Heat Checklist

advertisement

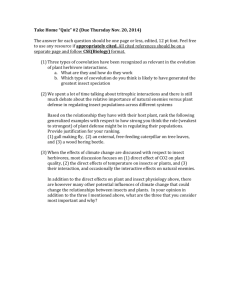

HEAT TREATMENT FOR CEREAL INSECT CONTROL CHECK LIST GENERAL GUIDELINES - By: Ole Dosland 5/2003 PRIOR TO HEAT-UP 1. Appoint site heat-up planning team (include engineering) with Plant Manager as chairman. 2. Identify specific areas to be heated and make site plan. Determine local heat / air source(s). 3. Identify heat sensitive structures and supports including roofs. If protection or engineering assurances cannot be developed, then abort the heat concept. 4. Identify heat sensitive equipment. Develop protection measures or protect with cool zone. 5. Identify sealing materials needed inside heat zone and outside. 6. Identify air movement plan, circulation equipment, fan placement, type and number. Identify energy source (s) and extension chords to spread out the amp load for air movement. 7. Establish fire protection plan. Check with insurance carrier. 8. Repair damaged doors, windows or other openings that would allow heat to escape. Eliminate major drafts from non-heated areas. 9. Notify Corporate safety, engineering and regional personnel of intent to conduct heat-up. 10. Notify local (city and county) fire and police departments of intent to conduct heat-up. 11. Notify contractors or other persons who may be using the facility so their equipment, materials and supplies can be removed. 12. Use 4 to 6 mil polyethylene sheets to seal off exhaust fans, dust collectors or air make-up systems that exhaust to the outside. Clearly note the ones to be used for de-heating. 13. Remove heat sensitive products or raw materials from heated area. Examples are vitamins, shortenings and some packing materials. Most products are not conducive to heat-treating. 14. Remove pressurized containers and cylinders from heated area. Label the fire extinguishers with proper location for emergency “near by use” during heat treatment. 15. Where possible, remove electronic equipment; any that cannot be removed must be deenergized. Where computer programs are involved, backup copies should be made. 16. Empty all trash, waste and product containers. Set containers upside down in the heated area. 17. Check sprinkler system and head sensitivity for > 200 degrees F. If not, replace each. An option is to drain the sprinkler system and post fireguards during inactivation period. Check system for tripped heads and refill slowly prior to activation. 18. Older sodium or mercury vapor lights should be turned off during heat. Check with engineering or supplier. Identify alternative lighting plan to minimize plant power use. HEAT TREATMENT FOR CEREAL INSECT CONTROL CHECK LIST GENERAL GUIDELINES - By: Ole Dosland Page 2 PRIOR TO HEAT-UP (Cont…) 19. Check bearing and belt types. Loosen where necessary. 20. Check lubricant type and reservoirs. Provide for expansion. 21. Identify plastic related materials including PVC piping and tygon tubes. Check for heat strength, remove where possible or monitor. Check for pneumatic line plastic connectors. Change over to soft metal i.e. aluminum where feasible. 22. Double check temperature limitations on all solid-state equipment such as any electronic controllers, small computers, photo eyes. Remove or protect with cool zone. 23. Double check magnets since some magnets such as rare earth type are sensitive to high temperature and can be demagnetized if exposed to temperature beyond their designed limits. 24. Remove loose rubber gaskets and sensitive caulking. Replace with heat resistant materials. Establish employee safety plan; warning signs, buddy system, clothing, drinking/eating, heat stress first aid (ambient room - not air conditioned), first aid kit - burns or rashes, emergency phone numbers, employee heat tolerance (need for physicals), cool vests, etc. Identify and provide appropriate personal protective equipment (PPE) such as bump hats with cloth lining, cloth gloves and light loose clothing. Note any metal should not contact the skin directly such as metal buttons, glasses or bras. 26. Establish temperature monitoring plan; key locations, sensors, frequency, thermometers, problem response. Calibrate all monitoring tools and identify the “chief” thermometer. 27. Identify areas adjacent to the heated areas. Spray with residual insecticide to preclude insect migration to non-heated areas. A Tempo 20 WP or Demand CS products are options to consider for excellent overall residual insecticides for heat-ups. Remove insect / rodent baits. 