RA_SG_1_Glass_Cutting

advertisement

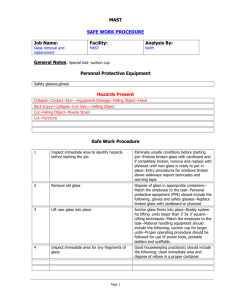

Schools’ Health and Safety Handbook Code of Practice for Secondary Design and Technology Risk Assessment SG1 Stain glass- Lead. November 2008 Risk Assessment SG 1 Stain glass cutting ESTABLISHMENT SECONDARY SCHOOL DEPARTMENT DESIGN AND TECHNOLOGY WORK ACTIVITY Stain Glass cutting HAZARDS WHO MIGHT BE HARMED (EMPLOYEES) All users should be aware of the following hazards: Poorly stored glass would be easily broken and could cause serious injuries and/or cuts. Fine glass shards are difficult to see, can cause cuts, become embedded in the skin and shards could be transferred into the eyes from hands. Glass cutters that are sharp and can cause cuts. Edges of glass are sharp and can cut. Design and Technology Teachers Design and Technology Teaching assistants Design an Technology Technical assistants WHO MIGHT BE HARMED (NONEMPLOYEES) Pupils and students. Visitors Cleaning contractors. Maintenance contractors. IS ANYONE AT SPECIAL RISK Persons working alone Inexperienced teachers Persons who have not been trained in the correct techniques to cut or handle glass. Persons who use the equipment infrequently Unauthorised users, for example, site manager, caretakers. RISK CONTROL MEASURES Safe Use Storage and handling. Glass should not be stored above head height. Glass should be stored vertically in a secure well constructed and stable frame, that is strong enough to take the weight of the glass. Always wear ? well fitting Kevlar gloves, goggles, long sleeved coveralls and strong shoes or boots that cover and protect the whole of the foot. Handling the glass should be kept to a minimum. Always carry glass in a vertical position, grasping it with both hands along the top and bottom edge. Do not slide your hands along a piece of glass, even with gloves on. Schools’ Health and Safety Handbook Code of Practice for Secondary Design and Technology Risk Assessment SG1 Stain glass- Lead. November 2008 Written Permission and protective clothing. Written permission should be sought from parents in a letter identifying the risks involved in working with glass, for all students under 18. It is a legal requirement that all protective clothing and equipment should be provided, cleaned and stored by the schools. This equipment should not be taken home by the students. Using glass supervision of students Instruction must be given to pupils regarding the correct use of the glass cutter. Inexperienced users will need careful supervision Glass should always be cut on a flat, steady work surface. Make sure that the table that the glass is being cut on is not too high-just below waist level is recommended in order to get the correct pressure required to cut glass. Goggles should be provided and used when cutting glass to prevent persons rubbing eyes when fine glass particles could be transferred into the eyes. Tiny glass particles should not be brushed away with hands, a small dustpan and brush should be provided and used whilst working. Waste glass should be stored in a labelled bin specially for this and should not be thrown or tossed into this bin. Clearing up and disposal of glass. Scrap glass should be disposed of separately in a container that is clearly labelled. Broken or waste glass should never be put into waste paper bins or plastic sacks as this can cause serious injury. A vacuum with a hepa filter should be used to vacuum tiny pieces of glass once work is complete. Clearing up the glass shards on the work surface should be swept carefully with a dust pan and brush and a vacuumed with a HEPA filter, as persons using the facilities after the glass cutting activity, will be unaware of the tiny glass particles. When vacuuming a systematic sweep of the area should be completed to ensure that all the glass particles and dust are removed. Take time to properly change the filters and Schools’ Health and Safety Handbook Code of Practice for Secondary Design and Technology Risk Assessment SG1 Stain glass- Lead. November 2008 FURTHER ACTION REQUIRED TO CONTROL RISK properly dispose of them. Goggles, a disposable dust mask (BSEN149:2001 FFP 2 or 3) and disposable gloves should be worn to protect the face, eyes and hands while carrying out this process. Filters should be double wrapped in plastic or a thick polythene bag for disposal. Clearing up the needle like glass shards on the work surface should be swept carefully with a dust pan and brush and then a vacuumed with a HEPA filter, as persons using the facilities after the glass cutting activity, will be unaware of the tiny glass particles. When vacuuming a systematic sweep of the area should be completed to ensure that all the glass particles and dust are removed. Take time to properly change the filters and properly dispose of them. Goggles, a disposable dust mask (BSEN149:2001 FFP 2 or 3) long sleeved coveralls and thick disposable gloves should be worn to protect the face, eyes and hands while carrying out this process. Filters should be double wrapped in plastic or a thick polythene bag for disposal. ACTION BY PERSON ACTION BY DATE DATE REVISION OF ASSESSMENT DUE ASSESSED BY DATE