speed at ambient temperature

for 0.5 h. The resulting solid was filtered using a small fritted funnel and was washed 3 times

with about 2 mL hexane during each rinsing. The solid was vacuum dried and placed into a preweighed vial (9.737 g). This vial was stored in a dessicator for 1 week. The final weight of the

vial was 9.824 g. The product was determined to be 1B (0.087g, 9.42 x 10-5 mol, 167% yield

based on the amount of 1A used). 1H NMR (CDCl3): δ 1.8-2.1 (5 H, overlapping signal, PCy3),

δ 7.1-7.9 (6 H, overlapping signal, Ph and indenylidene).

31

P NMR (CDCl3): δ 29.8 (s, Ru-P).

FTIR (ATR) ν 1921 cm-1 (m).

C11H16O4 (2). A hot, dry 100 mL 3 neck round bottom flask was obtained from an oven

and connected to it were a cold water condenser, septum, and sidearm stopcock. A gas inlet was

connected to the condenser and a bubbler was connected to the gas inlet. A stir bar was placed in

the round bottom flask and the apparatus was connected to a nitrogen source. The condenser

was connected to a cold water source. The round bottom flask was degassed with N2 until cool,

at which time 1B (0.010 g, 1.08 x 10-5 mol), anhydrous dichloromethane (6 mL), and diethyl

diallylmalonate (0.100 g, 4.16 x 10-4 mol) were subsequently added to the reaction vessel. The

mixture was stirred at a moderate speed at room temperature for just over 1 h. The solution was

then transferred to a 25 mL single neck round bottom flask at which time the solution was taken

off the N2 supply and was exposed to air for the remainder of the synthesis. The solvent was

removed via rotary evaporation. 1H NMR (CDCl3): δ 1.2 (t, -CH3), δ 2.6 (d, -CH2), δ 4.1 (q, OCH2), δ 5.1 (m, =CH2), δ 5.6 (tt, C-H), δ 6.8-7.7 (6 H, overlapping signal, Ph and indenylidene).

GC-MS (CH2Cl2): 212 (2.5%, (2)), 241 (82.2%, (3)).

The process described above was repeated by a laboratory partner using 1A in lieu of 1B.

1

H NMR (CDCl3): δ 0.9 (t), δ 1.25 (s), δ 1.55 (s), δ 1.84 (t), δ 3.74 (t), δ 6.8-7.7 (6 H,

overlapping signal, Ph and indenylidene). GC-MS (CH2Cl2): 212 (0.12%, (2)), 241 (59.1%, (3)).

C13H20O4 (3). The 1H NMR spectrum of (3) was obtained from Sigma Aldrich.2 1H

NMR (CHCl3): δ 1.25 (t, -CH3), δ 2.6 (d, -CH2), δ 4.2 (q, O-CH2), δ 5.1 (m, =CH2), δ 5.7 (tt, CH).

Results

The reaction of RuCl2(PPh3)2 with diphenylpropargyl alcohol yielded 0.069g of product,

which was determined to be 1A. This translated to 7.78 x 10-5 mol and thus a 41.6% yield based

on the amount of RuCl2(PPh3)2 used, which was the limiting reagent in the reaction. Proton

NMR spectroscopy of 1A yielded one series of peaks of interest. From δ 7.3-7.8 there was a

sequence of peaks representing the 6 different aromatic hydrogens from the phenyl and

indenylidene groups.

31

P NMR spectroscopy elicited one peak at δ 29.5 which can be attributed

to phosphorus coordinated with the metal, Ru. The IR spectrum of the substance gave one

notable peak at 1928 cm-1, but the identity of this peak was unable to be determined.

The reaction of 1A with dichloromethane and tricyclohexylphosphine yielded 0.087g of

product, which was determined to be 1B. This translated to 9.42 x 10-5 mol and thus a 167%

yield based on the amount of 1A used, which was the limiting reagent in the reaction. Proton

NMR spectroscopy of 1B yielded two series of peaks of interest. From δ 1.8-2.1 were noted a

faint sequence of overlapping signals, which were thought to be due to the 5 different hydrogens

from the PCy3 groups. From δ 7.1-7.9 there was a string of peaks representing the 6 different

aromatic hydrogens from the phenyl and indenylidene groups.

31

P NMR spectroscopy elicited

one peak at δ 29.8 which can be attributed to phosphorus coordinated with the metal, Ru. The IR

spectrum of the substance gave one notable peak at 1921 cm-1, but again the identity of this peak

was unable to be determined.

The reaction using 1B as a catalyst to perform ring closing metathesis on diethyl

diallylmalonate produced a product with a 1H NMR spectrum containing several peaks of

interest. The triplet δ 1.2 was thought to be due to the methyl group, the doublet at δ 2.6 was

thought to be due to –CH2 groups, the quartet at δ 4.1 was thought to be due to the O-CH2 groups,

the multiple peaks at δ 5.1 were thought to be from =CH2, the triplet of triplets at δ 5.6 was

thought to be from C-H, and lastly the extremely weak overlapping signals at δ 6.8-7.7 were

thought to be from phenyl and indenylidene groups. These assumptions are made taking into

consideration that the 1H NMR spectrum of diethyl diallylmalonate was identical, save for the

almost negligible peaks from δ 6.8-7.7.2 The GC/MS of 1B gave what were thought to be

signals of interest at times 6.648 min and 6.945 min. The reading at 6.648 min accounted for

2.5% of the scan and was thought to be C11H16O4 because its m/z of 212 appeared as a peak. The

reading at 6.945 min accounted for 82.2% of the scan and was thought to be diethyl

diallylmalonate because its m/z of 241 appeared as a peak, albeit very small. This gave a

proposed ratio of 33:1, reactant to product.

When using 1A as the catalyst in lieu of 1B in this reaction, proton NMR spectroscopy of

the product elicited several peaks, most of which were not able to be identified. The sequence of

overlapping peaks from δ 6.8-7.7 was attributed to the 6 different hydrogens from phenyl and

indenylidene groups, but the triplet at δ 0.9, the singlet at δ 1.25, the singlet at δ 1.55, the triplet

at δ 1.84, and the triplet at δ 3.74 could not be determined. A standard 1H NMR spectrum of the

desired product C11H16O4 was unobtainable for comparison. The GC/MS of 1A gave what were

thought to be signals of interest at times 6.648 min and 6.974 min. The reading at 6.648 min

accounted for 0.12% of the scan and was thought to be C11H16O4 because its m/z of 212 appeared

as a peak. The reading at 6.974 min accounted for 59% of the scan and was thought to be diethyl

diallylmalonate because its m/z of 241 appeared as a peak, again albeit very small. This gave a

proposed ratio of 491:1, reactant to product.

Discussion

The results of this experiment are inconclusive. The first reaction seemed to give a

decent percent yield of 1A and it was identifiable through 1H and 31P NMR spectroscopy,

however there were a few erroneous peaks noted on the 1H NMR spectrum and the peaks of

interest were somewhat weak. The 31P NMR spectrum of 1A was inconclusive at first, so a new

scan was done at a later time with a different sample. These facts seem to suggest that the

original 1A obtained was not very pure. During the procedure, the sand bath was not adequately

controlled, and this is most likely what caused the impure product. Because the reaction was

overheated, side products may have formed or the original reagents did not react to completion,

and in turn, the percent yield was in reality not as high as it appeared. This also attributes to the

extra peaks that showed up on the 1H NMR spectrum. The oxidation state of 1A is +4 and its

electron count is 16.

The second reaction resulted in a percent yield of 167% of what was thought to be 1B,

which again suggests some error. The 31P of this product gave a peak in nearly the exact same

position as 1A, so this seems to confirm that the product obtained from the second reaction was

not 1B, but mostly 1A. The peak should have shifted downfield to about δ 41, which is what

colleagues have reported. The proton NMR spectrum does show faint peaks from δ 1.8-2.1

which is where one would expect hydrogens attached to non-aromatic cyclo groups to be found.

This means that some of the -PPh3 groups did convert to -PCy3 groups, but a significant amount

on the whole. The IR spectra of the products after reactions one and two are also quite similar,

again hinting that nothing really transpired during reaction two. The procedure during reaction

two went as detailed by the laboratory manual, so this means the starting material was probably

impure and thus could not react to completion.1 The oxidation state of 1B would also be +4 with

an electron count of 16.

Because reaction one and reaction two seemed to yield the same product, the ring closing

reactions cannot accurately be compared for catalytic activity. Theoretically 1B is the better

catalyst, as it has PCy3 ligands opposed to the PPh3 ligands characteristic of 1A. PPh3 ligands

have a cone angle of 145o while PCy3 ligands have a cone angle of 170o.3 The larger the cone

angle, the bulkier the ligand and the faster it dissociates, allowing for expedited ring closing

metathesis.3 The mechanism in which this takes place can be seen in Scheme 4. The reaction of

diethyl diallylmalonate with 1B did not seem to elicit the ring closing mechanism. The 1H NMR

spectra of the product looks identical to that of the starting material, diethyl diallylmalonate, save

for one area around δ 6.8-7.7 where traces of what looks like aromatic structures, namely phenyl

and indenylidene groups can be found. It looks like there was such a minute amount of catalyst

available that it never interacted with diethyl diallylmalonate to close the ring.