28. Determine numerous locations for insect test cages with temperature indication charting. Make notes on plot plan. Use flour beetle and/or target insect stages for mortality evaluation. Order/make sufficient number of cages and temperature indication charts. 29. Identify “predicted” ambient temperature and weather conditions for the treatment period. Determine heat up and cool down plan. It is suggested not to exceed 10 degrees F. per hour. 30. Develop floor-by-floor and area-by-area specific checklist for planned preparation activity of the sensitive equipment within the heat treatment zones. 31. Identify the level of cleanliness needed for the treatment area, product inventory levels, material removal, which equipment to open & close, etc. Verify one week before treatment. 32. Identify the time and person responsible to turn off plant power, if necessary. This same person should also turn on the plant power during cool down. HEAT TREATMENT FOR CEREAL INSECT CONTROL CHECK LIST GENERAL GUIDELINES - By: Ole Dosland Page 3 DURING HEAT-UP 1. Before heaters are turned on, conduct a team walk through evaluation. Is this place / area “ready to go”? Is the cleanliness acceptable? Have critical items been removed? 2. Be cautious not to do too much, especially during the first few hours of heat up. 3. Elevate temperatures outside and around inward toward the infestation. Sequence the heat source (s) start up to run the insects into their home base “morgue”. 4. Target temperature is 120 - 140 degrees F. for 24 – 36 hours (structural) or 8 – 16 hours (equipment). Areas with temperature exceeding 140 degrees F. should be lowered within target zone immediately. Monitor a least likely area to reach the lethal temperature of 120 + for a lethal time of two hours minimum. 5. The heater rental company will be responsible for the operation of the rental power and/or heating equipment and assisting with temperature / humidity monitoring. 6. Heaters will be positioned in various areas to be treated. Numerous 24” to 36” air circulators will be used to provide general uniform heat distribution. Box fans can be used for small areas. Plan to have a fan morgue area for storage of dead air movers. Some may come back to life and others will not. 7. Plant and/or pest management service personnel with assistance of the heater rental personnel will monitor overall temperatures and humidity. Plant maintenance personnel will monitor specific structure areas and heat sensitive equipment in addition to providing “fire watch”. 8. Monitor and record temperatures and humidity at predetermined locations, initially every hour, then bi-hourly after temperatures are stabilized. Check areas near insect cages on a regular basis. Remember insects will enter a morbid (near dead) state still alive. 9. Establish the central heat treatment command center office with phone, first aid, communication boards i.e. flip chart paper, in a convenient ambient environment. HEAT TREATMENT FOR CEREAL INSECT CONTROL CHECK LIST GENERAL GUIDELINES - By: Ole Dosland Page 4 AFTER HEAT-UP 1. Discontinue heat operation after the desired exposure time and temperature is achieved. Keep air movers running during a sequential shutdown. 2. Uncover roof/wall vents, air intakes, etc. Open screened windows. 3. Turn on plant power when temperature cool down reaches 110 F. 4. Recover insect test cages and temperature indication charts. Record initial mortality %. 5. Where survival occurs in insect test cages, treat that area with a residual insecticide. 6. Start the exhaust fans in heated areas. Monitor cooling temperatures. 7. Replace fire extinguishers at proper locations and return plant to normal fire protection. If sprinkler system was drained, check each sprinkler head before activation. Refill slowly. 8. Start removing portable power or heater equipment and begin re-assembly of plant equipment preparing for normal operation. 9. Remove all sealing equipment and complete post treatment cleanup. “Flush” the initial material out of the process and dispose to trash. A high degree of insect fragments may exist inside the processing equipment. 10. Heat-up planning team reviews treatment activity, effectiveness, etc. making suggestions while memory is fresh to improve future application. 11. Prepare post heat treatment report. This report should be detailed for the first time heat treatment and used as a future reference. WARNING HEAT STRESS AREA