(EPA) Room Air Cleaner Energy Star program.

advertisement

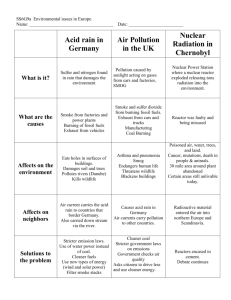

Test Method for Rating Performance of Portable Room Air Cleaners BY Ramona Saar, Director of Standards and Certification Association of Home Appliance Manufacturers 1111 19th St. NW Suite 402 Washington DC 20036 USA Phone: 202-872-5955 Fax: 202-872-9354 E-Mail: rsaar@aham.org Web Site: http://www.AHAM.org Ramona Saar AHAM Page 2 ABSTRACT Portable electric room air cleaners have become very popular over the last few decades. In order to measure and compare the performance characteristics of these appliances, the Association of Home Appliance Manufacturers (AHAM) developed a rating test method in the late 1980’s. The AHAM test method, prescribed in ANSI/AHAM Standard AC-1-2002 has been recently revised after careful review by manufacturers, technical experts and interested stakeholders in the indoor air quality field. The AC-1 standard rates the performance of room air cleaners using a metric called the Clean Air Delivery Rate (CADR), which is a measure of the appliance’s ability to reduce smoke, dust, and pollen particles, in the 0.10 to 11 micron (μm) size range from the air. The standard also prescribes a method for sizing room air cleaners to the appropriate room size, based on the CADR. In addition, it includes a procedure for measuring energy consumption in accordance with Energy Star. This paper describes the CADR test method, the revisions recently made to the standard, and the certification program that AHAM operates to verify the performance claims of room air cleaners. INTRODUCTION The main function of a portable household electric room air cleaner is to reduce indoor airborne particles. There are many types of portable room air cleaners available in the market today. These products vary in size from small table top units to large console units and utilize a number of different particle removal technologies, including mechanical filters, electrostatic plates, and ionization, for example. The majority of consumers that buy an air cleaner cite the desire to improve indoor air quality as the reason for purchasing the product.1 By reducing the particles, the potential harmful effect of those particles is reduced, improving the quality of the indoor air. How effective are portable household electric room air cleaners at removing particles? The Association of Home Appliance Manufacturer (AHAM) has developed an objective and repeatable performance test method for measuring this key performance characteristic2. The method, ANSI/AHAM AC-1, Method for Measuring the Performance of Portable Household Electric Room Air Cleaners is designed to evaluate the performance of the cleaners regardless of the particle removal technology utilized. ANSI/AHAM AC-1 forms the basis for an industry certification program for room air cleaners. The resulting performance measurement, called the Clean Air Delivery Rate (CADR), is placed on product packaging along with a recommended room size. This information helps consumers make an appropriate purchasing decision based on performance and needs. Since its original development in the early 1980s, the ANSI/AHAM AC-1 test method has increasingly become the credible industry standard for evaluating room air cleaner particle removal performance. The test method is utilized by the U.S. Environmental Protection Agency (USEPA) in its Air Cleaner Energy Star Program. Additionally, Consumers Union3 uses CADR to determine the air cleaner ratings and product comparison information that are published in Consumer Reports®. Air Quality experts often refer to CADR in technical papers as well. In a recent research paper on the use Ramona Saar AHAM Page 3 of air cleaners to reduce fine particulate matter during prescribed burns and wildfires in Colorado, the authors utilized the CADR metric to select appropriate air cleaners for the study, noting that CADR is a “useful parameter for characterizing effectiveness of an air cleaner.” 