2.2 Definition of `safe work instructions`

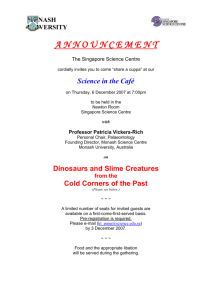

advertisement

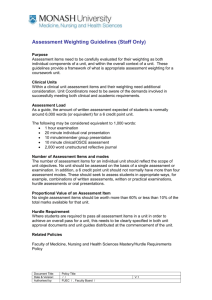

3 OCCUPATIONAL HEALTH SAFETY & ENVIRONMENT GUIDELINES FOR THE DEVELOPMENT OF SAFE WORK INSTRUCTIONS 1. BACKGROUND Monash University recognises that written safe work instructions are essential to ensure a safe work environment and are an important part of an overall occupational health and safety program. Safe work instructions provide information necessary to assist all staff and students to perform tasks safely. These instructions also assist in the training and orientation of new staff and students in the hazards of the tasks to be performed, as well as providing them with the rules and procedures necessary to ensure that they can perform their work in a safe manner. 2. SCOPE 2.1 Safe work instructions should be developed for all techniques, processes, equipment and machinery where there exists a risk of harm to any persons at Monash University. 2.2 Definition of 'safe work instructions' Safe work instructions are written instructions for tasks that outline the preferred method of undertaking a task whilst emphasising ways to minimise any risk(s) of harm. 3. 4. OBJECTIVES 3.1 To ensure, as far as practicable, the health and safety of staff and students undertaking their work and study at Monash University; 3.2 To ensure that consistently high health and safety standards are achieved and maintained in the work and study undertaken at Monash University; 3.3 To provide clear guidelines as to the requirements for the provision of safe work instructions at Monash University. RESPONSIBILITIES (Reference: Monash University Occupational Health and Safety Policy, which can be found at http://www.adm.monash.edu.au/ohse/document/policies/) 4.1 The responsibility for implementation of these guidelines rests with the Heads of Cost Centres. It is expected that the appropriate zone OHS committees will provide advice and feedback to Heads on actions needed to comply with these guidelines. These groups will be able to seek advice from Occupational Health, Safety & Environment. 4.2 All staff and students at Monash University are expected to familiarise themselves with and comply with the safe work instructions that exist in their area of work, including general safety instructions to be found in departmental safety manuals. 4 5. GENERAL RECOMMENDATIONS FOR SAFE WORK INSTRUCTIONS 5.1 Development of safe work instructions: 5.2 Safe work instructions should be written by a staff member or student with sound, hands on experience and knowledge of the tasks; Inclusion of the experience of several staff members or students will enhance the usefulness of the instructions; As far as practicable, the health and safety representative of the area should be consulted in the development of the safe work instructions. Priorities for the development of safe work instructions: It is recognised that, in some areas, the preparation safe work instructions for all tasks will take some time. The priorities for the preparation of instructions should be: 5.3 All new tasks should have safe work instructions prepared before they are put into general use. For existing processes, safe work instructions for high hazard tasks in use should be prepared first, lower hazard tasks in use next and then safe work instructions should be prepared for all other processes. A higher priority should be placed on the tasks that are carried out by students and/or the tasks carried out most frequently. Safe work instructions should include: Specific information regarding the hazards and associated risks of the task; Precautions to be undertaken before commencing the task; Personal protective equipment to be worn while undertaking the task; The environment where the task should be undertaken; Clear instructions for undertaking the task described in a safe manner; Specific instructions regarding ways of minimising the risks of the task; Instructions to ensure that the area is left safe for others to use; Correct waste disposal guidelines. 5.4 When complete, safe work instructions should be reviewed, signed and dated by the area supervisor and safety officer. 5.5 Safe work instructions should be displayed prominently or readily available in the areas in which they are to be used: 5.6 Equipment/machinery: Safe work instructions for each piece of equipment/ machinery should be displayed prominently close to the location of the equipment/machinery; Safe work instructions that are displayed prominently should be printed on standard Monash University safety stationary (see attached example); The manufacturer's user manual provided with the equipment/machinery is a good resource for safety information to include in safe work instructions. Safe work instructions for techniques/processes should be included in the safety manual of the area, which should be readily available in each area where the techniques/processes are carried out. An example of the headings that may be used in safe work instructions is attached to these guidelines. Safe work instructions should be reviewed when found to be inadequate and at appropriate intervals 5 SAFE WORK INSTRUCTIONS FOR Cold Mounting samples Campus: Clayton, VIC Faculty: Engineering Department: School of Physics and Materials Engineering Building:37 Room No: 172 Investigator 1. 2. Assessment Date : Phone # Signature Authorisation Project safety signed off Hazards associated with equipment/machinery/technique/process: Irritating and may cause redness and itching. Risk of sensitisation to epoxy compounds. Irritating to eyes. The product contains a substance which is harmful to aquatic organisms and which may cause long term adverse effects in the aquatic environment. Before you start work: Safety working instructions and risk control assessment signed off by supervisor and Dr Chris Hutchinson. Training by a qualified technician Read the information about the hazards, eg material safety data sheets Be aware of laboratory safety manual. 3. Personal protective equipment to be used: 4. The environment where the task is to be undertaken: 5. Step by step procedures for task 6. 7. 8. 9. Safety glasses/latex gloves/close toe shoes; laboratory coat Fume cupboard, glove box, local exhaust ventilation. -wear LabCoat, safety glasses and latex gloves -Samples should be clean and dry in ethanol -Plastic mounting caps need to be greased with Vaseline -Place samples in mounting caps – face down Struers Epofix Resin and Hardener -weigh Epofix Resin 25 parts by weigh (highest capacity: 100 gms) weigh Epofix Hardener 3 parts by weigh (highest capacity: 12 gms) -Mix mixture thoroughly under fume cupboard -Pour into plastic moulds -Let it set over night Clean-up procedures Cleaning of benches with wet paper towels, storage of used materials. If a spillage occurs, absorb spillage with non-combustible, absorbing material using spill treatment kit located in building 37 room 179. Waste disposal procedures Do not discharge into drains, water courses or onto the ground. The residue will be harden overnight and is disposed the next day into the waste bin Use ChemSafe to dispose of old bottles Emergency procedures Absorb spillage with non-combustible, absorbing material using spill treatment kit located in building 37 room 179. Provide easy access to water supply and eye wash facilities. 6 10. 11. After hours access procedures Ask Dr Chris Hutchinson for after hour access Associated Documents Risk assessments, MSDSs Prepared by: Date: