Structural changes in lignin during kraft cooking Part 4. Phenolic

advertisement

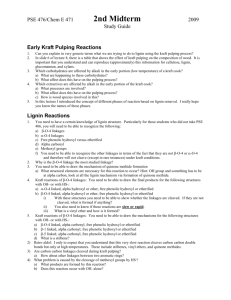

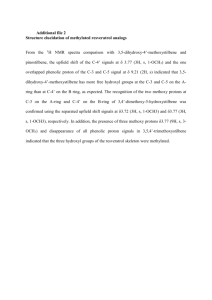

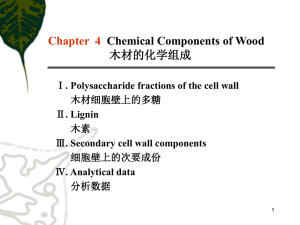

Structural changes in lignin during kraft cooking Part 4. Phenolic hydroxyl groups in wood and kraft pulps Göran Gellerstedt and EvaLisa Lindfors, Swedish Forest Products Research Laboratory, Stockholm, Sweden Keywords: Pinus, Alkaline pulping, Kraft pulps, Soda pulps, Lignin content, Phenol groups, Quantitative analysis, Acetylation, Aminolysis. SUMMARY: In a series of kraft pulps cooked to different yield levels, the content of phenolic hydroxyl groups present in the residual lignin has been quantitatively determined by means of aminolysis. For comparison, a soda pulp and the corresponding wood material were also analysed. The results obtained demonstrate that during the course of a kraft cook there is an increase in the content of phenolic hydroxyl groups per unit weight of residual lignin. Throughout the cook the content of these groups is, however, much lower than the content of phenolic hydroxyl groups present in the dissolved kraft lignins. It was further found that the residual lignin in a soda pulp contains a significantly smaller amount of phenolic hydroxyl groups than the lignin in a kraft pulp at the same degree of delignification. The importance of these results is discussed with reference to known features of alkaline pulping processes. ADDRESS OF THE AUTHORS: Swedish Forest Products Research Laboratory, Box 5604, S-114 86 Stockholm, Sweden. Numerous studies on the reactions of lignin in alkaline pulping have revealed the fundamental importance of the presence of free phenolic hydroxyl groups (1, 2). In lignin units containing such groups, the alkaline conditions prevailing in kraft and soda cooking liquors lead to the formation of methylene quin-ones. These structures are unstable and are readily attacked by nucleophiles such as hydrogensulfide ions or various organic carbanions present in the reaction medium. Alternatively, methylene quinones are stabilized via elimination reactions leading to the formation of stilbene and styrene structures. The extent and distribution of these reactions determine the structural modification of lignin, including lignin fragmentation and condensation, taking place during pulping. In addition to these reactions, the dissolution of lignin in the delignification of wood must be dependent upon the presence of hydrophilic groups (cf. ref. 2). In kraft and soda cooking these consist mainly of phenolic hydroxyl groups, minor amounts of carbox-ylic acid groups also being present (3). In a previous paper in this series, the content of free phenolic hydroxyl groups present in the residual lignin in a series of kraft pulps was calculated indirectly (4). These calculations were based upon the quantities of isolated low molecular mass carboxylic acids formed by oxidative degradation of phenolic structures present in the residual lignin. In the present work, the amount of phenolic hydroxyl groups present in the residual lignin of the same series of kraft pulps has been quantitatively determined by means of aminolysis. In addition, the corresponding wood material and a soda pulp have been analysed. The analytical procedure employed involves the selective deacetylation of phenolic acetates using pyrrolidine by adaptation of a method earlier developed for the analysis of phenolic hydroxyl groups in pure lignin materials (5, cf. also refs. 6,7). Results and discussion Analytical method The selective determination of phenolic hydroxyl groups by aminolysis utilizes the fact that there is a large difference in the rates of deacetylation of aromatic and aliphatic acetates in the presence of pyrrolidine. A rapid and quantitative formation of acetyl-pyrrolidine takes place in an amount, corresponding to the amount of aromatic acetyl groups originally present in the sample. The method has been used on acetylated lignin model compounds (6), on milled wood lignin (5) and on various kraft lignins (5,8). It has