4 HISTORY OF AC-1 Work on a test method for room air cleaners began in 1981. A number of air cleaner manufacturers came to AHAM requesting the establishment of a program to test and certify room air cleaners. At that time, there were no test methods for room air cleaners that approached real-world use conditions. Room air cleaner claims were usually based on testing conducted in small chambers and then the results extrapolated to indicate performance claims in larger rooms. In these small chamber tests, particles were often “fed” into the air cleaner in lieu of allowing the air cleaner to bring the particles into the system itself. This process would not allow for evaluation to see if the air cleaner’s fanmotor system was powerful enough to bring the contaminants from the room into the filter media on its own. In addition, the integrity of the air cleaner’s seals and the air flow pattern set up by the air cleaner were not being evaluated. Such tests measured the performance of the filtration media but not of the air cleaner system as a whole. Results of the different test methods were not comparable. Ramona Saar AHAM Page 4 The goal of the AHAM test method development task force was to come up with a metric that would show the initial performance of the air cleaner on the entire room and that could be used to compare performance of different units. This metric would hopefully reduce market confusion over air cleaner performance claims, which was a concern of the Federal Trade Commission in the early 1980s. In the fall of 1982, air cleaner manufacturers established a set of testing parameters that would more closely relate to consumer usage of air cleaners. AHAM sought technical guidance from the laboratories that had been performing some of the testing for air cleaner manufacturers and other experts in the field. Technical issues such as the size of the test chamber, the particulates to be used, the initial starting concentration of the particles, and how the particles were to be mixed were established through this initial effort and are consistent in the standard even today. The initial test procedure was completed through numerous technical meetings and experimental testing. In September 1984, it became an AHAM standard, AHAM AC-11984. The AHAM certification program was then formulated and it was officially started in August of 1985. In March 1986, AHAM presented AHAM AC-1 and the related certification program information to the FTC for its consideration and comment. The FTC retained a technically knowledgeable EPA consultant to aid in its review. With additional comments from the consultant, precision statements were added to improve the standard. The updated version was granted approval by ANSI as an American National Standard in December, 1988. In 1989, the FTC confirmed to AHAM that the ANSI/AHAM AC-1-1988 test method was a reasonable basis for measuring the degrees of reductions of airborne solid particulate matter from household rooms.5 2004 INDEPENDENT TECHNICAL EXPERT REVIEW On November 29, 2006, ANSI/AHAM AC-1-2006 was re-approved as an American National Standard by ANSI6. The changes reflected in the new updated 2006 version are a result of a unique AHAM-initiated independent technical expert review of the standard and a subsequent ANSI consensus panel review. In 2004, in response to comments suggesting that the test method might not be an appropriate standard for measuring the performance for certain air cleaner technologies, the AHAM Air Cleaner Council that oversees the AC-1 standard agreed that AHAM should contact independent experts earlier in the process of the ANSI/AHAM AC-1-2002 five year revision cycle so that the standard could be reviewed objectively for its relevancy to today's air cleaner technologies. The independent expert review was sought to specifically ensure that the method was technically sound and was not inadvertently and/or unfairly favoring any design or technology. This is important because AHAM does not promote any specific brand of air cleaner or any specific technology for air cleaners. Seven experts from the government, academia and the private sector agreed to participate in the independent review and submitted comments. The experts included representatives from Lawrence Berkeley National Laboratories, University of Texas (Austin), University of Tulsa, Clarkson University, an independent air quality testing laboratory, and the National Institutes of Standard and Technology (two from NIST). Ramona Saar AHAM Page 5 The experts were asked to review the AHAM standard within the limits of the current claimed scope (removal of particulate matter) and its application to today’s technologies. The most important outcome of the review was that the experts reaffirmed the technical validity of the test method and its application to all types of room air cleaners. In addition, the experts agreed with the scope expansion to include plug-ins and wallmounted air cleaner units and also with the inclusion of a new section on calculating room size. (Previously, room size calculation was a certification program feature, but was not