Liquid Level Mathematical Description

advertisement

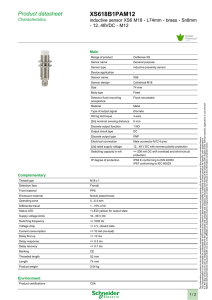

Liquid Level Mathematical Description Paul Petzar Phil Wetzel Jim Ritter September 25, 2003 Abstract In this lab, we determined a mathematical description of the water column apparatus. By finding step and steady state responses to motor voltages, we found a first order transfer function that approximates the operation of the system very closely, G(s), where the input is the voltage minus 2.34V and the output is the height above the pressure sensor. G s 9.63 8.81 1 This description is only correct if the water column is already at the pressure sensor or higher. Introduction The apparatus consists of a water jug with a valve at the bottom and a clear plastic tube sticking out the top. Refer to Figure 1 below for a diagram. A small electrically powered pump draws water out of the bottom of the jug and drops it into the top of the tube via surgical tubing. The apparatus described in this report is labeled as “Liquid Level System #3” and bears a mark “DEAS ROCKS” near the motor. This is important as each system has a slightly different motor and orifice size, which causes both drain and pump rates to change. Before finding a mathematical description of the system, we must define its inputs and outputs. For the purpose of this lab, we defined input as voltage supplied to the pump motor and output as the height of the water column above the pressure sensor measured in inches. We have two methods of measuring the height of the water in the column. First, there is a differential pressure sensor with its input mounted near the bottom of the tube. The pressure sensor provides a voltage output that can be converted to Figure 1: Liquid Level Apparatus inches. The second height measurement available is marker hashes on the plastic tube, marked in inches above the pressure sensor’s input. It is important to note that both of these methods measure height of the water column with respect to the pressure sensor, which is mounted about four inches above the orifice. This is only relevant in determining drain velocity, so in this document and in our mathematical model we measure height of the water with respect to the pressure sensor unless otherwise stated. Procedure The electric pump was powered by a variable six volt supply, allowing us to change the system’s input on the fly. The pressure sensor required twelve volts, which we powered with a 25V variable supply. The output from the pressure sensor was measured with an oscilloscope, providing the ability to download the data to a desktop workstation via a GPIB instrument interface. We first found a relationship between the height of the water column as marked by the hashes and the output of the pressure sensor. This relationship turned out to be linear, and is shown in Appendix A. We then measured the steady state response of the system by finding the stable final height of the water column for different motor voltages, which is shown in Appendix B. The relationship was found to be nearly linear, allowing a fit with R2 = .9956. These measurements were followed by step response measurements for different voltages in an effort to find a time constant (Appendix C). Results The steady state response of the system behaved linearly with respect to the voltage applied to the pump, as long as the input voltage was about 2.4V. The pump was not able to push enough water to maintain a height above the pressure sensor at any voltage below 2.4V. The data for these measurements are available in Appendix B, but can be fitted by a linear curve (Equation 1) with an R2 of .9956. hsensor 9.63V pump 23.31 Equation 1 The step response of the system is an exponential decaying growth that resembles the step response of a first order system. Working with this information, we decided to try to find a first order transfer function that would describe the column height as a function of voltage input to the motor. A time constant was found by averaging the time constants found graphically from step responses at 3, 3.5, 4, and 4.5 volts (shown in Appendix C), and found to be about 8.81 seconds. If we ignore the behavior of the column at low levels and the resulting offset, we obtain the transfer function in Equation 2. G s 9.63 8.81 1 Equation 2 To account for the offsets and lower limit of input voltage for linear operation, our system diagram appears in Figure 2. To reiterate, this system is only correct in linear operation, defined as input to the system at 2.4V or above and present output of the system at zero inches or greater (with respect to the sensor). 