also been demonstrated that under more severe reaction conditions the addition of pyrrolidine makes it possible to eliminate virtually all types of acetyl groups present in a sample. This can be utilized e.g. for the quantitative determination of the content of acetyl groups in wood (7). In solid materials such as wood and pulps, two major difficulties arise, viz. the achievement of a complete acetylation of all the phenolic hydroxyl groups present and the selective deacetylation of these in the presence of a vast amount of various aliphatic acetyl groups in both lignin and carbohydrates. In a separate experiment it was demonstrated that acetylated cellulose gave rise to a small amount of acetyl-pyrrolidine when treated with pyrrolidine under mild conditions (see Experimental). Approximately one equivalent of acetylpyrrolidine was shown to be formed from ßglucose pentaacetate whereas the formation of acetylpyrrolidine from sorbitol hexaacetate was negligible. These results demonstrate that the reducing end groups present in polysaccharides are able to undergo aminolysis of their acetates at rates which are comparable with those of aromatic acetates. Unrealistically high values for the content of phenolic hydroxyl groups were indeed found in aminolysis experiments carried out directly on acetylated wood and pulp samples. It is thus necessary to eliminate all reducing end groups in the samples by sodium borohydride reduction prior to acetylation. This reaction step was evaluated on pulp samples using two different methods of reduction viz. reaction with sodium borohydride in pure water (9) and in aqueous buffer solution at pH = 9.6—9.8 (10). After subsequent acetylation and aminolysis reactions, the samples were analysed for their contents of acetylpyrrolidine. It was found that reduction carried out in a pure water suspension gave by far the greater reproducibility in the aminolysis reaction. This is assumed to be due to the different degrees of swelling of the wood and pulp materials in water and in buffer Table 1. Content of phenolic hydroxyl groups, determined by aminolysis, in the residual lignin in wood, in kraft pulps and in a soda pulp. 1 Determined as Klason lignin and acid soluble lignin Assumed relative molecular mass for one phenylpropane unit = 183(12) 3 Mean value of two analyses 4 Mean value of three analyses 5 Soda pulp 2 solutions (cf. ref. 11). Samples present in the aqueous phase in a highly swollen state after the reduction step were thus found to be easily solvent exchanged into pyridine via acetone while still maintaining a high accessibility. The subsequent acetylation reaction could then be carried out as a one-step procedure. Otherwise repeated acetylation was necessary nevertheless leading to an inferior aminolysis reaction due to difficulties in achieving a reproducible and quantitative acetylation. After the various reaction steps had been optimized, the analytical procedure was found to give acetylpyrrolidine with a high degree of reproducibil-ity (standard deviation ± 3%) between the experiments. From the amounts of acetylpyrrolidine found in the different wood and pulp samples, the corresponding frequency of phenolic hydroxyl groups per 100 phenylpropane units was calculated assuming a relative molecular mass of 183 per phenylpropane unit in the lignin irrespective of pulp yield (table 1). The value of 183 used for the relative molecular mass comes from elemental analysis data on native spruce lignin and is based on 9.0 carbon atoms in the average phenylpropane unit (12). This number of carbon atoms may be somewhat too high since recent analytical data on the structure of native spruce lignin implies a certain "deficit" of side chains compared with the number of aromatic rings (13, 14). For lignins present in pulp fibers the structural data available permit no certain conclusions to be drawn concerning the composition of the phenylpropane units. However, it has been shown that during pulping the residual lignin in the fibers undergo various modification reactions (4, 15, 16). In addition kraft pulps contain small