included in the actual standard.) A number of comments were also submitted to improve the clarity of the document. New annexes were added for a derivation of the effective room size calculation and for example data sheets, a schematic of a test stand for wall-mounted units, a list of the test sequence steps, and a timeline of the data acquisition. Following the expert review, AHAM published AHAM AC-1-2005 and submitted the document for ANSI approval. During the ANSI consensus panel review process, optional performance tests for air cleaner operating power and standby power were added and appear in ANSI/AHAM AC-1-2006. The optional power performance tests are in line with those included in the Environmental Protection Agency (EPA) Room Air Cleaner Energy Star program. TEST METHOD - CLEAN AIR DELIVERY RATE (CADR) Given time, most particles decay out of the air naturally. To be effective, an air cleaner must be able to remove particles at a rate that is higher than the normal decay rate of those particles. The faster the air cleaner can remove the particles, the more effective it is. The ANSI/AHAM AC-1 test method describes a process for measuring the relative reduction by the air cleaner of particulate matter suspended in the air in a specified test chamber. The unique metric utilized to describe the room air cleaner’s particulate matter removal performance is the Clean Air Delivery Rate (CADR). CADR is defined as the measure of the delivery of contaminant free air by a portable household electric room air cleaner, expressed in cubic feet per minute (cfm). CADR is the rate of particulate reduction in the test chamber when the air cleaner is turned on, minus the rate of natural decay when the unit is not running, times the volume of the test chamber as measured in cubic feet. The final results are expressed in terms of a CADR rating for each of three contaminants used (smoke, dust, and pollen). These contaminants are used to simulate various sizes of particles that would typically exist in a home. The particle size ranges measured in ANSI/AHAM AC-1 are noted in Table 1. Table 1 Particulate Matter Particle Size Range Measured Cigarette Smoke 0.10 μm to 1.0 μm Fine Test Dust 0.5 μm to 3.0 μm Ramona Saar AHAM Page 6 Paper Mulberry Pollen 5 μm to 11 μm TEST METHOD - THE TESTING CHAMBER & SEQUENCE OF STEPS The AC-1 standard requires use of 1008 ft 3 (10.5 ft. x 12 ft. x 8 ft.) sealed chamber. Flooring in the chamber is specified as seamless smooth surface linoleum or vinyl. The walls must be painted with a washable latex semi-gloss paint. The environmental control system consists of humidifiers, a HEPA filter, blowers, supply dampers and return dampers. The chamber also has a ceiling fan and a recirculation fan that are used for mixing the air. The recirculation fan remains on during the duration of the test. The particle counters are located in the chamber. Figure 2 at the end of this document shows a diagram of the test chamber. TEST METHOD – TEST SEQUENCE The CADR for each particulate is determined by a separate test sequence in the test chamber. It is necessary to measure both the natural decay (air cleaner turned off) and the measured decay (with air cleaner turned on) separately for smoke, dust and pollen. Prior to the start of the test, the chamber must be thoroughly cleaned. The air cleaner is then set up in the chamber. Air cleaners under test are normally placed in the center of the chamber on a table. A separate test stand is provided for mounting plug-in and wall-mounted air cleaners. The chamber’s environmental system, the recirculation fan and the ceiling mixing fan are turned on. The background concentration of particles is monitored, and when an acceptable low background concentration level is obtained, the chamber’s environmental control system is turned off. Particles are then injected and monitored to obtain a natural decay. Next, a measured decay test is conducted. The particulate matter being tested (smoke, dust or pollen) is injected into the room to the required concentration level specified in the standard. The air supply used to inject the particulate matter is then turned off and the injection valve for the pollutant closed. The pollutant is allowed to mix for one minute via the recirculation fan and the ceiling mixing fan. The mixing fan is then turned off and one additional minute is provided for the mixing fan blades to stop. The particle counter sampling and the data acquisition then begin. There are slightly different sequences for the smoke, dust and pollen. The data acquisition