2.4V Input + G s 9.63 8.81s 1 Output Figure 2: System Block Diagram Conclusion The liquid level system is described by a first order transfer function with very good accuracy. This transfer function should be usable as a starting point for designing a control system for controlling the height of the water column. Appendix A – Pressure Sensor Output To calibrate the pressure sensor, we found its output voltage for a series of known water column heights. Again, all following heights are measured with respect to the pressure sensor, not the orifice. Voltage Height (Pressure) 16.3 3.32 10.6 2.345 5.6 1.522 8.1 1.962 14.3 2.962 22 4.18 14 2.869 3 1.12 2 0.931 1.1 0.793 Table A1: Pressure Voltage vs. Column Height Table A1 is graphed and curve fitted in Figure A1: Pressure Sensor Output (V) Pressure Sensor Output vs. Column Height 5 y = 0.1629x + 0.6198 R2 = 0.9996 4 3 2 1 0 0 5 10 15 Height (inches or marks) Figure A1: Pressure Sensor Output vs. Column Height This data results in the relationship Vsensor .163hsensor .620 (Volts), or hsensor 6.13Vsensor 3.8 (inches) 20 25 Appendix B – Steady State System Response Table B1 contains three trials of the steady state response of the system. In each trial and voltage, the system input was adjusted to the listed voltage and the height of the column was measured after it stabilized. Some of the data points vary wildly across trials, as for some reason the motor’s flow rate varied substantially and unpredictably. The motor could be “steady” across a range as great as an inch and a half during a five minute period. Voltage 2.340 2.500 2.600 2.650 2.688 2.750 2.875 3.000 3.125 3.250 3.375 3.500 3.750 4.000 4.250 4.375 4.500 Height (1) Height (2) 0 0.7 1.4 1.8 2.6 4 4.5 6.6 6.4 7 9.7 10.4 12.5 16 17.5 19.4 24 Height (3) 0 0.7 1.3 1.8 3 3.3 4.5 5.3 6.4 7.2 9.7 10 12.3 15 17.5 19.4 22.7 0 0.7 1.35 1.8 2.75 2.5 4.5 5 6.4 7.5 9.7 10.5 12.4 14.5 17.5 19.4 24 Average 0.00 0.70 1.35 1.80 2.78 3.27 4.50 5.63 6.40 7.23 9.70 10.30 12.40 15.17 17.50 19.40 23.57 Table B1 Figure B1 plots the data from Table B1 and shows a linear curve fit. Height vs. Motor Voltage Column Height (inches) 25 20 y = 9.6266x - 23.318 R2 = 0.9956 15 10 5 0 -5 0 1 2 3 4 5 Motor Input (V) Figure B1 This data gives the linear relationship between Motor Input and Column Height discussed in the Results section. Appendix C – System Step Responses The following graphs are the timed step response of the system to voltage inputs. The trials shown below were not continued to steady state since the final values were already known from the results discussed in Appendix B. On each graph, the steady state height is shown with a light triangle on the Y axis, and .63 of the steady state height is marked with a black diamond. These marks were used to graphically determine the time constant of each trial. 3 Volt from Zero 1 Height (V) 0.8 0.6 0.4 0.2 0 -0.2 0 5 10 15 time (s) Figure C1: 3 Volt Step Response, τ = 9.25 s 20 25 Appendix C, continued: Height (V) 3.5 Volt from Zero (2.45 stable) 2.5 2 1.5 1 0.5 0 -0.5 0 20 10 30 time (s) Figure C2: 3.5 Volt Step Reponse, τ = 8 s Height (V) 4 Volt from Zero (3.47V stable) 3.5 3 2.5 2 1.5 1 0.5 0 -0.5 0 10 20 time (s) Figure C3: 4 Volt Step Response, τ = 8.5 s 30 Appendix C, continued: 4.5 Volt from Zero (4.52V stable) 5 Height (V) 4 3 2 1 0 -1 0 10 20 30 time (s) Figure C4: 4.5 Volt Step Response, τ = 9.5 s The time constants from each trial, when averaged together, yield a system time constant of 8.81.