but increasing amounts of sulfur as the cook proceeds (17). This sulfur can be assumed to be chemically bound to the lignin. Therefore, the base value of 183 used in the calculations of the phenolic hydroxyl groups can lead to somewhat erroneous results and may need revision as more analytical data on residual lignins become available. Content of phenolic groups The frequency of phenolic hydroxyl groups present in the wood and pulp samples is plotted as a function of cooking time in fig. 1 together with values obtained for the corresponding dissolved kraft lignins (data from ref. 8). Thus, it can clearly be seen that there is a large difference in the number of phenolic hydroxyl groups present during the kraft cook. It seems reasonable to assume that in order to make a lignin fragment soluble in the cooking liquor, a minimum (but rather high) amount of phenolic hydroxyl groups is a necessary prerequisite. When the kraft cook approaches its maximum cooking temperature, i.e. at the beginning of the bulk delignifi-cation phase (cf. ref. 4), a slight drop in the content of phenolic hydroxyl groups in the residual lignin is observed. At this point in the cook a certain change in the chemistry of delignification is therefore indicated. Such changes have been observed before. Thus, it has been found that at the beginning of the bulk Fig. 1. Frequency of phenolic hydroxyl groups as a function of cooking time in wood and in the residual lignin in kraft pulps (open symbols, values from table 1) and in the corresponding dissolved kraft lignins (filled symbols, values from ref. 8). delignification phase a larger amount of vinyl aryl ether structures formed from phenylpropane-ßaryl ether structures is present both in the residual and in the dissolved lignin (15). Furthermore, in this part of the kraft cook, lignin samples precipitated from the black liquors have been found to contain rather high amounts of elemental sulfur (4). In pulping experiments it has been demonstrated that, at the beginning of the bulk delignification phase, a high sulfidity level is of fundamental importance in order to minimize the amount of residual lignin present at the transition point between the bulk and the final delignification phases (18). All these results imply that, during a certain part of a kraft cook, starting approximately when the bulk delignification phase is reached, the cook shows some of the characteristics expected to play a dominant role in soda pulping. The observed drop in the content of phenolic hydroxyl groups may thus be explained by a reduction in the degree of phenylpropane-ß-aryl ether cleavage due in turn to a decreased sulfidity level at this point of the cook. Towards the end of the kraft cook the content of phenolic hydroxyl groups was found to level off. In the indirect analytical method employed previously (see above) a decrease in this content was in fact calculated (4). This result is not unexpected since the possibility of creating new phenolic hydroxyl groups should decrease as the cook proceeds both because of a decreasing concentration of hydroxyl ions in the cooking liquor (8, cf. réf. 2) and because of a decreasing amount of phenylpropane-ß-aryl ether structures present in the residual lignin (15). In the present work, a value of 27 phenolic hydroxyl groups per 100 phenylpropane units was found in the residual lignin of a kraft pulp having a kappa number of 31.4. For a residual lignin, obtained from a kraft pulp (kappa number 35.6) after enzymatic hydrolysis of the polysaccharides, values of 36 and 38 phenolic hydroxyl groups have recently been published (16). These high values may possibly arise as a result of the enzymatic treatment which was carried out under weakly acidic conditions which offer the possibility of acid hydrolysis of residual aryl ether bonds in the lignin. The content of phenolic hydroxyl groups in wood has been investigated before using ultraviolet spec-troscopy (19,20, cf. also ref. 21) and pyrolysis in combination with gas chromatography (22) as experimental techniques. Oxidative degradation and quantitative