GC/MS of 1B shows two signals which may account for diethyl diallylmalonate and the

closed ring. At time 6.648, a peak accounting for 2.5% all that was picked up by the scan

contains a signal of 212 can be seen which corresponds with the m/z of C11H16O4. At time 6.945

min, a peak accounting for 82.2% of the scan contains a signal of 241 can be seen which

corresponds with the m/z of diethyl diallylmalonate. This gives a ratio of 33:1, reactant to

product, which means the yield was rather poor. It does seem to suggest that some product may

have been formed, however product was not visible on the 1H NMR spectrum, so this

interpretation may be inaccurate.

The reaction of diethyl diallylmalonte with 1A yielded a different 1H NMR than the

reaction with 1B did. It also shows overlapping peaks at δ 6.8-7.7 indicative of phenyl and

indenylidene groups, but these peaks are much more noteworthy, meaning there was an

abundance of catalyst available, where in the other reaction there was almost no catalyst

available. Hence, upfield peaks are seen and are believed to be product, but these peaks are

unable to be confirmed. A standard 1H NMR spectrum of C11H16O4 is unobtainable for

comparison. The peaks reminiscent of the starting material seen in the 1H NMR spectrum for the

reaction with 1B are not visible, which means there was some sort of change in the starting

material.

GC/MS analysis however does not seem to confirm the presence of a closed ring product.

At time 6.648, a peak accounting for 0.12% all that was picked up by the scan contains a signal

of 212 can be seen which corresponds with the m/z of C11H16O4. At time 6.974 min, a peak

accounting for 59% of the scan contains a signal of 241 can be seen which corresponds with the

m/z of diethyl diallylmalonate. This gives a ratio of 491:1, reactant to product, which means the

almost no product formed at all despite the presence of what seems to be a copious amount of

catalyst. The reaction with 1B has a ratio of 33:1 and had almost no visible catalyst in its 1H

spectrum, so it could be possible that the GC/MS was analyzed improperly.

The sources of error are difficult to pinpoint, but one issue may have been the flow of

nitrogen through the system. If the flow was too great, solvent would have been lost and it

would have hindered the reactions. If the hot 100 mL three neck round bottom flask was not

allowed to cool completely, that may have also caused a side reaction to occur due to the

unwarranted heat. Also, as noted earlier during the synthesis of 1A, the reaction was overheated,

which could have caused side products to form and thus inhibit the results of the following

syntheses.

Conclusion

The main purposes of the experiments were to synthesize 1A and 1B, confirm their

structures via 1H, 31P, and IR spectroscopy, and to determine their relative catalytic rates during

ring closing metathesis of diethyl diallylmalonate. 1A was identifiable by a series of overlapping

peaks at δ 7.3-7.8 representative six different hydrogens attached to phenyl and indenylidene

groups. This material was collected in a 46% yield, but in reality the yield was likely lower due

to contaminants. 1B was synthesized with 167% yield, which suggests error. It was vaguely

identifiable through its 1H NMR spectrum by a series of peaks found at δ 1.8-2.1 representative

of protons attached to cyclo groups, namely the PCy3 substituents. This spectrum also contained

the same series of overlapping peaks found around δ 7.3-7.8 for 1A. The 31P NMR and IR

spectra for 1A and 1B are nearly identical, suggesting that almost no change in structure took

place during the synthesis of 1B from 1A.

Because 1B did not properly synthesize, or did in an extremely low proportion, it was not

feasible to measure 1A and 1B in comparison of their catalytic properties. It would be expected

that 1B would be a better catalyst, as it contains bulkier groups which in theory dissociate faster.3

The 1A and 1B synthesized were both used as catalysts for ring closing metathesis of diethyl

diallylmalonate. The product from the synthesis with 1B gave a 1H spectrum nearly identical to

that of the starting material, diethyl diallylmalonate, which says that there was too low of a

concentration of catalyst for the reaction to occur in the time allotted. The product from the

synthesis with 1A gave a different 1H with peaks that are thought to be the desired product, but

no standard 1H NMR spectrum of the product is obtainable. The results from the GC/MS of both

products runs contrary to the belief that any significant amount of C11H16O4 was synthesized at

all, and thus the results from this laboratory experiment are inconclusive.

References

(1) Pappenfus et al. Synthesis and Catalytic Performance of Ruthenium Carbene Complexes for

Olefin Metathesis: A Microscale Organometallic Experiment. Journal of Chemical Education.

2007, 84, 1998-2000.

(2) http://www.sigmaaldrich.com/spectra/fnmr/FNMR005436.PDF

(3) Miessler, G. L.; Tarr, D. A. Inorganic Chemistry: Third Edition. Pearson Prentice Hall:

Upper Saddle River, 2004; pp 523-546.