is done through a 20 second sampling at one minute intervals. The test for smoke and dust is 20 minutes. For pollen, the test is 10 minutes. The minimum number of acceptable data points must be obtained (at least 9 for dust and smoke, 5 for pollen). Following completion of the test sequence, the data analysis is performed. TEST METHOD - DATA ANALYSIS – DECAY CONSTANT For each particulate, the decay constant, k, is calculated. Since the test chamber air exchange is negligible (less than 0.03 air changes per hour) the air exchange rate is not included in the calculations. Ramona Saar AHAM Page 7 The decay constant, k, for particulate matter is based on the formula: Cti=Cie-kti where: Cti = concentration at time ti (particles/cc) Ci = concentration at t = 0 minutes k = decay rate constant (minutes -1) ti = time (minutes) The decay constant, k, is obtained using the linear regression on the lnC ti and ti using the formula: k= SXY SXX where: N Sxy = Sxx = N ∑ti lnCti - (1/n) (∑ti) i =1 i =1 N N ∑(ti)2 - (1/n) i =1 N (∑ln Cti) i =1 ( ∑ti)2 i =1 When the above calculations are used for natural decay measurements, the results represent the natural decay rate in the room air. When the above calculations are used for the total particulate matter removal measurements the results represent the air cleaner particulate matter removal rate, which includes natural decay of the particles also. TEST METHOD – CADR CALCULATION Ramona Saar AHAM Page 8 The CADR is then calculated using the following equation: CADR = V(ke - kn) where: CADR = clean air delivery rate (cu. ft/min) V= volume of test chamber, cu. ft. ke= total decay rate, min-1 kn = natural decay rate, min -1 LIMITS OF MEASURABILITY There are defined limits of measurability for AC-1 based on the statistical accuracy of the method. Only CADR rates within the limits specified below can be considered statistically valid: Dust CADR = 10 cfm to 400 cfm Smoke CADR = 10 cfm to 450 cfm Pollen CADR = 25 cfm to 450 cfm The maximum CADR values stated here were determined through analysis of the acceptable minimum number of available particles, an average background natural decay rate (from statistical study), the size of the chamber, and the available minimum experiment time. CADR values outside the ranges listed will not have the necessary statistical data required by this method. PRECISION The precision of the method, expressed as 2 standard deviation limits (95%) are: Dust Smoke Pollen CADR = + 10 cfm CADR = + 10 cfm CADR = + 25 cfm DETERMINING ROOM SIZE7 Along with CADR performance ratings for dust, smoke and pollen, ANSI/AHAM AC1-2006 now includes a process for calculating the Suggested Room Size for a specific Ramona Saar AHAM Page 9 room air cleaner. The methodology used for this process was developed in 1992 and was added to AHAM’s Certification Program following FTC confirmation that the methodology proposed was scientifically valid8. The room size is based on several standard construction criteria for rooms and a history of the natural decay of small particles (cigarette smoke). Cigarette smoke was selected because smoke particles are the hardest to remove from the air and have the slowest natural decay rate. The effective room size is based upon the CADR obtained for cigarette smoke and the ability of the air cleaner to reduce the concentration of particles in a room at steadystate to a new steady-state concentration 80% less than the original, when the air cleaner is operating. The 80% reduction criterion was determined by examining different room sizes within a home or office and observing the significant differentiation between air cleaners. 80% particle remove was considered realistic for the selection of an air cleaner. The theoretical assumptions of the room characteristics are based upon (1) a mixing factor equal to 1.0, (2) an air exchange rate of 1.0 hr -1, (3) a cigarette smoke particle natural decay equal to the average background natural decay rate, (4) a ceiling height of 8 ft (2.4 m), and (5) a cigarette smoke particle generation or influx rate such that a cigarette smoke particle concentration of unity is maintained at the initial steady state. A detailed derivation of the room size calculation, as it appears in ANSI/AHAM AC-12006, is included in the following section. Based on the assumptions above, the equation for the Suggested Room Size is: Room Size (ft2) = Smoke CADR x 1.55 DERIVATION OF ROOM SIZE CALCULATION Concentrations of particles in indoor air are dynamic and result from the competition between various source and removal