determination of the resulting carboxylic acids has also been employed as an indirect method of analysis (4,23). In the present work, the pine wood used was found to contain 13 phenolic hydroxyl groups per 100 phenylpropane units. This value is in excellent agreement with the most recent data obtained for the secondary wall and middle lamella lignin in spruce wood (15 and 10 phenolic hydroxyl groups respectively) (19). Conclusions Aminolysis of acetylated wood and pulp samples with pyrrolidine can be used for the quantitative determination of phenolic hydroxyl groups. The accuracy of the method is, however, critically dependent upon both the elimination of all reducing sugar end groups and the quantitative acetylation of the hydroxyl groups. If these reaction steps are properly controlled the method gives highly reproducible results. The contents of phenolic hydroxyl groups in the residual lignin in kraft pulps were found to be much lower than the values earlier found in dissolved kraft lignins. In order to make a lignin fragment soluble in the cooking liquor a large number of new phenolic hydroxyl groups must therefore be created during the cook by cleavage of aryl ether bonds. Towards the end of the kraft cook, such cleavage reactions become less and less abundant so that the residual lignin becomes more resistant to dissolution in the cooking liquor. During a soda cook, the cleavage of aryl ether bonds is less efficient than in a kraft cook and this difference is reflected in the low number of phenolic hydroxyl groups found to be present in the soda pulp lignin. Experimental Preparation of samples The pulp samples were obtained from kraft (soda) cooks of pine wood (30% sulfidity, 18% effective alkali and 25% effective alkali respectively) and were the same as those previously used. The preparation and purification of these samples as well as of the wood sample have been thoroughly described in ref. 4. Cellulose acetate, ß-D-glucose pentaacetate and sorbitol hexaacetate were obtained as commercial products (Fluka AG, Sigma Chemical Company). Analytical procedure An accurately weighed amount of wood or pulp sample corresponding to approximately 25 mg of lignin was placed in a centrifuge tube (volume 10 ml) equipped with a Teflon screw cap. (In these tubes an upper limit of approximately 300 mg of sample could be used.) To the sample was added 4 ml of water (distilled and deionized water was used throughout) and subsequently 50 mg of purified sodium borohy-dride. Without closing the screw cap, the mixture was immediately placed in a laboratory centrifuge (Wifug, Sweden) at 1250 r.p.m. for 60 minutes. (This procedure was necessary in order to prevent part of the sample from escaping from the reaction mixture together with the bubbles of hydrogen being formed.) Subsequently, a further amount of sodium borohy-dride was added to the reaction mixture so that the total quantity of sodium borohydride added was equivalent to the amount of sample used. After the screw cap had been loosely closed, the reaction mixture was placed in the centrifuge for 2 more hours and then allowed to stand for 2 days with gentle magnetic stirring. To the sample was then added 3 ml of water, after which the tube was closed and centrifuged at 5700 r.p.m. for 15 minutes. The aqueous solution was removed and the residue washed with 7 ml of water by homogenization and centrifugation. The washing was carried out three times (until the liquid was neutral). Solvent exchange was carried out by first treating the sample with 7 ml of acetone. After homogenization and centrifugation, which was again carried out three times, 7 ml of pyridine was added. This procedure was also carried out three times. To the centrifuged residue, 2 ml of pyridine and 2 ml of acetic anhydride were subsequently added and the reaction mixture was allowed to stand with gentle stirring for 3 days at room temperature (or alternatively for 20 hours at 40°C). The reaction mixture was then violently stirred for 30 minutes in the presence of 5 ml of diethyl ether with the screw cap closed and subsequently