Bernoulli and the Free Jet

advertisement

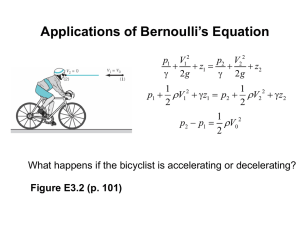

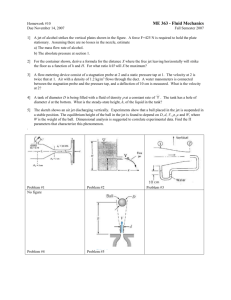

Bernoulli and the Free Jet Objectives In this laboratory you will measure fluid velocities in a free jet using a stagnation tube. You will confirm that the Bernoulli equation can be used to measure fluid velocities using a simple stagnation tube. Theory The conservation of mechanical energy will be verified using the Bernoulli equation. p V2 z C 2g 1.1 A stagnation tube will be connected to a pressure sensor. The stagnation tube will be filled with water prior to connecting to the pressure sensor and the pressure sensor output will be zeroed with the stagnation tube held vertically (in the same orientation used for taking measurements.) Thus the pressure sensor will measure the pressure at the stagnation point (Figure 1-2). From the Bernoulli equation we can obtain the following relationship. p1 z1 V12 p2 V2 z2 2 2g 2g 1.2 Point 1 is on a vertical line in the jet immediately upstream from the stagnation point, point 2. V22 The stagnation pressure, p2 , will be measured using a pressure transducer. Since and 2g are zero and z1 z2 we can obtain p1 V1 2 p2 1.3 Thus by measuring the stagnation pressure we can calculate the velocity of the jet (Figure 1-1). Experimental Methods and Analysis Set up a small jet powered by a centrifugal pump connected to the 10 cm diameter column. Install a valve between the effluent of the centrifugal pump and the elbow. Install a 7 kPa pressure sensor in the bottom of the 10 cm diameter column. Fill the 10 cm diameter column with 15 cm of water. Fill the stagnation tube completely with water before connecting the 7 kPa pressure sensor. Monitor the pressure sensors with the Process Controller software and apply scaling so the output is measured in Pascals for the stagnation tube and in mL 4 3 V( p ) 2 m 1 s 0 0 1400 2800 4200 p Figure 1-1. Velocity as stagnation pressure for water. 5600 7000 Pressure in Pa a function of of water for the 10 cm diameter column. Zero the output of the stagnation tube pressure sensor with the stagnation tube held vertically in air. Set the flow rate using the valve so the stagnation pressure at z = 0 is approximately 300 Pa. Make the following measurements and calculations. 1) What is the stagnation pressure at z = 0? 2) What is the velocity at z = 0 obtained using equation 1.3? SS Tubing with 7.25 mm ID 7 kPa Pressure Sensor z Free Jet Stagnation Point Stagnation Tube filled with water Centrifugal Pump 3) Measure the jet flow rate using the 7-kPa pressure sensor connected to the volumetric Figure 1-2. Stagnation tube and detector. Log the data to file and with the pressure sensor used to measure pump running turn the jet so it discharges into velocity in a jet a different container. You will use the initial slope of the resulting data to determine the flow rate out of the volumetric detector. 4) What is the flow rate that you obtain from the initial slope and how does it compare with the flow rate calculated using the stagnation tube? 5) Fill the volumetric detector to 15 cm again and measure the stagnation tube pressure at various elevations in the jet. Use Excel to plot the velocity in the jet as a function of elevation. On the same graph plot the prediction based on Bernoulli’s equation. z1 V12 V2 z2 2 2g 2g 1.6 where points one and two are any two points in a free jet. Make sure that the theoretical model is plotted as a smooth curve. Format the graphs (from 3 and 5) correctly (http://ceeserver.cee.cornell.edu/mw24/cee331/lab_report.htm#graphs ). Insert a textbox or Word object into Excel and summarize what you learned and your suggestions for improving this laboratory exercise. Email the Excel file to the TA and to the Instructor. Lab Setup 1) Plug both 7 kPa pressure sensors into the middle row of ports. 2) Make sure the middle row of ports is configured with a maximum voltage of 20 mV. 3) Use the Process Controller to turn on the pump and the solenoid valve attached to the pump. 4) Use #14 Pharmed tubing to connect the pressure sensor to the stagnation tube. 5) Configure the Process Controller at each station so it is monitoring the correct pressure sensors at each station. Apply the correct conversions to both pressure sensors (Pa for the stagnation tube and mL of water for the 10 cm diameter column).