processes. Steady state can be defined as when neither the source nor the removal processes are rapidly changing and thus the indoor concentration is relatively constant. In this situation, C = source terms removal terms (1) C = indoor sources+outdoor sources ventilation+air cleaning+deposition Without air cleaning, particle removal is through ventilation and deposition. Rearranging these terms and substituting decay parameters for words in equation (1): Source terms C k V k dep , (2) where kV is removal rate due to ventilation (minutes-1), kdep is the removal rate due to deposition (minutes-1) and when used in equation (3) below, kAC is the removal rate due to air cleaning (minutes-1). Steady-state for cleaning is defined by AHAM Air Cleaner Ramona Saar AHAM Page 10 Council as being 20% or less of the initial particle load in a room, or in other words: at least an 80% continuous removal of smoke particles. This defines a new steady state particle concentration, now with the air cleaner operating, CAC, which equals 0.2C. Using the same formula as in equation (2) above, Source terms 0.2C k V k dep k AC (3) Since the source terms do not change – only the use of an air cleaner – the two equations can be combined through the equivalent source terms to give C k V k dep 0.2C k V k dep k AC (4) Canceling the C’s from both sides, rearranging and solving for the air cleaner removal rate: k AC 4k V k dep . (5) Recall that CADR is defined as V k e k n , where V is the room volume (ft3) and ke and kn are the decay rates with and without air cleaner operation, respectively (as defined in section 8.4). Effectively then, air cleaner operating decay = ke = (kv + kdep + kAC) (6) and natural decay = kn = (kv + kdep) (7) This difference in decay rates is kAC, thus CADR V k AC 4Vk V k dep . The objective is to show what size room results from the minimum air cleaner performance needed to provide an 80% reduction in steady-state particle concentrations. For simplicity, it is assumed that the ceiling height is 8 feet; this permits recasting of the equation in terms of floor area, A, a more commonly known description of room size than is room volume, A (8) CADR . 32k V k dep (9) Ramona Saar AHAM Page 11 Commonly accepted values for the two decay parameters are used. Typical air exchange (ventilation) rates for houses in the U.S. is 1 per hour, or kV = 0.01667 minute1. For smoke, average deposition rates are 0.0034 minute -1, as provide by AHAM through actual measurements by a third party independent laboratory. Substituting these values in equation (9): A (ft 2) = CADR / [32(0.01667 + 0.0034)] = 1.557 CADR (cfm) (10) In a meeting of the AHAM Air Cleaner Council, the value of 1.557 was rounded to 1.55 for simplicity, thereby providing the standard equation (11): Room Size in Square feet = 1.55 x cfm Based on this equation, an air cleaner with a CADR rating of 50 cfm can be used to clean a small room (78 ft2). Likewise a CADR rating of 100 cfm would permit an air cleaner to be used in a 156 ft2 room (~10 x 15 ft), and so forth. Conversely, this equation can also be used to determine what the CADR requirement is for a room or indoor space of a given size. For example, for a room size of 100 ft 2 a CADR rating of at least 64 cfm is needed. INDUSTRY CERTIFICATION Since 1985, AHAM has administered a portable room air cleaner certification program for industry. Both AHAM and non-AHAM members are eligible to participate in the program. To reduce market confusion, participants must include all the units they manufacture in the program. In 2005, there were 24 manufacturers participating in the program. Three samples of each air cleaner model entering the program must be submitted for initial certification testing at the independent AHAM-contracted testing laboratory. Initial certified CADR results are calculated from the averaged results of the three tests and the recommended room size is determined form the averaged certified smoke CADR results. Air cleaner models included in the program are then independently tested on a periodic on-going basis to ensure that the units meet the claimed ratings. The models to be tested are randomly selected and are obtained from either the participant’s warehouse or the open market. Units that do not successfully pass the on-going verification process must be re-rated or withdrawn from the market. AHAM provides all participants with the following CADR ratings seal shown below in Figure 1. Ramona Saar AHAM Page 12 FIGURE 1. CADR Ratings Seal Participants are required to include the seal on the packaging of