centrifuged. The residue was washed three times with 3 x 7 ml of diethyl ether as described above and dried in vacuo overnight at 50°C. The acetylated sample was suspended in 1.0 ml of dioxane containing 5.36 mg/ml of 1propionylpyrro-lidine (internal standard) and an additional 0.5—1.0 ml of dioxane was added. The mixture was allowed to homogenize while being stirred for approximately 1 hour. The aminolysis reaction was started by adding 3 ml of dioxane containing 50 mg/ml of pyrrolidine to the centrifuge tube, tightly closing the cap and vigorously shaking the tube to homogenize the mixture, which was then allowed to stand with stirring. The formation of 1-acetylpyrrolidine was followed as a function of time by gas Chromatographic analysis on a 2.5 mx 1/8" I.D. glass column filled with 5% Castorwax on HP Chromosorb G, 80— 100 mesh at a column temperature of 180°C, injector 230°C and detector 250°C. A flow rate of 20 ml/min of nitrogen was used. Peak quantification was carried out with an electronic integrator. The reaction mixture was centrifuged for 3 minutes at 5700 r.p.m. prior to withdrawal of each sample in order to get a clear solution. The tube contents were then homogenized again by rapid shaking and subsequent stirring. The first gas Chromatographic analysis was done after approximately 30 minutes and subsequently 5—6 additional analyses were carried out at intervals of about 15 minutes. The amount of 1acetylpyrrolidine formed and thus the amount of phenolic hy-droxyl groups present was calculated as described in ref. 5. In the aminolysis of acetylated cellulose, glucose and sorbitol, approximately 100 mg of sample was used in each experiment. The reaction conditions were the same as those described above. In the present work, thoroughly milled samples of wood and pulp have been used throughout. A few experiments with kraft pulps milled through a 40 mesh screen in a Wiley mill gave similar results. The quantitative handling of coarse samples is, however, extremely difficult unless a more powerful centrifuge than the one used in the present work is available. Acknowledgement The authors are indebted to Dr. Tommy Iversen and Dr. Per Mànsson for many valuable discussions during the course of this work. Literature 1. Gierer, J.: Wood Sei. Technol. 74(1980) 241. 2. Ljunggren, S.: Svensk Papperstidn. 55(1980) 363. 3. Morton, J. and Adler, E.: Tappi 4(5(1963) 92. 4. Gellersted t, G. and Lindfors, E. L.: Holzforschung 55(1984) 151. 5. Mànsson, P.: Holzforschung 57(1983) 143. 6. Mànsson, P.: Tetrahedron Lett. 25(1982) 1845. 7. Mànsson, P. and Samuelsson, B.: Svensk Papperstidn. 54(1981):3, R 15. 8. Robert, D.R., Bardet, M., Gellerstedt, G. and Lindfors, E.L.: J. Wood Chem. Technol. (in press.) 9. Assarsson, A., Lindberg, B. and Theander, O.: Acta Chem. Scand. 75(1959) 1231. 10. Lidman-Safwat, S. and Theander, O.: Svensk Papperstidn. 67(1958)42. 11. Lindström, T. and Carlsson, G.: Svensk Papperstidn. 55(1982):3, R 14. 12. Freudenberg, K. and Neish, A.C.: "Constitution and Biosynthesis of Lignin", Springer-Verlag, Berlin-Heidelberg-New York 1968, p. 69. 13. Adler, E.: Wood Sei. Technol. 77(1977) 169. 14. Matsumoto, Y., Ishizu, A. and Nakano, J.: Mokuzai Gakkaishi 50(1984) 74. 15. Gellerstedt, G., Lindfors, E.L., Lapierre, C. and Monties, B.: Svensk Papperstidn. 57(1984), R 16. 16. Yamasaki, T., Hosoya, S., Chen, C.-L., Gratzl, J.S. and Chang, H.-m.: "The Ekman Days 1981". International Symposium on Wood and Pulping Chemistry, Stockholm, June 9—12, 1981. Proceedings of Papers, Vol. 2, p. 34. 17. Gellerstedt, G., and Lindfors, E.L.: unpublished results. 18. Axegàrd, P. and Wikén, J.-E.: Svensk Papperstidn. 56(1983):15, R 178. 19. Boutelje, J. and Eriksson, L: Holzforschung (in press). 20. Yang, J.-M. and Goring, D.A.I.: Can. J. Chem. 55(1980)2411. 21. Yang, J.-M., Yean, W.Q. and Goring, D.A.I.: Cellulose Chem. Technol. 75(1981) 337. 22. Whiting, P. and Goring, D.A.I.: Pap. Puu 64(1982) 592. 23. Hardell, H.-L., Leary, G.J., Stoll, M. and Wes-termark, U.: Svensk Papperstidn. 55(1980) 44. (Manuscript received June 6, 1984. Accepted August 1984.)