all certified room air cleaners. The seal provides the consumer with a simple tool to compare the performance of room air cleaners, making that purchasing decision easier. It includes the participant’s certified CADR rates for tobacco smoke, dust and pollen, and a suggested room size that is based on the tobacco smoke CADR results. Using the ratings seal, consumers can comparison shop, selecting the unit the meets their room size and performance needs. By knowing the size of their room, consumers can choose an effective air cleaner. Certified models are listed in an on-line searchable Directory of Certified Room Air Cleaners at a dedicated product web site: www.cadr.org. SUMMARY ANSI/AHAM AC-1 provides a realistic, effective measurement of the ability of air cleaners to reduce indoor particulate matter by examining the decay rates of particles in a sealed chamber when an air cleaner is turned off and when an air cleaner is turned on. The test method, developed through AHAM and the manufacturer members, reviewed in 2004 by an independent panel of technical experts, and re-approved by ANSI in 2006, has been shown to be a technically sound, reproducible protocol that can be used for all types of portable household electric room air cleaners. The information provided through AHAM’s Room Air Cleaner Certification Program ratings seal, and placed directly on the air cleaner packaging provides the consumer with an objective, easy way to determine which air cleaner is best for their use. ABOUT AHAM AHAM is a full service trade association representing the major appliance, portable appliance, floor care appliance manufacturers and suppliers to the industry. AHAM provides its members with service in the following areas: government relations, business data, communications, technical standards development and product certification. In the standards development area, AHAM is an accredited standards development organization (SDO) through ANSI (American National Standards Institute). Selected AHAM appliance performance standards are processed through the ANSI consensus review process. This process is designed to ensure that American National Standards have been developed through a consensus process that included a balance Ramona Saar AHAM Page 13 of interest and lack of dominance by any stakeholder group. The ANSI/AHAM AC-1 standard that is the subject of this paper was re-approved by ANSI at the end of 2005 and is being published as ANSI/AHAM AC-1-2006. In the area of product certification, AHAM has been operating industry programs since 1967 to independently verify manufacturer performance claims. The AHAM Room Air Cleaner certification program that is the subject of this paper has been operating since 1985. Ramona Saar AHAM Page 14 FIGURE 2. AIR CLEANER CHAMBER SCHEMATIC SCHEMATIC (O) (N) (Q) (P) (R) (S) (T) (L) (M) (K) (J) (F) (G) (E) (H) (I) (D) (C) (B) (A) (A) VOLTAGE REGULATOR (B) DATA ACQUISITION AND CONTROL INTERFACE (C) AIR SUPPLY (FILTER/DRIER) (D) COMPUTER TERMINAL (E) CIGARETTE SMOKE POT (F) POLLEN GENERATOR (G) DUST AND POLLEN MONITOR (H) SMOKE MONITOR ( I ) CIGARETTE SMOKE DILUTER (J) (K) (L) (M) (N) (O) (P) (Q) (R) (S) (T) DUST GENERATOR TEST UNIT CEILING MIXING FAN RETURN AIR DAMPER (2) RECIRCULATION FAN HUMIDIFIER PREFILTER BLOWER SECTION HEPA FILTER ELECTRIC HEATER SUPPLY AIR DAMPER Ramona Saar AHAM Page 15 REFERENCES 1 2002 consumer research study commissioned by AHAM. Other room air cleaner performance characteristics such as the ability of the air cleaner to reduce gases, odors or microbiological components, or the sound and ozone emissions levels of the product are outside the scope of ANSI/AHAM AC-1. Some of these additional performance characteristics such as sound and ozone production are covered under other standards, including ANSI/AHAM AC-2 (Sound), and UL 867 (Section 37 – Ozone). 3 Consumers Union (CU) is a nonprofit organization whose main mission is to ensure that there is a fair and safe marketplace for consumers. CU tests products and publishes the product ratings in its magazine. 4 Henderson, Milford and Miller. Prescribed Burns and Wildfires in Colorado: Impacts of Mitigation Measures on Indoor Air Particulate Matter; Air & Waste Management Association. 2005, 55, 1516-1526. 5 Sanger, William S, Associate Director for Enforcement, Bureau of Consumer Protection, FTC, Letter dated June 1989. 6 American National Standards Institute. 7 ANSI/AHAM AC-1-2006 8 Dingfelder, Justin, Assistant Director, Enforcement Division, Bureau of Consumer Protection, FTC, Letter dated May 21, 1993. 2